When the owners of vintage carburetor- and distributor-equipped vehicles see that a shop has a big-box engine analyzer, they believe they may have found somebody who can actually take care of their performance concerns.

Part of the challenge of owning a classic carburetor-equipped vehicle is that it can seem almost impossible to find a shop that can properly diagnosis and repair the ignition and carburetor problems that often come up as you drive it. The ignition and fuel systems that were used just a few decades ago are very simple when compared to today’s computer-controlled, hyper-efficient systems. Almost every auto repair shop actually has the tools needed to service these older vehicles, but young technicians often think they lack the training necessary for working on them. If the technician is capable of diagnosing problems with modern computer-intensive fuel-injected engines, he or she should be able to diagnosis (and repair) any ignition or fuel system problem encountered on a carbureted engine.

Tuning spark advance for today’s gasoline

A big-box engine analyzer such as this Sun unit will have an ignition scope, cylinder balance tester, dwell meter, cylinder leak-down tester, and a vacuum gauge. Some of the higher-end Sun analyzers also had two-gas exhaust analyzers built in.

The PCM/computer of a modern electronically-managed fuel-injected engine is continuously tuning for optimum performance, fuel mileage, and the lowest possible exhaust emissions. The job the PCM is performing is sort of like having an incredibly-fast tuner aboard who is adjusting the fuel injector pulse and ignition timing in real time while you’re driving down the road. It would be nice if this were possible with a vintage engine so that the adjustments needed for it to perform properly with today’s reformulated unleaded gasoline would be made as needed, but that is decidedly not the case.

Actually, older carburetor- and distributor-equipped vehicles are not really that difficult to re-tune for modern fuel, but it does take a few specialized tools, such as an exhaust gas analyzer and a dial-back timing light that will allow the tuner to observe the air/fuel mixture and spark advance curves in operation.

One of the main reasons a vintage engine needs specialized tuning attention is because reformulated unleaded gasoline will often cause the carburetor to supply an air/fuel mixture that’s too lean. The changes in fuel formulation will also cause an older engine to need more initial spark advance than it did with the leaded gasoline it was built to burn, typically in the 1960s and 1970s, but the distributor must have its mechanical advance system recurved to avoid too much spark advance. Generally, it will also need less vacuum-based spark advance than it needed with the leaded gasoline of past decades.

