There are multiple components necessary to attain proper combustion within the modern engine. Oxygen, fuel, compression, ignition, not to mention everything coming together at just the right moment in order to have a successful event. Since the very beginnings of the internal combustion engine, there have been misfires. It could be argued that during development, the misfire actually precluded actual combustion! As much as things have remained the same, things have also changed dramatically. Technology has taken over much of the role of mechanical workings as far as spark and fuel are concerned. Add to that variable valve lift and timing and we have now opened up a wide range of potential failures. Nissan engineering has stood up very well over the years, but at some point something is bound to act up and a misfire may develop.

The tools available to technicians today dramatically improve the speed at which the root cause of the misfire can be found. The key to a successful diagnosis is utilizing this tooling, the service information available, and methodically working through the steps to ensure no system or component is overlooked. Nissan service information found at Nissan-techinfo.com will be the most valuable resource for any diagnosis one may have.

When it comes to a misfiring engine, proper identification of the offending cylinder(s) is an obvious first step, and utilizing the CONSULT III Plus will allow you access to corresponding diagnostic trouble codes (DTCs). Nissan engine management systems do a great job at making sure they set a misfire code for the correct cylinder. As unlikely as it is that the incorrect cylinder would be flagged for a DTC, you may benefit from keeping an open mind until the offending cylinder is verified. Fortunately, you have the ability to utilize a power balance feature within the CONSULT III Plus software. It is a great way to ensure that the P030X code you retrieved previously actually shows up as a low contribution for that cylinder. Furthermore, in cases where a misfire can be felt but doesn’t set a code, the power balance feature will help guide you to the correct location.

So now you know which cylinder(s) should get your attention, next is determining which component is responsible for the poorly-performing engine. In this day and age, regardless of how straightforward the problem appears to be, a check of your technical service bulletins is a good idea. You may not find any reason for the misfire you are dealing with. However, updated parts information or service procedures may be found in your search. An example would be bulletin number NTB06-075, affecting 2004-2006 Altima, Maxima, and Quest models with the 3.5L engine, as well as the 2007 Quest with the same 3.5L engine. Failed ignition coils that have a blistered appearance, may simply be replaced without a second thought. Had TSB information been checked, a closer look at the negative battery cable would be performed and the root cause actually found.

A balancing act of system and component testing is at the doorstep, but before going elbows deep into scan data or swapping parts around, remember that some of your best tools aren’t in the tool box. Sights, sounds, smells are all important inputs to steer you towards the end goal. Only a minute or two of poking around under the hood while pondering the possibilities may garner some valuable clues. What condition is the rest of the vehicle in? Does it appear to have been properly maintained per Nissan recommendations? How many miles are on the odometer? Has any major or even minor work been done recently?

OK, it’s time to do some actual work. What test would you expect to be able to perform in the least amount of time, that may actually give you the most information? No really, take a second and answer that question in your own mind. There are no wrong answers, and every vehicle has its own diagnostic process. Keep in mind though, that when dealing with misfires, clear flood mode is your best friend. The new technicians may not be thinking about it, and the seasoned ones may have forgotten about it at times, but the reality is that it’s a tremendous tool in your arsenal. Nissan for the most part has incorporated this feature for quite some time. Turning the key on, then depressing the accelerator pedal to beyond 80 percent, then turning the key to the Start position should result in an engine that simply cranks but does not start. The cadence of the engine can be listened to, and any possible compression issue can subsequently be heard as an out of

rhythm frequency.

Imagine the time savings when you suspect right off the bat that there is a compression issue. While the cause still needs to be determined, this information will help keep you from making assumptions with scan data or secondary ignition patterns. Also, all the spark plug ignition coils and injectors in the world aren’t going to remedy a compression fault misfire. That said, if ever a compression issue is determined to be the fault, you will be wise to make sure that the ignition and injection systems are functioning properly. Replacing a cylinder head only to have to sell an ignition coil or injector after the fact will most certainly affect customer confidence.

