This issue of Performance Technician features a major article on restoration. Fabrication is often a major part of that pursuit, so our man Greg visited the best “make-anything” shop he knows of to create this story. In the early days of automobiles, the U.S. was a “fabrication nation,” but now the necessary skills and talent are rare.

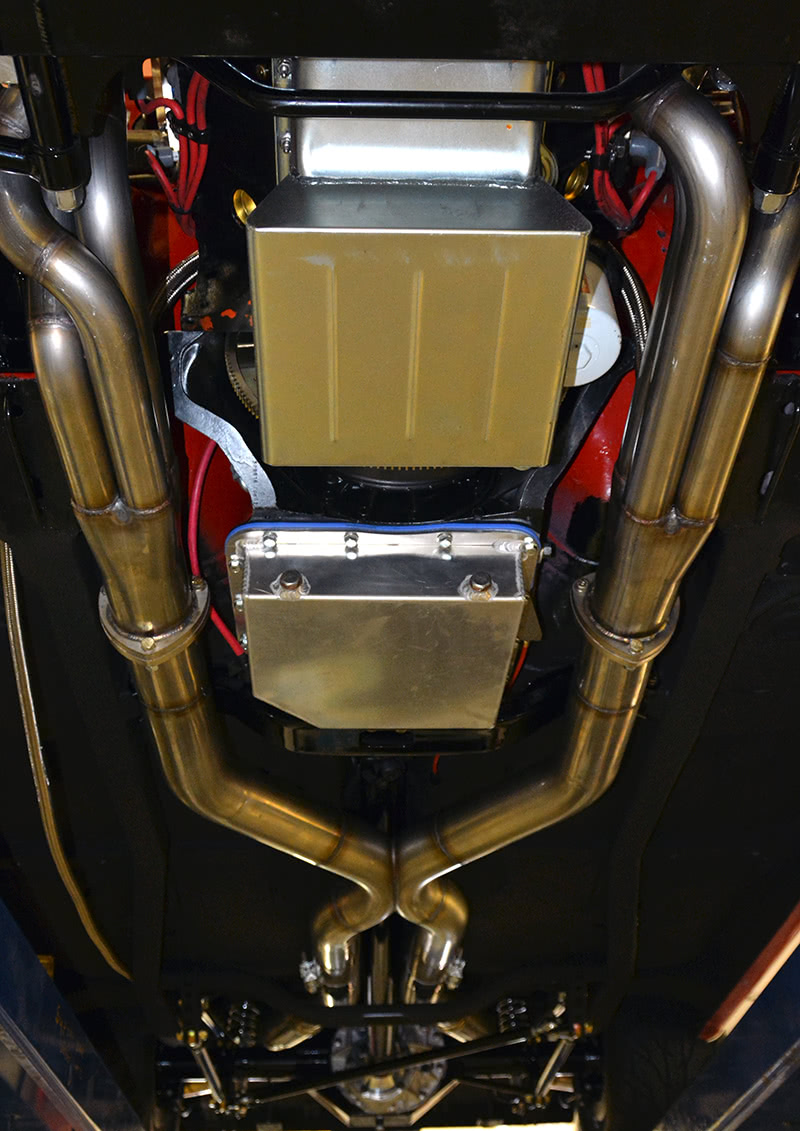

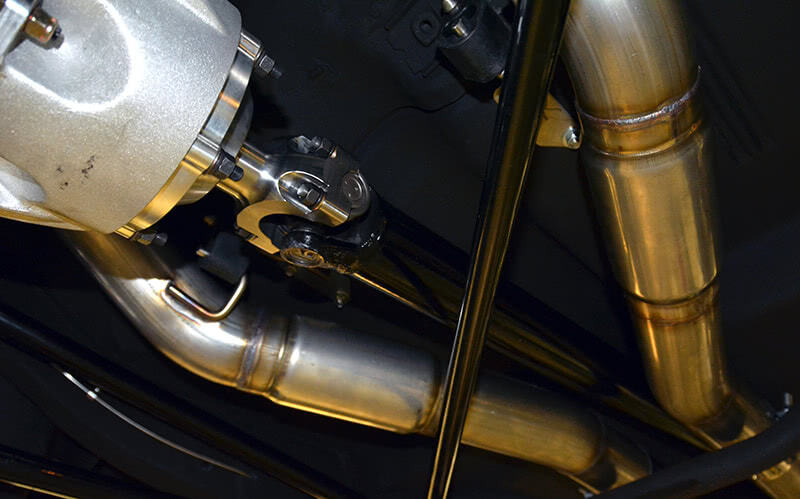

I know, I know: I’m a car guy, which means I’m not normal in more ways than one. But this is the prettiest thing I’ve seen in a long time. A three-inch “X†pipe system in stainless steel. The artist is Troy of Advanced Chassis.

