Fixing the Car and the Process

Newer Volkswagen vehicles include extensive use of Ultra-High-Strength Steels (UHSS) and other lightweight materials, plus advanced electronics and optional rear view camera technologies that may be embedded in or attached to bumper and body panels. Collision repair service providers must update their equipment and technician training to properly repair these new materials and technologies. The Volkswagen Certified Collision Repair Facility (CCRF) program is helping collision repair service providers adapt.

The Volkswagen CCRF program provides technical information and training to help collision repair facilities better serve their customers, gives dealers a process for ensuring that they have a local collision service provider that can restore their customers’ vehicles to Volkswagen specifications, and offers assurance to vehicle owners that they have brought their damaged car to the right place.

Information Is Power

The key to success is information. Automotive technology is changing almost as fast as computers. Even the best technician needs continuous training just to keep up.

Volkswagen uses advanced hot-formed high-strength and ultra-high-strength steels on many vehicle models. Each requires different repair methods.

For example, boron (a type of high-strength-steel), has a low tolerance for heat. MIG welding is not recommended due to this heat sensitivity. Instead, squeeze-type-resistance spot welding is preferred, with or without adhesive bonding and riveting, depending on the component.

If bent, boron cannot be straightened. It must be replaced as a complete structural member.

Many technicians are now aware that Squeeze-Type Resistance Spot Welding (STRSW) is the best way to weld most high-strength steel. You need application-specific training however, to know whether a structural UHSS part can be repaired or must be replaced, or where to section a part in order to help maintain the required strength of the finished repair.

You need information that tells you exactly where and how a frame rail is attached to other structural components. Without such information, you may crack or fracture a flange seam, weakening the bond and compromising the safety of the vehicle.

Worse, you may attempt to straighten a part that should only be replaced, or weld parts together that should be attached instead using adhesive bonding and riveting. Some advanced or ultra-high-strength steels respond to heat in a manner that, unlike regular steel, weakens them.

A new door may look like a traditional panel, but may be made of a material that you’ve never worked on, or that requires cold straightening rather than heat to remove damage. A new roof panel may feature layered construction that requires special attachment methods.

Volkswagen CCRF participants can link to VW technical and repair information, research a part, and download step-by-step repair or replacement instructions.

Winning on Price

VWoA Approved Paint Suppliers |

| • DuPont Refinish • Standox • Spies Hecker • Akzo Nobel-Sikkens • Akzo Nobel-Lesonal • PPG • NEXA • BASF-Glasurit • RM-Diamond |

Volkswagen wants to help ensure the use of Genuine VW parts in after-collision repairs because they help keep repair quality high. CCRF participants must use new Volkswagen parts for a minimum of 90 percent (in dollars) of the final repair order.

To help make it easier for service providers to meet insurer demands, VW offers a price matching program. Part of the VW OE Parts Connection, the program allows CCRF participants to purchase Genuine VW parts at a lower price that satisfies the insurer.

This price-matching arrangement is a wholesale support program for dealers. It is also a business-building feature for collision facilities, and it is available only to CCRF program participants.

Like a Factory Robot

As recently as fifteen years ago, most collision shops used frame machines that attached to the vehicle at each corner and perhaps a few additional points. As a result, a pull in the front may have affected measurements in the opposite corner at the rear.

Today’s dedicated frame bench has many more attachment points. The technician typically pulls a section that is rarely more than a foot away from the nearest anchor point along the component’s length. It is no longer necessary to inspect or measure the other end of the vehicle after every pull.

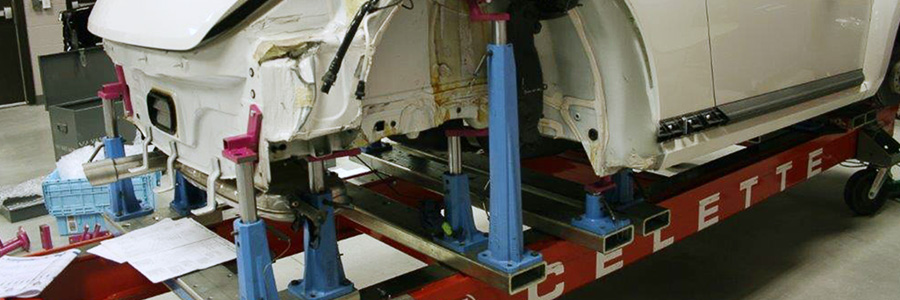

The Volkswagen Certified Collision Repair Facility program requires the use of a bench with fixtures that are specific to individual Volkswagen models. Fixtures and jigs hold the vehicle in place and help allow the technician to place the structural member being repaired or replaced in only one position – with factory measurement precision.