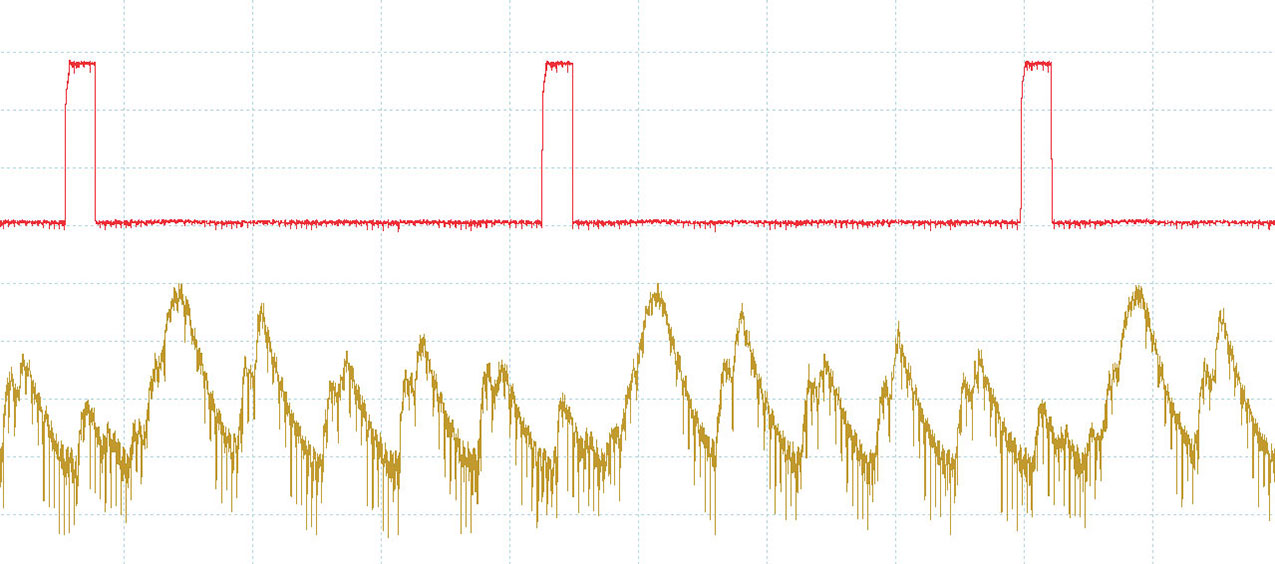

Just imagine a scenario where the compression has been decreasing in a particular cylinder for a while, without the customer actually noticing much of a difference. If most driving occurs under light load conditions, this is a very possible scenario. Now the ignition coil or injector fails, and the misfire is much more severe. The quick relative compression check is always a good thing, but it may not be the only factor. Take the Murano 3.5L engine pictured in the right-hand column.

It came into the shop running very poorly. A single cylinder was found to be the culprit from the code retrieval using the CONSULT III Plus. A clear flood mode relative compression test was performed, and as you can see from the screen capture, there is a low cylinder.

