Reformulated gasoline (RFG) made with 10% ethanol (E10) lowers evaporative emissions and reduces NOx and other exhaust pollutants. However, despite laws regulating fuel composition, storage, and retailing, it is difficult to guarantee a minimum quality level for the gasoline sold in every market. Misfires, knocking, volatility problems and other issues can occur due to lack of adequate fuel quality controls. RFG quality variations can result in different engine performance from one tankful to the next.

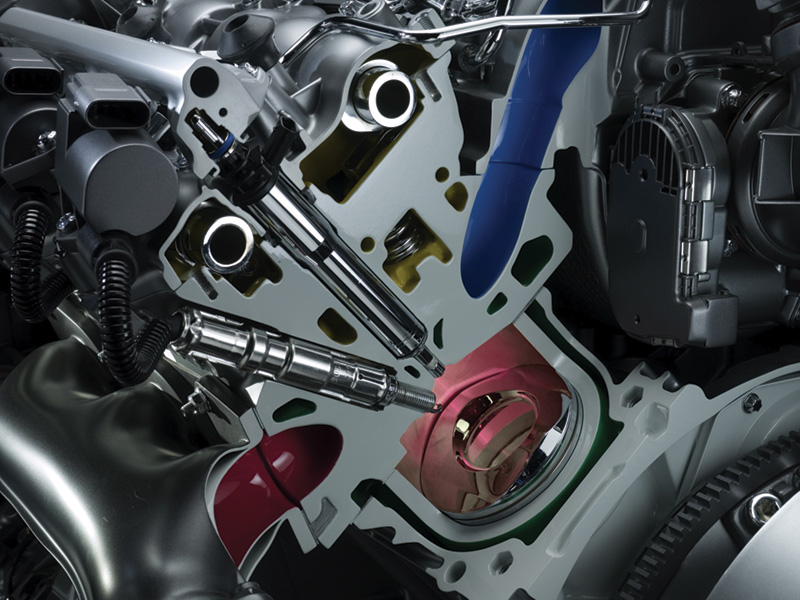

The Mercedes-Benz lambda control system manages the air/fuel ratio so that the mixture is perfectly balanced for the engine load under startup, idle, acceleration, or cruise operating conditions. Low-quality reformulated gasoline brands can cause carbon buildup in the injectors, leaky valves due to seat deposits, corrosion of sensors, and other problems.

Gasoline in the early days of the automobile was pretty unrefined, and tended to ignite prematurely in the combustion chamber. The old Keystone Cops movies made fun of that with their police wagons that were constantly backfiring and belching smoke out of the exhaust.

For decades, we added tetraethyl lead to gasoline to help minimize the performance-robbing effects of spark knock. Then, air quality concerns gave us catalytic converters and oxygen sensors, and lead had to go. It coats the catalyst and O2 sensor surfaces, rendering them ineffective. Plus, we learned that lead was not such a good thing to allow into our groundwater.

Along with banning lead, the Clean Air Act Amendments (CAAA) established regulations to reduce air pollution beginning in 1995 in US cities that had high atmospheric ozone levels. Cities had to reduce air pollution (CO and NOx), and reduce volatile organic compound (VOC) emissions during the summer when it contributed more to ozone formation.

To accommodate these environmental impact reduction objectives, the Environmental Protection Agency (EPA) established new regulations for fuel used in ozone non-attainment areas. Reid Vapor Pressure (RVP) levels — a measure of a fuel’s volatility — were reduced for summer months to help cut ozone-forming VOC emissions. More recently, the EPA lowered sulfur limits because that element increases the light-off temperature of advanced three-way catalytic converters, reducing their conversion effectiveness. Mercedes-Benz suggests the use of low-sulfur (< 10 ppm) or sulfur-free gasoline in its vehicles that have NOx catalysts featuring alkaline earth/rare metals, although higher levels (30 ppm in California, 80 ppm elsewhere) are acceptable.

Benzene, an octane booster and knock reducing fuel component, was limited to 0.62% due to concerns about its carcinogenic properties. Similarly, MMT (manganese), another octane enhancer, was limited to 1/32 gram per gallon due to concerns about adverse health effects in humans.

Reformulated Gasoline

All of these regulations ultimately resulted in the mandatory use of Reformulated Gasoline (RFG) in at least a third of the U.S., and voluntary adoption of the standards in other major North American markets.

We replaced lead with new compounds called oxygenates that are designed to increase the oxygen content of fuel. Increasing oxygen levels results in more complete combustion and a reduction of carbon monoxide emissions, which helps decrease harmful ozone formation in our atmosphere. The primary oxygenates in use include methyl tertiary-butyl ether (MTBE, which has recently fallen out of favor due to concerns about it getting into our groundwater and causing illness), ethanol, and tertiary-amyl methyl ether (TAME, used with diesel).

The ethanol in reformulated gasoline (RFG) increases its octane level. Octane is a measure of a fuel’s ability to withstand compression without igniting. Low octane gasoline can ignite at lower temperature than a high-octane fuel. So, a gasoline with a higher octane rating helps prevent spontaneous ignition of the air/fuel mixture (see detonation sidebar).

