Electronic Power Steering (EPS) is becoming common on Nissan vehicles. Here’s some technical information and help for when the PS light comes on.

More Nissan vehicles are coming equipped with electronically assisted power steering than ever before, and the trend will almost certainly continue. Electronic power steering is superior to belt-driven hydraulic power steering in almost every way. A large portion of Nissan’s lineup is already equipped with some type of EPS. The Cube, JUKE, LEAF and Rogue have a direct drive electric motor (EPS). The Altima and Quest have an electro-hydraulic system (H-EPS).

The greatest advantage of EPS is improved fuel economy over a belt-driven system. A belt-driven pump system maintains pressure any time the engine is running. This means the engine is burning fuel to operate the power steering pump all the time, even when driving straight down the road and no assist is necessary. An EPS system will only draw power when needed to provide steering assist. This saves fuel.

EPS systems are also typically lighter than traditional hydraulic systems and the less the car weighs, the better it is for both fuel economy and performance.

Another advantage is that an EPS system can tailor the assist to match the driver’s needs. When driving on the freeway, very little steering effort is needed, but when parallel parking, a lot of assist is needed. A conventional belt-driven hydraulic pump will spin slower when parking and faster on the freeway; the exact opposite of what would be desirable. An EPS system is not tied to engine RPM in any way, and torque or pressure can be easily regulated to match need for a better driving experience.

Finally, there are fewer moving parts and less maintenance involved with EPS systems, compared to conventional hydraulic systems, especially with the direct drive systems. Belt-driven hydraulic pumps work hard all the time, and will eventually fail due to vane wear, bearing wear, seal wear, etc. Metal flake lost from the pump can find its way into control valves in the rack and between the rack gear and bushings, leading to premature rack failure. Hydraulic lines going to an engine-mounted pump will flex with every acceleration and deceleration, eventually fatiguing and leaking. EPS systems have none of these issues.

Nissan uses two varieties of EPS: a pure EPS system that uses an electric motor to directly drive the steering column or pinion gear. This system is called EPS, and is most often found on lighter cars. Nissan also has an electro-hydraulic system that uses an electric motor to power a hydraulic pump that provides pressure for a traditional hydraulic power steering system. This is call H-EPS and is usually found on mid-sized vehicles.

An EPS motor is often mounted directly to the power steering rack, but it can also be mounted to the steering column.

H-EPS

Other than the electric motor-driven power steering pump and its speed control system, H-EPS is very much like a conventional power steering system. The power steering pump generates the pressure for assist and valving in the power steering rack controls the flow of the pressurized fluid to assist with steering to the right or left. The advantage of H-EPS over belt-driven power steering is the ability to control the pump speed to meet the need for assist.

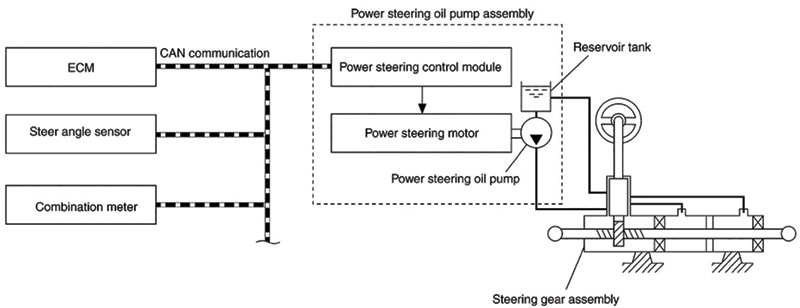

The pump speed is controlled by the power steering control module, which is typically located with the H-EPS motor/pump assembly. The power steering control unit is connected to the CAN communication network, and receives inputs from the steering angle sensor, the ECM, and the combination meter via the CAN bus. The steering angle sensor lets the control unit know the rate of change in steering wheel position. The ECM lets the control unit know the engine status. The combination meter lets the control unit know the vehicle speed. Which control unit provides which input may vary a bit model to model, but you’ll likely see the same inputs on all models. The H-EPS system does not need a torque sensor because the amount of assist is controlled by the valving in the power steering rack.