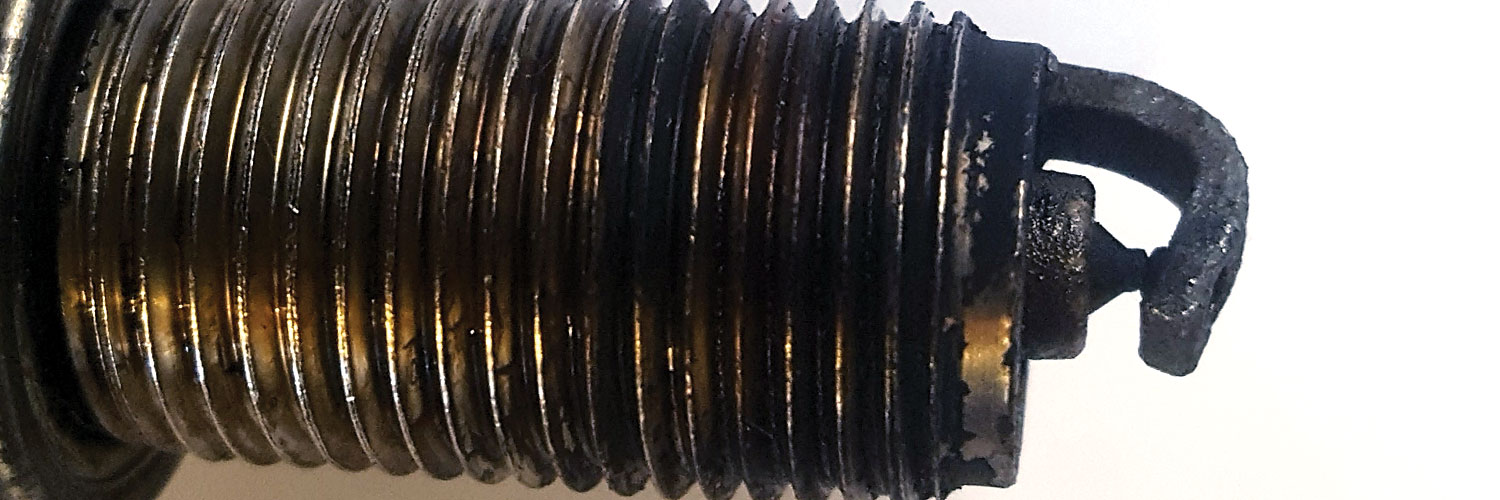

Fortunately on this particular V type engine, the cylinder in question is easily accessible, and so the ignition coil and spark plug were removed for inspection and further testing to determine the source of the low compression. Upon removing the spark plug, it was evident the electrode gap was missing.

This should solidify the reason behind making sure that all systems related to proper combustion are verified.

The fuel delivery and injection systems on Nissan vehicles have proven to be robust and for the most part trouble free. It is easy to overlook these areas when a problem vehicle arrives, but it would be wise to verify their operation under any driveability concern scenario.

Without the proper fuel volume delivered to the engine management system everything will be off, so starting with the fuel delivery system may be advantageous in both the short and long run. Have you gone looking for a fuel pressure test port lately? Fuel pressure testing isn’t quite as straightforward on Nissan vehicles as some others. However, it is still possible to attain the reading, albeit intrusive and potentially messy. Keep in mind the particular misfire concern being dealt with before diving right in on fuel pressure. Are there other ways to establish whether this system is healthy or not?

The CONSULT III Plus is a perfect way to get some bearing. First it will already be deployed for interrogation of the modules for codes. While it’s in use, and as a test drive should likely be performed, graphing fuel trims and air/fuel ratio or oxygen sensors could rule out the possibility of fuel pump issues. Some experience on known good vehicles will be handy when analyzing fuel trim data on a misfiring vehicle. It is said that a fuel misfire causes higher fuel trim readings than an ignition misfire. However, if an injector is shut down due to a misfire, the ECM has now created a fuel misfire and the potential for fuel trims that can lead you astray.

