This issue of Performance Technician has so much great content on carburetors, I decided to expand my regular column into a feature as an opportunity to share some facts, experiences, and observations on the “magical mechanical mixture maker†that I hope you’ll find interesting. Our Exec Tech Editor and main contributor, Greg McConiga, says this piece is “A testimony to Yankee engineering and frugality — forgotten values for many — from back when we did what we had to with limited resources.†So, there might be a little more nostalgia in here than you expect of a technical magazine, but, hey, it’s my column.

I’ve always enjoyed working on carburetors, and still do in spite of the usurpation of their function by fuel injection. I started when I was a mere boy. Except for cleaning bowls and making adjustments, the first job I remember doing was fixing a sunken float from an old tractor carb — gasoline all over. The pontoon-type brass float had corroded through in spots at the bottom, so there wasn’t enough air inside to provide sufficient upward pressure on the needle. It would’ve been quite a hassle and expense to find and acquire a new one, so I had to enlist ingenuity. I drilled out the pitted places, then let the gas drain onto a rag for a day or so. When I was confident that I wasn’t going to blow myself up, I soldered over the holes I’d made. Worked fine.

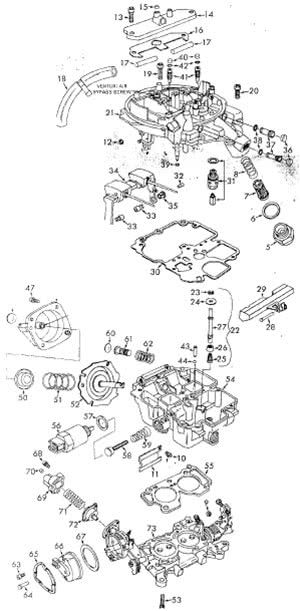

I made a point of taking all kinds of carbs apart, from little ones on construction generators, lawnmowers, motorcycles, and outboards to big Quadrajets, Autolites/Motorcrafts, and Holleys, until I got a solid understanding of their theory and operating principles. My old-school favorite was the Carter AFB four-barrel, as might have come off a Chrysler 413 or 440, because I really got to know how to set it up.

Mechanical computer

I remember calling the carburetor “a mechanical computer†in a tech article long ago because it made “decisions†about the air/fuel mixture on the basis of input (temperature, throttle position, vacuum, and in some of the later versions, atmospheric pressure in the form of an altitude compensator). That’s not really such a bad description, come to think about it again.

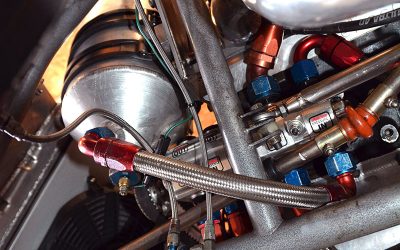

The latest-model vehicle I remember working on that came from the factory with a carburetor (non-feedback) was a 1985 Chevy S10 2.8L V6 — that’s over 30 years ago! There were some later ones up to about 1990 on certain Oldsmobiles and Buicks, and the Subaru Justy, but we’re still talking decades since EFI took over. That doesn’t mean there aren’t millions upon millions of carbs out there, however. Besides old passenger cars and light trucks still in service, there’s high-performance and racing, vintage and antique, marine, industrial, etc.

