A look at the MR16DDT turbocharged, direct-injection gasoline engine in the JUKE, covering the engine design, direct injection system, turbo, and continuously variable valve timing. Also, a few service procedures and diagnostic considerations for this engine.

Small Displacement, Big Output

The Nissan JUKE comes standard with advanced engine design and engine management systems that may become much more common across all manufacturers. The reason is simple: the MR16DDT engine achieves a great balance of power, fuel efficiency and low emissions. Automobile manufacturers are under constant pressure to reduce their vehicles’ emissions while increasing fuel efficiency. These gains are almost always at the cost of engine power and performance. The engineers at Nissan have developed an all-aluminum, 4-cylinder, 1.6L engine that boasts 188 hp and achieves approximately 27 mpg in a 3000 lb. JUKE.

The MR16DDT utilizes many technologies to achieve its excellent power-efficiency-emissions balance:

- Advanced internal engine mechanical design

- Extraordinary fuel control through gasoline direct injection (DIG)

- Continuously Variable Valve Timing (CVVT)

- Â Forced air induction through turbocharging

The JUKE also utilizes a high-efficiency automatic transmission, intelligent throttle control, and other vehicle-specific systems.

It’s also worth mentioning that the Nissan JUKE NISMO edition further improves the performance of the stock MR16DDT with ECM tuning and modifications to nearly 100 individual components. The NISMO RS can output 215 hp, thanks to increased exhaust flow from larger diameter piping, enhanced ECM tuning, reinforced piston connecting rods, and a limited slip differential to ensure the power meets the ground.

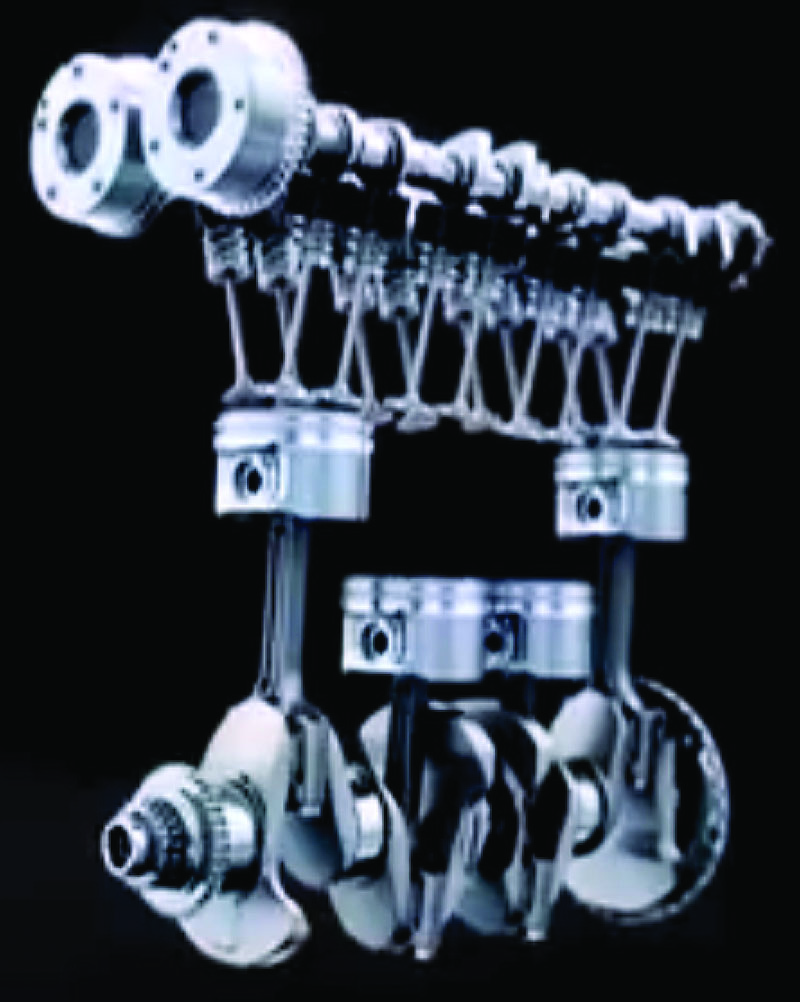

Shiny on the Inside! Upgraded Engine Mechanical Parts

Friction is an ever-present tax on the efficiency of machines. From the movement of the pistons to the rotation of the crankshaft, there is friction in every tiny engine motion. Every bit of power lost due to friction further reduces the net efficiency of any internal combustion engine. The MR16DDT reduces friction by polishing the cam and crank journals to a mirrored “Nano-finish.â€

