As automotive designers seek to lighten the vehicle weight to attain safety and higher mileage levels, stronger steels are being employed for body structure. Here’s an update on those steels, how they are used in Nissan vehicles and what every collision facility should know about the latest advances in body materials and how to repair them.

Safety and crash worthiness are important factors in automotive design for several reasons. Obviously, occupant safety is of supreme importance, along with meeting regulatory and insurance standards. But, structural integrity for durability and fuel economy are high on the list of desirability. These factors become a valuable marketing tool for auto manufacturers such as Nissan that promote safety, durability and therefore, confidence in the vehicle.

The term for designing these evolving vehicles toward lighter, but stronger structure is called “lightweighting.†If you haven’t heard the term by now, you will shortly as vehicle design and construction material producers and automobile manufacturers work together to create vehicles for the future. The use of new, stronger “Super Steels†is one area where automobile manufacturers are implementing lightweighting.

The Steel Marketing Development Institute (SMDI) works with automakers, government agencies, universities and industry entities to share information in an effort to develop new materials and promote the use of advanced technology. In 2011, SMDI formed FutureSteelVehicle (FSV), a program to developed fully-engineered, steel-intensive designs aimed at reducing mass by more than 29 percent over a benchmark vehicle and reducing total life cycle emissions by nearly 70 percent. This design effort can meet a broad list of global crash and durability requirements and enable five-star safety ratings, while avoiding high-cost penalties for mass reduction. Nissan has participated in this consortium to stay on the cutting edge of the latest and best technologies.

We’ve outlined some of the development of these super steels over the last few years in the November, 2011 issue of Nissan TechNews, so we’ll focus on the two types most commonly found in the design of Nissan vehicles. You can read the previous article: “Paradigm Shift: Coming to Grips with Super Steels†on the Nissan TechNews website at NissanTechNews.com.

HSS & UHSS

High Strength Steel (HSS) is steel with a yield strength value of 440 MPa – 979 MPa. Yield strength, or yield point, denotes the level of stress at which the collision-damaged material will not return to its original configuration when the stress is removed. It’s measured in millipascals (MPa). A steel panel with a yield point value of 965 MPa is equal to about 140,000 psi, so you can see that the term “High Strength Steel†is quite accurate.

Ultra High Strength Steel (UHSS) has a yield strength value of 980 MPa or greater. These materials provide superior strength, rigidity and integrity while lowering the weight of the overall vehicle. Nissan designs vehicles with both steels, as well as other materials.

The Nissan Body Repair

Manual Fundamentals

Earlier this year, Nissan launched an updated version of its Body Service Manual Fundamentals for 2015. It can be accessed on the Nissan TechInfo website at nissan-techinfo.com. You must be a member subscriber or purchase a short or long-term subscription to access the information. On the site you will also find body service manuals for certain specific Nissan models over the past twenty five years.

The 276-page 2015 Nissan Body Repair Manual Fundamentals covers all aspects of body service for Nissan vehicles. If you are in the body service business, this manual can be of great value to you in servicing Nissan vehicles.

Among the vast variety of topics covered are the procedures for newer structural components and metallurgy, including High Strength Steel (HSS) Ultra High Strength Steel (UHSS) and aluminum. As a matter of updating, the BSM points out cautions for servicing HSS and UHSS components.

Cautions for Working with HSS

When replacing an HSS welded panel, it is not recommended to heat components such as reinforcing side members as this may weaken the component. When heating is unavoidable, do not heat above 550°C (1,022°F). Verify the temperature with a thermometer; Crayon-type or other similar types of thermometers are appropriate.