Celette® and Car-O-Liner® are the two frame benches approved in the CCRF program. Celette® manufactures a Volkswagen-dedicated bench, and Car-O-Liner® makes a universal bench that, with optional VW-specific fixtures and jigs, can pinpoint a frame rail as well as a factory robot.

Both manufacturers develop their equipment using Volkswagen chassis blueprints. Each bench offers zero tolerance placements of structural components, and can detect damage so small that it may not easily be found with other equipment.

The model-specific jigs add time to the process of setting up the bench, so shops must recover that cost. Shop estimators present insurance adjusters with the structural component tolerance limits published in Volkswagen vehicle specifications, plus the necessity of a dedicated fixture bench to accomplish repairs within those factory tolerances. It helps adjusters recognize the need to allow extra labor time for setup.

Selling Peace of Mind

CCRF participants promote the program directly to vehicle owners as assurance that they are bringing their vehicles to the right place. They educate their customers about how their Volkswagen-trained technicians, access to OEM technical and repair information, and use of genuine Volkswagen collision parts combine to help ensure that their collision-damaged vehicle will be restored to like-new condition.

Selling peace of mind directly to the vehicle owner gives CCRF participants a potential ally in any discussion with the insurance adjuster about whether or not a specific repair procedure or part is necessary. If you’ve explained that the traditional frame machine is not as accurate as your company-approved dedicated Car-O-Liner® or Celette® bench, and that the genuine VW part, like a suit that has been altered to fit your body, is exactly what your customer’s car needs, it helps overcome price arguments the adjuster may pitch to the vehicle owner.

The Smart Way

In addition to a frame bench that’s dedicated to VW vehicles, Volkswagen lists a few other common-sense requirements for the collision repair facility. There are more special tools required, but the list below hits a few highlights.

- Fully enclosed downdraft paint spray booth

- Dedicated paint mixing room with air extraction available

- Company-approved paint supplier (see below)

- Squeeze-Type-Resistance-Spot-Welder (STRSW)

- Smart Spot Welder

A Smart Spot Welder is designed for two-sided or single-sided spot welding on multiple types of metal, including advanced high-strength steels. A smart spot welder senses the sheet thickness and material type (HSS, UHSS, boron, etc.) and automatically selects the correct weld power, time and tip pressure for the material being welded. There’s no guesswork required, even where there is corrosion protection between metal layers.

Boron steel is hard enough that it can quickly wear out the cutting edges of conventional spot weld drills, cutters, and reciprocating saws. You’ll need stronger spot weld bits and drill bits for making rivet holes in boron.

Volkswagen does not use a lot of aluminum for structural components and body panels. So, unlike certified collision repair programs for many other OEMs, there is no requirement for a major investment in equipment and tools for working aluminum.

Market Opportunity

Volkswagen is not putting a certified collision center on every corner. There are many markets with no, or only one or two, Volkswagen CCRF participants. In those markets, the certified shops draw business from a wider area than the typical non-certified collision repair facility.

VW dealers that have no in-house body and paint capability refer their customers with collision-damaged vehicles to CCRF shops. Independent collision shops that have not had Volkswagen repair training send vehicles with damage in sensitive areas to CCRF shops.

Smart shop owners do not want the risk that comes with working on a vehicle for which their technicians have not been trained. The liability if a structural component or electrical system is not repaired properly is a strong incentive to not take the risk.

A Certified Team

To become a certified VW collision repair center, a shop must also agree to keep its technicians up-to-date as new technology is introduced on Volkswagen vehicles. The training explains how to work with the different metals on specific vehicle models, when to use certain welding or adhesive bonding and riveting techniques, and how other factors such as nearby sensitive electronics may affect the choice of repair procedure.

Talk to the owners of facilities that have already qualified for the CCRF program, and they will tell you it is worth it.

Help your customers better understand collision repair issues, and the reasons that OE parts are recommended.

0 Comments