Heat management of internal engine components is a critical consideration for reliability and longevity. Using a design typically reserved for high-performance applications, the MR16DDT has hollow, sodium-filled exhaust valves. Like shaking a ketchup bottle, as each valve moves, the force pulls the liquid sodium toward the stem or the face. This facilitates the movement of heat away from the hotter face, and reduces mechanical wear. Sodium is a reactive metal, and there are necessary safe handling steps to manage valve disposal after repairs. They must be broken in half and “defused†in a controlled situation. Consult the repair manual for exact steps.

The design of the intake manifold is tied closely to the engine’s optimal operating speed. The MR16DDT has acoustically equal intake runners that sport secondary “tumble†valves. The tumble valve controller can adjust the runner length as needed by the ECM to introduce turbulence when the engine is very cold or idling. When closed, the runners are shorter and the velocity of the air charge is greater. Upon entering the cylinder, the swirling air charge promotes better coalescence with the fuel charge and can also improve the burning speed of the mixture. When open, the runners are longer and the length of the runners is tuned to reduce intake flow resistance. The acoustically equal runner design also adds to the joy of driving by reducing the often rough sounds of intake and dramatizes the pleasant sensation of acceleration.

Along the same lines of driver experience, the MR16DDT is equipped with a “silent†timing chain design. The naturally occurring impact noise of chain-to-sprocket mesh is lessened by spreading the impact points from just the pin of the chain to other points on the cam sprocket. Distributing the impact lessens the sewing machine type sound.

The MR16DDT runs at 9.5:1 compression ratio, with a bore and stroke of 79.9mm by 81.1mm. It calls for 91 octane gasoline for best performance. Lower octane fuel can be used, but with potential losses to power and efficiency. It is lubricated with 5W-30 API SN oil, and cooled using Nissan Genuine Long Life Blue Coolant. Ignition is achieved using long life iridium-tipped spark plugs and direct ignition coils.

Gasoline Direct Injection (DIG)

