Part 1: This is what happens to vehicles when repair facilities do not have the proper tools and training when addressing customer complaints. The vehicle is question is a 2006 Jetta 2.0L TFSI BPY engine with DSG transmission. The question asked in addition to repairing multiple issues was, “Can you get the high beams to work?â€

The high beams did work, but in “flash to pass†only.

Side Note: This customer called in desperation after visiting three other shops where none of the complaints were repaired correctly. The main issue was stalling when driving at normal operating temperature. The original scan is included to read as a supplement to this article. The list is what other shops replaced:

- Used radiator (I replaced it again with a new component)

- Used throttle body (I cleaned it and re-set back to basic settings)

- Used Central Electrics (the mystery)

- With a few tests, G28 (crank position) sensor was replaced and the block surface cleaned with a new oil separator.

Step 1: Get an autoscan using a stable power supply.

Note: Addresses 16 – 09 – 55 are on a network. Address 19 is the gateway.

At Address [16] Steering Wheel Electronics, my interest was to measure the live groups to see if Steering Wheel Electronics was capable of producing the proper CAN signals for [09] Central Electrics. Possibly, the output control may also be seen at [55] Headlamp Range.

With the schematic in view, I can see the switch E4 connected to J257 [16] Steering Wheel Electronics and that controller is also attached to J519 [09] Central Electrics and [19] Gateway.

The network command is sent via voltage impulse from:

- E4 > J257 > J519 > Switching N348 and N347 (High-Low beam switch over solenoid) to enable M30 and M32 (High beam lamps).

- That’s all I needed to understand for the moment.

- With VCDS, I should be able to match network connectivity and see the measured value differences.

- [16] Steering Wheel Electronics J257 has two networks attached to [19] Gateway J533.

Address [19] Gateway J533 has part number 1K0-907-530-F

With live data, I can see network connectivity in groups:

- Group 126, field 4,Headlight Range (J431)

- Group 130, field 2,Central Electronics (J519)

- Group 132, field 2,Steering Wheel Electronics (J527)

- All are OK [1 = OK and 0 = n.OK]

- Coding at address [19] was obviously correct.

Address [16] Steering Wheel Electronics, J247 has part number 1K0-953-549-AH

With live data, I can see E4 activity in groups:

- Group 001, field 1, Blinker or Signal Lamp Status

- [Range: n. operated/left/right]

- Group 001, field 2, Headlamp High Beam Flasher

- [Range: n. operated/operated]

- Group 001, field 3,High Beam High Switch

- [Range: n. operated/operated]

- Everything operated as normal and coding is correct.

Address [55] Headlamp Range J431 has part number 1T0-907-357-F.

There are no values of interest except for coding and that is also correct.

Address [09] Central Electrics J519 has part number 3C0-937-049-23-H

With live data, I can see the network command from [16] in group:

Group 004, field 3,Left/Right High Beam [Range: 0.0…100.0 percent]

The circuit reads 100.0 percent with the switch in Flash position.

The decision was to look at the coding for [09] Central Electrics because all of the inputs and outputs are as they should be. Looking at [19] Gateway, all of the installed controllers are in communication.

What I found:

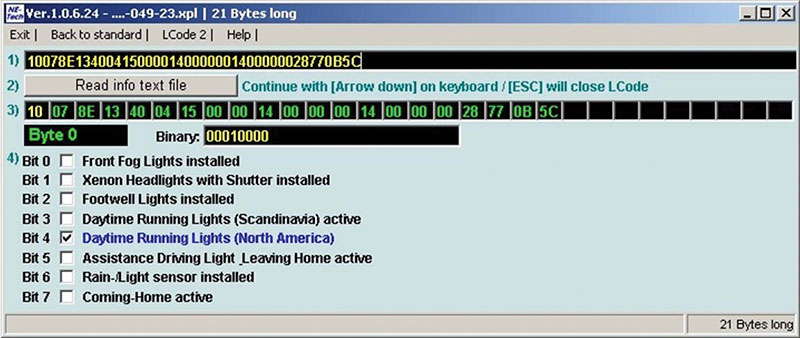

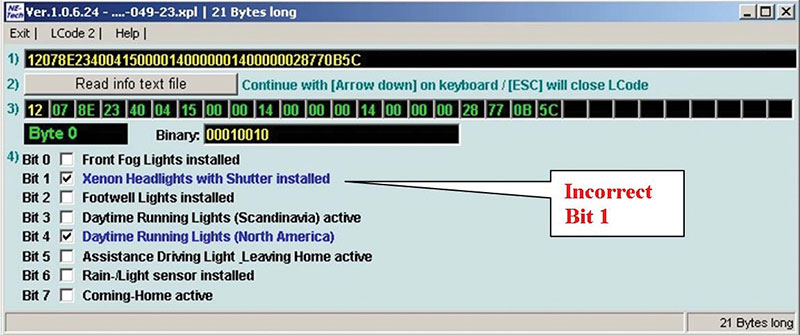

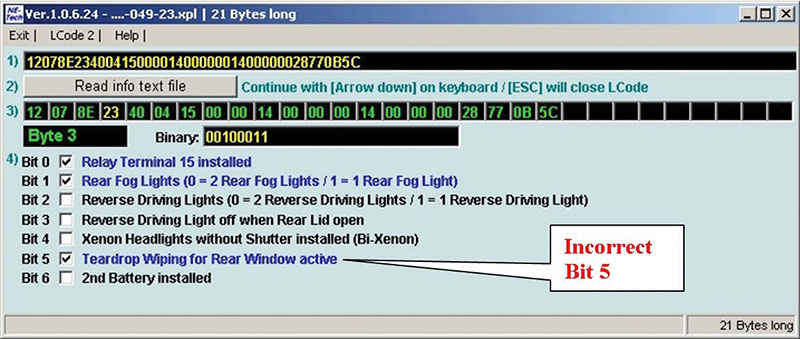

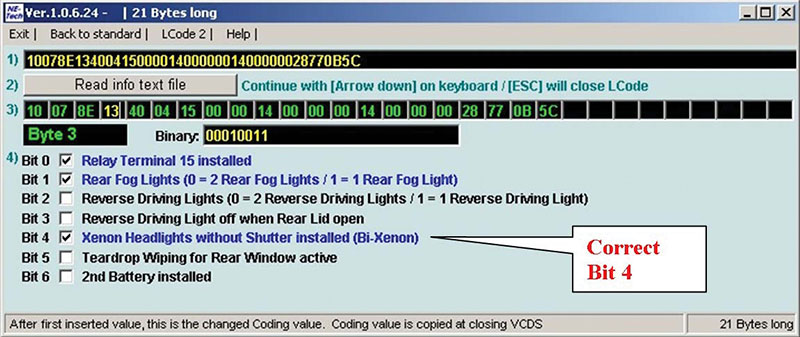

Coding was incorrect at address [09] Central Electrics.

Incorrect coding:

12078E234004150000140000001400000028770B5C

Correct coding:

10078E134004150000140000001400000028770B5C

(A) This model did not have the Xenon Headlights with Shutter option.

(B) This model did not have the Teardrop Wiping for Rear Window Option

The reason is because the used controller came from a Jetta wagon. The model being repaired is a sedan.

Therefore, the incorrect coding was left or attached to this controller.

This article is the testament of what a complete autoscan can offer a professional technician! The article should also serve as a warning to technicians that do work on these models. Simply; keep every scan and log in a respected folder because that scan indicates the condition of the vehicle as it arrived in the repair facility. You may need that original scan in the future.

This was tested on-line and off-line by using NE-Tech Long Coding tool:

- The next two images are correct.

- The coding is saved and now the high beam function works correctly.

On a final note: Not one controller was opened, removed or probed in any way, shape, or manner. Everything was diagnosed using the original autoscan, ElsaWin and VCDS measuring values.

With the correct .xml file within VCDS, coding can be tested off-line by using the coding value from the scan. In most cases, there are very few .xml files because coding is now found within the encrypted label.

Part 2: This part of the article examines small mistakes that created larger headaches and fortunately, all of the participants were in sync to correct a problem that should have never been created.

This all began as a theft recovery through an insurance company and the greatest damage was the instrument cluster. How difficult can this be? You would have to pay attention to the “investigation.†The model is a 2008 Jetta S with the 2.5L R5 and 09G Automatic Transmission.

Mistake number 01. No original autoscan was created or saved.

Mistake number 02. The dealer installed the instrument cluster and coded address [46] Comfort Control incorrectly (explanation will follow).

Mistake number 03. An incorrect diagnosis was thought correct and the dealer provided the incorrect Comfort Control Module.

This adventure begins with a simple call from a friend asking for technical support for the mentioned Jetta S. As usual, details were passed back and forth but we decided it was far faster for the dealer to install the instrument cluster and program the keys into the immobilizer because he lacked the required equipment for immobilizer adaptation.

The second call was far more interesting for the same vehicle.

Can you imagine the fuel door opening when unlocking the doors with the remote? I’ve never encountered or seen a fuel door being remotely opened and neither did my friend.

So we start from the beginning and requested the original autoscan. There was none saved from the first time it arrived and before it was at the dealer for the instrument cluster replacement.

It is at this point, we decided to initiate a remote diagnostic session to see how it is possible the fuel door was commanded open via remote.

