Traditional or updated? Carb or EFI? Crate engine? Package from a donor car? Here’s help making those decisions.

When the engine in a classic vehicle is in need of an overhaul or an upgrade, the question many people ask is should they rebuild their original engine or replace it with something more modern. To my mind, a classic vehicle only looks right when it has the original powerplant or maybe a high-performance carburetor-equipped engine under the hood. There is also the option of installing a late-model computer-controlled fuel-injected engine, but most of these just don’t fit with the image of a classic when you open the hood. No matter what your or your customer’s choice is, you need to be sure the selected package matches the way they drive.

Match making

If you’re contemplating either a rebuild or replacement, the most important things are that the engine is compatible with the rest of the vehicle’s drive train and, as already mentioned, the way the vehicle will be driven. An engine built for high rpm power is not the best choice for a vehicle that will be used for cruising, just as a “stock†engine is not the best match for a driver seeking maximum high-speed performance. The time you spend finding out how customers will really drive their vehicles and what they expect to get for the dollars they are spending will allow you to be sure your customer will get all the power and driveability they desire.

The questions you need to ask before you rebuild an original equipment engine or select a crate engine package are things such as:

- How will the vehicle be driven?

- Will the original carburetor and intake manifold be used, or will the engine be updated with a performance intake manifold and aftermarket carburetor(s)?

- Would it be a good idea to install a modern computer-controlled fuel-injected engine, or should the original be updated with an aftermarket fuel injection system?

- What rpm band will the engine normally be operating in given the owner’s driving habits?

- Will the car be used as a daily driver or a weekend hot rod?

- Will the vehicle have an automatic or manual transmission?

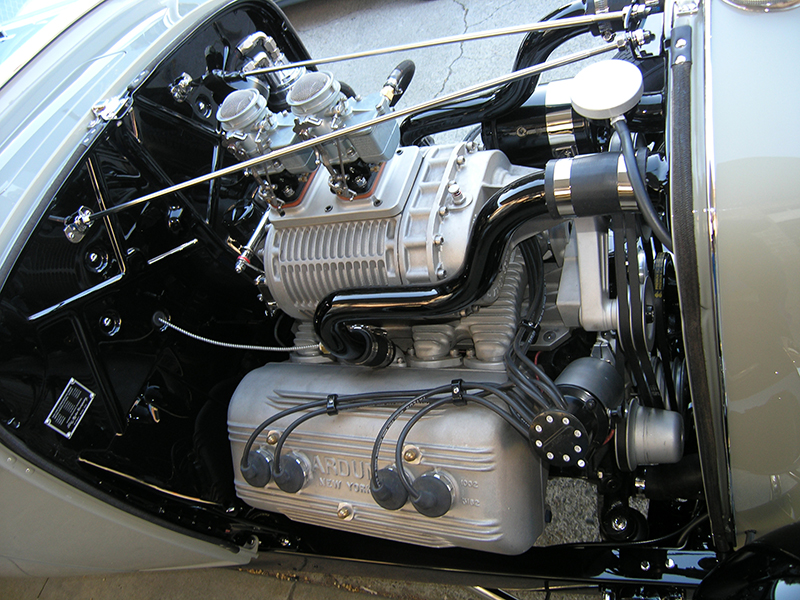

Ardun heads have transformed this flathead Ford into a potent and eye-catching OHV engine. The supercharger and dual two bbls. add to the visual impact. A modern EFI engine might be easier to live with, though.

Note: If an automatic transmission is being used, you need to be sure that the torque converter stall speed is correct for the engine and camshaft package because it is vital for a stable idle.

The answers to those questions will determine the conditions the engine will be performing in, and allow you to provide the best, most practical package for the intended use. With the proper selection, idle will be stable in gear even when the air conditioning compressor is cycling, or when the amp load of an electric fan load is causing the alternator to drag the rpm down.