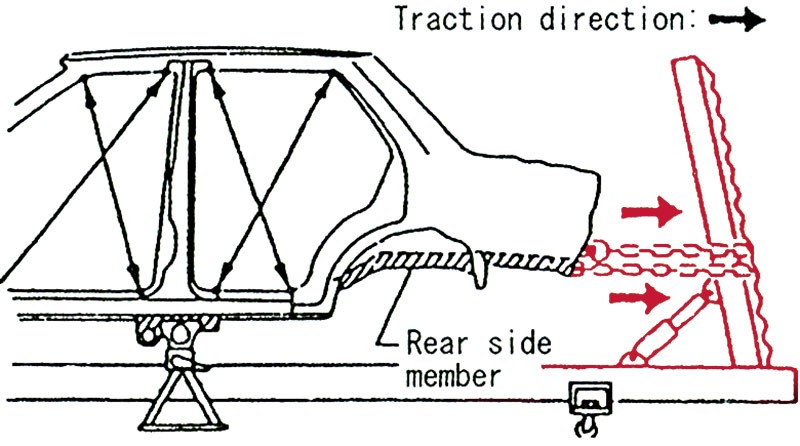

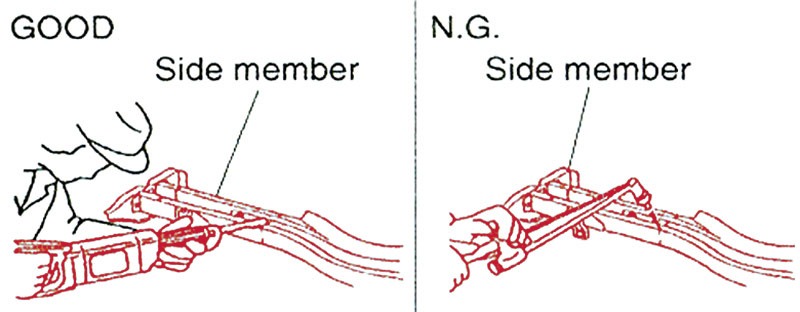

When straightening body panels, use caution in pulling any HSS panels. Because HSS is very strong, pulling may cause deformation in adjacent portions of the body. In this case, increase the number of measuring points and carefully pull the HSS panel.