Good Intentions

At least your customers always get a warning that the gasoline they’re buying contains potentially-troublesome ethanol.

Reformulated gasoline (RFG) means well. It helps reduce evaporative emissions and lowers the amount of smog-forming particles and toxic pollutants in the exhaust, both of which reduce harmful greenhouse gases that are possibly contributing to the warming of the planet. Also, because it contains 10 percent ethanol — a fuel component derived from corn grown here in America — RFG contributes to a reduction in our dependence on foreign oil.

Detonation (Spark knock)

|

Properly produced and maintained, RFG is safe to use in most 2005 model year and newer spark engine vehicles. The majority of Mercedes-Benz, Maybach, AMG, and Smart models with gasoline engines can safely use RFG with 10 percent ethanol (E10). E10 compatibility information is available at www.mercedes-benz.de (option: Mercedes world/Innovation/Biogenic fuels). The homepage also has an interactive tool for an immediate E10 compatibility check against a VIN. In the harsh real world, however, Mercedes-Benz vehicles of all possible model years are commonly burning reformulated gasoline.

Controlling Engine Timing

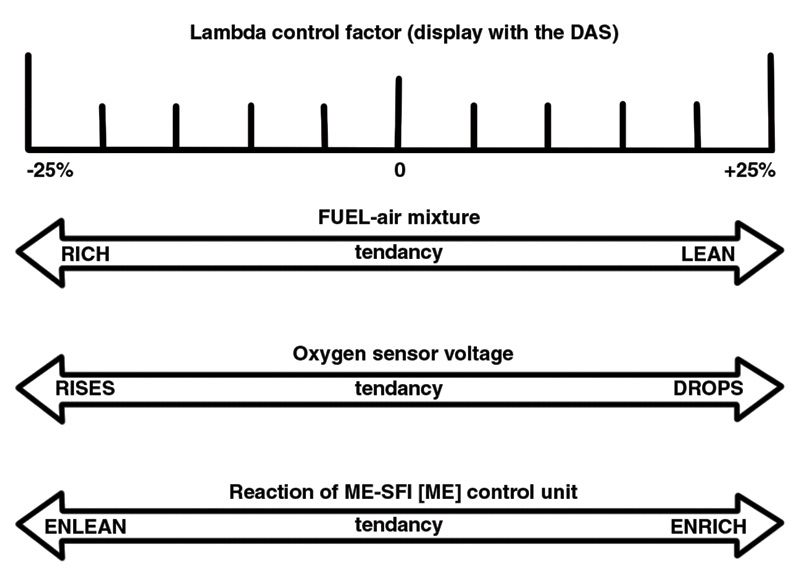

The Mercedes-Benz Motor Electronics Sequential Fuel Injection (ME-SFI) and ignition system controls engine timing. It adjusts the air/fuel mixture to compensate for many variables, including the fuel volatility and pressure, engine load (cold start, idle, cruise, or acceleration), temperature, Mass Air Flow (MAF) and O2 sensor inputs, and other sensor data to balance engine performance against emissions requirements.

One difference of E10 versus traditional unleaded gasoline is its higher evaporative cooling of the air/fuel mixture. Although this helps reduce knock tendencies, the lower charge temperature also reduces fuel volatility, which hurts cold start efficiency.

The Mercedes-Benz ME-SFI system is up to the challenge. Its sophisticated mixture control software divides the cold start process into three separate stages: Start, Post-start, and Warm-up. During the first stage (Start), lambda control monitors temperature, engine load, and injection time. Based on these and other sensor inputs, the ME-SFI unit enriches the air/fuel mixture by extending the injection time. This monitoring and adjusting process is repeated until a rich mixture is no longer needed. The ME-SFI control unit alters the mixture with a time delay if necessary to ensure a smooth, jerk-free start.

After the first phase of cold start, fuel condensing on the walls of the combustion chamber could cool or lean out the air/fuel mixture and cause a stumble. For a few milliseconds after the initial cold start, the ME-SFI unit runs a second, Post-start stage in which it checks coolant temperature and other sensor input and extends injector time as needed to ensure continued smooth engine operation.

After the first two stages, A/F mixture enrichment continues a bit longer to compensate for fuel that has precipitated on the combustion chamber walls in any cylinder. The ME-SFI control unit checks the hot film MAF, intake air temperature, engine load, EGR rate, and other sensor input and continues enrichment as needed to ensure that engine and emissions operation matches the performance map in the computer.

This third, Warm-up stage is the last of three cold-start stages in the ME-SFI system sequence. As startup progresses, hot exhaust gases heat up the combustion chambers, fuel evaporation is increased and enrichment can be reduced.

Of course, knock control is part of the ME-SFI control unit function. When it detects knocking, the ME-SFI unit retards timing for the offending cylinder.

Cost Cutters

“Garbage in, garbage out†applies here. All of the sophisticated Mercedes-Benz A/F management procedures lose effectiveness if the gasoline used does not meet minimum quality standards.