Restoration service is complicated even on the most straightforward jobs you take on [Still more so with major race vehicle builds — Ed.]. It’s a business requiring a burdensome investment of time and money, and on the customer contact side it’s rife with opportunities for misunderstandings and acrimony. Few can really understand how much time it takes until they’re immersed in the project, and at that point there’s no choice but to stop and take a loss or punch through to completion.

Communication today is complicated by people who have for several years now used technology to isolate themselves from each other — using email, texting, cell phones, and computers to insert a buffer between living souls. I use all these things myself, but I’m a fan of face-to-face, people-to-people contact because I don’t think you can see the soul of someone by remote control. I think that every personal interaction changes both people involved in small but measurable ways that an email, voice mail, or phone call can’t — for the better, I hope. Too many clues are missing from our communication without body language, a firm handshake, and looking into another living person’s face as we converse. Yeah, I know: I’m a Neanderthal, a living fossil, which might explain why I try to establish a personal relationship with my most critical vendors.

Ahead of the “X” pipe is a custom-built, equal-length set of stainless steel headers. This is where your fabricator really shows the level of skill he’s attained. The primaries have to be of equal length, they have to land on the collector, clear all the various components, allow you access to the starter, oil filter, transmission pan, and spark plugs, and you have to be able to service them if the engine needs to come out — you can’t just weld them in, you must be able to take them off and put them back on.

If you think that starting to dabble in restoration services might be in your future, you’ll need to find vendors to help you get your work done. You’ll need metal plating, dash and interior specialists, and you’ll need a fabricator: someone who has the knowledge, tools, equipment, and attitude to make things fit your specific application. A guy who lives by the creed, “Can do, will do — I’ll figure it out.â€

There are not enough hours in all of our days for everyone to learn everything, not enough lifetimes to learn and master all the associated trades that make up the whole of restoration. And while you might have the wherewithal to buy all the necessary equipment, how will you manage to learn how to use it all when in some cases it takes 10 years to become proficient at the requisite skills? If you think about it, it’s why we use engine machining experts to do our block preparation, cylinder head specialists to perform our porting and flow verification — and fabricators to perform hundreds of custom jobs for us, large and small. As a restoration service provider, you don’t want or need to know how to do everything yourself. You need a basic understanding, but what you really need to know is the guy or gal who knows how to do everything in his or her field of expertise.

Hardy Midwesterners at Work

If you drive 35 minutes east of Fort Wayne on U.S. 24 and take a couple of right hand turns between the corn fields, you’ll arrive at the sleepy little town of Antwerp Ohio, home of Advanced Chassis — appropriately located on Victory Lane. It’s an unassuming cluster of buildings with no external indication of the buzz of activity going on inside. Started by Ken Bowers 26 years ago and now headed up by his son, Dan Bowers, it’s a tight-knit group of 12 hardy Midwesterners with a love of making things that are loud and fast out of piles of plate, round and rectangular steel, and aluminum stock. I’m partial to Midwesterners — I’ll admit it. They tend to be friendly, hard-working, helpful, and honest in their dealings with others, and Dan and his crew are no exception.

Here’s what the entire system looks like, and you have to admit it’s impressive. Everything clears, it tucks up nicely under the car (important here in the Midwest where every winter turns our roads into tank trap testing facilities), and access to normal service items is unimpeded.

