Despite what you may have heard, this is really not a troublesome system as long as you heed some real-world maintenance and diagnostic advice from the trenches of auto service.

The owner of this Mercedes-Benz SL500 had allowed bad fluid and “trash†to enter into the ABC system. The vehicle’s front end would collapse after a few hours of sitting because debris was holding the valve block open.

Since its introduction in Germany in 1999, and in the USA in 2000 220 and 215 models, Active Body Control (ABC) has logged enough successful years and miles to be worthy of the spotlight. But some may say that ABC is renowned for the wrong reasons. Instead of being showcased for being the sophisticated, high-performance system it is, ABC tends to only get attention when a problem should arise. It’s our hope that by taking a closer look at this industry-changing technology, we can restore ABC to the prominence it deserves.

Been There, Done That

Hydraulically-assisted suspension is by no means a new idea. In fact, the technology in one form or another has been in use since the mid 1950s and was adopted by Mercedes-Benz for use on various models starting in the 1970s. The topic of ABC has been covered a multitude of times with its basic principles of operation and benefits widely publicized. For this reason, we won’t be rehashing the inner workings again for this article. If you are among those new to the field, have never had the time to check it out, or who have shop personnel that are unfamiliar with the basic principles of hydraulic operation and how these systems work, now’s the time to learn.

These types of systems are likely to evolve and expand their presence in the automotive world. A quick check of the web or Mercedes-Benz service literature that can be subscribed to through the Startekinfo website will provide a wealth of knowledge. A solid understanding will give you, the Independent Service Provider (ISP), help in the diagnosis and repair of these systems, but also has other benefits. These same basic hydraulic principles are used in numerous other systems, such as braking and steering, just to name a couple. A firm grasp of the principles will make it easier to quickly diagnose problems across systems past, present, and future.

Overlooked

As much as customers would love a vehicle that requires no maintenance and has parts that never wear out or break down, for now and for the foreseeable future, that’s just not a plausible vision. This means that there will be a continued need for technicians and ISP service centers, and we will keep doing what is honest and right by trying to give customers an automobile closest to the perfect quality they deserve.

Over time, we have seen various troubles with ABC. When not operating properly, vehicles with this system show up in the service lane, perhaps coming in on the tow truck with the suspension allowing the chassis to sink to the ground, or pumping out large amounts of fluid from various locations. The repairs required can be costly, so the system sometimes gets a bad reputation with customers who forget the driving enjoyment and safety benefits it’s given them over the years.

Generally, we see the same types of failures, sometimes at less than 100,000 miles, and we’ll look at a few later. Before we do, however, what can we do to stave off some of these problems? The answer is maintenance! We believe a lot of expensive repairs could be avoided by simply following a prudent care regimen even though Mercedes-Benz, usually the car manufacturer with the most conservative maintenance advice, doesn’t give fluid/filter-change intervals for ABC. In fact, the company says that it is a maintenance-free system (on the other hand, the procedure is outlined in WIS).

Our function at StarTuned®, however, is to give our esteemed readers the benefit of our real-world experience, and maybe some new ideas for profitable services. We believe it stands to reason that since ABC contains hygroscopic fluid, has a changeable filter, and works hard under high pressure, it is a candidate for preventative maintenance. That work will also make a nice addition to your shop’s menu of services. Commonly overlooked by technicians, ABC (like most items that are on the service check list in the owner’s manual) tends to display telltale signs that a problem is developing and should be corrected before a messy leak develops, or the vehicle becomes undriveable.

Cleanliness is next to… well, you know

Hydraulic fluid is the lifeblood of ABC. Most failures can be traced back to it, whether it’s an improper fill level or contamination of the fluid. Fluid is simple to check and can tell a lot about the health of ABC. Experience has allowed most seasoned technicians to quickly identify dirty, burnt, or contaminated vehicle fluids, so there is no reason that ABC fluid shouldn’t be given equal scrutiny during routine maintenance.

