(Editor’s Note: Combined, Henry and Lars have well over 60 years of experience tuning carburetor-equipped engines)

The changes in how today’s reformulated unleaded gasoline burns in a vintage carburetor-equipped engine will often cause it to not perform as it should. These new blends are not as volatile, but still burn somewhat faster than the leaded gasoline of the distant past. The initial timing setting, amount of spark advance, the rate of mechanical advance, and the amount of vacuum spark advance that was used when the vintage carburetor-equipped vehicles were new was designed for a blend of gasoline that no longer exists.

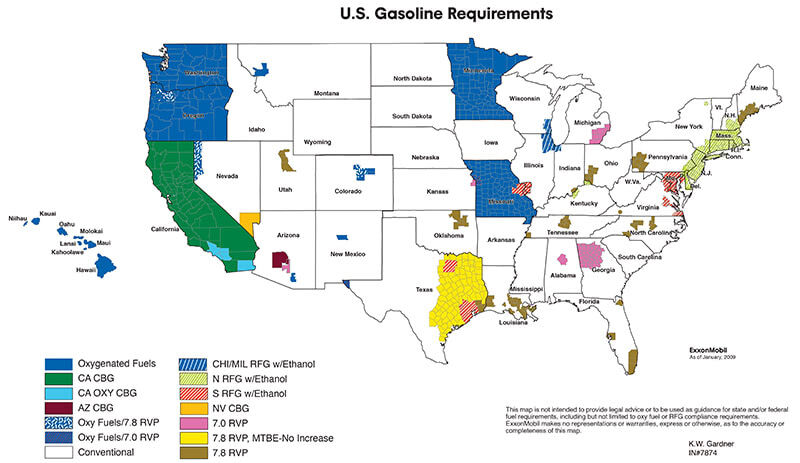

This map shows the various blends of reformulated and oxygenated unleaded gasoline that are sold throughout the United States.

The easiest and most often ignored method for unlocking the power, drivability, and fuel economy of such a vintage engine is to optimize the ignition spark timing for the blend of gasoline that the engine is actually burning today. Optimizing spark timing at idle, cruise, and during acceleration will allow an engine to have its best idle quality, throttle response, run cooler, and provide the power that was built into it. The amount of spark advance an engine needs varies with engine load, speed, coolant and air temperature, air/fuel mixture, and the formulation of the gasoline. The systems that control the spark timing of a vintage carburetor-equipped engine are the initial timing setting, and the centrifugal and vacuum advance systems.

Initial Timing

A five-gas exhaust analyzer is one of the best tuning tools that you can have. The readings show the air/fuel mixture, the misfire rate, the efficiency of the engine, and inform the user if the spark timing is too far advanced.

Since gasoline formulation has changed so much over the years, the initial timing setting the factory specified may no longer allow an engine to idle properly. The guideline we refer to when we are trying to determine the optimum initial timing is based on the lift and duration of the camshaft. This guideline can be found at the Demon carburetor website: www.demoncarbs.com/.

In short, it recommends 10 to 12 degrees of initial timing for an engine with a stock/mild cam, 14 to 16 degrees of initial timing for an engine with a performance cam, and 18 to 20 degrees of initial timing for an engine with a radical cam.