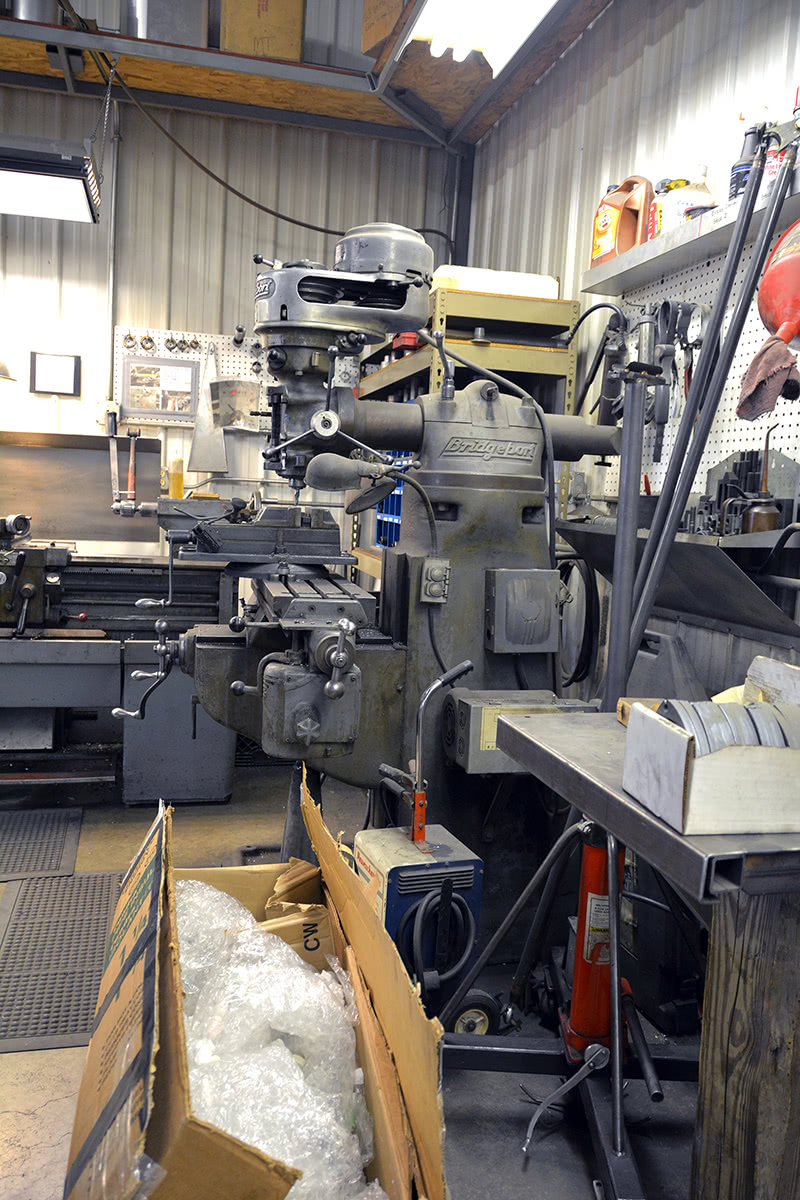

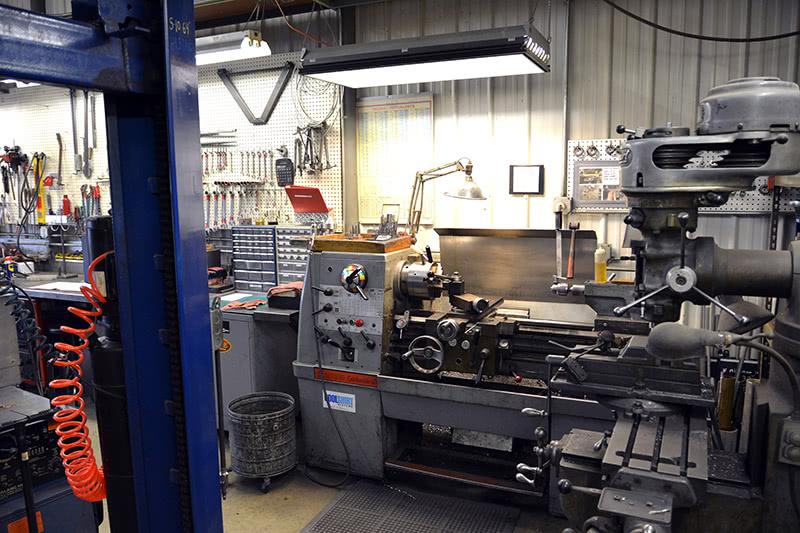

When you walk in the door you can see right away that this is about business. There’s just enough space to stand at an opening cut through the wall into the tiny office to talk about what you need to have done, or to pay your bill. Shop space is reserved for the work that has to be done and there is plenty of work going on. There are tools everywhere, stuffed into every nook and cranny, and between the tools and welders there are cars and car parts. Everywhere you look there are templates, jigs, cutters, grinders, and cars. Really cool cars. Really fast cars. This is like big boy toy heaven; and moving around in all this is a band of dedicated folks cutting things apart and welding things together.

I’ve used Dan’s services for various small jobs over the years, and he’s built chassis for a number of my friends fortunate enough to be able to race competitively. There are three things that come to mind about this shop: excellent quality, helpful, and friendly.