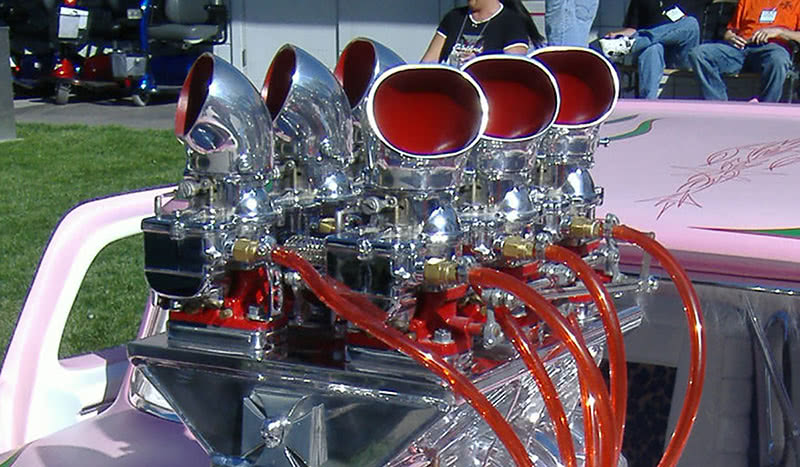

So, the carburetor business is still alive and well. Recently, I had an interesting and pleasant experience getting to know National Carburetors of Jacksonville, Florida. It’s core business is remanufacturing carbs to the highest standards I’ve ever seen, and every one is actually engine tested before it’s shipped. With $30M in inventory, it has the largest stockpile of carburetors in the U.S., and ships them under various brand names. Volume has actually been growing as people are starting to restore cars from the ‘70s and ‘80s. About 30% of the business is high-performance with surprisingly affordable new and remanufactured Holley and Edelbrock products, and even three-deuce set-ups for Ford flatheads.

It was a lot of fun to tour the factory and showroom, and talking to the C.E.O. Eddie Obi, whose dad founded the business out of a service station/repair shop in 1954, and his assistant, Ryan Edenfield. They really understand the inner workings (and weak points) of any carb you can name. Visit nationalcarburetor.com and you might save yourself some money and frustration.

Imagine using a wick…

The word “carburetor†is derived from the French “carburer†for adding carbon (in this case, the familiar liquid hydrocarbon).

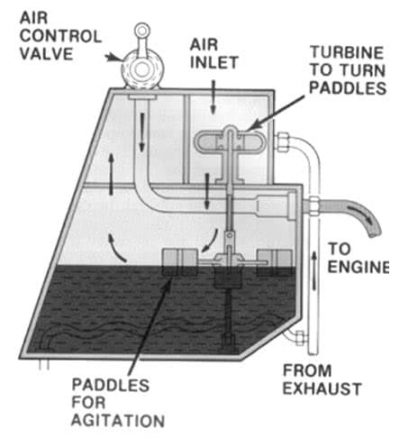

In the late 19th century, some carbs actually used a wick — intake air flowed through a piece of woven fabric that was kept soaked with what was called variously “petrol†or “benzine†in those days. How was the air/fuel mixture controlled? It wasn’t. In that same period, there were also the “surface†types — air passed over gasoline in a bowl and picked up the flammable vapors. In some cases, the liquid was kept in an agitated state by either bubbling engine vacuum through it, or by a little vacuum-powered paddle wheel, believe it or not.

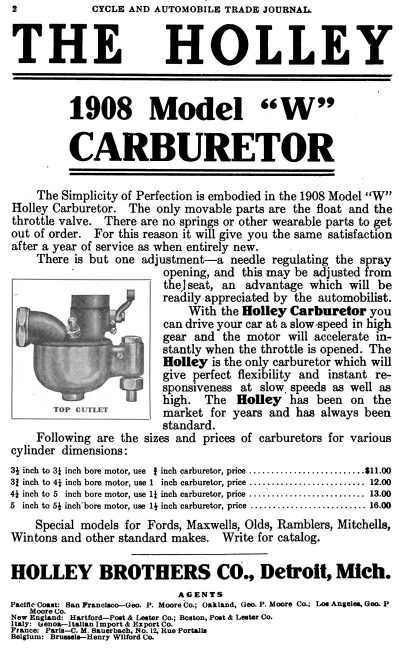

In about 1885, famous German inventors Gottlieb Daimler, Wilhelm Maybach, and Karl Benz all came up with the same idea: a float system to control the fuel level in the bowl. In 1892, Mayback produced the first spray carburetor, which used the venturi principle to make enough vacuum to induce gasoline to move into the air stream through a jet.

Random carb items

Maybe my childhood experience with that sunken tractor float mentioned above was what made me an early discoverer of the plague of heavy foam floats that occurred in the late 1970s (I still have the cool little scale one of the carb parts makers made available — I later heard that the reason so many were sold was that they were convenient for weighing out marijuana). Newer float materials are more resistant to gasoline absorption, but I’ve heard that new blends (I’ve called them “Frankenfuels) can attack them, too.

Epoxy? Really?

