Sensors, actuators, and electronic controls make repairing Mercedes-Benz doors a lot more important to vehicle safety and passenger comfort than in the past. The collision repair technician must deliver not only excellent fit and finish, but also ensure that all electronics function as required by the original equipment specifications.

Mercedes-Benz has always been on the cutting edge of safety technology. These head and thorax air bags were introduced way back in 2001.

There is more to repairing today’s doors than just fit and finish, and that Mercedes-Benz sound is still a winner.

There are many sophisticated electronics inside the driver’s and other doors in newer Mercedes-Benz vehicles. The most critical may be the side airbag and its sensors and activation controls, all of which are built into the doors on some vehicles.

In addition to these Supplemental Restraint System (SRS) components, there are motors and electronic controls for the windows, door locks and exterior mirrors. There may also be controls for seat comfort settings, air circulation blend doors, the sunroof and other vehicle features. And of course, there are in-door speakers.

Your door repair must take all of these things into account. At minimum, you must test every feature to make sure it works before you invite the customer back to pick up his or her vehicle.

Feel the Pressure

One big fact you should be aware of is that on all Mercedes-Benz vehicles with side air bags, the SRS is activated when a side impact collision causes an increase in air pressure inside the door cavity. An air pressure sensor mounted in the door cavity registers the pressure increase and sends a signal to the SRS control unit to ignite the airbag.

Other sensors also send signals to various control modules to initiate additional safety measures. Depending on the severity of impact and the locations of vehicle occupants, the SRS activates the seat belt Emergency Tensioning Retractor (ETR) to tighten the belt of every occupied seat. Other safety modules unlock doors, shut off the engine and open side windows slightly to allow smoke and gases from the airbag ETRs to quickly disperse from the vehicle.

In appropriately equipped models, safety systems also automatically move the steering column up to help make it easier for the driver to exit the vehicle, make a call for emergency assistance, turn off the air conditioner and close the fresh air/recirculation door to reduce the entry of hazardous gases to the vehicle interior.

Safety from Simplicity

Older vehicles may have located a side impact sensor in the floor between the frame rails and the seat. Switching to an air pressure sensor and locating it in a sealed door cavity was a Mercedes-Benz engineering “Aha!†moment.

Moving closer to the point of impact helps initiate the airbag response to a side impact a few milliseconds earlier. Shaving a few milliseconds off airbag response time offers potential for significant improvement in passenger protection outcomes, depending on the side impact severity.

Mercedes-Benz engineers accomplished this by sealing every opening in the door with rubber grommets around all bolt holes, gasket receptacles for every clip, and rubber plugs or even tape over any other hole that cannot be permanently sealed.

When your repair is complete, the door cavity must function once again as a sealed unit in order for the replacement side airbags to work. Order a few extra clips and clip gaskets to replace any that break or get lost as you do the repair. Make sure no bolt is installed without a grommet.

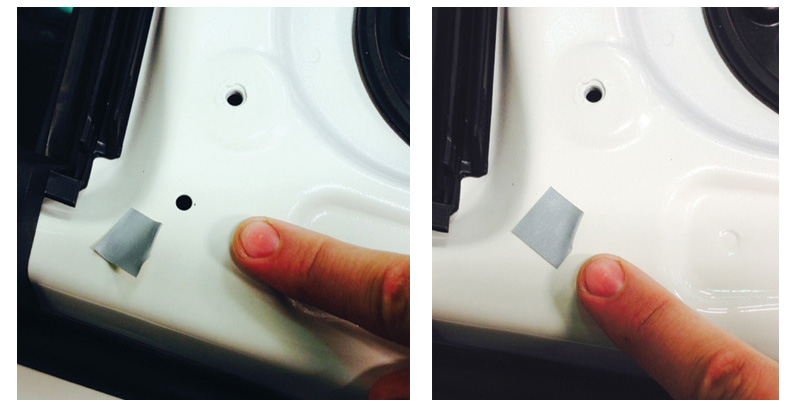

For a variety of reasons, some openings were originally covered at the factory with sealing tape instead of a grommet and bolt or clip. So yes, that little piece of tape that fell off while you were disassembling the door had an important safety-related purpose and must be replaced.

In some older Mercedes-Benz models, instead of sealing individual openings with plugs and grommets, plastic sheeting sealed the entire door cavity. The new system of plugs, grommets, clip gaskets and tape make it easier to restore the integrity of the door cavity seal after a side impact accident.

To ensure that the air pressure sensor mounted in the door cavity can register an increase in pressure that occurs in the event of a side impact collision, every opening must be sealed. Sealing tape was applied at the factory to this small hole in this M-Class SUV rear door, and must be replaced if removed during a door repair.

Electrostatic Discharge Caution

Electrostatic discharge (ESD) is harmful to many electronic components, including sensors, airbag components, and the Controller Area Network (CAN) bus connections used extensively in automobiles to carry data between sensors, control modules, actuators and devices. Even ESD that is too small to be noticed can cause significant damage to electronic components and control modules.

Every contact with or movement of solids, liquids or even some gases can generate an electrostatic charge. Something as simple as walking on carpet or plastic flooring, or putting on a piece of clothing made with synthetic materials can create a buildup of electrostatic charge.