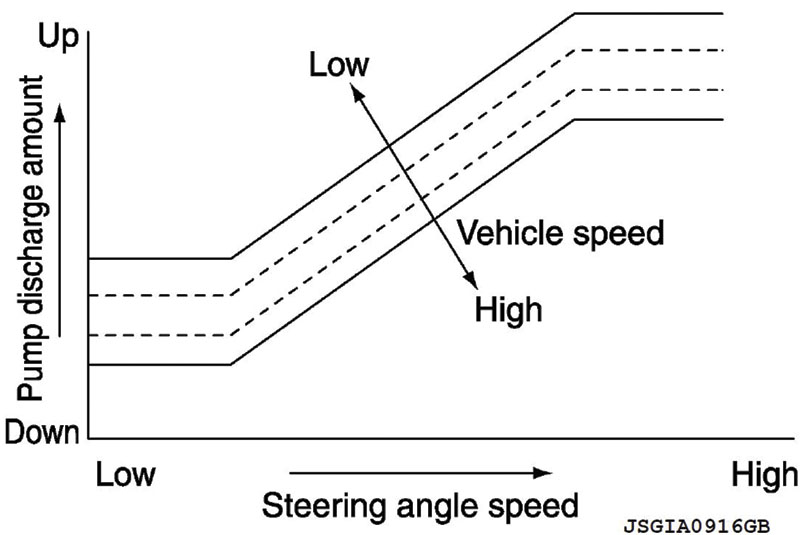

The vehicle speed and steering angle sensor inputs control the pump speed and pressure. The pump speed increases when the vehicle speed is low or the steering angle speed is high because more assist is needed when the vehicle is moving at low speeds and when the driver is turning the steering wheel quickly. Likewise, when the vehicle speed is high and the rate of steering angle change is low, the pump speed and pressure will drop to save power and fuel.

The H-EPS system is better suited to larger cars because the reduction ratio is greater than can be achieved through gear reduction on pure EPS units. This means the size and weight of the system is less than it would need to be for a pure EPS system.

EPS

A pure EPS system needs no hydraulic fluid, lines, pump, or valving. The steering assist is provided directly by a motor. The electric motor can be mounted to either the power steering rack or the steering column.

Mounting to the rack provides the advantage of not subjecting the flex joint between the column and pinion gear to high torque. Because the reduction ratio is smaller, the motor RPM is much lower.

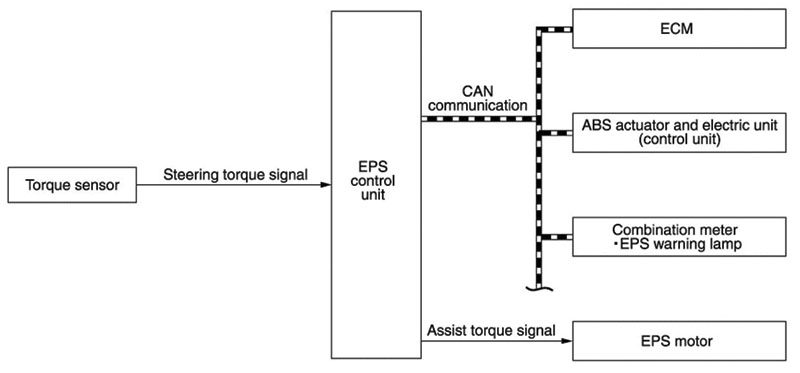

The sensor input to the EPS control unit is a little different for this system. Instead of monitoring rate of steering angle change, the EPS control unit monitors a torque sensor which can be mounted on either the steering column or inside the power steering rack on the pinion shaft. The torque sensor input and vehicle speed input are used by the EPS control unit to calculate the optimal level of power assist.

Because low RPM, high torque electric motors can overheat and be damaged, a protection circuit is built into the system. Often, the temperature sensor is mounted in the EPS control unit instead of the motor, so the motor temperature is inferred rather than directly measured. If motor temperatures become too high, the EPS control unit will lower or completely eliminate the output to the motor. This will not typically happen during normal driving, but the motor can be made to heat up by holding the steering at full lock, or working the steering wheel back and forth while stationary. Once the motor cools, normal operation will be restored.

If you suspect the protection circuit is active, you can check using the CONSULT. In the data monitor there is a PID called “ASSIST LEVEL.†This PID will normally read “100%â€, but will decrease as output to the EPS motor is limited.

EPS Warning Light

- The EPS warning light will illuminate for any of the following reasons:

- The EPS is in failsafe mode (no assist) due to motor overheating.

- A control unit has detected a fault with the EPS system.

- The combination unit is performing a bulb check because the ignition is in the ON position (not running).

Failsafe Mode

In failsafe mode, steering will be more difficult, especially at lower speeds. Failsafe mode can be caused by motor overheating or an EPS system fault. Nissan EPS and H-EPS are not control-by-wire systems. There is always a direct mechanical connection between the steering wheel and the front wheels. The worst that can happen is a loss of assist, not a loss of steering.

Diagnosing EPS Problems

Nissan’s EPS system is more reliable on the whole, so failures are less likely. However, any system can be damaged by external factors such as a collision or improper repair procedures. Let’s start by looking at problems that can be inflicted upon the system. If a wheel is hit hard enough to blow a tire, bend a rim, or tweak a tie rod end, it’s a good idea to check the EPS rack for damage. If the rack gear is bent it will cause excessive steering effort and sometimes the power steering rack will be overlooked during collision repair. If a customer complains that it’s difficult to steer and you find no codes, lift the car and check for binding by sweeping a wheel side to side by hand. If it feels stiffer than normal, disconnect the outer tie rod ends from the knuckles. If there is no binding in the ball joints or strut top mounts, check the pinion rotating torque to see if it is within specification. There is typically no pinion to rack preload adjustment on EPS racks, so if you find pinion rotating torque is higher than specification, replace the rack.