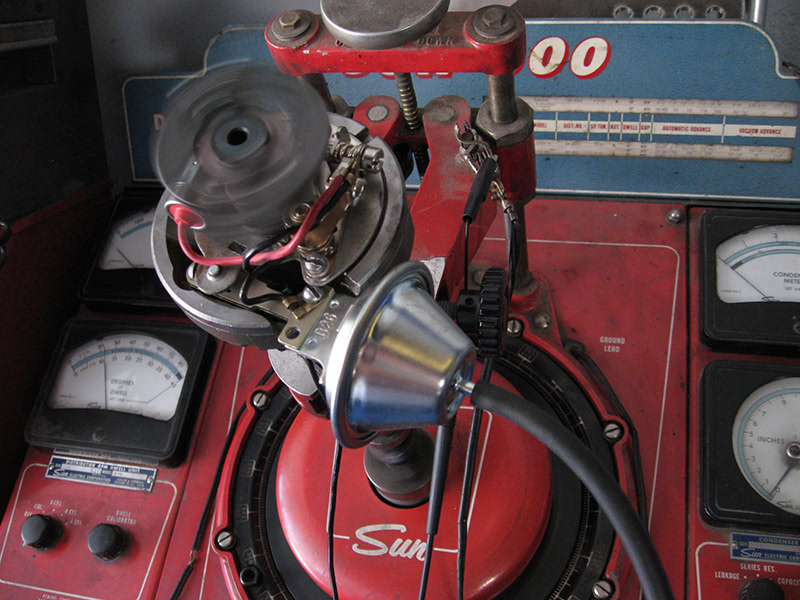

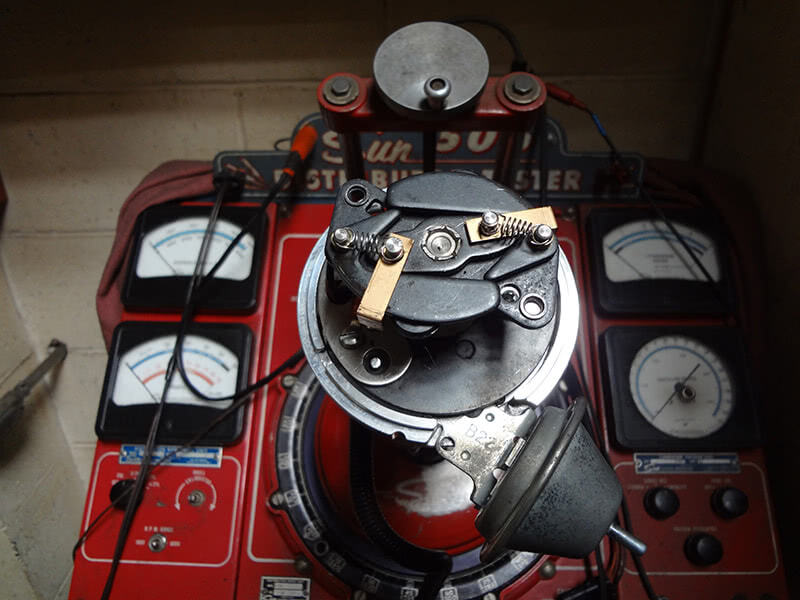

A distributor test stand can allow you to easily check the spark advance at any rpm or vacuum level.

Note: Keep in mind that whenever you change the initial timing setting, the total timing must be checked and properly adjusted. Engine damage will result if the amount of spark advance is too much for the needs of the engine.