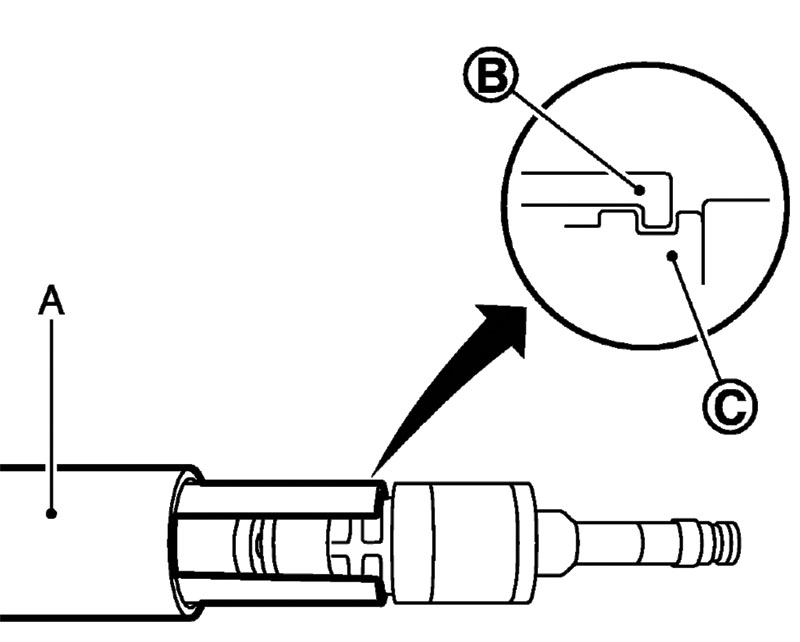

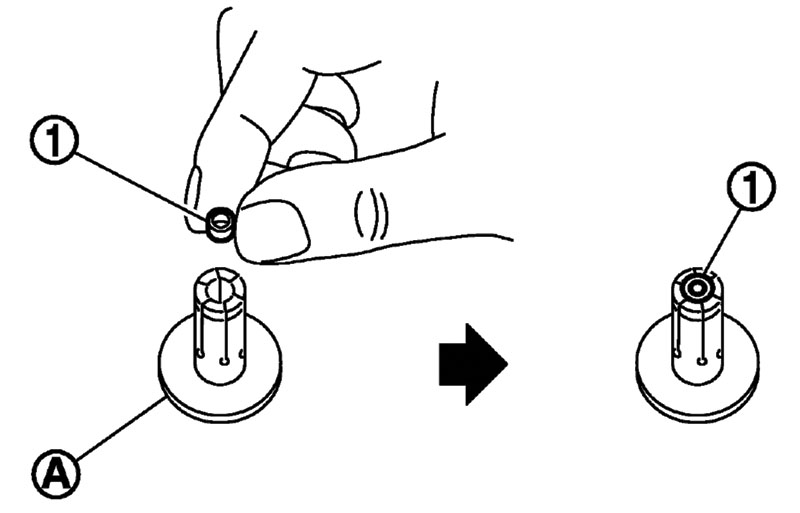

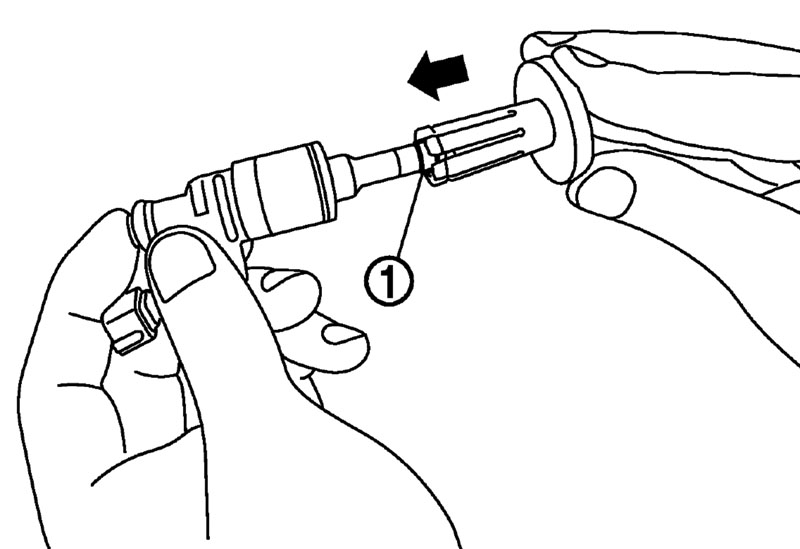

| Figure 1-4: Special service tools remove the press-fit injector and install the suitable replacement seal ring. |

Gasoline direct injection is becoming more popular. Here, we’ll focus on the design specifics of the MR16DDT engine in what Nissan refers to as DIG. High pressure fuel injectors are located in the side of the head, and are controlled by the ECM in two ways. The first notable difference from conventional fuel control is that rather than grounding the injectors, the ECM provides up to 65V to power them to spray when necessary. Second, the ECM commands the high pressure fuel pump control valve solenoid to adjust the pressure – and therefore volume – of the spray. Having such fine control over fuel delivery is truly what makes direct injection such a step forward.