Step 1. Gather the entire scan

Step 2. Gather a complete schematic

Step 3. Measure the command – it was true and measured

Step 4. Stare at the screen in bewilderment

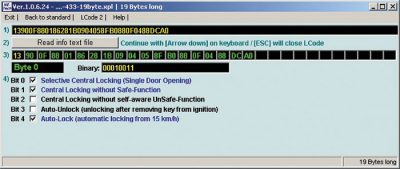

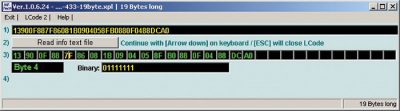

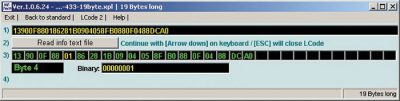

Using the coding string from the latest scan and reading the coding with the VCDS Long Coding Helper, much of the coding options can be in view from Byte 0 to Byte 2. However at Bytes 3 to 5, nothing is in view to describe the meaning of each Bit. From Byte 6 to Byte 16 coding options are in view. The remaining Bytes 17 and 18 are again with no description.

Here is the exact example for this controller of what the coding tool looks like with the correct and incorrect string.

The following is the corrected version and final scan of Address [46] Comfort Control (aka Central Conv.) and the FINAL result

Address 46: Central Conv. Labels: User\1K0-959-433-CT.lbl

Part No SW: 1K0 959 433 CT HW: 1K0 959 433 CT

Component: A_ KSG PQ35 RDK 052 0221

Revision: 00052000 Serial number: 00000000000000

Coding: 13900F887F86081B0904058FB0880F0488DCA0 (Incorrect)

Recoded at dealer during the first repair

Coding: 13900F880186281B0904058FB0880F0488DCA0 (Correct)

Corrected code at dealer and final repair

Shop #: WSC 2250x 444 102980

Component: Sounder n.mounted

Component: NGS n.mounted

Component: IRUE n.mounted

No fault code found.

How did we get there?

When reading the schematic and operating the remote, the fuel door was commanded open. The tests also proved that there was no stray signal to open the fuel door (V155). The switch at the driver panel was tested via scan tool and meter to prove the signal is correct. The motor at the fuel door was monitored with the correct signal. The signal is true but incorrect for this model. It sure looked like there was an internal problem with the Comfort Control Module. One was ordered (mentioning the scan having the correct part number) and also to order via VIN.

The wrong version was installed, look at the images provided.

With the wrong version installed, more faults, more headaches and the painting became clear. Now for the proof and admitting to a series of mistakes by the parties involved.

(a) The original scan should have been saved for future use (containing the original coding).

(b) Calling a defective Comfort Controller was a mistake.

Looking back at the first scan and with the original invoice, that match was evident of how this all came about.

(c) The dealer installed an instrument cluster and adapted the keys.

Address 17: Instruments

Part No SW: 1K0 920 954 SX HW: 1K0 920 954 SX (remanufactured)

Component: KOMBIINSTRUMENT 3HL 1222

Address 25: Immobilizer

Part No SW: 1K0 920 954 SX HW: 1K0 920 954 SX

Component: IMMO 3HL 1222

Revision: V0005000 Serial number: VWX7Z0Hxxxxxxx

Shop #: WSC 2250x 444 102980 (last shop that coded or replaced)

Address 46: Central Conv.

Part No SW: 1K0 959 433 CT HW: 1K0 959 433 CT

Component: A_ KSG PQ35 RDK 052 0221

Revision: 00052000 Serial number: 00000000000000

Coding: 13900F887F86081B0904058FB0880F0488DCA0

Shop #: WSC 2250x 444 102980 (last shop that coded or replaced)

Since the dealer mistakenly supplied the incorrect replacement controller and recoded the original controller incorrectly, they assumed responsibility and refunded the shop that I worked with. That was very good of them to quickly solve that issue. The proof was supplied/derived from VCDS and their own parts invoice because of their dealer code. The dealer agreed to recode the original controller as it should have been and everything worked perfectly. The vehicle was returned to the shop and again a complete scan was recorded along with the correct coding to Address [46] Comfort Control.

Later on and with some serious digging of saved scans within spare data drives, one matching vehicle was found with the identical coding. Go figure!

The proof?

We changed the coding ourselves and noticed how the remote opened the fuel door as it arrived with the new cluster installed. The correct coding was retuned and Comfort Control worked normally.

The initial scan held a few bits of information of “who†worked on that vehicle last and “who†coded Address [46] Comfort Control last.

Remember that the instrument panel was replaced, and that means that the keys were adapted to the immobilizer. Dealer or non-dealer registered VAG equipment has a dealer number that writes to the controller as “who†if any equipment is coded or adapted via GEKO.

The Message

There will be many times that new components require replacement for whatever reason. In this specific case, the correct part number MUST be installed AND the original coding has to be used or searched from previous saved scans as a direct fit. This and many other models do share the same controller. That is another reason why the new coding formula is used — fewer controllers having multiple options fitting multiple models that can be turned ON or OFF via Long Coding.

Download PDF

0 Comments