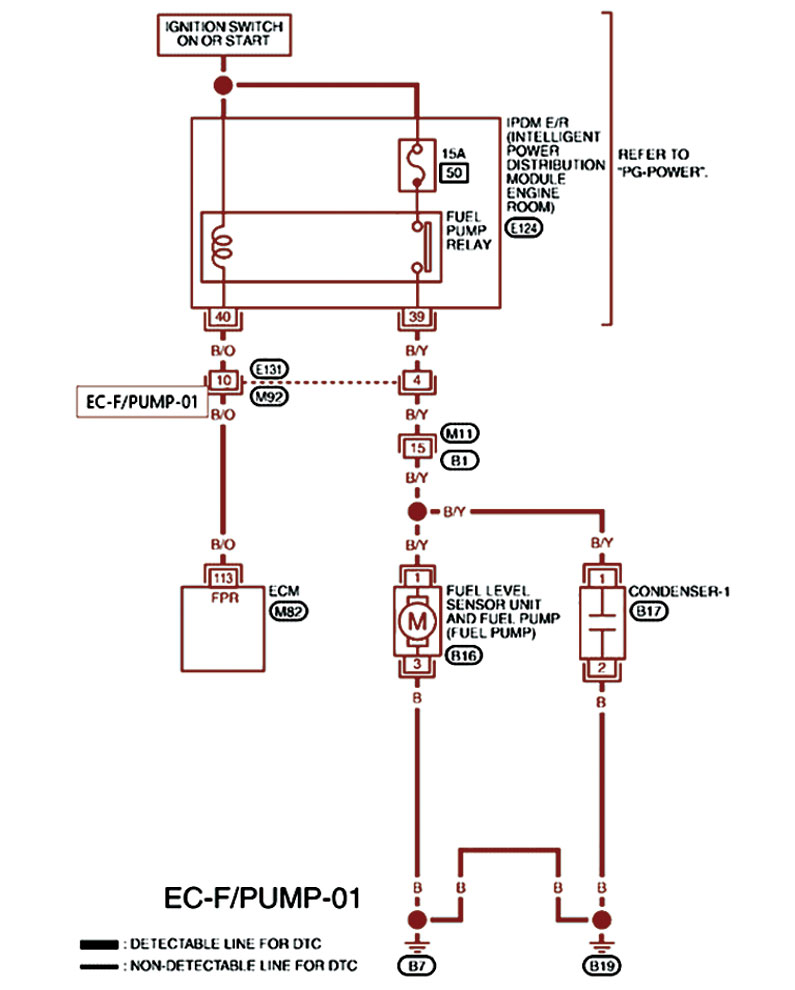

Another source of valuable fuel pump performance information lies in the circuit’s amperage and voltage signatures. Typically the fuel pump is on a circuit along with a dedicated fuse and relay.

This allows quick and easy access to insert a fused jumper either at the fuse or the relay terminals. Reference Nissan-techinfo.com for the proper wiring diagrams to aid in setup. Some practice with evaluating fuel pump waveforms will go a long way in this area. Once familiar however, you’ll be able to quickly narrow down specific fuel delivery issues.

Take for example an amperage waveform that shows low current and low pump speed. This is typical of high resistance in the circuit. The resistance lowers the ability for current to flow which in turn results in a slow spinning pump. How about high current draw but slow pump speed? This isn’t going to result from high electrical resistance, but possibly high mechanical resistance. You may also have a restriction to fuel flow causing high current but low pump speed. Coupling current testing with the results obtained on a road test with the CONSULT III Plus should allow fuel supply to be ruled in or out alone, without the need for messy fuel pressure testing.

On the other end of the fuel supply system is the fuel delivery system, namely the fuel injectors and rail connecting them. Again, Nissan has been solid for years in regards to injector reliability. However, they must not be overlooked. As spark plugs have been becoming difficult to access in recent years, then you are well aware of the hidden nature of the fuel injectors. It is still possible most of the time to get your stethoscope into hard to reach areas, and using the CONSULT III Plus to control the injectors while listening to an audible click is an extremely time saving go/no go test.

Wiring diagrams. Wiring diagrams. Wiring diagrams. There, that was three times, hopefully it will stick. This road map of testing will give you a jump start in your quest for flushing out any injector problem. Right off the bat you will be able to ascertain where your best test points are. Many times injector supply voltages are linked together. Even better, many times they share the same fuse without any other loads also on that fuse. This is another great place for an amp clamp to be put to use. Hey, remember that ignition misfire that caused the ECM to shut down an injector, that in turn drove fuel trims on that bank high? Guess what, watching to see if you have a missing injector event with your amp clamp could point you in that direction.

Would it also be advantageous to see if the testing would much more effectively be done at the control module instead of at the component? The ability to check the complete circuit beginning to end may provide you the information you need to rule the injector complete out of being at fault. If the injectors are buried under the intake, yet the module is clearly accessible right there under the hood, it may be a good idea to just go right there. Plus, the entire circuit is being tested first. If there is an issue present, then acquire additional facts in order to dig deeper, you now have a reason to do so.

