Traditional collision repair techniques are not effective at restoring today’s automobiles to pre-collision performance. Restoring integrity to modern advanced high-strength steel components and structures requires that decisions regarding whether to repair or replace damaged components, what attachment methods to use, and even what tools and equipment to use, are all made properly.

Volkswagen vehicles are made with advanced high strength steels (HSS), and that changes everything. How many times have you heard, or asked, “Can I straighten this high-strength steel part?†What impact does the fact that a part contains several types of HSS in different layers of its material stack have on the choice of attachment method? Did you know that some structural components can have one type of reinforcement on one end and transition to a completely different HSS reinforcement on the other end – of the same part? The answers to these and many other critical collision repair questions are in the Volkswagen High-Strength Steel Training course.

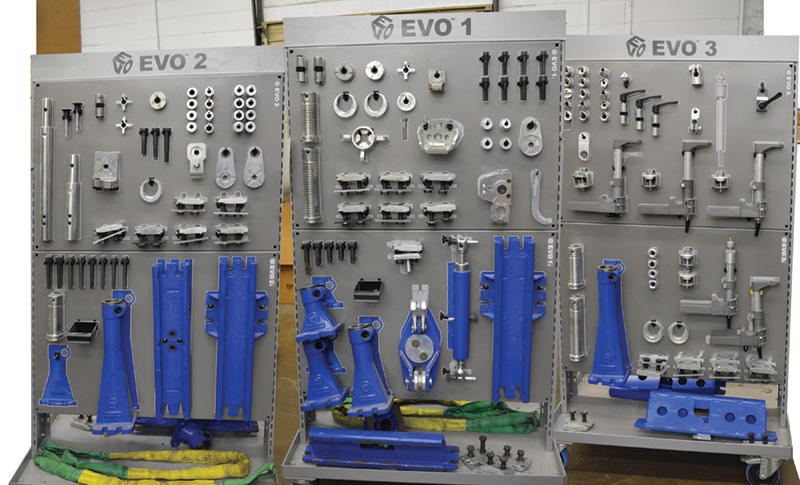

You know that Volkswagen publishes detailed information in excellent collision repair manuals and online resources. However, there is nothing like live, instructor-led training. Now you can get state-of-the-art training on Volkswagen’s advanced high-strength steel repair procedures in a 40% classroom, 60% hands-on format. The two-day class is limited to 8-10 technicians, so you’ll get plenty of personal attention from Volkswagen instructors.

High-strength steel is less workable than mild steel

Post-collision workability of high-strength steel tends to be less than mild steel because HSS has already been hardened to the desired level for its automotive application. Any bending or re-forming, such as occurs in a collision, can cause work hardening that tends to make the steel brittle. If you then attempt to cold-straighten and bend the steel back to its original dimensions, the brittle material may tear, or develop micro-fissures and cracks that leave it vulnerable to part failure in a future collision.

Repair or Replace?

Knowing what the damaged component is made of, and whether that material can be repaired or must be replaced after sustaining collision damage, is critical. Thanks to ingenious chemists, metallurgists, and engineers, there are dozens of different types of high-strength steel in use on today’s Volkswagen vehicles.

Different steels offer a range of properties important to automobile safety. Each type is formulated to offer a specific range of tensile strength (the maximum force the steel can handle before it will fail), ductility (the ability to be easily formed into different shapes), joining capabilities (how well the material responds to welding or other attachment methods), and other factors. These and other material properties have a major impact on which collision repair options are acceptable for a given component and damage scenario.

If the damage is not too extensive, some HSS exterior panels can be cold-straightened. If an HSS part is a structural component, replacement is the only option. There will be a factory-required location where you can install a replacement.

You don’t have to know the metallurgy. Thankfully, there is Volkswagen’s high-strength steel training program. The class covers the types of HSS used on various models, and which parts are made of HSS. It walks you through using the company’s Elsa and erWIN online repair information systems. You’ll learn where HSS parts are located on any VW model, and how to access factory-approved step-by-step replacement procedures. You’ll see demonstrations of how various components respond to heat, pulling, and different joining technologies, and get live, on-car practice in the repair or replacement options that Volkswagen deems appropriate for a given component.

Master Welder

Technicians in the Volkswagen Certified Collision Repair Facility program and in Volkswagen Dealer-owned body shops can attend the HSS and other Volkswagen collision training classes. Contact Ashley Biggs, Volkswagen CCRF Program Coordinator (703) 364-7642 or Warren Barbee, Collision Technology Instructor, Volkswagen Academy (703) 364-7192.

After completing this Volkswagen class, you’ll know so much about working with HSS, your repair efficiency, cycle time, and repair effectiveness will be off the charts. You won’t want to wait until next year to see what’s new to learn.

Download PDFPhotos courtesy of Jim Ellis Collision Center, a Volkswagen Certified Collision Repair Facility in Atlanta, Georgia.

0 Comments