While the latest Mercedes-Benz turbochargers “spool up†much faster than older designs did, until recently there was still a lag before they reached the rpm necessary to provide boost. In 1998, the SLK got a supercharger that provided the “right now†feeling normally associated with larger engines. These and other later models should be showing up in your shop by now, so you’d better know how they work.

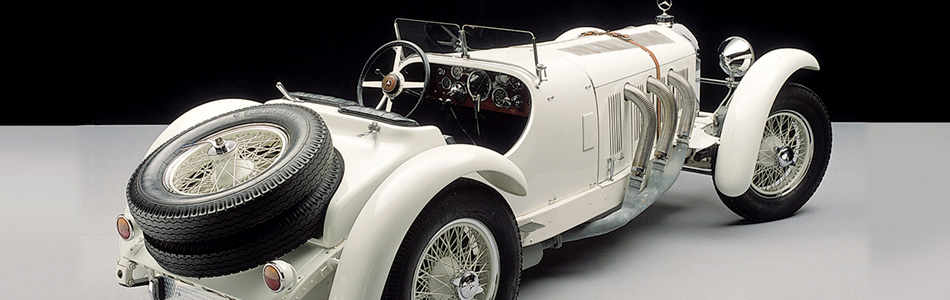

Artificial respiration in the form of a clutched supercharger helped make the original SSK an automotive icon. How about 250 hp and 146 mph in that era? By1931, the SSKL produced 300 hp and topped out at 150 mph.

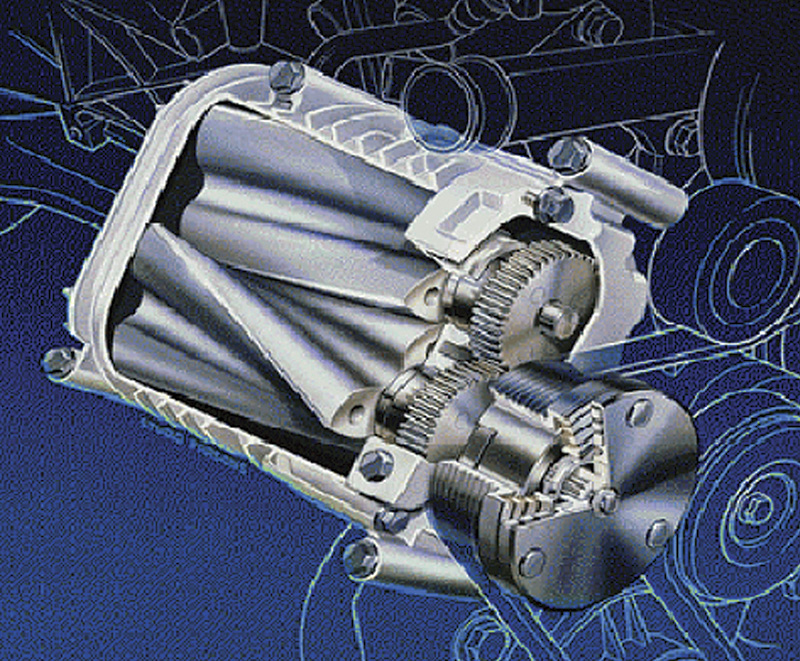

In 1854, the brothers Philander and Francis Roots of Indiana tried to improve the efficiency of their textile mill by redesigning its water driven machinery. What they came up with was a pair of wooden figure eight shaped rotors inside a metal casing. The choice of materials was unfortunate — the wood swelled when it got wet and jammed the contrivance. While waiting for it to dry out, Philander spun the rotors by hand, and a blast of wind blew his hat off. Being reasonably alert fellows, this effect was not lost on them, and they developed their invention to the point that it was patented in 1860. It found commercial use in coal mine ventilation.

While this blown “Hemi†with its six “deuces†is about as impractical an installation as you could imagine, the supercharging principle can be tamed and put to good use through intelligent engineering.

Auto engineers at the beginning of the 20th century were quite alert, too, and they realized that this type of pump could be used to stuff more air into the cylinders of

an engine than atmospheric pressure could, thus increasing its output.Â

Although race cars as early as 1909 were using blowers and Daimler technically started developing them in 1921, the 1927 SSK was the first vehicle to really put supercharging on the map.