Top Ten Tools

Fabrication is equal parts art, engineering, and hand skill. Advanced Chassis has an on-staff engineer to help with design and layout. Some work is done from prints, some from experience, and some by necessity as all the working components of a race or street car have to fit into the space available. Much of what determines the success of a fab shop is constantly rediscovering what’s out there. That entails staying on top of parts suppliers and shopping for new sources. This street application needed “mufflers,†but with a custom coil-over rear suspension and three-inch stainless pipes there just wasn’t a lot of room. I didn’t get to hear it run, but I’m betting it had a nice exhaust note.

In preparation for this Performance Technician article, we sat down and tried to compile a list of things that someone working in fabrication, or looking for a fabricator, might find useful. It proved to be a challenge given the work load (he’s actually got one of the cars I’ve been working on in there right now, so I’m partly to blame), but we did manage to come up with a few good points to ponder. My first question was, “What tools do you use every day that you just can’t live without?†His top ten list:

- “A good 90-degree cut-off wheel. This thing can do so many things that it’s one of our most used tools. It’s the jack-of-all-trades, must have — the fabricators other right hand.â€

- “90 degree two-inch sanders. A rough cut has to be properly finished, right? There are discounters that offer an import version priced very reasonably. Oil it regularly and don’t waste your money on a good one unless you can find a production tool for sale at an equipment auction.â€

- “A good metal-cutting band saw. I have cut up to one-inch-thick plate on mine. Two things to remember: One, buy the best blades you can get, and, two, the thinner the blade the sharper the curve you can cut.â€

- “A TIG welder. I know, I’m biased toward TIG welding, but with one machine you can weld any kind of material together and with the competitive prices of some of the new small units available it’s more affordable than a MIG welder.â€

- “Throw away your old torch and buy a small plasma cutter and you’ll never look back. Torch sets are for heating, plasma cutters are for cutting. Faster, easier, neater cuts and a lot less heat to control or worry about getting into the material that could potentially change its properties.â€

- “A wide selection of layout tools. This includes circle templates, French curves, squares, and angle finders. You can’t lay out all the cool stuff without these simple tools. At least half of making it right is laying it out right.â€

- “A pocket pen light. You’ll be amazed at how many times this comes out of your pocket in a day.â€

- “A quality (and it must be quality) Gerber or Leatherman multipurpose tool. After you get used to having it, it will save you at least five tool-hunting trips a day.â€

- “A high-quality, high-torque 1/2-inch drive impact. When things say they don’t want to come out, this will change their minds when nothing else will!â€

- “An iPhone, or the equivalent. I can’t tell you how many times a day I need to look something up to see how others did it, or take pictures to remember how things will go back together. You can order parts while under a car, you can ask my personal friend, Mr. Google, anything and he will almost always find you some answer (it’s up to you to determine if it’s the RIGHT answer, but you’ll at least have a starting point).â€

Skills and Traits

I showed up unannounced to take a few pictures, and the only hints that this place does what it does are a couple of finished projects sitting in the front yard. Don’t be fooled: The building is stuffed to the gills with projects and the tools of the trade. It’s a mechanical paradise — a maze of cars, parts, and fabricating gear manned by a colorful cast of car-crazy characters. Advanced Chassis serves a large clientele from all over the Midwest from custom car guys, restoration shops, and track racers to a bunch of those crazy street and grudge racers like you see on TV. You just never know what will be lying around.

Next, I asked Dan what skills or personality traits he looks for in a fabricator. I’ll be honest, I’m in awe of people who can do what these guys do. I can do a little welding, and if I’ve got enough time I can whittle out a part or two on the lathe or a mill. But these guys? They make it look easy.

Dan’s response: “To me, one of the first things I look at is how fast do they walk. You can tell a slow person from a mile away, and with the time constraints and the cost of labor this one of the easiest places to ‘make up’ time or improve efficiencies. With a slow walker, you’re going to get a great finished product, but if the time he takes makes the profit margin small or non-existent, then it’s not worth it to the business. On the other hand, if you hire a banshee you have to follow him around and make sure no corners are cut and that nothing is missed. It might seem counterintuitive, but the time it takes to monitor the work output done by a naturally fast-moving worker pales in comparison to the time lost by a methodical person who can’t force himself to speed up.

“This next characteristic probably should have been first, but it takes a little longer to figure out if your new hire possesses it. Common sense! Unfortunately this one takes enough time to figure out that by the time you see if they have common sense you’ve usually already hired him or her.

“We have a saying around here: ‘If it don’t look right, it ain’t right.’ This is where people lacking common sense will drive you crazy. They’ll bring you a “finished†product that you can see from halfway across the shop isn’t right, and they don’t recognize that it’s not right while they’re holding in their hand! Usually these people just get fired, but please note there are jobs for people like this if your organization is big enough to need clean-up people and parts packers. These are the kind of people who generally come to work on time, all the time, and do a good job as long as you spell it out and leave no room for interpretation.