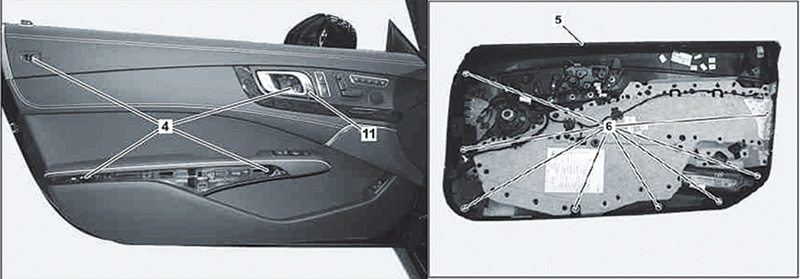

In this SL 400 Roadster driver door, four bolts (4) and eight clips (6) hold the lining (5) to the door.

A few precautions can help minimize potential ESD problems:

- Use antistatic seat protectors when working inside a vehicle.

- Leave replacement electronics in their original packaging until ready to use. Cut rather than tearing the package open, as tearing creates more movement that can generate ESD.

- Avoid contact with materials that can hold a high electrostatic charge, such as polyethylene (PE), polyvinyl chloride (PVC), and Styrofoam. Do not place electronic components removed from a vehicle on PE, PVC, or styrofoam.

- Touch electronic components on their housing or wiring harness only. Do not touch pins or contacts.

- Install electronic components before connecting them, so that equalization with the body can occur.

OE Information Makes It Easy

Accessing any of the many components in the door is not difficult. The trick is to know whether the piece you need to remove to get to the desired component is attached using a bolt, clip, or other type of attachment device.

That is where the Mercedes-Benz Workshop Information System (WIS) comes to your rescue. WIS provides the number and location of each bolt, clip, or other attachment device, and the exact sequence of steps so that you don’t miss a screw or clip and break a trim panel or mounting bracket.

A combination of bolts and clips typically hold the armrest and control panel to the door.

Two bolts are under a trim piece that is best removed starting at the rear (near the door end that opens), using a plastic wedge that won’t scratch the trim or cut into leather, fabric, or plastic interior surfaces as a screwdriver might.

A third bolt is behind the cover of the door handle inset. It is buried in an angled inset opening. Even after the cover is removed, the bolt is difficult to see. If you assumed the panel was held there by a clip, you might pull hard enough to damage the seat for that bolt. That would make the panel unusable, unless you have that extremely rare customer who would not mind a vibration noise at the door handle whenever the vehicle is moving.

The fourth bolt is under the airbag badge, and easy to see once the badge is removed from its clip.

After removing all bolts, unclip the door lining from the eight clips by sliding a plastic wedge under the lining and pushing up near each clip. Inspect the lining to make sure that none of the retaining tabs for the clips have been torn out.

Pull off the door lining, being careful not to damage the attached electrical connectors.

That Mercedes-Benz Door Closing Sound

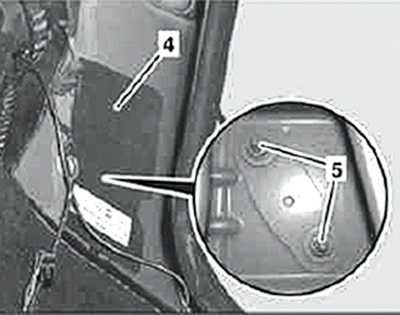

A small insulation mat (4) covers the area where a component is bolted (5) onto the front door liner panel of this C 300 sedan.

Precision fit is a major part of why the sound of a Mercedes-Benz door closing is one standard of excellence by which other vehicles are often judged. In the C 300, the vertical gap where the door meets the B pillar, A pillar, or front fender is only 4 mm, plus a maximum 1 mm tolerance.

The tight tolerance significantly reduces the likelihood of a door sitting off-kilter and striking too hard against a part of the frame when closing. However, vibration-absorbing insulation may be the greater contributor to that solid “thunk†sound when you close a Mercedes-Benz door.

The Only Good Vibrations

An object tends to vibrate at a rate determined by its size, shape, and material composition. This vibration rate is called the object’s natural frequency, or resonance. The object will vibrate when it is in contact with something else that is moving at a frequency equal to or near its natural frequency.

An example of resonance vibration in an automobile would be if a component or piece of trim vibrates only when the car is traveling at a certain speed. The component or trim material has a natural frequency equal to the vibrations of the engine at that speed.

Thanks to this transferability property of resonance, a weak vibration in one object can cause a strong vibration in another. This enables resonance to increase the intensity or loudness of a sound.

For example, the relatively weak vibrations produced when a pipe organ key is struck cause the air in the related pipe to vibrate in resonance. The air movement causes the metal in the pipe to vibrate. The larger the pipe, the greater the sound increase the vibration produces.

This tendency to pick up vibration from other objects that vibrate at the same natural frequency combined with an ability to magnify the sound from the vibration of another object is a major part of why a vehicle can often present a symphony of noises.

With a healthy respect for the physics of resonance, Mercedes-Benz engineers place a lot of vibration-absorbing insulation throughout their vehicles. It helps make the interior of a Mercedes-Benz as quiet as the library in a Tibetan monastery.

Inside the door, in addition to insulation that blankets large areas, you may find extra insulation strips tacked to small parts of the door where a component presents a high vibration noise risk.

If you had to remove any such insulation pad in order to gain access to a component or area for the repair, you must reinstall or replace the original insulation.Â

0 Comments