Mercedes-Benz has developed the century and a half-old Roots concept into a thoroughly sophisticated state.

Of course, exhaust-driven turbochargers also provide a breathing boost, but a blower is different. There’s no wait for the extra power to kick in. It’s just there, all the time as if the engine had a much-larger displacement than it actually has. As you must realize in this era of increased concern over mpg and carbon footprints, big engines aren’t very “green,†so getting sprightly performance out of small ones, or to put it another way, achieving more power per unit of displacement, is a worthwhile goal.

Lag and drag

When intake air is compressed by whatever means, it gets hot, which promotes detonation, among other things. This

2.3L’s big intercooler helps eliminate the problem.

The adoption of mechanically driven, positive displacement superchargers is a good way to achieve that goal. You might argue that a supercharger is less efficient than a turbo since the latter gets a free ride in the exhaust stream. But is it really free? Backpressure is increased, you know.

True, spinning a supercharger does indeed result in a parasitic loss, but this is mitigated during part throttle operation because vacuum helps drive the rotors, taking the load off the crankshaft. As far back as the original SSK, drag was eliminated altogether by means of a disc type clutch that only engaged the supercharger when you floored the accelerator.

Mercedes-Benz introduced the SLK (170 chassis) two-seat sports car in 1998. To help keep it light and nimble, the new 2.3L four-cylinder was used (designated M111). While this is a solid engine, a sports car really should offer more performance than an entry-level C-Class (C230).

The solution to this was the addition of forced air induction in the form of supercharging. In ‘02, the SLK by AMG received a 3.2L supercharged V8, in ’03 the C230 got a 1.8L supercharged engine, and all of the AMG 5.5L engines of the time were “blown†as well.

Managing boost and minimizing acceleration lag were engineering challenges that the Mercedes-Benz engineers dealt with very well indeed. You should definitely have an understanding of the configuration and operation of the supercharging system so that you can diagnose any problems logically. Not that there have been many problems — a search for TSB’s on the topic turned up exactly one result (a tear in the partial-load vent hose at the connection to the crankcase, which allows air to bypass the MAF and cause a lean condition), but it’s still a factor in the overall engine performance picture, and as such part of the puzzle.

Theoretically…

A review of the principles involved makes a good beginning. As an engine rotates through its four cycles, it generates a vacuum in the cylinder as the piston drops to BDC. The atmosphere provides outside pressure to the tune of approximately 14.7 psi (one Bar), depending on your altitude and the weather. This pressure flows toward the vacuum in the cylinder through the open intake valve. At this point, the intake valve closes (depending on the camshaft profile and “scavenging†designed into the system), and the piston starts to travel upwards toward TDC, creating more and more pressure. The power produced by the following combustion stroke is limited by how much air has found its way into the cylinder during the intake stroke, thus how much fuel can be turned into useful work.

By increasing the pressure in the intake system to something higher than 14.7 psi, we can force a greater quantity of air into the cylinder, therefore creating more power. Supercharging achieves this by using the engine’s crankshaft rotation to drive a belt that spins the air-compressing mechanism. This forces higher-pressure air into the engine’s intake. This “boost†can produce significant horsepower gains.

There are limits to this, however. With too much pressure, the mixture may ignite before the intended time. This pre-ignition (also known as detonation) can quickly destroy an engine. This is why on turbocharged and supercharged engines the compression ratio is typically reduced. Also, lower-octane fuels compound this problem by being easier to ignite. So, there must be some pressure-limiting feature built into the supercharging system. A pressure “pop-off†valve can be used, but it’s inefficient to waste engine horsepower to drive a supercharger only to blow-off excess pressure that’s not needed.