High-performance crate engines

We have had quite a few customers tell us that the high-performance engine they just installed in their car does not perform as well as they think it should. More often than not the problem is that the engine was built to produce power at higher engine speeds at the expense of low- and mid-range rpm power and drivability. A high-performance crate engine such as a Chevrolet ZZ430 or Roush 427R does make a lot of horsepower, but most of that is in the 3,000 to 6,000 rpm range. Too many people seem to want an engine that makes big horsepower, but are not aware that it may not be all that drivable below 3,000 rpm. The main question you need to ask before you buy or build any high-performance engine is, “Does the power band match the way the owner will be driving the car?â€

Selecting or building-in an engine’s power curve

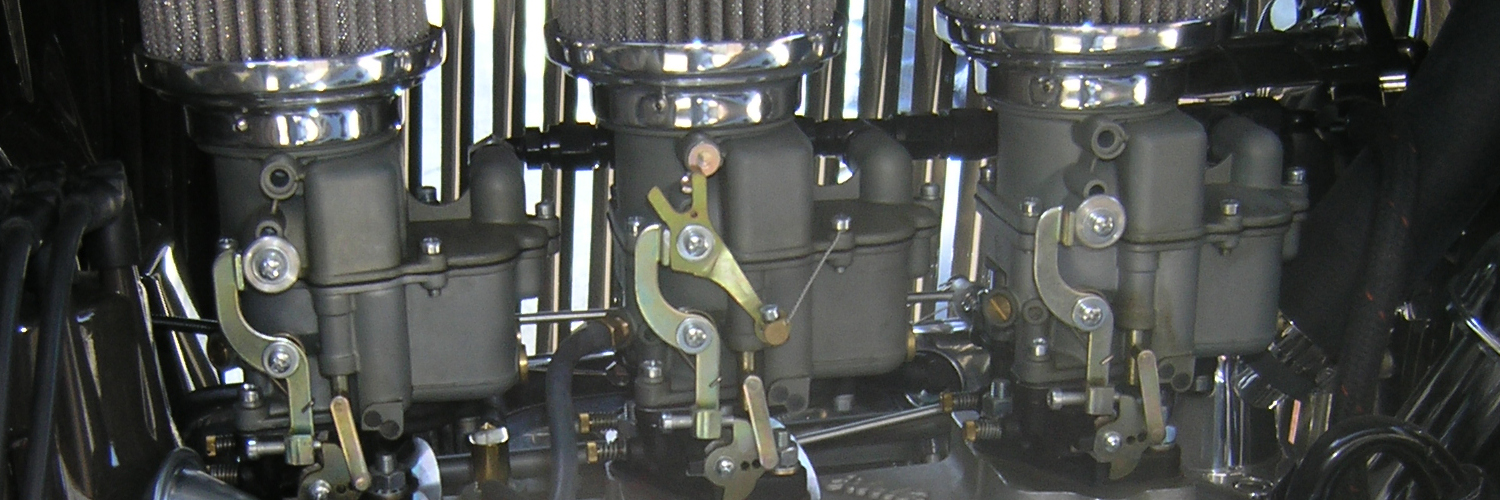

This one-off small-block Chevy has a set of Smokey Yunick heads with a cross ram intake manifold fed by two Holley four bbls. Will this match the customer’s actual driving habits?

The cornerstone that an engine is built around is the camshaft. Therefore, you should select a cam and matching valve train components that are designed for the way the driver will use the engine. Also, make sure the valve springs are designed for both the cam profile and the cylinder heads being used. Whenever you are selecting a high-performance camshaft for a modern fuel-injected engine, be sure that it is designed to work with the computer’s program and its various sensors. There are no free lunches — when a hot cam is used to gain power at high rpm, it will produce less power at lower rpm. The same thing applies when you select a camshaft to give a satisfyingly lumpy idle — low rpm performance will suffer. A better choice would be a camshaft that will allow the engine to have both a usable rpm range in which it will produce its best horsepower, and an ideal cruise rpm where it will operate at peak efficiency. Typically, camshaft manufactures supply the necessary data in their product catalogs.

