There’s more to those tubular columns than you might think.

| There are lots of options and solutions for racers struggling with shortened pushrod life on extreme applications. Here are a couple of examples; they both use a self-lubricating tool steel, hardened to 60, Rockwell c-scale on the ball or cup ends to help reduce end failures on high-power, high rpm applications. Centerless ground, they are available in lengths from six to 13 inches. I’ll take sixteen of each, please. |

The lowly pushrod. How many times have you really given this critical piece of the cam-in-block, overhead valve engine linkage a second thought? Have you ever contemplated its existence? Thought about how little appreciation it gets?

It’s not sexy — it doesn’t whine, thump, toss clouds of nitrous into the air at the starting line — it just quietly does its job, nearly always without complaint. If it gives up, it’s usually because we picked the wrong part for the job, failed to make sure it was installed correctly, or something else in the engine blew through it on the way to freedom. The pushrod is the working man of the racing parts community.

As an engine builder, what should you know about a pushrod? As it turns out, more than you might think. Let’s think about length, type, materials, diameter, taper, clearance, resonance, and lubrication. On a racing engine with healthy spring pressures, a pushrod operates in constant boundary lubrication on the ends where it seats in the lifter and rocker cups. It’s subject to tremendous compressive forces, undergoes large axial and lateral loads (on those engines where the pushrod isn’t directly in line with the lifter below and rocker above and it must operate at an angle), absorbs the pounding handed out when the spring goes into surge, and it may be one of the most affordable racing parts in the whole engine. It’s the last piece you buy, ordered at the last minute before you button the whole thundering mess up.

Growing diameters

In days past, the .080 in.-wall 5/16 in. and 3/8 in. diameters were suitable for virtually all street applications and quite a few performance engines. There have been a lot of theories that have come in and out of vogue about valve train weight and how much pushrod you need for a given spring pressure, but the current thinking seems to lean toward simply stuffing the largest pushrod into the engine that will fit and don’t worry so much about weight on the lifter side of the rocker arm, at least at engine speeds up to about 9,000 for drag engines. On the lifter side of the rocker, you have the issue of the multiplication of the spring pressure by the rocker ratio that is more of a concern than a few extra grams of pushrod weight. Given the spring pressures we use today, the trend toward higher rocker ratios, the rate of lift of the cam, and the use of power adders of all sorts, pushrod strength now trumps weight. At the end of the day, you still have to translate the cam lobe profile accurately to the valve, and a flimsy pushrod, challenged by high spring pressures and higher cylinder pressures, just can’t get the job done.

On the valve side of the rocker, we still sweat every gram, and titanium small-stem valves and titanium retainers are the norm, and even the rocker itself is chosen to get the lowest inertial moment with the most strength.

| This is a 7/16 in. double-taper .165 wall Trend pushrod that we use in some of our big block Chevy engines. With proper installation, we have never had galling or a failure over several seasons. You can order stocking pushrods in a number of configurations from 5/16 up to 5/8 in., and even 3/4 in. on a special-order basis. Wall thicknesses range from .105 in. up to .200 in., with 5/16 or 3/8 ball ends, 5/16 or 3/8 cup ends in full taper, half taper, double taper and neck-down styles with additional clearance options available for the lifter and rocker ends if needed. |

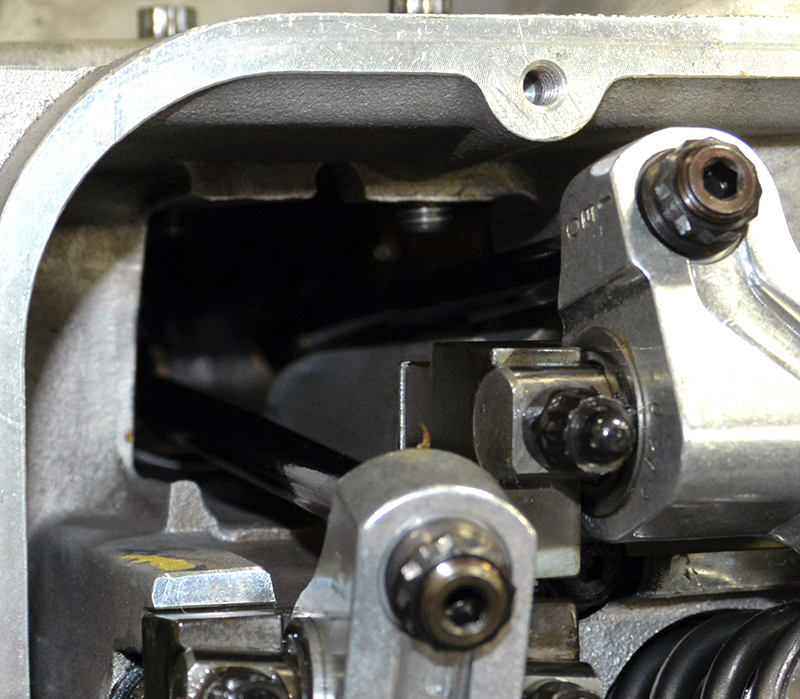

Above: When too much isn’t enough, there’s always more — in this case H13 tool steel pushrods. If you break this, you’ve got a problem.

If you’re talking about 80-110 lbs. of seat pressure and 250-300 lbs. over the nose with a mild cam, then standard off-the-shelf .080 in.-wall pushrods will work fine and last a long time. Don’t mess with it.

Of course, pushrods built today are nothing like those built in the bad old days. Chrome moly is the go-to material with a couple of different kinds of tool steels out there, along with hybrid pieces that use different materials for the body and the seating element of the pushrod. The other thing that’s happened is the exponential improvement in manufacturing technique and quality. Just perfecting one-piece pushrods has eliminated most failures and the materials and manufacturing quality is outstanding.

You selection of pushrod type is mostly determined by engine speed, spring pressure, and the use of supercharging or nitrous. If you’re running 1,000 lbs. of spring pressure over the nose, a 7/16 in. pushrod in single or double taper will get the job done on an unblown or non-nitrous engine. If you move up to 1,200 lbs. over the nose, you’ll need to look at a 9/16 in. pushrod. Of course, if you’re starting with supercharging or using nitrous, you need everything you can get, up to and including telephone pole-sized pushrods.

Pushrod manufacturers now have 5/8 and 3/4 in. pushrod options for those of you with serious over-compensation issues. The limiting factor is space, particularly with the cavernous size of the intake conduit on today’s racing heads. You can only put so many things into one spot before they start colliding. If needed, offset lifter seats and cantilevered and bent rocker systems can help make the trip from lifter to rocker, but offset lifter seats come with a penalty in regards to side loads on the lifter wheel or foot and on the lifter bore bushings. If you must use offset seats, try to get the seating depth down as low as possible to center the load in the lifter bore bushing. Also remember that you only need the barest static clearance between the pushrod and the object in close proximity — .010 in. is fine — and don’t be disturbed if after pulling the pushrod out of the engine you see it’s marked by contact. If there is clearance there on assembly, statically, and it makes contact while running that contact just helps dampen out pushrod oscillations, so it’s all good. Just make sure you verify clearance all the way through full travel. You do not want to side load an axi-symmetrical component like a pushrod. The compressive forces may cause it to bend and collapse if it sees a large lateral load component while under compressive load.

Pushrod sources:http://trendperform.com/ |

Â

0 Comments