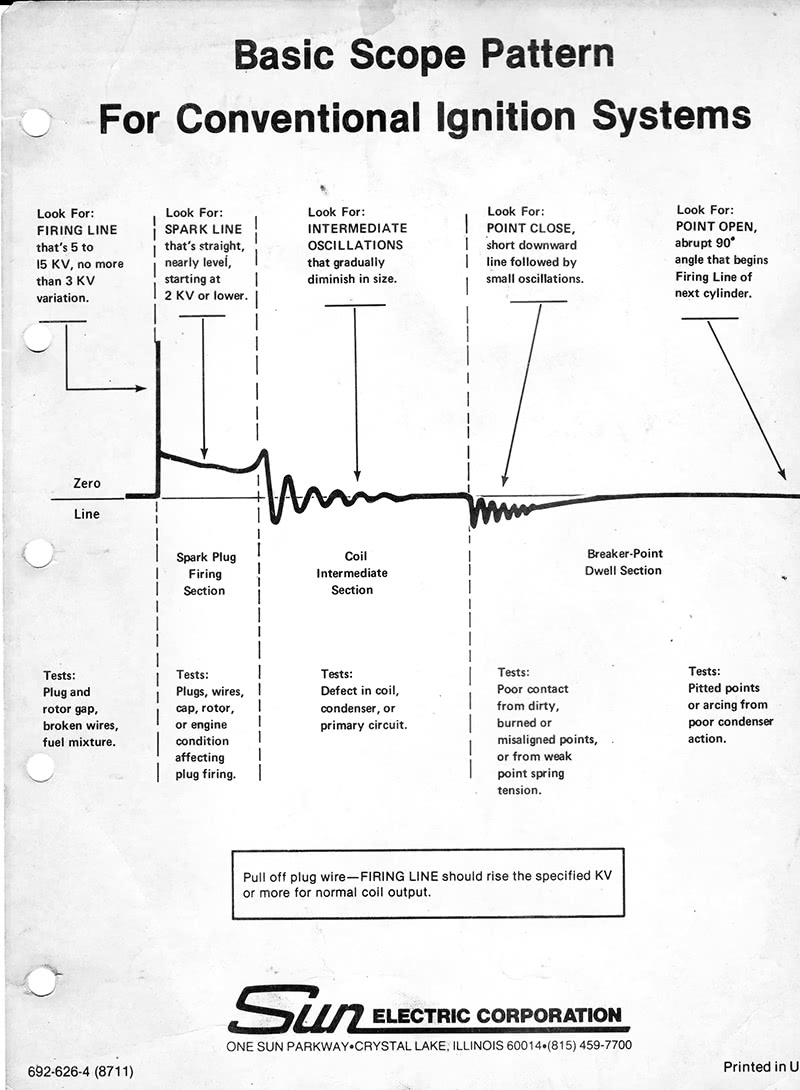

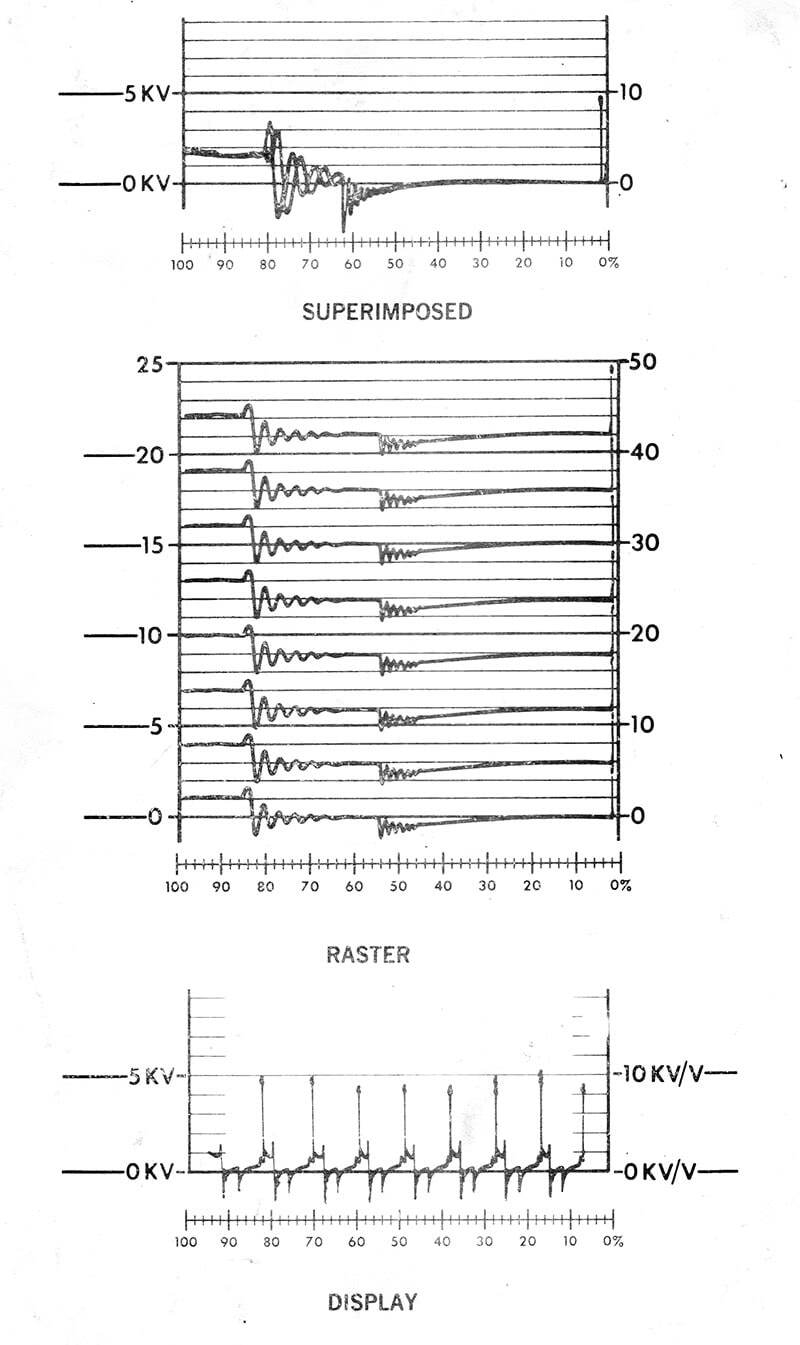

These charts that came with our old Sun Engine Analyzer show typical scope patterns. Courtesy Snap-on. These charts that came with our old Sun Engine Analyzer show typical scope patterns. Courtesy Snap-on. |

Routine maintenance for point-type ignition systems

One of the most valuable skills involved in servicing and maintaining a vintage vehicle is the ability to troubleshoot the ignition and fuel systems. Modern engines commonly go 100,000 miles before they need a “tune-up†(although you might have trouble extracting the spark plugs after that interval), but an older carburetor- and distributor-equipped engine may need to have its spark plugs cleaned or changed and its ignition points adjusted or changed every 12,000 miles. Due to fouling, the life of the spark plugs will be shorter if the air/fuel mixtures and ignition spark advance curves are not correct for the needs of the engine. The ignition points can burn if the key is left on when the engine is not running, and don’t forget to use distributor cam lube to slow the wear of the moveable point’s rubbing block, which helps keep the gap and thus the spark timing right. It’s getting harder and harder for the owners of a vintage vehicles to find a shop that has both an ignition analyzer/scope and a technician familiar with the required maintenance.

Isolating problems using an ignition analyzer/scope