If the engine will be used as a daily driver with stock gearing and an automatic transmission with a stock torque converter, a camshaft with a duration in the 195 to 210 degree range (measured at .050 in. of lift) may be the best choice. High-performance cams typically have durations ranging from 220 up to 280 degrees or more. The longer the duration, the rougher the idle and the higher the rpm at which improved power will occur. A cam with a duration of 240 degrees or higher will typically perform its best in the 3,500 to 7,000 rpm range.

The best cam for any application will have an ideal cruise rpm that matches the conditions the driver will be operating it in most of the time. If the engine is fuel injected, the cam you select must be designed for the EFI system you’re using because the computer relies on vacuum sensors, air flow sensors, and oxygen sensors to determine the amount of fuel the engine needs to run its best (also, for efficient spark timing).

Carburetor or fuel injection?

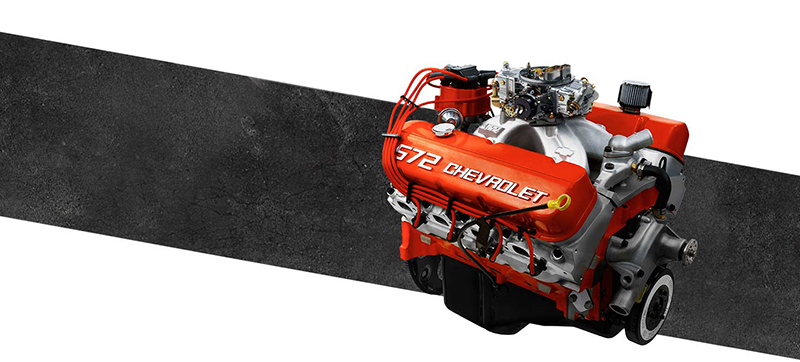

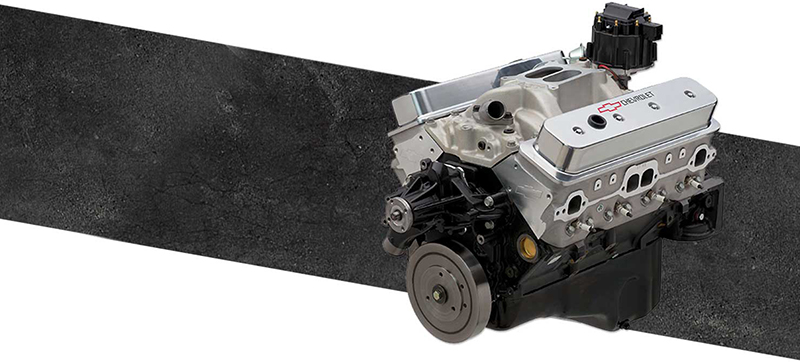

This Chevrolet ZZ572 crate engine produces 620 horse-power at 5,600 rpm, and still has plenty of torque at low rpm for cruising.

One of the more passionately debated issues in the hot rod world revolves around which is better, EFI, or a carburetor? I often hear vintage vehicle purists say, “If you want a modern fuel-injected engine, you should go to a dealership and buy a new car. If you have a vintage carburetor-equipped car, learn how to make the carburetor system work its best and enjoy the ‘Vintage Experience’â€! The retort to that statement is that when a modern computer-controlled fuel-injected engine is working properly, it is a wonderful thing, so why exclude this new technology from your choices when you are trying to build a functional and efficient vintage vehicle or street rod? All things considered, it’s easier and cheaper to build a carburetor-equipped engine than it would be to build an engine that makes the same power with fuel injection.