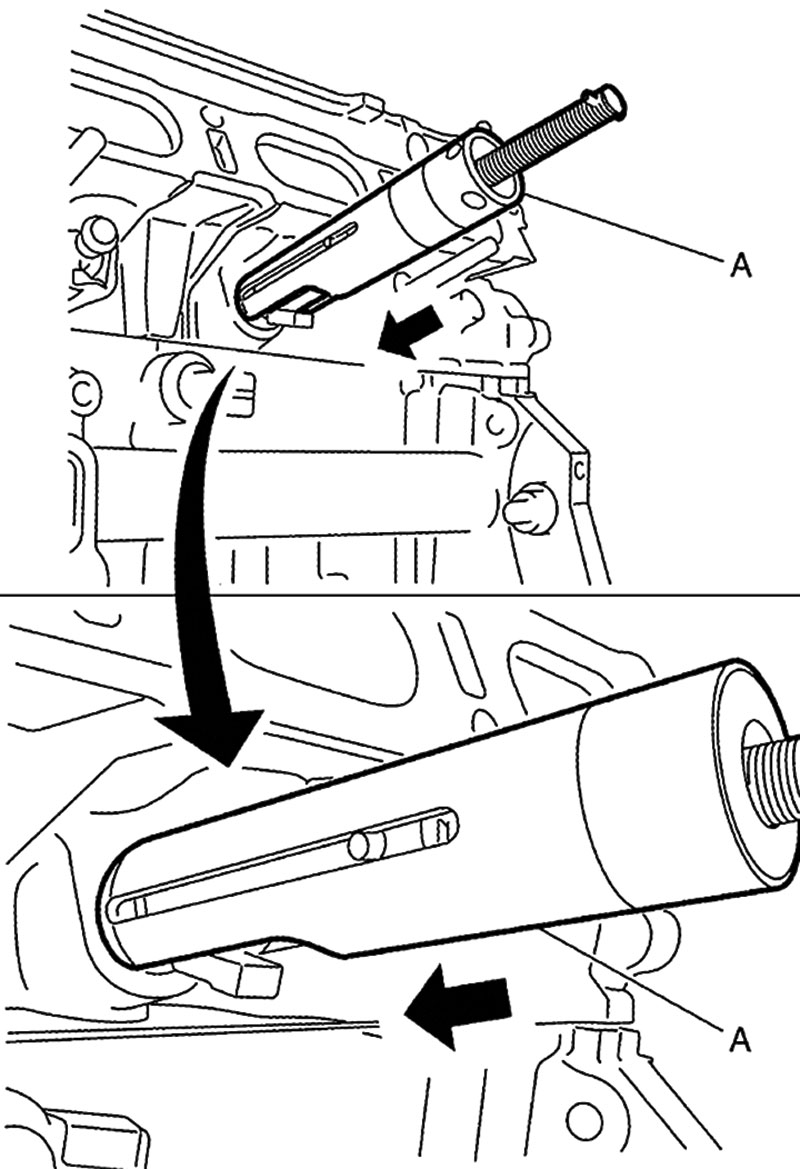

There are high and low pressure sides of this direct fuel injection system. The low pressure side of things looks very much like a traditional design: an in-tank fuel pump provides constant fuel pressure available to the second, high pressure fuel pump mounted on the head. At idle, the low pressure fuel pump should generate 73 psi. Note that special service tools are necessary to remove the low pressure fuel pump on all Nissan vehicles (KV101207S0 & KV99110600 for pump lock ring removal). All evaporative emissions components are also low pressure, and purge occurs into the intake air charge, as is typical.