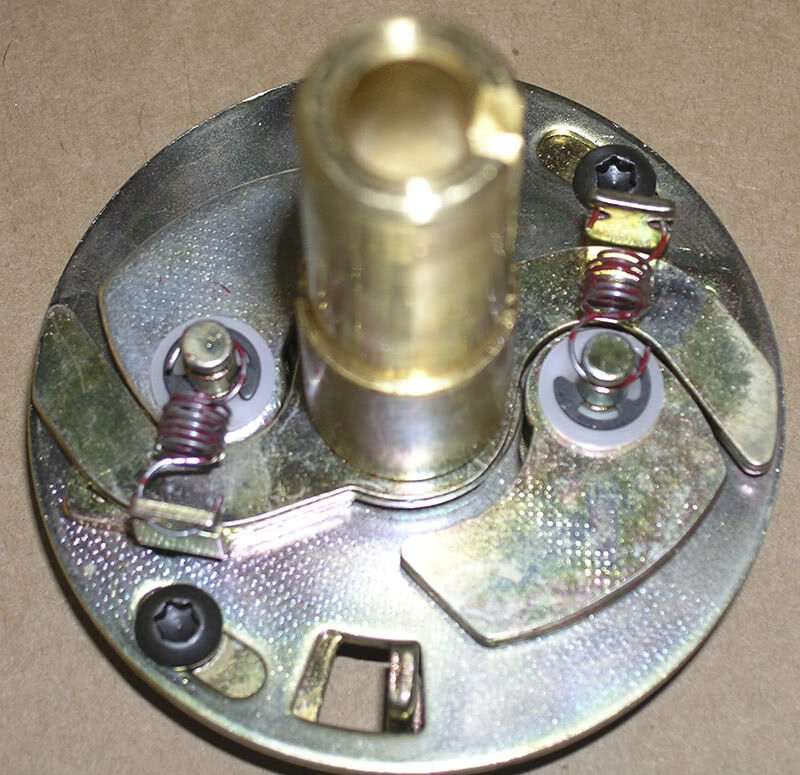

Mechanical/Centrifugal Advance

As engine rpm increases, the “fire†in the cylinder must be started earlier in order for the air/fuel mixture to have time to fully burn. The mechanical advance mechanism in the distributor pushes the spark ahead as the rpm increases via the weights and springs. With a high-performance engine, this should start advancing the spark just above idle speed, and in most cases should be “all in†by 2,800-3,400 rpm. The total mechanical spark advance must be reduced whenever you increase the initial timing so that the total spark advance does not exceed the needs of the engine.

Vacuum Advance

The vacuum advance system is used to provide additional spark timing advance when the load on the engine is light to moderate. This is needed because the flame travel in the combustion chamber is slower due to the leaner air/fuel mixtures and lower cylinder fill conditions that are seen at the low load/part throttle operating conditions. When the load on the engine increases, the engine vacuum drops, thus the spark advance from the vacuum mechanism will be reduced or eliminated. The additional advance from the vacuum system can both increase fuel efficiency and help the engine to run cooler because the engine is converting more of the energy in the gasoline into power.

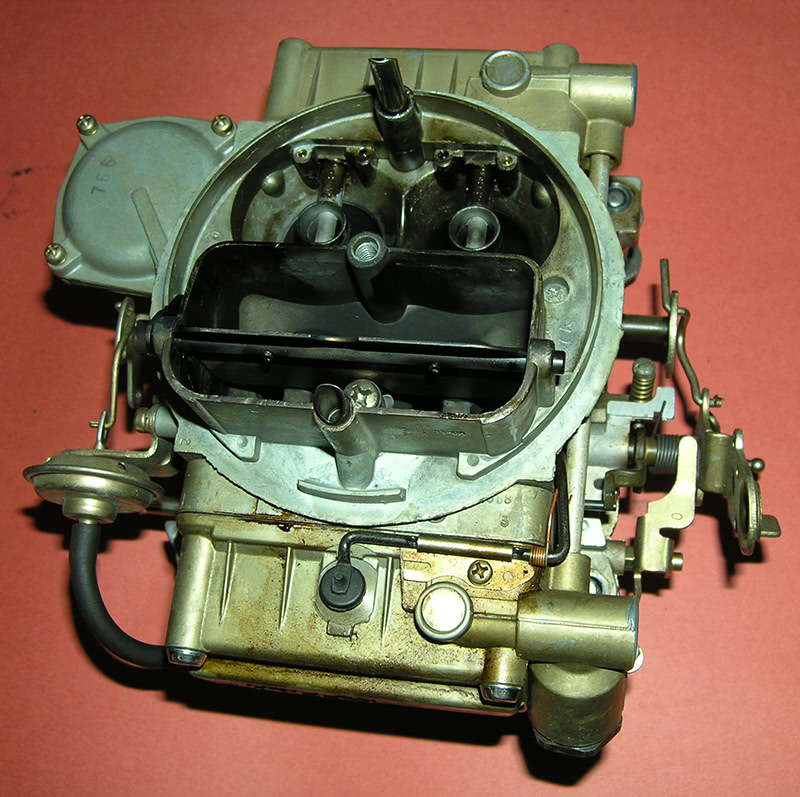

Pertronix Flame Thrower Billet electronic distributors for GM applications come with an assortment of advance stops and springs to allow you to tune the spark advance curve.