I once had a Mercuiser 3.0L four that wouldn’t run over idle. The bowl was literally full of pinkish aluminum oxide, and when I cleaned it out thoroughly I could see daylight through pinholes in the bottom of the casting. A new part was hundreds of dollars, and I’ve never learned how to weld aluminum, so what was the expedient fix? You can’t have a gas leak in a boat, after all.

So, I investigated epoxies. Most said on the label, “Impervious to motor oil, transmission fluid, and antifreeze, RESISTANT to gasoline.†Not satisfactory. Then I read the claims on the J-B Weld package: “Impervious to gasoline. Use on gas tanks.†That was worth a try, so I smoothed a nice, neat coating of the stuff inside the bowl filling and covering the pinholes (I’ve heard since that some rebuilders do the same thing — from the outside/bottom, too). Not a drop for five years that I know of, then the boat got shipped to Denmark, if you can believe that.

Another marine problem illstrates something else. A 2.3L Volvo had sat for a year in a hot climate. It started up fine, but wouldn’t rev over 2,500 — it leaned out before it got the boat up on a plane. Naturally, the first thing I did was examine the jets. Held up to a strong light, their borings looked fine with no visible deposits. But the float level and everything else was okay, so it had to be the jets. I have a nice collection of drill bits down to very small diameters, so I started trying them until I got to the size that required a little force to twist. Out came a spiral of hard varnish exactly the color of the brass. I moved up in drill size until I was actually into metal, and that engine hit 5,200 rpm with ease.

Language barrier

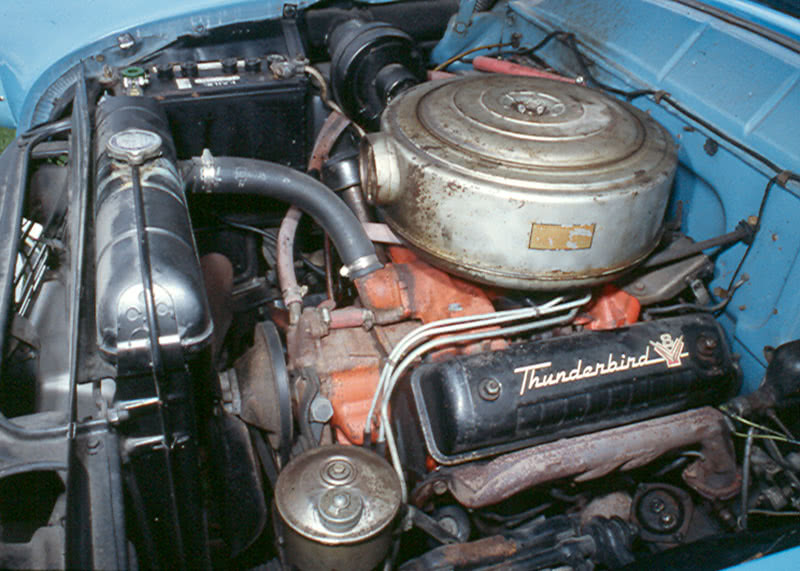

My dad’s ‘55 Ford 272 V8 developed severe hesitation/bog when I was a kid. One of my Swedish cousins, a brilliant, inventive engineer, happened to be visiting the U.S. on business and was staying with my family. When I popped that ponderous hood, he removed the air cleaner, worked the throttle, and immediately pronounced that the problem was the “fuel pump.†I was confused because the engine ran fine otherwise. Didn’t that mean the pump that forced gas into the bowl was working? So, this was a language thing. His English was good, vastly better than my Swedish, but he didn’t have “accelerator pump†in his vocabulary. He said, “the fuel pump in the carburetor.†I finally got it, and the fix on that two-barrel was easy. That old “Y-Block†carried us around for years and years afterwards.

When I worked as a line mechanic in a Ford dealership after college, I dealt with “elastomer†valves frequently. Just a small, molded-rubber part, it was the one-way valve for the accelerator pump on those old carburetors. Nothing to replacing them when they dried out or cracked. Today, they’re mostly made of silicone rubber so should resist even the destructive, corrosive gasoline of modern times.