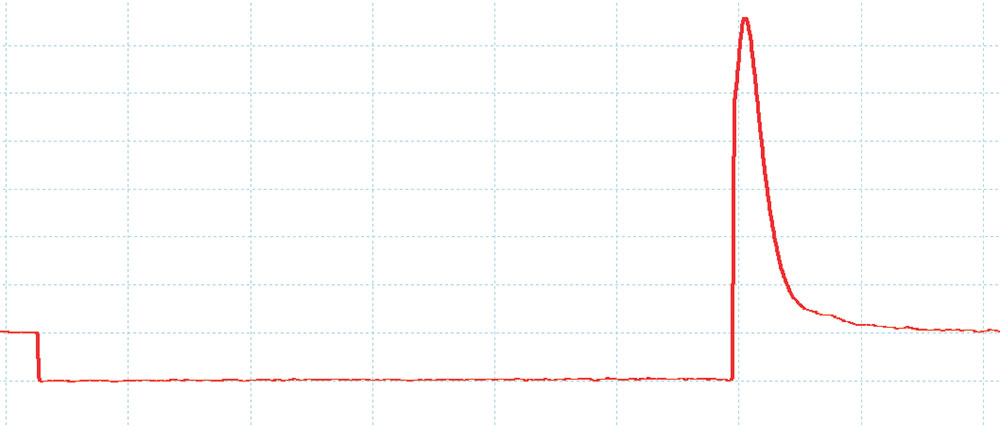

The digital storage oscilloscope is fired up, the amp clamp is deployed around a fused jumper loop at the IPDM, and leads are carefully attached at the ECM in order to check the voltage of the circuit while still intact and operating. By now pintle hump may be something you have heard about. It is the usually noticeable dip in the rise of the current when the injector has been turned on.

The reason for this dip, is because now as the pintle moves off its seat and within the windings of the unit, by laws of electricity it creates an opposing flow of current. Albeit only very momentarily, but it’s definitely there. Let’s say that dip is missing, the cylinder in question is the same as the injector current we are viewing, and the fuel trims are heavily in the positive on that bank. It’s now hard evidence of why an additional test is required to verify lack of fuel flow through the injector.

Say you see no current rise at all for a given injector. Look to the voltage readings. If the ECM is pulling the control side all the way to ground, yet there is no, or very little current flow, then high resistance in the circuit is to blame. No really, that’s it, it can’t be anything else. Now where that resistance is will be something that has to be narrowed down, but just check the wiring diagram you have pulled up on Nissan-techinfo.com. Where is the next place to check that circuit that will yield the most information?

Be aware that Nissan vehicles in particular have some interesting injector voltage signatures. Some vehicles have voltage traces you will not find on other car lines. Testing and practicing on known good vehicles really is the best was to create a foundation of knowledge for yourself.

It is entirely possible, however, that the injector screen is gummed up and dirty, causing a lack of actual fuel flow. This may not show up very easily in any of the voltage and current traces. Here is a scenario where it may actually be necessary to hook up that fuel pressure gauge mentioned before. Once installed, priming the fuel system through the bi-directional controls of the CONSULT III Plus will establish your baseline pressure. Next, using a suitable tool calibrated to pulse the injector for a specific, and repeatable, period of time, will allow the injectors to be flow tested while still installed on the vehicle. A word of caution here would be to make sure the same injector is not energized too many times before actually running the engine a bit. Excessive fuel sitting in a cylinder is not the best thing for the engine.

Up to this point the focus has been on engine cylinder misfires that are present at all times. Of course, that’s the only way misfiring occurs right? The real world technicians live in is not so easy. Many of the misfire complaints that come into your bay are not always occurring. It may take a considerable amount of effort to even duplicate the issue. There are some tips you can use to attempt to make those misfires show up much more easily.

Lean conditions really stress ignition system components. Back when throttle cables were still around, a very quick snap of the throttle to wide open would create a momentary lean and high compression condition that would reveal most misfires. Not as easy to do these days with electronic throttle control, but other methods can be used. Why not just drive the engine lean purposefully? Vacuum brake boosters are still quite common, and also generally have large vacuum hoses for them. Pulling off this hose and controlling the bleed rate can possibly achieve the lean conditions necessary to recreate the misfire in the bay, instead of on the road. Using the CONSULT III Plus, there are times when you will have the ability to drive fuel trims. Usually this test is to aid in diagnosing oxygen sensors, but why not use what they give you?

Water helps create “new paths†to ground for secondary ignition parts. A light spray over the secondary wires, or even ignition coils themselves may create the conditions needed for that spark to start taking the path of least resistance. It’s quite likely that spray bottle is already close at hand, so use it. Always take care when coaxing secondary ignition to stray. These days you really can hurt yourself, or one of the many electronic parts on the vehicle. Creating the conditions where the misfire can happen long enough to either set a code, or register during power balance testing is the goal here.

Misfires can be easy to find on Nissan vehicles if the tools available are utilized to their fullest potential. Creating a standardized and comprehensive testing strategy will yield continued success for years to come.

0 Comments