Roots routes

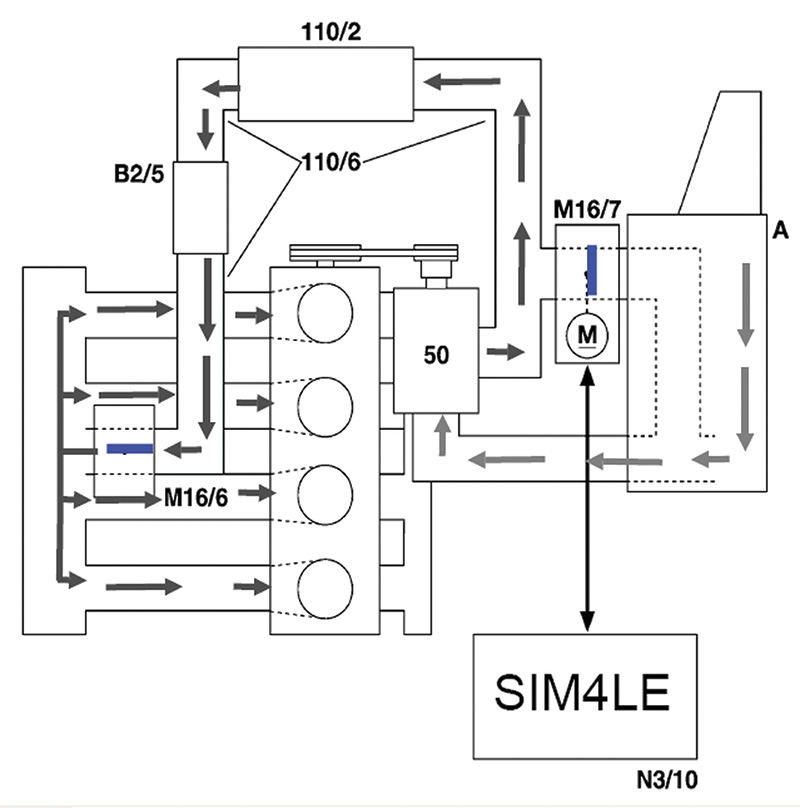

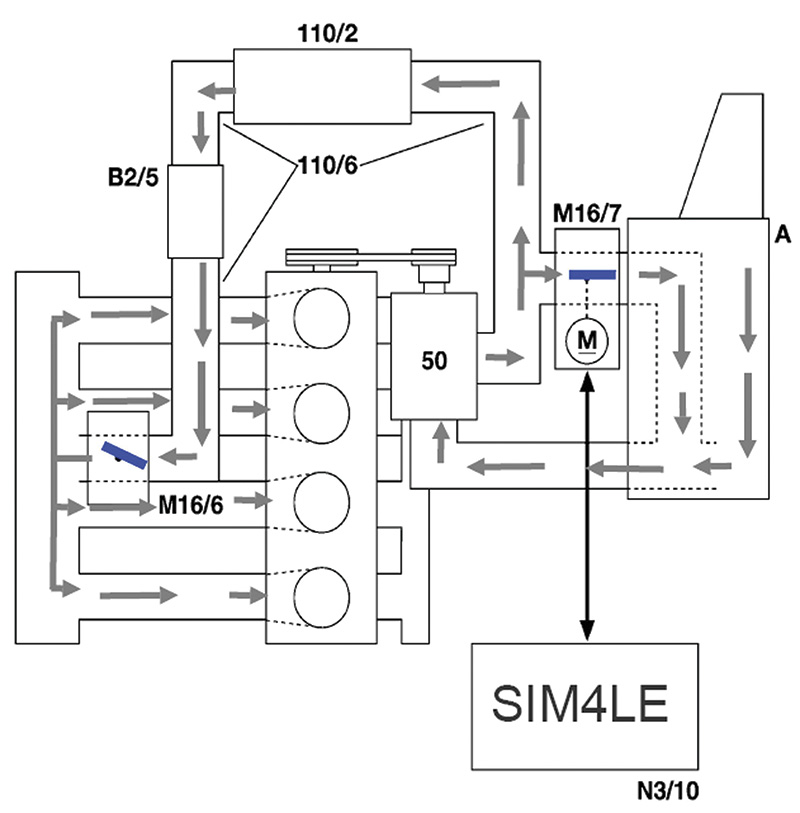

The Recirculating Air Valve Actuator flap is normally open, and is controlled by a pulse-width modulated signal. The larger the duty-cycle (positive slope), the more the flap is commanded closed. When fully closed, all of the intake air goes through the blower.

