There’s no such thing as a “minor fire†at an auto service shop. Beyond the obvious loss of property, equipment and business income, the threat to the safety of humans is paramount.

We’ve all heard the stories or know someone who has had it happen to them. Perhaps it has happened to you. A fire at an auto service shop can be devastating for everyone involved.

The shop owner faces a miserable loss of business income; the fact that everything on the property may not be covered by the insurance company; the decision to rebuild and get back into business; the interminable length of time it takes to get back up and running; claims from any customers who had a vehicle damaged in the fire; how to pay outstanding invoices for parts, services, utilities, taxes and such at the time of the fire. The list goes on and on.

This unfortunate shop might have been spared or saved if a fire emergency plan and preventive measures where implemented.

Shop employees out of work due to a shop fire are also face the loss of income, and maybe the personal tool boxes they use make their living. However, the more important aspect of a fire can be the possible loss of life or injury to anyone in the shop at the time of an explosion or fire.

Safety is the Number One Priority

The National Fire Protect Protection Association estimates that a little over 5,000 fires a year occur at automobile service facilities. While that number may include gas stations with a greater risk of fire at the gas pump areas, it’s safe to say that at least a portion of that number includes mechanical and collision service shops.

If you are a shop owner, you want to make sure that you run a safe place to work and protect your business, your employees, your personal health and your customers. If you are an employee, you make want sure you work in a safe environment. The fact is: safety is everyone’s responsibility. Even the best safety plan won’t work if just one person refuses to follow the plan and observe the rules of safety.

Have a Fire Emergency Plan

The best thing to do is have a plan. That plan should not only address the steps to handle a fire emergency (both during and after), but also fire prevention.

First and foremost, everyone in the shop should know the emergency phone numbers for the local Fire and Police departments, or 911, if it is available in your area. Those numbers should be posted in several locations around the shop and everyone should have those numbers posted in their cell phones. That’s the best way to ensure that help arrives quickly.

Next, everyone should be trained in when and how to exit the building and assemble in a designated area well away from the building. Remember, there are lots of flammable and explosive items in all auto service shops so don’t make that assembly area right outside the office or anywhere close to the building.

Other phone numbers to record are the insurance agent, family members of all employees and surrounding businesses and homes to notify them of the dangerous situation. This list should not be kept only in the office as would most likely be unobtainable during a fire, or at least, too dangerous to retrieve.

Fire alarms should be installed and monitored by an alarm company. While it costs to have a system installed, it can avoid serious damage and can become a business tax deduction. Most insurance companies offer lowered fire insurance rates if you have a fire alarms system installed.

Lower the Risk: Make a Prevention Checklist

Blocking access to a fire extinguisher can spell disaster when the difference between putting out a small fire or letting the blaze get out of control may be mere seconds.

To minimize the possibility of a shop fire, you should have a checklist of things to do and things to avoid. Many business insurance companies provide a fire prevention checklist for their customers, so check with your insurance agent for any possible suggestions. Share all information on the checklist with all employees to ensure they understand why it’s important to follow the rules.

Here are some basic suggestions for a fire safety check list:

Fire Extinguishers

Have the correct number and type of portable fire extinguishers placed at strategic locations. Train all employees in their use to stop small fires and when to call for the fire department if it gets out of control. Class ABC extinguishers are best for all around use. If you work on brake pads with magnesium content, you should have a Class D extinguisher placed at the bay where brake work is done. Do not block access to the fire extinguishers. All fire extinguishers should be in good physical shape, inspected and certified by a fire extinguisher service company annually. What good is a fire extinguisher if it doesn’t work when needed?

Enforce “NO SMOKING” rules within the building

If a smoking area is required, make it in a safe place, usually outside and away from any combustible materials. Always check that area for any possible burning materials prior to leaving the shop for the day. Many fires flare up into blazes after employees have left for the day.

Practice Electrical Safety

Use electric fixtures and switches that are designed for use in explosive environments. Inspect all electrical equipment for wiring that is broken, cracked or frayed that could be the source of sparks. Make sure that all equipment is properly grounded. Have building electrical system inspected at least every couple of years.

Welding and Cutting Safety Issues

Welding and cutting should be performed in areas free of combustible materials. Gas tanks used for welding should be properly labeled. They should be stored away from heavy traffic areas, out of direct sunlight, in a ventilated area and should be chained securely to avoid damage or explosion from tipping over or falling. Never weld containers that have held flammable or combustible material until the container has been thoroughly cleaned. Be sure the welding cart includes a fire extinguisher. Make sure hoses are in good condition. Make sure that your employees are properly trained and have proper certification to perform cutting and welding.

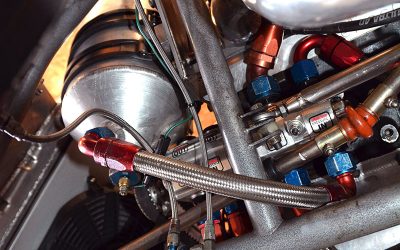

Storage of Flammable and Combustible Liquids

Flammable and combustible liquids should be kept in covered containers when not in use. Containers should be bonded and grounded when liquids are transferred from one container to another. A wire with alligator clips can be used to connect one container to another (bonding) and one container to an underground water pipe or electrical ground (grounding). Store flammable paints, thinners, and adhesives in approved fire-rated cabinets away from ignition sources. Obtain Material Safety Data Sheets from manufacturers to be sure you are storing and using these materials in a safe manner. Proper equipment should be used to drain and fill gas tanks for removal. Establish maximum ventilation, disconnect the vehicle’s battery, and store the empty tank outside.

Practice Proper Painting Procedures

Spray painting should be done in a spray booth designed for that purpose. Keep portable lamps or any flame source out of the spray booth. Be sure that fire extinguishers and sprinklers in spray booths are operational. Check that spray booth ventilation is working as designed. Clean filters, ducts, and interior walls of the booth. Operate the ventilation system for a period of time after painting to remove residue vapors and paint. Do not use space heaters where spray painting or welding is done, or near oil or gas storage tanks.

Good Housekeeping Prevents Problems

To limit the fire potential, stock rooms should be kept clean and orderly. Aisles providing access to fire exits should be clear. Service bays should be kept clean and should not be used to store combustible materials. Clean up spills immediately, especially flammables and oils and dispose of daily. Avoid the accumulation of cardboard cartons and packing/crating materials that would feed an accidental fire. Combustible waste materials placed outdoors for trash collection should be located away from the building. Trash dumpsters should be located so that fires will not spread to the building. Remove trash daily. Keep oily rags and clothing in a closed metal container until you dispose of or launder them.

Know the Laws and Regulations

Be aware of the national (OSHA), state and local laws and regulations that affect your shop. If you are not incompliance, you could be subject to fines or penalties. Plus, it may be grounds for denial of claims by your insurance carrier. The vast majority of insurers will gladly work with you to provide a fire prevention plan and to help you meet applicable laws and regulations.

It’s All about Safety

The whole point of this article is to get you thinking about fire safety – emergency plans and preventive measures. If you’ve ever been involved in a shop fire or known someone who has, you’ll agree that the results can be devastating. Your personal safety should always be considered as the primary concern in safe shop operation.

0 Comments