The EPA requires all gasoline to have detergent additives that help reduce harmful deposit buildup on pistons, intake valves, and other engine components. Carbon and varnish deposits interfere with intake valve seating, clog fuel injectors, disrupt spray patterns, and reduce fuel delivery. It leads to misfires, detonation, rough idle, reduced fuel economy, and increased emissions.

Recommending that your customers buy only “Top Tier†brands of gasoline from high-volume “pumpers†will go a long way in heading off fuel-related troubles.

Of course, the EPA cannot check every bulk truck as it leaves the fuel distribution point. Enforcement is limited to setting the occasional example via large fines. That leaves room for unscrupulous manufacturers to use the cheapest, or even eliminate, some additives in an effort to cut costs.

Phase Separation

In some locales, ethanol-free gasoline is available. It’s sold at a hefty price premium, however, so is mostly used for boats, RVs, yard equipment, and other engines that don’t see regular use.

Ethanol naturally absorbs moisture from the air as well as from condensation inside the underground storage tanks (UST) at gas stations. Water absorption continues until the ethanol becomes saturated, at which point it is heavier than gasoline and falls to the bottom of the UST. Called “phase separationâ€, this layer can consist of up to 80% ethanol and 20% water.

Phase separation depletes the remaining fuel in the UST of some of its ethanol, altering its ability to meet RFG oxygenate specifications. The fuel will deliver less than the required 10% ethanol to the vehicle, which reduces its octane rating and causes A/F mixture problems in the engine. If the phase separation is above the tank pickup and is drawn directly into a vehicle, the 80% ethanol concentration can cause stalls or even damage the engine.

Traditional UST test floats are designed to identify “pure†water, and are less likely to detect phase separation due to its higher density compared to water.

Stoplight Blending

The gasoline, deposit control additives, and ethanol that make up reformulated gasoline arrive at the fuel distribution terminal as separate ingredients. They are poured into a bulk tanker with the expectation that by the time the truck arrives at its delivery point, it will have been through enough hills, valleys, and red lights to have fully mixed the fuel ingredients. Unfortunately, if blending is not complete, the first stop may get a “hot load†– a delivery of a higher-than-specified concentration of ethanol. Too much ethanol in a vehicle can increase NOx emissions and cause lean misfires, which increase emissions of undesirable hydrocarbons.

Use By?

The Mercedes-Benz lambda control system manages the air/fuel ratio by timing injection so that the mixture is perfectly balanced for the engine load under startup, idle, acceleration or cruise operating conditions. Low quality reformulated gasoline brands can cause carbon buildup on the injection valves, leaky valves due to deposits at the seat, corrosion on the fuel pressure sensor, and other problems.

Gasoline freshness is critical to smooth engine operation. Performance tuners and racers will tell you that the shelf life of gasoline is 60 to 90 days. After about 90 days, the light ends of the hydrocarbons start to evaporate. This leaves behind a less volatile fuel – which will cause problems with the A/F mixture, and possibly alter engine performance, fuel economy, and emissions.

Gasoline that is allowed to get truly old will begin to oxidize. Symptoms of oxidation are a sour odor, dark color, and, eventually, formation of a gummy residue. Oxidized gasoline can clog fuel filters and create varnish deposits in the fuel pump and injectors. A major fuel pump manufacturer conducted teardown tests on warranty returns and found that 62% were returned for reasons other than defects or pump breakdown.

Buyer Beware

Luckily, there are easy, common sense things vehicle owners can do to protect themselves from the potential problems with reformulated gasoline. Using only the Mercedes-Benz recommended fuel type and grade is at the top of the list. Use of non-approved fuel grades may void the vehicle warranty.

Buying nationally-known, high-quality brands is next. Over two dozen gasoline retailers in the United States participate in a program that sets standards for reformulated gasoline deposit control, intake valve cleaning capability, ethanol content by volume, fuel volatility, and levels of other components, including sulfur, aromatics, and olefins. Called “Top Tier Detergent Gasoline,†the program is endorsed by top automakers, including Mercedes-Benz.

The fuel manufacturing guidelines are based on ASTM content and performance standards, Federal (EPA) requirements, and voluntary testing to verify that fuels meet the standards.

Vehicle owners should also avoid pouring do-it-yourself additives in the tank. Mercedes-Benz invests a huge amount of research, in the lab and on vehicles, into determining the correct type, quantity, and mix of additives to optimize fuel performance. Do-it-yourself additives may not be adapted to the mix already in the factory-recommended fuel grade, and may have negative consequences that void the warranty.

When fuel problems do arise, the owner should be encouraged to bring the vehicle in to an ISP (Independent Service Provider) or dealership for evaluation and service. For example, Mercedes-Benz has specific products and procedures for deposit removal, and for fuel injector cleaning or replacement.

We’ve come a long way since the days of the Keystone Cops. With a little attention to what they put in the tank, vehicle owners can keep their cars from belching and sputtering down the road.Â

0 Comments