Using the supercharged 2.3L as our example, filtered intake air can take two different paths. Under acceleration, it is directed into the Roots unit, which is a positive-displacement pump that starts to build pressure at relatively low rpm (about 2,000). Pressurizing air makes it hot, so it is routed through an intercooler, which may be of the air-to-air or air-to-water type. The SLK’s air-to-air unit travels along the lower front bumper and resurfaces on the driver’s side of the engine, entering the throttle body upstream of the plate. Later-model larger-displacement supercharged engines use an air-to-water intercooler.

This is the path airflow takes when the Recirculating Air Valve Actuator flap is closed. All intake air is routed through the blower so maximum boost can be achieved.

The SLK has a “fly-by-wire†electronic throttle, or EA (Electronic Accelerator), mounted on top of the intake manifold on the driver’s side. But how does Mercedes-Benz control the boost pressure in the intake? Perhaps you’ve noticed what looks like an electronic throttle assembly right at the air-box. This is indeed a similar assembly, but it has a different task. Called the Recirculating Air Valve Actuator flap assembly, it controls which path the air takes.

Here, the Recirculating Air Valve Actuator flap is open, so any boost generated is recycled back into the airbox. No positive pressure builds up.

When it’s closed, intake air is routed through the supercharger, then the pressurized air is sent to the engine. If too much boost is being created for the throttle position (determined by monitoring CPS, TPS, and MAP sensor signals), the Recirculating Air Valve Actuator is opened incrementally to allow air to bypass the blower and continue straight to the intake manifold, or to allow any boost pressure to bleed off back through the airbox. This reduces the amount of air entering the supercharger, thus limiting boost pressure. The actuator flap is not just open or closed. The ME control unit can vary the position of the valve to maintain consistent boost pressure. This helps reduce lag when changing from deceleration to acceleration, and also reduces boost if the level becomes dangerous to the engine.

On early M111.973 engines, an electromechanical clutch was used to drive the supercharger, in the fashion of an A/C compressor clutch. This allowed the blower to be disengaged entirely so it didn’t generate any boost or cause any parasitic drag at low rpm. Above 2,200 rpm, the clutch is engaged and boost is produced. In 2001, the clutch mechanism was phased out, so boost was managed by the Recirculating Air Valve Actuator alone.