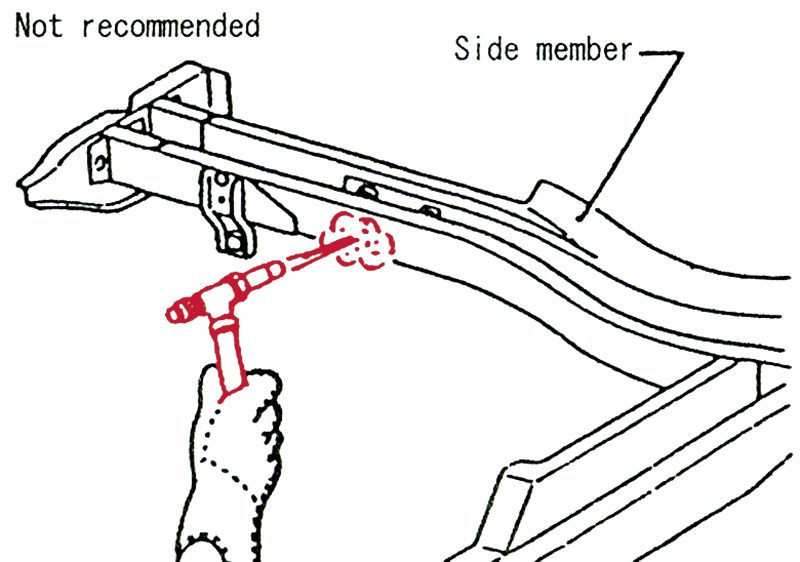

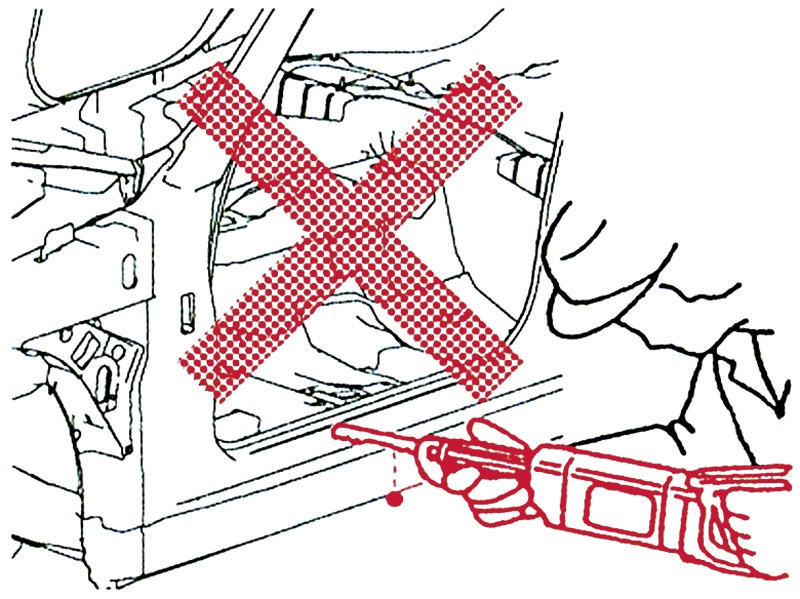

When cutting HSS components, avoid gas (torch) cutting if possible. Instead, use a saw to avoid weakening surrounding areas due to heat. If gas cutting is unavoidable, allow a minimum margin of 50mm (1.97 in.) from other components.

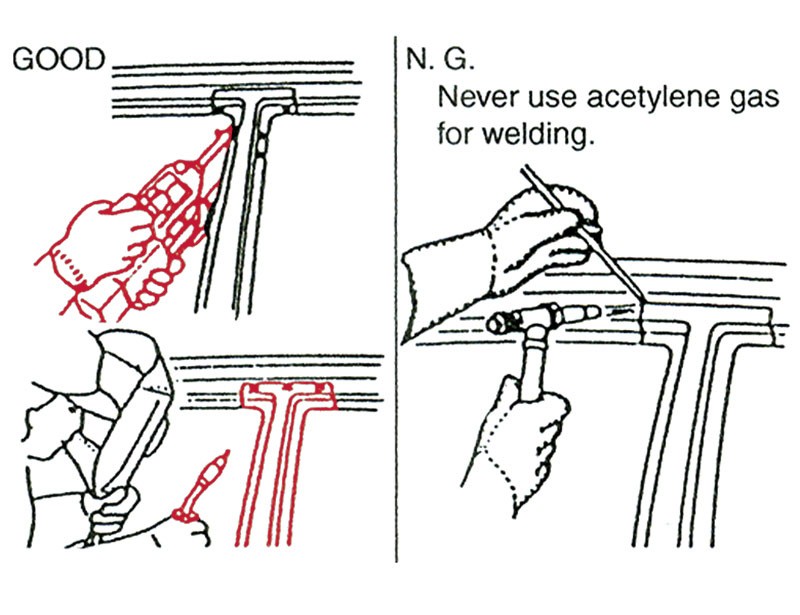

When welding HSS panels, use spot welding whenever possible in order to minimize weakening surrounding areas due to heat. If spot welding is impossible, use gas shielded arc (GSA) welding. Do not use acetylene gas (torch) welding because it is inferior in welding strength.

The spot weld on HSS panels is harder than that of an ordinary steel panel. Therefore, when cutting spot welds, on an HSS panel, use a low-speed high-torque drill at 1000-1200 rpm to increase drill bit durability and facilitate the operation.