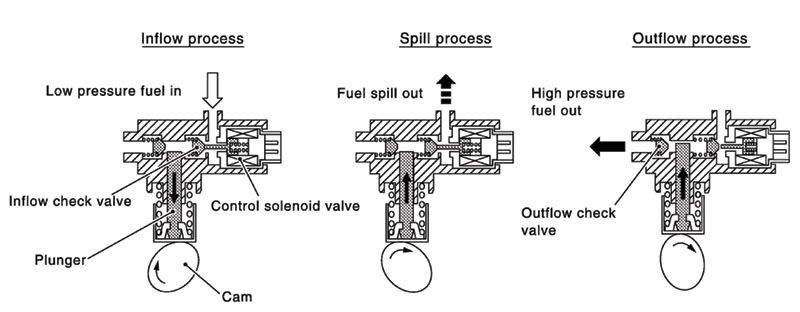

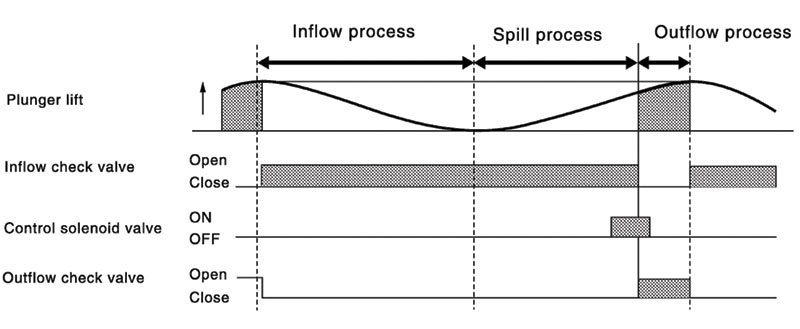

Things get interesting on the high pressure side of the equation. A mechanical high pressure fuel pump is attached to the exhaust camshaft and receives fuel from the low pressure side. The high pressure pump forces fuel into the fuel injector rail where pressure builds and remains present even when the vehicle is turned off. A fuel rail pressure sensor (FRP) reports available pressure to the ECM in the form of voltage. Using CONSULT, you can check live data for this information. Expect to see ~400 psi at idle, or about 1.14V.

Fuel rail pressure will vary based on the calculated demand for fuel. By modulating the high pressure fuel pump control solenoid, the ECM can adjust how much high pressure “spills†back to the low pressure side. By default, pressure will be low; upon solenoid activation, a one-way valve will close and prevent spillage to increase pressure. As solenoid on-time increases, the greater the rail pressure will build. More fuel per injection event will be delivered when rail pressures are higher.

The amount of fuel injected is a program value stored in the ECM based on engine operating conditions determined from input signals generated by the crank position sensor (POS), camshaft position sensor (PHASE), mass air flow sensor (MAF), FRP, and turbo boost sensor. Higher load, faster engine speeds, everything that you would expect to demand more fuel is picked up by the ECM and the fuel pressure adjusted. As with most cars, a feedback loop is established using air/fuel ratio sensors to maintain stoichiometric balance.

The ECM can also modify fuel injection behavior based on special operating conditions. For example, more fuel is added during starting, acceleration, hot engine operation, shifting the CVT from neutral to drive, and high load. Less fuel is added during high speed cruising, and no fuel is added during deceleration.

Direct injection allows for a technique called stratified-charge combustion. The timing of the fuel injection event is delayed, and the amount of fuel is diminished to extremely lean numbers. At the end of the compression stroke, the small very rich injection charge is sprayed directly at the spark plug. The final mixture is local to the plug electrode, but surrounded by lean mixture. The ignition event creates a flame front from the rich mixture, igniting the remaining air. As a result, a less homogenous air-fuel mixture is needed for compression and combustion, which saves fuel overall. The MR16DDT will utilize this technique whenever the engine is cold (ECT reads 41°F – 104°F). Stratified-charge combustion increases the rate of warm-up and improves emissions. At all other times, the air-fuel mixture is comparable to similar modern engines.

The injectors themselves are installed directly to the side of the cylinder head. Removal and reinstallation of these components requires special service tools. Due to the high pressure nature, incorrect repair procedures can introduce potentially hazardous fuel leaks. Always refer to the service manual before attempting repairs.

As fuel pressure is ever-present within the rail, a special fuel pressure release procedure is necessary prior to work. Using the CONSULT, connect to the ENGINE computer sub-category, choose WORK SUPPORT, then perform FUEL PRESSURE RELEASE. Start the engine, and after it stalls, crank 2-3 more times to release all pressure. Turn the ignition off to complete the procedure and begin work. Do not restart the engine.

Continuously Variable Valve Timing

Overcoming the physical limitations of valve overlap timing has always been a discussion of trade-offs for engineers. Do we design the engine with high valve overlap for high RPM range operation? Should the engine be tuned for better low and mid-range efficiency? Implementations of variable valve timing have been around for quite a while, but Nissan’s CVVT design allows for significant control over intake and exhaust valve overlap.