Ported Vacuum vs. Manifold Vacuum

The best vacuum source for the vacuum advance (ported vacuum vs manifold vacuum) is more based on personal preference and experience than it is on anything else. I personally prefer to use ported vacuum (while Lars prefers manifold vacuum) for most of the vehicles we tune as long as the initial timing setting has been optimized for the needs of the engine. But if the engine wants more spark advance at idle than it gets from the initial timing setting, connecting the vacuum advance can to manifold vacuum can be a good way to get additional advance at idle. The selection of ported vacuum or manifold vacuum can be used as a tuning tool to match with the timing needs of the specific engine.

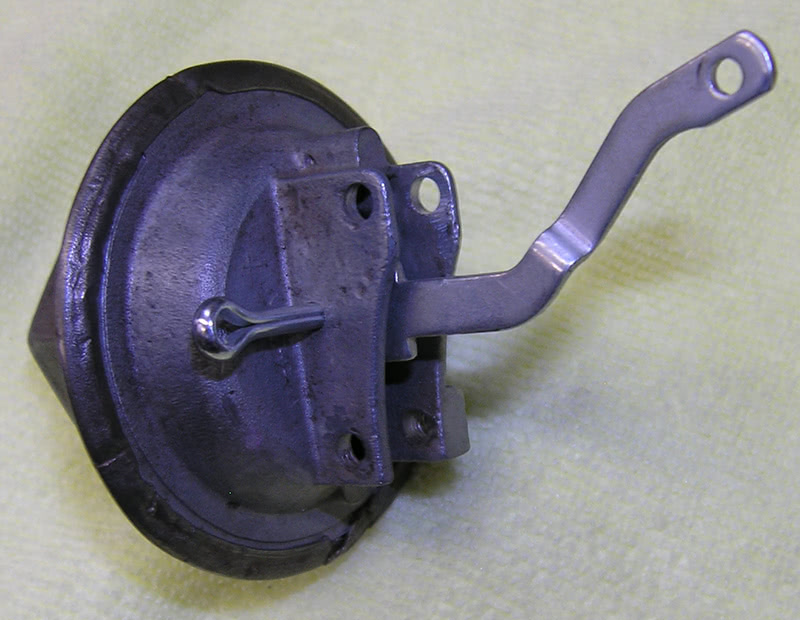

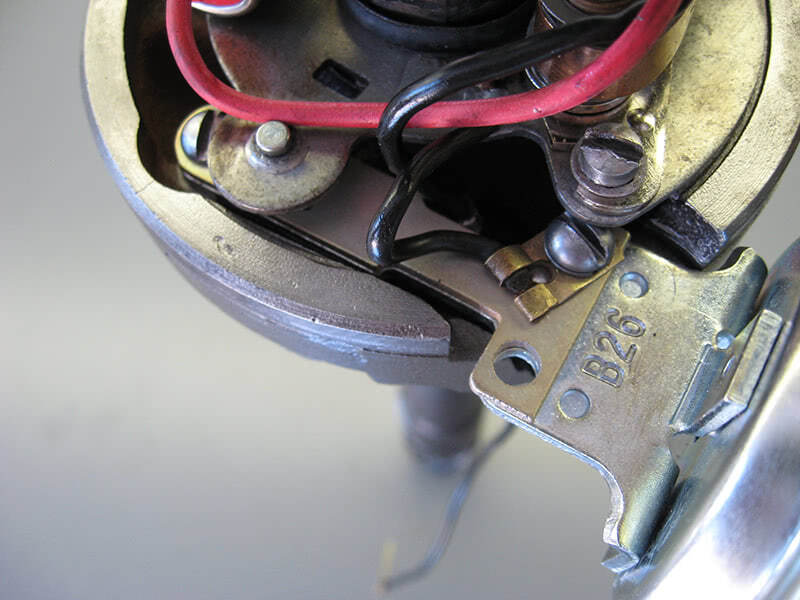

This Mallory-designed advance system is from a replacement Direct Connection (Mopar) distributor that is very tunable.