Carbureted engines

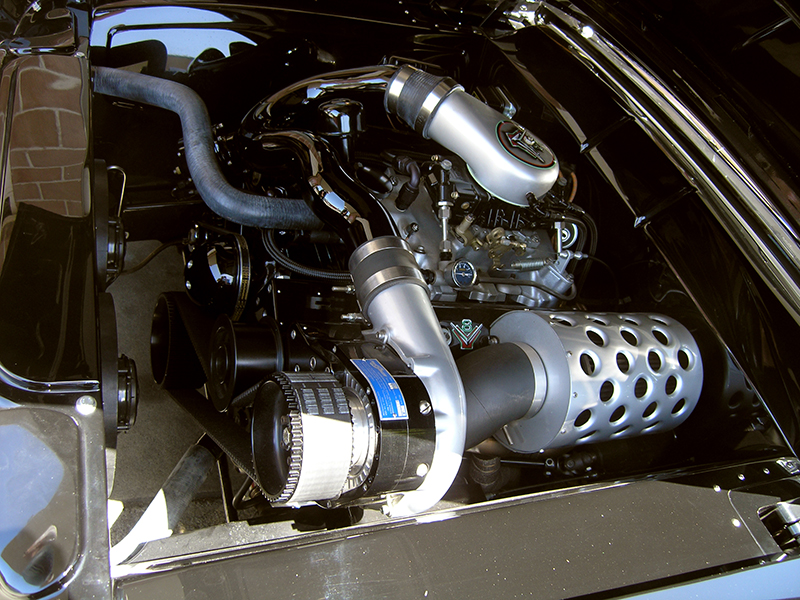

This supercharged Y-block Ford has a very special look. If you have something unique like this, it doesn’t make sense to swap it out. Overhaul it when needed.

The original equipment carburetor(s) and intake manifold can be “jettedâ€/retuned to work with today’s reformulated unleaded gasoline so the engine will perform at its best.

Note: For more info on today’s gasoline, visit Frankenfuel: Reformulated Gasoline and Vintage Vehicles.

If an upgrade to the intake manifold and/or carburetor(s) is being considered for the making of more power, the carburetor/intake manifold combination should be selected based on the way the engine will be used. A dual-plane intake will help an engine make more low-rpm power, while the single-plane type can make more power at higher rpm. Air-gap style intakes may make a little more power, but at the expense of balky cold engine operation and low rpm power due to the lack of heat in the manifold that helps keep the air/fuel mixtures vaporized.

Note:Â For more info on fuel vaporization, visit Running on vapors and mixing it up.

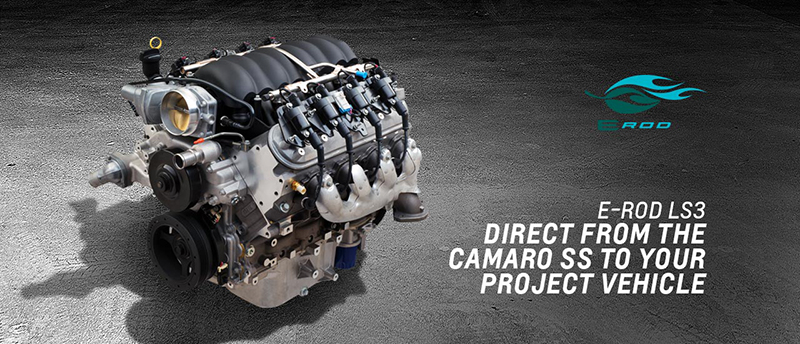

A Chevrolet E-Rod engine with a matching automatic transmission and PCM is a good choice if you want a modern fuel-injected package in your vintage vehicle.

Timing the spark

A modern computer controlled engine has had the ideal spark advance programmed into its PCM, but the advance curves of a vintage carburetor-equipped engine were designed for a blend of gasoline that no longer exists. The initial spark timing, the mechanical spark advance curve, and the vacuum advance all must be tuned to the match the needs of the engine and the fuel being used if you want to experience all the potential power that was built into the engine. It is also important to know that even if the engine was “dyno-tuned,†that does not mean the initial timing setting, the mechanical spark advance curve, and the vacuum advance curve are ideal for the engine once it is in the car.