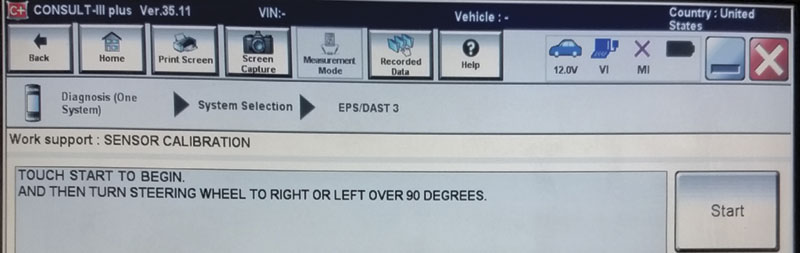

Some models also require a torque sensor calibration after repairs or if the torque sensor reading has drifted. The torque sensor may be located in the steering column or the EPS rack. If the unit containing the torque sensor or the EPS control unit has been replaced, and the torque sensor calibration has not been performed, a C1613 trouble code may set. A C1613 is not an indication of a fault; it’s only an indication the calibration must be performed before the EPS system will operate properly. If the torque sensor value has drifted, you probably won’t find a fault code.

However, you will probably notice that steering in one direction is easier than the other. Also, if you check the EPS data list, you’ll find that the torque sensor value is not “0†when the steering wheel is at rest. The torque sensors on some other models self-calibrate so no calibration is necessary. The only way to perform a torque sensor calibration is with a CONSULT.

The steering angle sensor is another sensor that may require calibration. On H-EPS systems, the steering angle sensor (SAS) is an important input for determining desired EPS pump speed. On EPS systems, the SAS is primarily for the traction control system; the torque sensor is the primary input for the steering system. Regardless, the SAS will be located in either the column or the rack, so when replacing steering components, you may need to perform a calibration. However, you’ll likely find the EPS ECU receives SAS data via the CAN bus. The SAS may exist as its own node on the bus, or it may report to the ABS/VDC ECU. You’ll need to check the service manual to find out which unit has the SAS calibration utility for the car you’re repairing.

Self-Diagnostic Capabilities

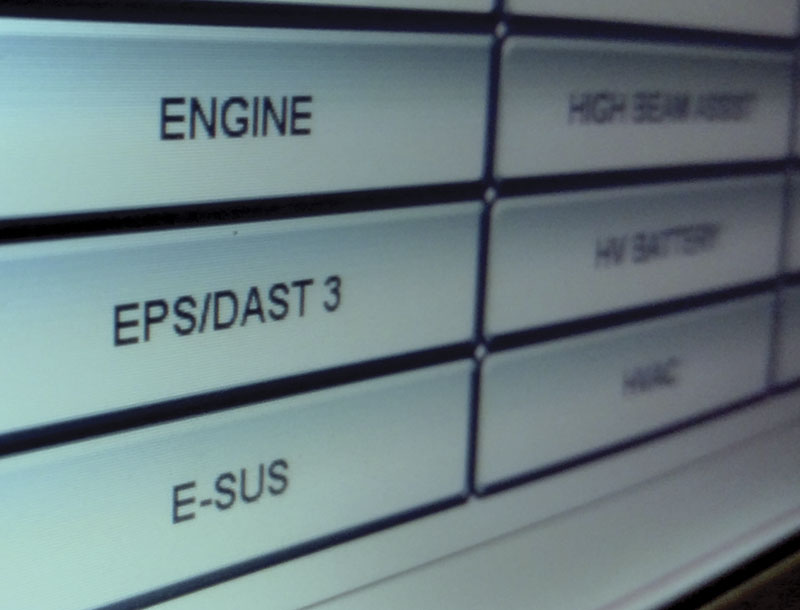

The EPS and H-EPS systems will offer some diagnostic help if things go wrong. The available self-diagnosis and trouble codes will vary from model to model.

C1143 – Steering angle sensor. This code will likely appear in the EPS ECU on vehicles with the H-EPS system. On vehicles with pure EPS, this code will likely set in a different ECU.

C1601 – Battery power supply. This code most often sets because the 12V battery becomes discharged while the vehicle is sitting with the key in the ON position, but it can also set if the alternator or DC/DC converter fails, or if the power supply to the EPS ECU is too low (< 8.5V) or too high (> 18.5V) for any reason.

C1604 – Torque sensor. This code will only occur on EPS systems, not H-EPS systems

C1606 – EPS motor. This code will set on both EPS and H-EPS systems. On H-EPS systems it refers to the pump motor. On EPS it refers to the drive motor.

C1607 & C1608 – Both of these codes indicate internal EPS ECU faults. If they reset after being cleared, the EPS ECU needs to be replaced.

C1609 – Vehicle speed sensor. Only some models will set this code. Others will only set a P0500 code.

C160A – Overheat protection. Only some models will set this code, even though all models will limit torque to prevent overheating. This code does not indicate a fault, it just indicates the temperature protection was activated. This code can be handy if a customer complains his power steering stopped working for a while, because it allows you to confirm that overheat protection was likely the cause.

U1000 – CAN communication circuit. This code will set if the EPS ECU can’t receive or transmit on the CAN bus for a period of time, usually around 2 seconds.

Always check the proper service manual or visit the Nissan Tech Info site at www.nissan-tech-info.com for the correct information for the model and year of the vehicle you are servicing.

0 Comments