Replacement Vacuum Advance Control Units

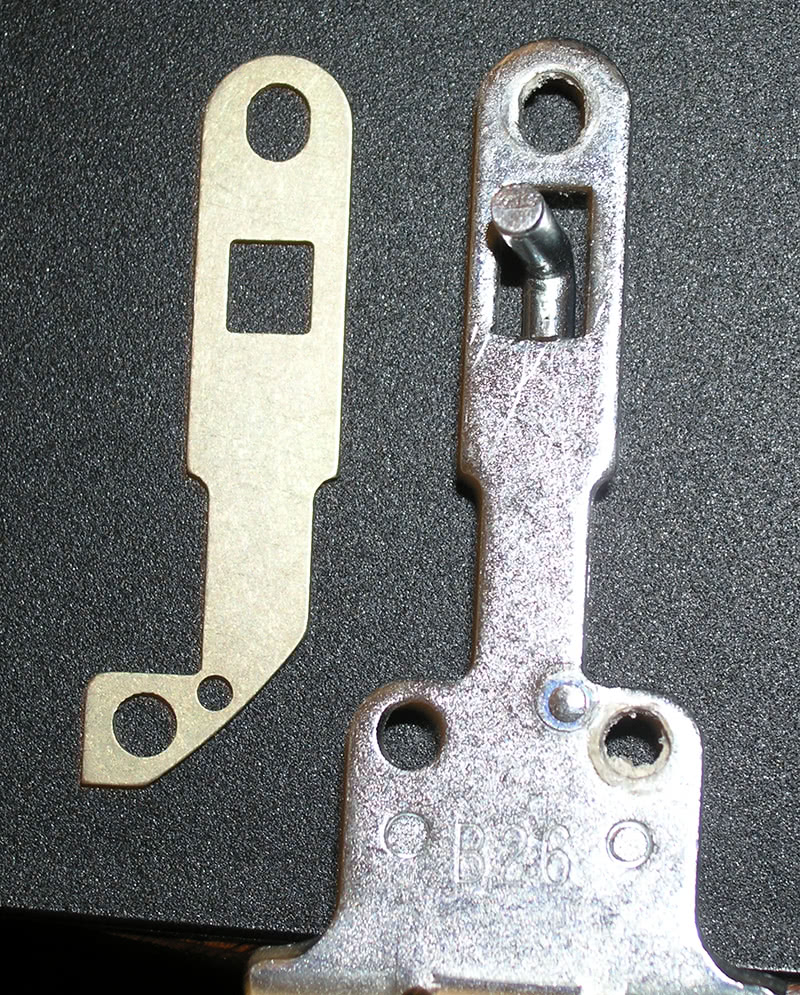

The vacuum advance control units we use most for General Motors ignition point distributors, including the non-HEI style MSD Billet distributors and the Pertronix Flame Thrower Billet electronic distributors is the Standard Motor Products Part Number VC181, which is also sold by Echlin as Part Number VC1765 (stamped “B26â€). This starts advancing at six in. Hg of vacuum, and is fully advanced at 12 inches Hg. This works well with most engines with ported vacuum, or an engine that has over 14 in. Hg at idle if it is connected to the manifold. When we are tuning an engine with a GM HEI distributor, we use the Standard Motor Products Part Number VC302 vacuum advance. The selection of vacuum advance units for Ford and Chrysler is somewhat more limited, but those that are still available are sometimes adjustable for different vacuum situations.

Here’s the VAC vacuum advance limit plate we use to limit the advance of the GM, MSD, and Pertronic distributors that have B28-style vacuum advance units to the 10 to 12 deg. of vacuum advance we target.

The amount of vacuum-based spark advance

The original equipment manufacturer (OEM) and replacement vacuum advance units often supply the engine with as much as 16 to 25 deg. of advance. That much vacuum-based advance worked fine with the factory mechanical advance curves and initial timing settings that were used with the leaded gasoline back in the day, but will often create drivability problems with today’s unleaded and reformulated gasoline blends, especially if the initial timing settings or mechanical advance curve is changed. The total spark advance combined with the advance from the vacuum mechanism should be limited to about 48 deg. maximum with any of today’s blends of commercial unleaded and reformulated gasoline blends.