One of the most valuable tools we use when we are troubleshooting or tuning a vintage vehicle is an ignition analyzer/scope. In the 1960s and 1970s, almost every automotive repair shop had a big-box version that often included a basic exhaust gas analyzer to help the “mechanics†diagnose performance problems. These big scopes have the advantage of a large display screen that makes it is easier to see the details of the ignition patterns, plus the sheer size advertises to a potential customer that your shop has the diagnostic tools needed. So, size can be a promotional factor, but modern technology has allowed today’s analyzers to contain all the electronic functions into a hand-held unit.

A dial-back timing light is a very valuable tool when you are checking the spark advance of a distributor.

An analyzer/ignition scope can allow the user to ascertain the health of an engine and its ignition system by observing the spark plugs’ firing voltage for each individual cylinder. What the ignition scope portion does is allow the user to observe the primary and secondary ignition pulses as a waveform/pattern displayed on the screen, enabling him or her to see problems such as open spark plug wires, fouled plugs, low or high spark plug firing voltage demands, and ignition output issues. Also the cylinder balance test function allows a technician to electronically disable or shut down one cylinder at a time to be sure each one is functioning properly. If the rpm change caused by each cylinder being disabled is not the same as that of the others, the cylinder that does not cause the rpm to drop as much will need diagnostic attention, especially a traditional dry/wet compression test. Problems such as a lean air/fuel mixture in any one cylinder caused by a vacuum leak to that intake runner, or any number of mechanical problems such as a worn cam lobe, can cause that cylinder to not perform as well as the others.