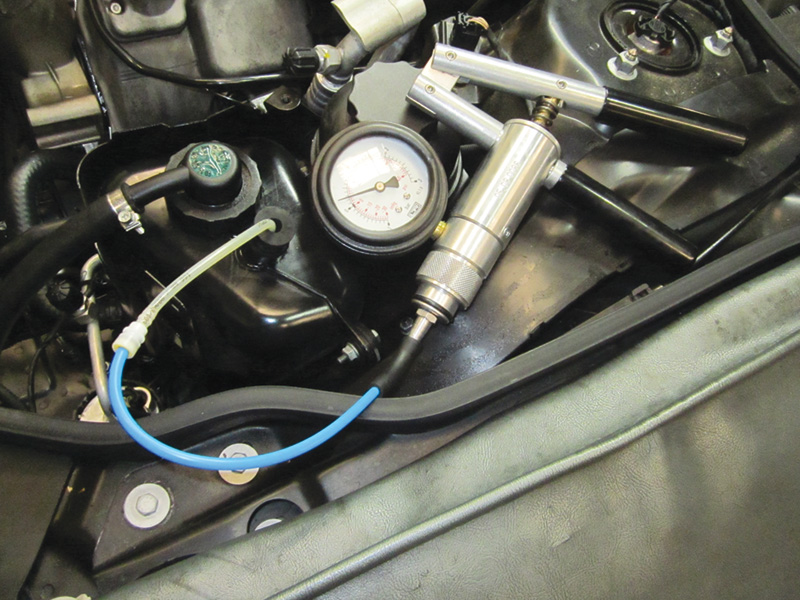

The ABC fluid reservoir must be pre-pressurized to prime a new pump before startup. Failure to do so will dramatically shorten the new part’s life.

When it comes to the ABC system as a whole, fluid cleanliness is most important. Even though Mercedes-Benz specifies the highest-quality synthetic hydraulic fluid available (Pentosin), as with any other hard-working fluid it can deteriorate. Like brake fluid, the ABC liquid medium is hygroscopic — given the opportunity, it will absorb moisture – and like engine oil, it is subject to thermal breakdown.

Operating at 200 Bar (2,900 psi), the ABC system has to be able to withstand immense forces. Fluid deterioration, heat, humidity, and driving conditions are all factors in system wellbeing. Worn-out fluid decreases lubrication and accelerates wear, which affects all components. For example, a neglected system will have micro-fine metal and rubber combined with corrosive moisture flowing through it. Even though there is a superb-quality Mercedes-Benz 3-micron filter in the fluid return line in the reservoir tank, like all filters there is a limit to how long it will continue to function.

The ideal situation would be vastly-increased system longevity through preventative maintenance. We’ve seen ABC remain trouble-free for 300,000 miles when this is done. Realistically given our decades of experience in auto service, we know it’s a tough sell to vehicle owners to spend money when there’s no complaint. The fact is that when this complex system does have a failure, it usually results in the need for significant repairs costing in the thousands. This is reason enough to at least give customers the option of a fluid and filter change — in terms of your reputation, it’s always best to help your clientele avoid big, unexpected bills.Â

It’s important to remember that once a part has failed due to fluid breakdown or contamination, the rest of the system has experienced the same conditions and similar failures should be expected. No amount of the flushing that is performed after a repair is completed can erase damage in other components. Another noteworthy thing: If there have been multiple failures of the same part, a laboratory fluid analysis would be a logical diagnostic step. The in-depth report may reveal an overlooked fault. This leads us back to why system cleanliness is so important. In fact, we even take the time to carefully clean the top of the reservoir before removing the cap.

Down Time

So, it’s not working. What can you do? Fortunately, over the years we have developed great expertise in trouble-shooting issues, which shortens diagnostic time. We’ll take a brief look at some of these to help you get the customer on the road again:

On the left is a ruptured accumulator. Compared to the good one on the right, you can see the difference in straw lengths

- One or more struts collapses after sitting a short time. This is often incorrectly diagnosed as a bad strut because the technician believes basic ABC operation is the same as that of an Airmatic system. The only thing that both systems really have in common is that they were designed by Mercedes-Benz. ABC struts have no internal holding or locking valve. All strut movement is directed from either the front or rear valve assemblies.