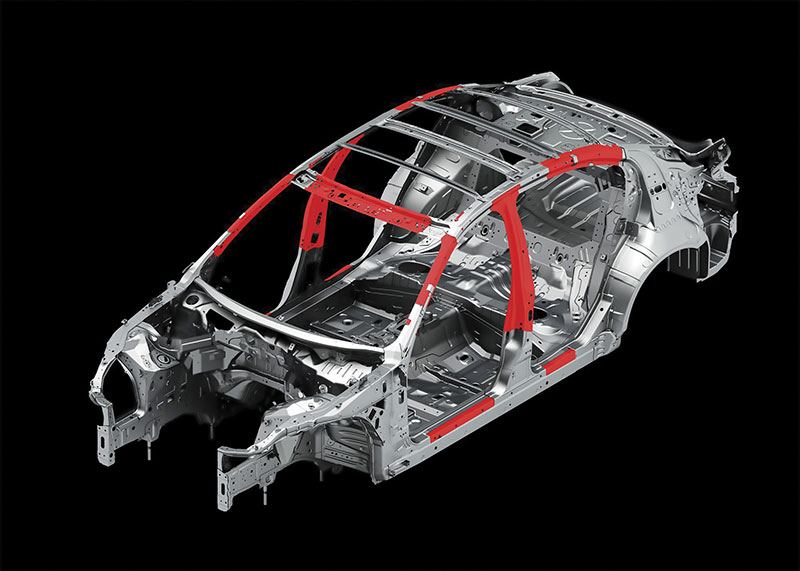

Ultra high Strength Steel (UHSS) is used in the areas of vehicle construction for maximum strength as shown here in red.

Caution for Working with UHSS

Never cut and join the panel, plate and reinforcement made of Ultra High Strength Steel (UHSS). If such a part is damaged, replacement is required.

Descriptions, yield strength and diagrams of where HSS and UHSS components are located in the BRM section of the service manual. Before attempting body repairs, it is advisable to check this section and familiarize yourself with the material requirements. Model specific details can be found in the BRM section of the service manual.

Training

I-CAR, the Inter-Industry Conference on Auto Collision Repair, is an international not-for-profit organization dedicated to providing the information, knowledge and skills required to perform complete, safe and quality repairs. I-CAR offers online training and live classes, including sessions on HSS and UHSS, at certain industry events throughout the year. I-CAR also offers training for qualifying independent body shops to become officially certified as Nissan Certified Collision Repair Network facilities. For more information, visit i-car.com.

For more information or questions regarding becoming a Nissan Certified Collision Repair Facility contact NNACollisionRepairNetwork@Nissan-usa.com or visit getnissancertified.com to begin the shop application process.

Tools and Equipment

Working on and with HSS and UHSS may require dedicated specialty tools and equipment. The Sheet Metal Work section of the BRM has a list of suggested and required hand tools, along with tool usage methods and techniques.

The Tool and Equipment section at the end of the BRM describes specialty tools and equipment. All Nissan-specific tools and equipment is available on the Nissan Tech-Mate website at nissantechmate.com.

For further reading regarding body service, you can check out the Body Basics: Equipment and Tools article in the August, 2011 issue of Nissan TechNews. You can also read that article on the Nissan TechNews website at NissanTechNews.com.

The Genuine Nissan Original Equipment Collision Replacement Parts AdvantageA customer who has experienced a collision is very likely to be under stress from the accident. They may incur unplanned expenses; they may have been injured; their means of transportation has been damaged; they are going to be without the vehicle for a specified time; they will have to make alternate plans – perhaps renting or borrowing a vehicle and their family life is likely to be disrupted until the vehicle is back. These factors can lead to an overwhelming state of confusion and stress. As a collision and body service professional, you are an important part of the process of returning the customer’s vehicle – and life – to normal. Benefits to the CustomerUsing Genuine Nissan Original Equipment collision replacement parts holds benefits for the customer in the following ways:

Benefits to Your ShopYour shop also benefits by using Genuine Nissan Original Equipment collision replacement parts:

Considering all the facts, shouldn’t you be urging your customers to demand the use of Genuine Nissan Original Equipment collision replacement parts for the repair of their Nissan vehicle? |

Â

0 Comments