The problems an engine will exhibit when it has too much spark advance at cruise are engine misfire (often to the point that you can both feel and hear the engine misfiring during cruise driving conditions), or a complaint that the vehicle seems to be “bucking†while it is being driven down the road at light throttle. If you were to disconnect the vacuum advance from its vacuum source, the misfire and drivability problems would disappear, thus confirming that the problem is related to vacuum advance.

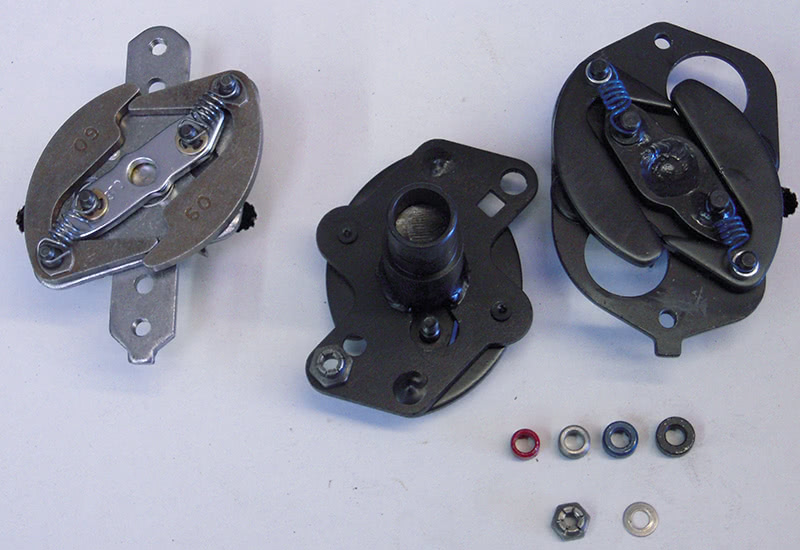

Today, most tuners are limiting the amount of spark advance from the vacuum system to 10 to 12 deg., but it seems to be almost impossible to find a vacuum advance unit that matches that target. We have not been able find a source other than the before-mentioned unit for HEI-style distributors, therefore we are modifying them to limit the amount of spark advance to what the engine needs. The modifications involve fabricating some type of mechanical stop to limit the amount of vacuum spark advance.

The cotter pin that is installed in this Ford vacuum mechanism limits the vacuum-based spark advance to our 10-12 deg. target.

Ole’s Carburetor & Electric of San Bruno California (www.olesautoparts.com) working with Lars Grimsrud from Colorado (V8FastCars@msn.com) developed a product that can be can be used to limit the advance of the vacuum advance system to 10 to 12 degrees on all GM points-type distributors, T.I. distributors, and Unitized Ignition distributors from 1962 through 1974. A second version of this can also be used on all MSD small-diameter vacuum advance distributors for GM, Ford, and Mopar applications, and the Pertronix Flame Thrower billet electronic distributors for GM applications. This “Vacuum Advance Corrector†allows total timing to be set for maximum power, yet eliminates the problems associated with over-advanced timing at cruise by limiting the vacuum-based spark advance to 10 to 12 deg.

We used a flat washer (that we cut so we could put it i n place) to limit the advance from this Chrysler vacuum advance.

Calibrating the initial timing, the mechanical advance curve, and the vacuum advance system is the first step in the process of tuning an engine for today’s blends of gasoline, and it is one of the best investments in time you will ever spend when tuning your engine. Once the ignition advance systems are properly adapted for today’s reformulated gasoline, the next step in the tuning process is to adjust the air/fuel mixture the engine is getting from its carburetor for the new gasoline. A properly tuned carburetor-equipped engine should perform every bit as well as, or maybe even better, than it did when the vehicle was fresh off the show room floor and running on the leaded gasoline of the day!

Before we tuned the ignition advance systems of this 427/435 hp 1967 Corvette with side exhaust, you could hear the engine miss when it was driven at highway speeds. Now it sounds and performs as good as it looks!

0 Comments