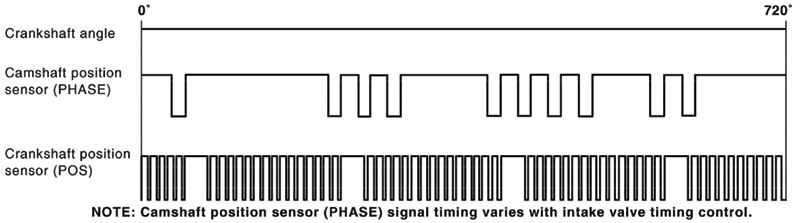

Both the intake and exhaust camshafts are engineered with the CVVT sprocket on the timing chain side, and a sensor plate on the other. Each sensor plate has teeth whose rotation past a Hall Effect sensor induces a digital voltage signal that the ECM uses for timing purposes – nothing strange there. However, the intake camshaft sensor plate is unique; it has a number of teeth based on the cylinder firing order. This is reported by means of the PHASE sensor, which would have traditionally been called the camshaft position sensor (CMP). On the exhaust camshaft, the sensor plate has four equidistant teeth, and the exhaust valve timing control position sensor generates a traditional-looking square wave.

The PHASE sensor can also function in place of the crank position sensor in the event of malfunction.

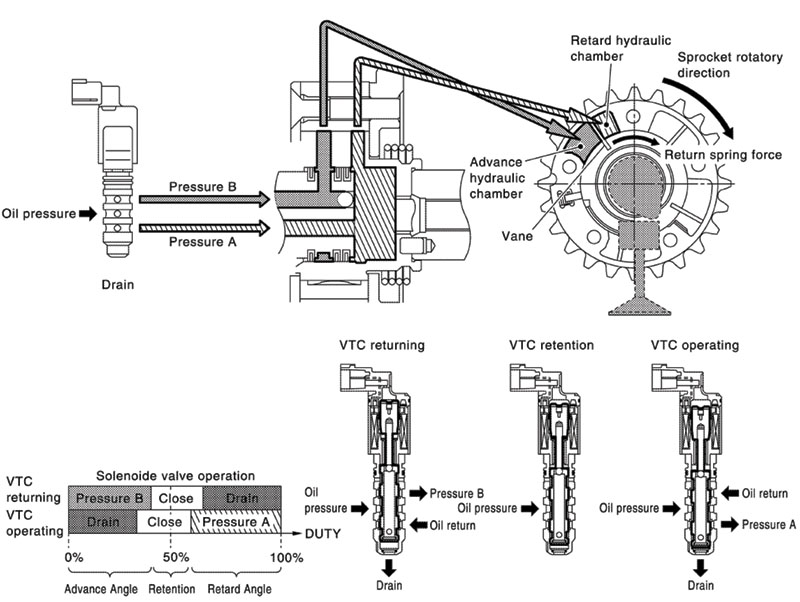

The ECM can advance or retard both intake and exhaust cams by using oil pressure to actuate the appropriate sprocket in the necessary direction. The exhaust valve timing (EVT) control solenoid changes the valve angle of opening based on the pulse duty ratio signal from the ECM: shorter signals advance, longer signals retard timing. The signal moves the valve within the EVT control solenoid to allow for oil pressure to flow in a combination of two directions: toward advanced or retarded. Oil can also flow out a drain for displacement. There is a return spring applying pressure within the sprocket toward a rest state.

If the signal pulse widths are equivalent, both control solenoids will hold their sprockets in a stable position. The intake valve timing (IVT) control solenoid operates identically to the above-described EVT control solenoid, except that the pulse length behavior is opposite: longer signals advance intake timing, and shorter signals retard. Also, the direction of the return spring force is opposite.

With the CONSULT, technicians can verify the current cam sprocket angle using live data. INT/V TIM at idle should be between -5 and 5 degrees cam advanced (CA), and between 0 – 20 degrees CA at 2000 rpm. EXH/V TIM is identical at idle, but at 2500 rpm and rising, exhaust timing should be between 0 – 30 degrees CA.