- These are remotely-located, typically near the left-side wheel wells. Since the struts have no valves, if one or more struts have collapsed there can only be two logical reasons. The first is that there is a fluid leak in the line between the shut off valve, and/or the strut itself is leaking. This should be verified with a complete visual inspection. The second (and most common cause of collapsed struts) is an internal problem with the valve assembly. Debris between valves and seats, or internal seal wear are both causes of leak-down. Some technicians have had success flushing the system to clear a blocked valve, but a seal problem requires a new part as no rebuild kit is available. It’s important to know that ABC valve blocks were never manufactured to be a perfect seal. A vehicle that has been sitting for long periods of time may sink down, which is a normal characteristic of this system and does not necessitate a repair.

- Low engine speed noises from ABC are typically under 2,000 rpm. There are several service bulletins about this problem. The most common cause for this is bad pulsation dampeners. These are small globes very similar to an accumulator containing a nitrogen-filled bladder that absorbs vibration and smoothes sudden fluid starts and stops. Depending on the system, the noise can originate from two different locations. On the first version of ABC from 2003 to 2006, dampener noise will come from just behind the left front wheel where the dampener is located. ABC Plus-equipped vehicles from 2007 on can be a little more difficult to diagnose. The ABC Plus system relocated the pulsation dampener to the pump itself. This makes differentiating a dampener noise from pump noise more difficult. A tip on pinning down the problem is that a bad pump when checked with a stethoscope will typically have the noise only in the pump itself. A bad dampener will not only have noise at the dampener, but also produce the same noise along the high-pressure line coming from the pump.

- Cluster warnings and codes for low pressure are caused by an ABC pump that’s producing little or no pressure. These codes can have a number of different causes and need to be vetted thoroughly for accurate diagnosis. Live data and system actuation coupled with Mercedes-Benz SDS or an equivalent diagnostic tool should be used to test for a weak pump. Running dynamic testing (or “rodeo,†as it is also known) is the best way to test pump health. Running the engine at 3,000 rpm, the suspension pump should be regulated at very near 200 Bar. A reading over that would suggest a pump regulation valve problem. Once the test is active and the vehicle is in motion, a 50 Bar pressure drop would be in the normal range for a healthy pump. Anything below 150 Bar for a significant time would indicate a weak pump, and at anything below 100 Bar SDS will stop the test to prevent further pump/system damage.

A cautionary tip for those that would run dynamic tests because it looks “cool,†or are showing off to friends, remember that this test stresses every part of the system, so if there are marginal parts running a rodeo may expose the weakness and unintentionally cause an undue headache for you and your business.

Once it’s been determined that the suspension pump has failed, some important steps need to be taken to insure the best possible repair. First off, evacuate as much of the old fluid possible. After replacement, the pump MUST BE PRIMED before start up. Running a pump dry will definitely destroy it in seconds. The full fluid reservoir must be pressurized with a stable tool 5 to 8 psi to ensure the pump does not have a dry start. Once the system is running again, the system should be flushed following the procedure outlined in Mercedes-Benz service literature.