“I’ll try to be delicate here, but there’s just no other way to say it. I subscribe to the rule that Robert I. Sutton, Ph.D., wrote about in his book, The No Asshole Rule. I hate difficult, brash, arrogant trouble makers. No a-hole has lasted in my shop for more than a couple weeks. Life’s too short and your other employees are too valuable for the a-hole to stay no matter how good they might be. The low morale and damage done to the attitudes of others can’t be easily undone, and the behavior can’t be allowed in the shop no matter how good he or she is!â€

Vendors

Even vendors need vendors. Everyone in business out there has people and sources that help extend the business’s capabilities. I asked Dan to tell me about his favorite vendors, and here’s his list:

- “Brown Industrial Products in Botkins, Ohio. You don’t have to use these guys, but whoever you use you must form a great relationship with the people who actually do the work [See my comments above about having personal relationships! G.M.]. Brown does all of my laser cutting and CNC bending. Large places really don’t like to do small batch jobs for smaller businesses like us, but if you grease the wheels you can usually get your “little†jobs pushed through. Pizza works well — your “spiff†has to be more than doughnuts, and you need to identify the mover and shaker who can make things happen for you and make him or her feel real special — because they are special to you! I’ve given out tee-shirts and adult beverages when the time was right as a little additional incentive for helping our business. Never, ever make these guys mad — they are integral to your success.â€

- “Strange Engineering of Morton Grove, Illinois. I deal with a guy named Edwin at extension 4792, and he’s very easy to deal with and knows his stuff. We have been doing business with Strange since we started our company and have never had a problem that wasn’t promptly resolved.â€

- “Aircraft Spruce Catalog — A lot of the stuff you get from the big-name wholesalers comes from China, and the only way to really get better quality components is to go through the aircraft industry. Not all of their products are made here in the U.S.A., but most are. I hate to buy from outside the U.S.A.! From aircraft bolts to toggle switches, check these guys out.â€

- “AED in Indianapolis. This is where I get all of my chrome moly tubing and specialty metals. They deal with small businesses very well, and come up with competitive prices as your business grows and you begin ordering larger quantities.â€

- “Motor State up in Michigan. This is a great wholesale catalog performance part supplier that keeps a huge inventory, and you can order up to 5:30 at night and still get your parts the next morning. I use them a lot! Vehicle Specialties Inc. out of Hammond IN is another company that I sometimes use.â€

- “Moser Engineering in Portland, Indiana is a great company to work with, and they give dealer discounts that make it worth your while to sell their parts. They have a great turn-around program and they are easy to work with. My only issue with them is that they don’t finish some of their products off very nicely. They leave more burrs and sharp edges than I like to see and that makes their products look and feel like they aren’t as high-quality as they actually are. Their gear always works well — it just needs a bit of finessing.â€

- “WSI (Welders Services, Inc. of Fort Wayne) has been handling our welding supplies for years, and when you don’t even think of a competitive vendor for a long time you know it’s because your current vendor is doing his job.â€

- “MSC, Grainger, McMaster Carr. I keep these catalogs handy. They have everything in the world and they ship out the same day.â€

- “I use eBay for a lot of things that don’t come through regular channels. You can load things you’re looking for onto this site and they will send you emails whenever those things come up for auction.â€

- “I try to use the local guys — hardware stores, auto parts stores, and so on — as much as I can. If you take care of these guys, they will always go out of their way to help you and promote your business. It’s all about relationships . . .â€

Next, I asked Dan, “What do you and your employees find most personally satisfying about this kind of work?â€

“This one is easy,” he said. “You get to look back at the end of a build and say, ‘I did that!’ It comes down to pleasing the customer. If the customer comes in and fawns all over the work you did, that is the most satisfying experience we can get in our profession. Winning is second!†[I’d bet lunch that the racers might dispute the order on that one — just saying. G.M.]

Finally, I asked him about what he found most irritating about the job and got a really, really short answer (apparently, Dan has little sympathy for my need to generate an acceptable amount of copy). “Not getting paid!,†he said (as someone who also does long-term projects, I can empathize — customers are naturally reluctant to invest in things they cannot possess until later).

We’ll continue our discussions with Dan next month and cover some of his best fabricating tricks and tips, his list of things that he sublets, and some of the products he builds. Also, some of the projects he’s most proud of.

Â

0 Comments