I once drove a 1973 Ford Torino 351 Cleveland (big top-loader four-speed) across the U.S. pulling a 15-foot Scotty travel trailer. Everything was going okay, but when I crossed the Western continental divide in Wyoming at about 10,000 feet, things got really rich. Less oxygen per cubic foot of air. The nice, white paint job on the front of the trailer was covered with black soot. No altitude compensation with that carb. An aside: There was a Porta-Potty in the Scotty. When I stopped at the apex of the divide to check things out, I found it rolling around. It had assumed the shape of a huge basketball because it was full of Bar (short for “barometric,†some prefer it all upper-case — BAR —in other words, sea-level atmospheric pressure of about 15 psi). It didn’t burst, thank goodness, but its seal was sorely tested.

One of Performance Technician’s regular contributors, Henry Olsen, is the proprietor of Ole’s Carb in California. He’s the most gifted tuner I know of, and has also invented various products that fix carb problems that are inherent in their design or materials. He’s a great resource. You can contact him through olescarb.com.

When I was unhappy with how the vacuum-operated secondaries of an Autolite four-barrel on a 351 Windsor-powered Mustang opened, I made up a small-diameter steel cable to do it mechanically. A little drilling of levers and clinching of attachment points and I had secondaries controlled “real time†by my right foot.

VVs

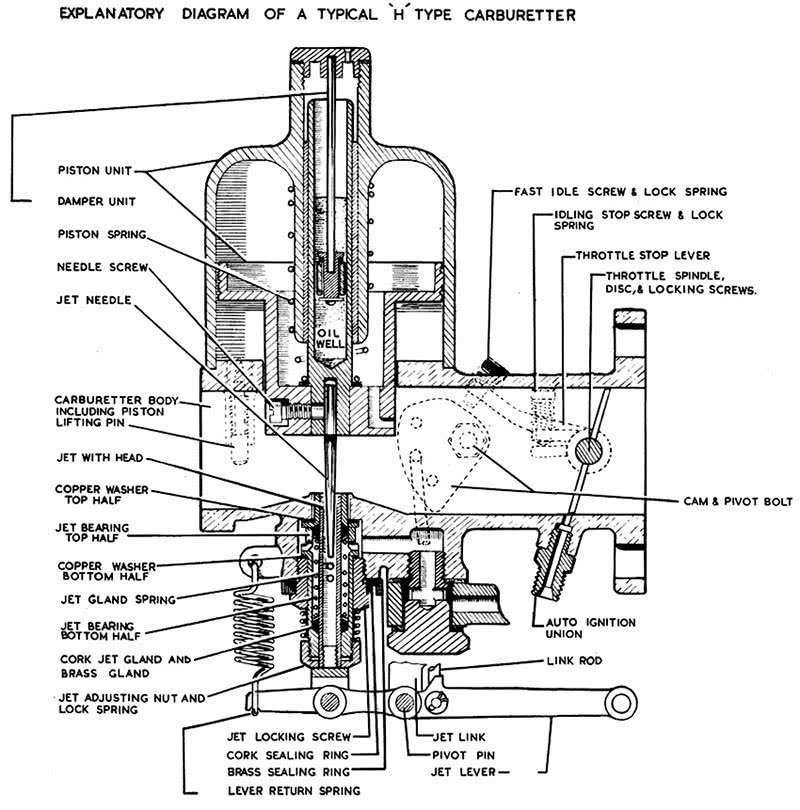

Did you ever tune up an English sports car with twin SU variable-venturi “carburetters,†as the Brits call them? They worked very well indeed providing good performance and efficiency, but synchronizing them so that all the cylinders received the same CFM was a bit of a challenge. One method was to hold a piece of hose to the same spot in each carb while you held the other end to your ear, and adjusting until the volume and pitch sounded the same, which was too subjective to be very accurate. A better means was the use of a Uni-Syn or similar device that actually measured and displayed the amount of air flow. You can still buy these, and they’re useful on any multi-carb set-up. They’re available through Edelbrock, among others.

Speaking of variable venturis, the Ford/Motorcraft VV 2700/7200 was introduced in 1977 on 2.8L and 5.0L California cars. It provided instant response and increased mpg slightly while lowering emissions. Except when it didn’t. Lots of trouble with it, especially during starting and cold-weather operation. I may still have the OTC service kit in my tool “archives†somewhere.

0 Comments