Diagnosis and service

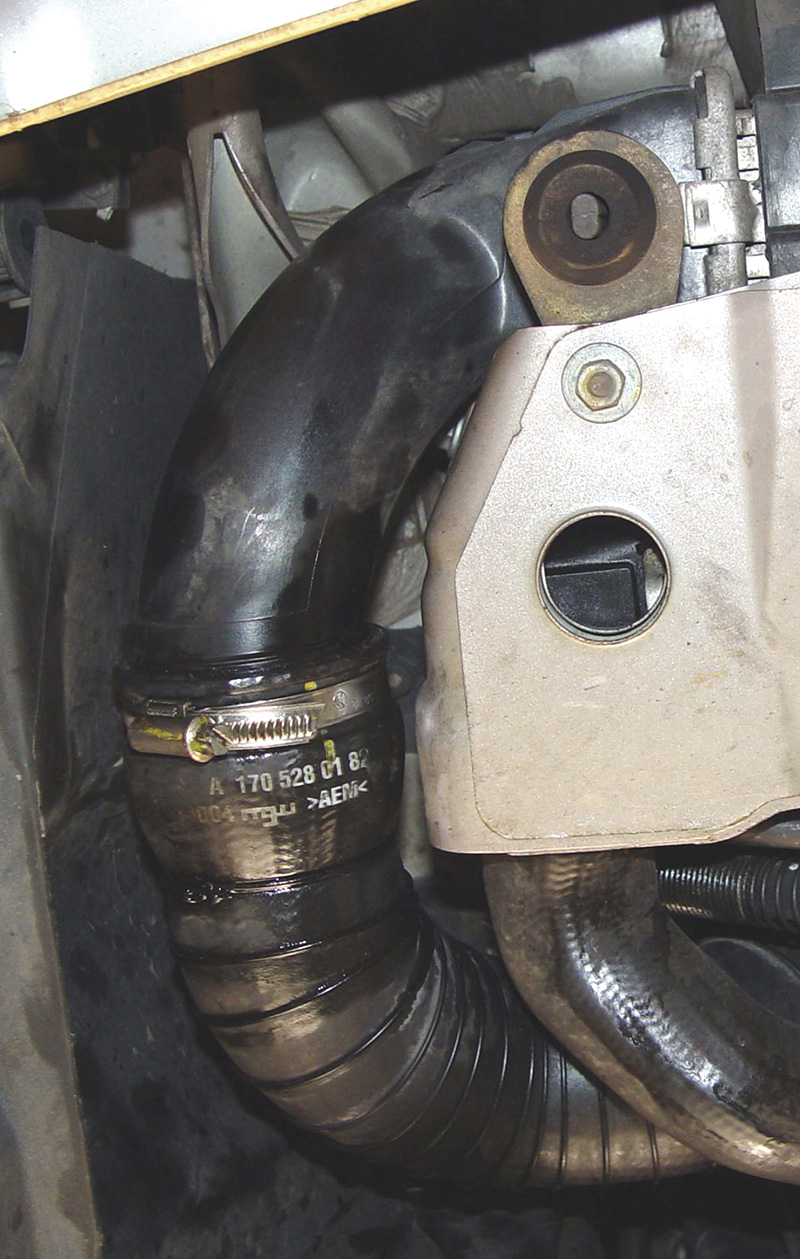

Oil contamination may soften the intake boots over time. If the clamps are not tight, pressure may be lost at these boot connections. This is difficult to detect since it may take eight psi to force the leak to open, but visual and tactile inspection should uncover any problems.

When you’re presented with a complaint that might be related to supercharging, do a visual examination first, then it’s logical to investigate DTCs. If you pull a code P0805 and/or P1235, you’re dealing with overall supercharger function. Connecting a pressure gauge to the intake will tell you if proper supercharging pressure is being achieved. With the 92- to 94-octane gasoline that’s typically available, any forced-air-induction engine will detonate if boost is excessive, so it is limited to just under eight psi. The codes mentioned are letting you know that even though rpm, throttle application, and load should be leading to boost, it’s not actually being achieved. This could be caused by a binding air flap, but it’s more likely that there’s an air leak in the intake path. A torn boot or a leak at any plumbing joints will often lead to these codes, which may be accompanied by a driveability problem such as a sudden loss of power, or “bogging.â€Â

Using your smoke machine might not help you find the source of the leak since it may only open when significant pressure is applied. Keep in mind that worn or broken motor mounts can add stress to air intake plumbing.

Monitoring boost pressure with a gauge while under load is a good way to determine if it is being lost — just verify proper operation of the actuator flap.