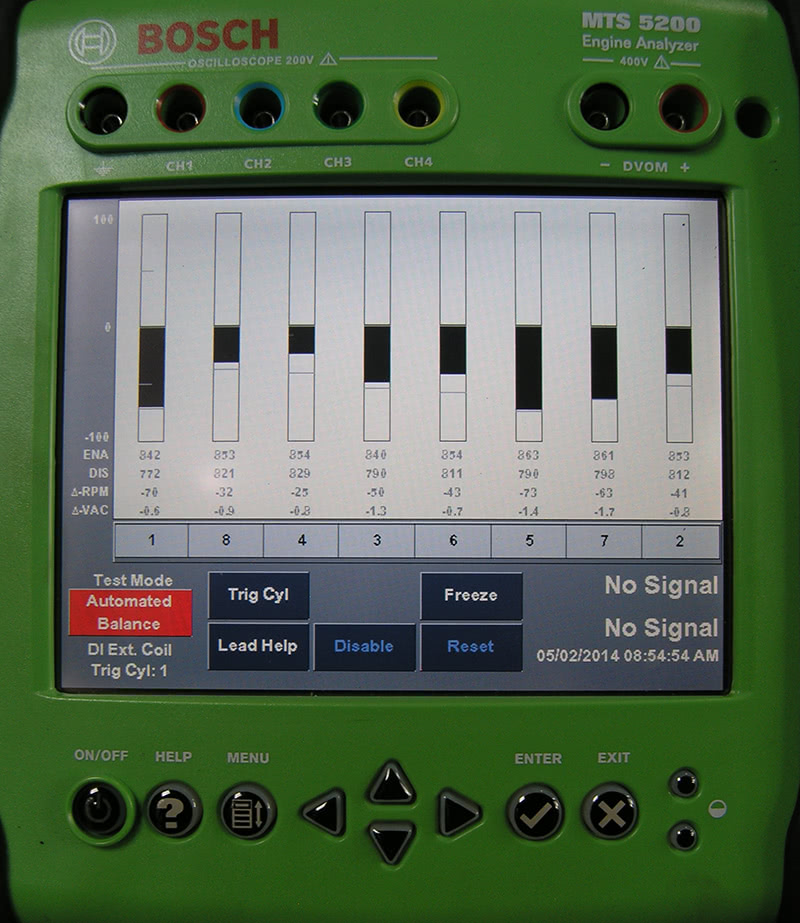

We use both a big box engine analyzer and a hand-held since our 40+ year-old Sun engine analyzer is both bulky and at times finicky. The hand-held is a Bosch MTS5200, which can perform all the same cylinder-balance, primary and secondary ignition tests as our Sun scope, its display screen is very clear, plus it allow us to observe the vacuum signal produced by each cylinder. Obviously, they should all be the same, but if any mechanical problems are present the vacuum waveform display of the MTS5200 can show which cylinder is in trouble.

Some of the other tools needed to diagnosis problems with vintage engines — or any engine, for that matter — are a five-gas exhaust analyzer, a cylinder leak-down tester, a compression gauge, and a vacuum gauge.

An ignition scope allows you to observe the required firing voltage of each cylinder’s spark plug, plus it graphically tips you off to problems such as open or shorted spark plug wires, misadjusted spark plug gaps, or a cylinder with low compression. The firing voltage of each cylinders spark plug can vary with cylinder pressure and the air/fuel mixture in the cylinder therefore if the firing voltage is lower for any one cylinder that cylinder may have a richer air/fuel mixture or lower cylinder pressure than the other cylinders in the engine. The voltage it takes to jump the gap of a spark plug is affected by the resistance of the secondary ignition circuit, things such as the spark gap, rotor to distributor cap contact gap, cylinder pressure and the air the air/fuel mixture in the cylinder all effect how much voltage it takes to create the spark at the spark plug. It takes more voltage to fire a spark plug when the air/fuel mixture is lean (14.7/1 a/f mixture) than it takes when the air/fuel mixture is rich (12 to 1 a/f mixture).

Spark output

A modern engine analyzer such as this Bosch MTS 5200 offers an ignition scope, cylinder balance, and vacuum per cylinder, all in a hand-held unit.