The most commonly observed failures with any variable valve timing system is lack of oil pressure. Without sufficient oil pressure, VVT cannot operate, and the MIL will illuminate with potentially misleading faults pertaining to valve timing. Check engine oil level first before chasing a cam timing code down the rabbit hole.

Turbocharger

Forced induction is a simple method of improving engine performance without increasing displacement. The MR16DDT has great power per liter as a result of turbocharging. Let’s skip over how turbo works in general, and instead focus on the specific boost control methods used by this particular engine.

Whenever the throttle valve is shut completely, the turbo-produced intake air charge doesn’t just stop and wait for the door to open again. Pressure will back up, accumulating in the intercooler. Eventually, pressure can stall or reverse the direction of the compressor turbine. This can put heavy stress on the turbine bearings and fins, which may reduce reliability and longevity of the parts. The MR16DDT mitigates chances of so-called compressor surge with computer-managed boost control.

The boost sensor is a second intake air temperature sensor that lives on the outlet side of the intercooler. It can also sense pressure, which it sends to the ECM in form of a voltage signal (higher voltage is higher pressure). The ECM will observe pressure and appropriately route exhaust gas toward the turbo inlet for increased boost, or back into the intake through the recirculation valve for decreased boost. To adjust boost, the computer commands the boost control solenoid to change pressure against a diaphragm within the boost control actuator. Longer duty cycle to the boost control solenoid moves the diaphragm open, which in turn increases the exhaust flow to the turbo inlet.

Technicians can use the CONSULT to check the commanded boost solenoid value in live data. BOOST S/V should read 0% at idle. With the accelerator pedal depressed at least half travel, BOOST S/V should read 100% below 3000 rpm and somewhere between 30-60% over 3000 rpm.

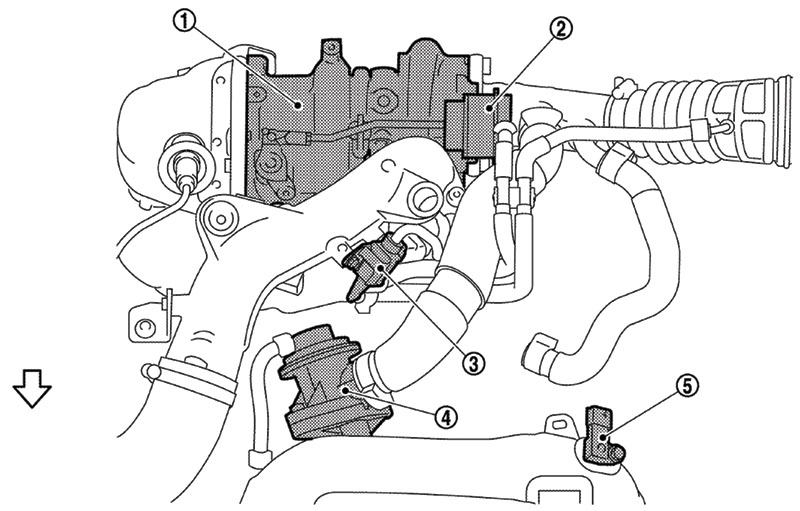

The turbo’s (1) boost is managed by the computer’s signal to the boost control solenoid (3) based on input from the boost sensor (5). The boost control actuator (2) will then route a percentage of the exhaust gas into the turbo, or back through the recirculation valve (4).

Fail-Safe Mode

Various MIL faults will induce a fail-safe mode. Check the repair manual for details. For example, P0045 (boost control solenoid circuit) sets the boost actuator to zero boost by default. P0190 (FRP sensor circuit) opens the high pressure fuel pump solenoid at all times to provide full pressure at the fuel rail. P0087 (FRP control circuit) may cause limited power due to incorrect fuel pressures. As with any diagnostic approach, begin with the service manual and common sense before reaching for complicated explanations.

2015 Generational Changes

The second generation of the MR16DDT is standard on 2015 model year JUKE and JUKE NISMO editions. You will find a different spark plug, a lighter-weight 0W-20 synthetic oil, changes in the engine management system, and different driveline lubricants (and CVT options). The net effect is a 1-2 mpg fuel economy improvement and 10 increased horsepower and torque.

0 Comments