Accumulators for instant response

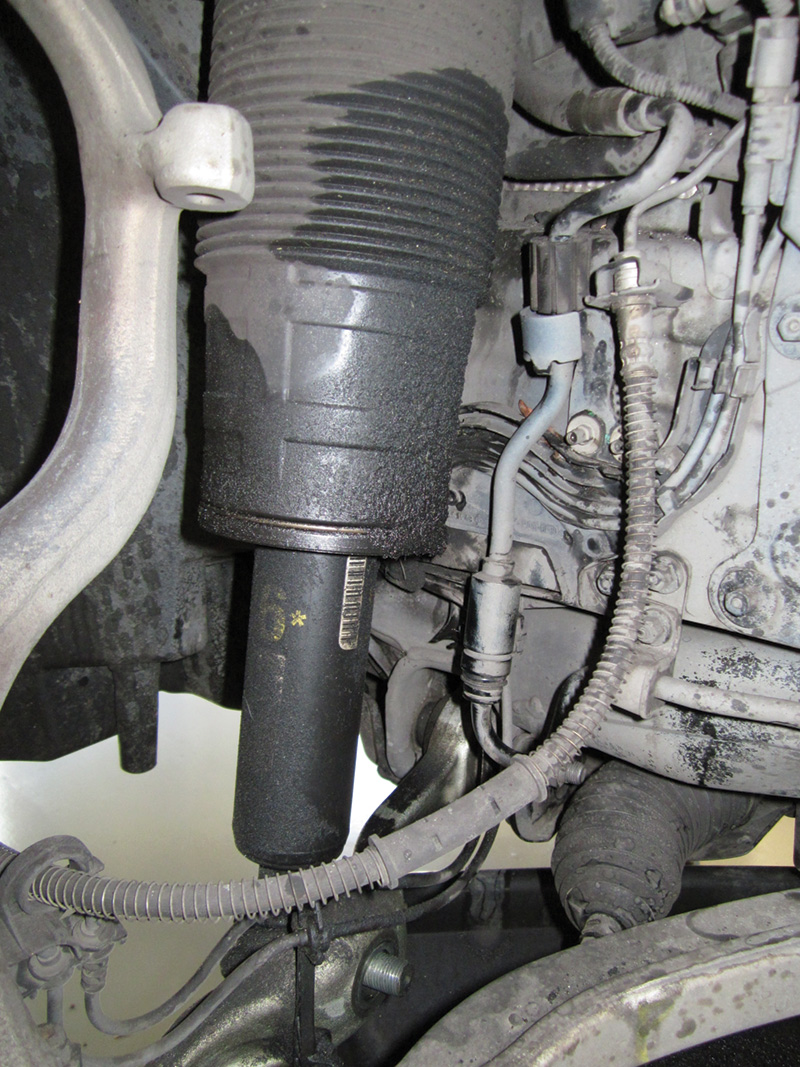

On the rear ABC shock unit, a small leak such as this caught in time can greatly reduce the repair bill.

Lastly, we will take a look at some issues that can be caused by accumulators. The design of ABC accumulators is basically the same as found on early active dampening (ADS)-equipped Mercedes-Benz vehicles. It is used to store hydraulic fluid under pressure for immediate use by ABC when strut fill action is commanded. There are usually two common faults that occur when an accumulator is no longer functioning properly: The first is a sign that the pressure vessel has started to leak its internal nitrogen charge. The scenario is a brief ABC warning light on the instrument cluster, usually after hitting a bump in the road. Not being able to move fluid into the strut causes the system pressure to drop momentarily. This will usually set a low pressure code because the accumulator can no longer react fast enough. Assuming the pump is healthy and passes dynamic testing, the task of determining which accumulator (front or rear) is at fault can be difficult. Unlike earlier ADS-equipped models, physically bouncing the vehicle when stationary is not a valid test on a modern ABC system. This is because the valve block is closed when inactive accumulators are isolated from the struts.

Remember, if fluid can get out, dirt can get in. This heavy leak had been neglected and led to pump replacement along with the shock repair, an expensive proposition.

The second issue we see is the mysterious ABC reservoir tank overflow after sitting. This one can be spotted before it begins during routine service with a simple fluid level check. If fluid is found to be low and no external leaks are found, where did the fluid go? You guessed it: into the accumulator. An internal rupture of one or both accumulators, now void of nitrogen, will allow fluid to fill the now-empty space. The slow overflow happens when, for whatever reason, someone tops up the low reservoir with fluid without investigating why it was low in the first place. Even though the accumulator is ruptured, it still contains a spring and diaphragm which was compressed by system pressure and the missing fluid. After the vehicle has been parked, system pressure subsides and spring pressure in the accumulator slowly pushes fluid back into the tank and causes the spill.

In either case, the best practice is to replace both accumulators as a set along with a fluid and filter change.Â

0 Comments