Note:Â For more info on tuning the ignition spark advance, visit Re-Curving Ignition Timing.

Aftermarket fuel injection

Ford Racing offers a Coyote crate engine package for a transplant that provides modern performance and driveability.

There are several different aftermarket fuel injection systems that can be used on a vintage engine. These start in the mid-$2,000 range, and they’re advertised as “self-tuning,†but they’re not foolproof. The engine must be in good shape with a camshaft that is compatible with the fuel injection system you’re using. These systems do a good job of tuning the cruise and power air/fuel mixtures, but tuning the idle and off-idle systems can be challenging if the engine has a performance camshaft or an automatic transmission with a tight torque converter.

An engine management system injects the fuel and supplies the spark as the factory engineers programmed it to do with the “stock†engine in the vehicle it was designed and programmed for. Any modification that causes a change in the vacuum or intake airflow may create performance and drivability issues. The computer was programmed to look at the output data from its various sensors so it can provide the engine with the perfect air/fuel mixture and fire the spark plugs at the correct time. When the data coming from these sensors does not match up with what the computer was programmed to expect, performance will suffer.

The OEM fuel injection option

The best choice when you want to install a modern fuel injected engine in a vintage car or truck would be to purchase a package that is designed and programmed to work properly in a generic vehicle. General Motors offers several different fuel injected engine and transmission packages that include the electronic control module, all wiring harnesses, and other key components you will need to install it in a vintage vehicle. An O.E.M. engine package from the factory was designed and programmed for that specific vehicle with its exact aerodynamic profile, weight, and all the other load factors, which may be quite different once the engine is in a vintage vehicle, and this can cause driveability and performance issues. By the way, be very careful when you’re working with an engine package that has an electronic throttle system. If all the controls and sensors are not designed to work with each other, you could end up with unintended acceleration and legal liability problems.

Fuel injected donor engine option

As technically complicated as the modern fuel injected engine packages are, it might make sense to obtain a healthy engine package (engine, PCM, and harness) from a running vehicle that you are sure has no performance or drivability problems, or any PCM trouble codes. Since most modern automatic transmissions are controlled by the PCM it would also be wise to use the transmission from the same donor vehicle to avoid potential safety and/or liability issues that could arise if you use components that were not designed to work with the factory PCM.

If you do go the donor car route, it would also be smart to make a printout of the PCM data through a scan tool before you remove the engine package. Then you can be sure it matches the data you get once the engine is transplanted into its new home. The donor vehicle’s VIN should also be kept since it is often needed when ordering parts.

This is the PCM, harness, and sensor package for a Ford crate engine. Everything works together properly.

An advanced scan tool such as the OTC/Bosch Genisys Touch can perform a comprehensive health test of the vehicle’s PCM and supported systems. Many of the tests can help you determine if the engine has any mechanical or electronic issues by looking at generic or enhanced DTCs (Diagnostic Trouble Codes), freeze frame data, Mode 6 component tests, and data stream readings, You can perform fuel injector control tests and cylinder power balance tests to determine if the engine is operating properly. You can then record and/or print the results for later reference if you should have any problems after the transplant. Engine misfire data and the short- and long-term fuel trim readings that can be accessed with an advanced scan tool are good indicators of fuel system adjustments being performed by the PCM to compensate for engine wear issues.

Note:Â For more info on modern engines in a vintage vehicle, visit Out With The Old, In With The New.

Results

Proper planning will give you an engine that is built for the needs of the owner, and that can supply all the power he or she wants while being designed for the type of driving that will be done. A good engine builder/supplier who knows how all the engine parts will work together should be able to match an engine package with the needs and desires of the customer for performance, yet be reliable and fun to drive.

Â

0 Comments