It takes about 3,500V to jump a 0.045 in. plug gap at normal atmospheric pressure (one Bar), but it can take as much as 20,000V or more to fire the same spark plug when it is in the combustion chamber of a typical engine running at full power. During idle and no-load engine conditions, it typically takes 8,000 to 12,000V to form a spark. If all the cylinders have a higher-than-normal voltage demand and the spark plugs are gapped properly, it may indicate a problem with the distributor rotor or cap, or the coil or its wire. If the scope shows that a single cylinder has a different voltage requirement than the others, it could be caused by a damaged spark plug wire, incorrect spark plug gap, a vacuum leak causing a lean air/fuel mixture, or perhaps that cylinder has a compression issue.

The scope pattern can help the user see what’s happening in the combustion chamber. A burn line that slopes gently upward is an indication of a lean condition, while a burn line that slopes down can be indicative of richness. You can further distinguish between air/fuel mixture and cylinder pressure issues by watching for changes at 2,500 rpm versus idle, and the reactions in the pattern when you snap the throttle to wide open.

In order to make the spark powerful enough to ignite the air/fuel mixture under compression, the plug gap must be correct, the ignition coil must generate enough voltage, and the insulation of the secondary ignition system must keep the spark from finding an easier path to ground. It is important to note that loading the engine during testing will allow you to see many problems such as lean air/fuel mixtures, valve problems, and ignition components such as a partially fouled spark plug or a plug wire with faulty insulation that may only show up under load.

We often spray a mist of water on the spark plug wires and distributor cap (commercial sprays are available for this, too). If the engine suddenly develops a miss, plug wires insulation is marginal somewhere. It often helps to dim the shop lights and look for leaking sparks. Other important diagnostic tools we use are a compression gauge, a cylinder leak-down tester, a five-gas exhaust analyzer, a vacuum gauge, and a propane enrichment system (to look for vacuum leaks — you pass the wand-like nozzle over likely areas and listen for the idle to speed up).

Checking for misfire with a non-contact infrared pyrometer

The readings you get from the vacuum-per-cylinder test function of the Bosch MTS 5200 allow you to see which cylinder has a low vacuum problem that may be caused by a flat cam, a vacuum leak, or a valve train problem.

The temperature of various engine components can be used for diagnostic purposes. Just as the temperature drop readings of the inlet and outlet areas of a radiator can be used to confirm that it’s doing its job, temperature readings can also be used when you’re diagnosing engine performance problems. An Infrared thermometer such as the Actron CP7876 we use can measure surface temperatures at the exhaust manifold/header runner for each cylinder. It’s as simple as pressing the button, aiming the laser at the target area, and reading the display. If the reading at an individual cylinder is not the same as the others, that cylinder is in need of diagnostic attention. The low reading could be caused by an ignition or air/fuel mixture problem, especially a misfire whether due to an ignition fault or a too-lean-to-fire mixture from a vacuum leak. Regardless, the combustion process is not occurring normally.

The exhaust manifold runner temperature readings you get from an infrared thermometer should be about the same for each cylinder. If the reading at any cylinder is lower than the others, that cylinder is in need of diagnostic attention.

Once you have determined which cylinder is not performing properly, the first step is to remove that spark plug to see if it’s fouled, or has too large a gap. If the plug has deposits on it, you will need to determine if they are from an overly-rich mixture (in this case, you should see the same condition on the other spark plugs since we’re not talking port injection, but perhaps not to the same exact degree), or from an oil-control problem such as deteriorated valve seals or worn guides. If the deposits are on one side of the spark plug, it’s a hint that oil is getting into the fire through the valve guides.

So, misfires can be caused by an improper air/fuel mixture, vacuum leaks, or ignition problems. It is also important to note that if the misfire is occurring at idle or higher rpm, and if it is in just one cylinder, or multiple cylinders.

A properly-tuned carburetor-equipped engine should perform as well as, or maybe even a little bit better than, the same engine with stock EFI. All it takes is some fine-tuning attention to be sure that vintage engine has the correct air/fuel mixture and ignition spark timing along with healthy compression and valve synchronization to allow it to reach its potential and to perform at least as well as it did when the vehicle was new. It’s very satisfying when customers come back from a test drive and say that they don’t remember when their car ran so great.

0 Comments