Code mode

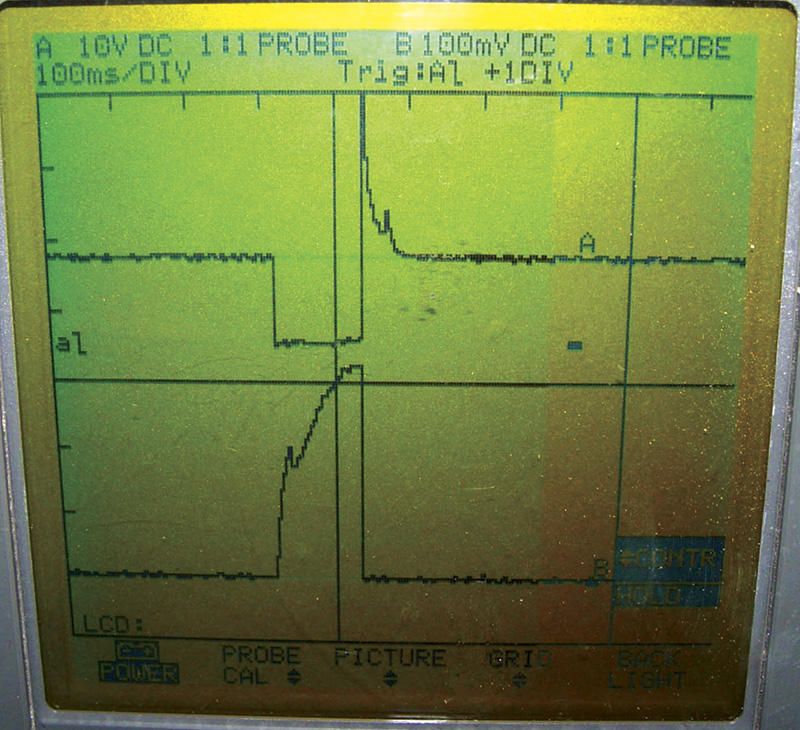

Codes P0806 and/or P1236 deal with supercharger clutch operation. There is no speed sensor for the blower, so proper operation is determined by monitoring the clutch’s electrical circuit. You can visually check for proper activation, then measure the voltage and current draw of the clutch. This is most easily achieved at the powertrain control unit. For example, on a ’98 SLK 230, power is provided to the clutch from fuse F2 in the relay module (mounted in the under-hood, passenger-side electrical box). This fuse also powers up the O2 sensor heaters and the Canister Vent Shut Off Valve, so be sure you know what you’re looking at. By evaluating the wiring diagram, you can see that the control unit, connector F, Pin 21, is the ground control of the clutch. By monitoring the voltage and amp draw of the solenoid, you should be able to determine proper clutch operation and isolate a fault between the clutch and the ME’s driver.

On this scope, we are monitoring the voltage pattern (top trace) and amperage pattern (lower trace) of a supercharger clutch. Notice how the draw peaks at just over 3.0 amps. About 3.5 amps is the maximum you should see on a good one.

Codes P0803 and P1243 are for the operation of the Recirculating Air Valve Actuator flap assembly. As already mentioned, a pulse-width modulated signal sent from the ME to the flap’s actuator commands it to close and produce boost pressure when the driver wants to accelerate vigorously. As a general rule, the wider the duty cycle (positive slope) of the signal, the more the flap is commanded closed. The ME monitors the boost pressure, throttle angle, and mass air flow signals and determines if the flap is working. If you are using a dual-trace scope, you should scope the pressure sensor and the flap actuator command signals. As long as rpm is increasing, the pulse width on the command line should increase as the signal voltage on the pressure sensor indicates more boost. If the pressure is dropping while the duty cycle command is increasing, either the actuator flap is malfunctioning, or boost pressure is leaking out of the intake system.

Double duty

On the M111 engine, the supercharger doubles as the secondary air pump. This means the supercharger clutch must be activated for 30 to 90 seconds after the vehicle is started to supply the exhaust system with fresh air to aid in heating up the catalytic converters. So, diagnosing a secondary air injection code includes testing supercharger function. Activating the blower clutch and the secondary air control solenoid while at idle should pump fresh air into the exhaust. You can monitor additive (idle) adaptation to see that fuel is being added. Remember to have the fuel system in closed loop so that fuel trim adaptation is functioning. You can also watch O2 sensor voltage to see that it drops to under 100mV indicating a lean condition.

Specific super lube

Any Roots-type supercharger has a non-contact air gap, so rotor vanes should not be rubbing together. The supercharger assembly, however, does require special lubrication. The C230K and SLK230 have their own oil, Part Number 000 989 62 01. It is added through the fill/inspection plug hole. The 3.2L and 5.5L AMG engines use a different supercharger lubricant — Mobil Jet Oil II. Also, the 3.2L and 5.5L AMGs have a Charge Air Cooler Circulation pump. This uses liquid coolant to keep the temperature of the supercharger within bounds. As mentioned earlier, the 3.2L and 5.5L engines by AMG use an air-to-water intercooler, so be sure to drain coolant and bleed the cooling system when servicing the intercooler. As with any other belt-driven component, belt wear and proper tension are important.

0 Comments