Reflashing, recalibrating, and marrying are now essentials of the auto service business. You need XENTRY!

Cars are getting more complex every year, and as a technology leader, Mercedes-Benz’s vehicles are no exception. Time was, you could bolt in a new control unit and it worked. These days, that’s only half the job: Initialization, adaptation and updates are needed for almost every control unit there is.

First, the bad news: If you don’t have a XENTRY Diagnostics machine, you’re mostly out of luck. Although there are aftermarket products that can absolutely communicate with some of the control units (particularly those related to emissions), the real problem is getting the software for the control unit, and for that you need access to Daimler’s update servers in Europe.

Then, the good news: Mercedes-Benz USA has offered the XENTRY Diagnostics machine for years now to anyone who wanted one, and it includes access to those update servers. Because the market for these machines is relatively small – we speculate that there are under 2,500 in the United States – the cost of the machine itself (a ruggedized touchscreen tablet) added to the costs to develop and maintain the software (cars as old as the 1990s are still supported) make the system seem expensive.

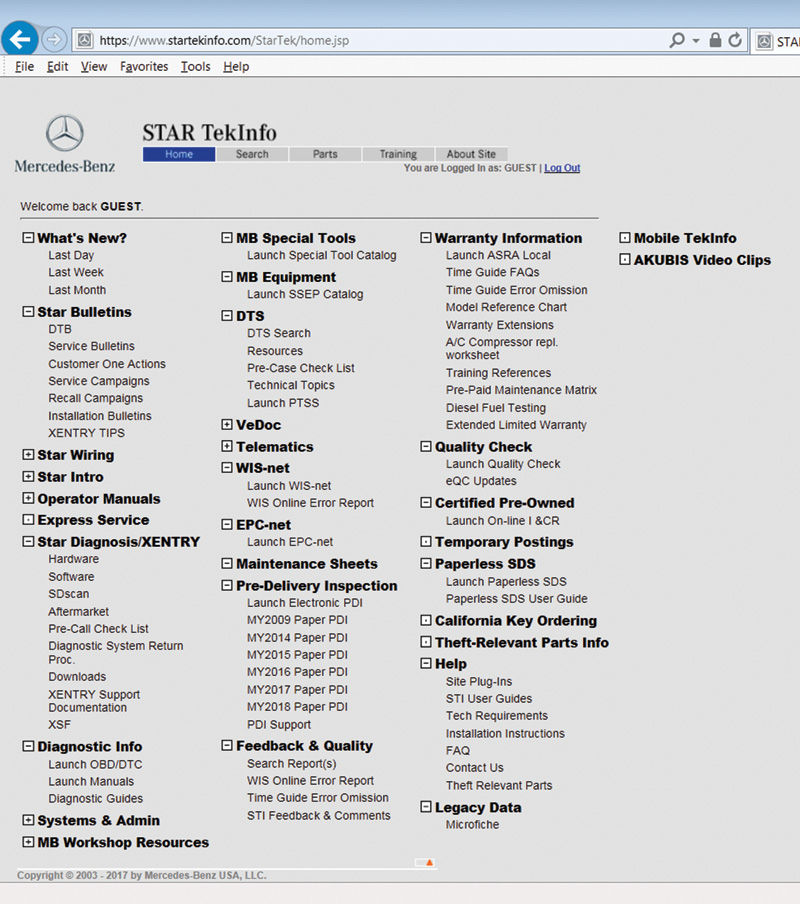

We say seem, because when you add up all the benefits, it turns out that even a small shop can make a good profit by buying one. Included with access to the update servers and the diagnosis machine itself (plus its accessories), you get three years of semi-monthly diagnosis software updates and fairly complete access to StarTekInfo, worth a bit over $9,000. But we’re not here today to sell you on the virtues of boatloads of genuine Mercedes-Benz information systems, we’re just trying to explain that, without all that, your role as a complete automotive repair shop will quickly shift to a role of a mechanical parts installer, which unfortunately will not be enough to make your customers happy with you.

Think of it this way: In the 1960s, a carburetor adjustment could be done with some skill, but really needed little equipment aside from a flat-blade screwdriver. Fast-forward 20 years, and how many 1980s models used carburetors? Well, we’re almost 40 years past the 1980s: How long do you really think you can continue as you are? We’re reminded of the famous line from the movie Father of the Bride, where Frank (Martin Short) tells Steve Martin in the title role, “Welcome to the ‘90s Mr. Banks.â€

Okay, on to the actual purpose of this article, reflashing, recalibrating, and marrying. We’ll start with some definitions.

Reflashing is when we update the software in a control unit, whether the unit is new or has been in service for years. Daimler AG, the manufacturer of Mercedes-Benz vehicles, may periodically release new operating software for control units, available only through an online data connection. These updates are intended to tweak or improve performance, address a market concern, correct unintended operation, and so on. In many cases, unless there is a customer complaint, the software that’s already in the control unit is just fine and doesn’t need to be re-flashed. But a brand new control unit might not have software installed, or an older control unit might have a problem that’s been solved that the customer has complained about, or should be installed even if the customer has not yet noticed the problem, and for these the software needs to be updated.

Recalibrating is when a system simply needs to be reset and adjusted for optimal performance. This might be needed if there is a customer complaint, or, again, when a part is being replaced. A mechanical analogy is wheel alignment: Sometimes you need to realign the vehicle, for instance if tire wear patterns indicate a need, and if you replace a key component like a tie rod or control arm.

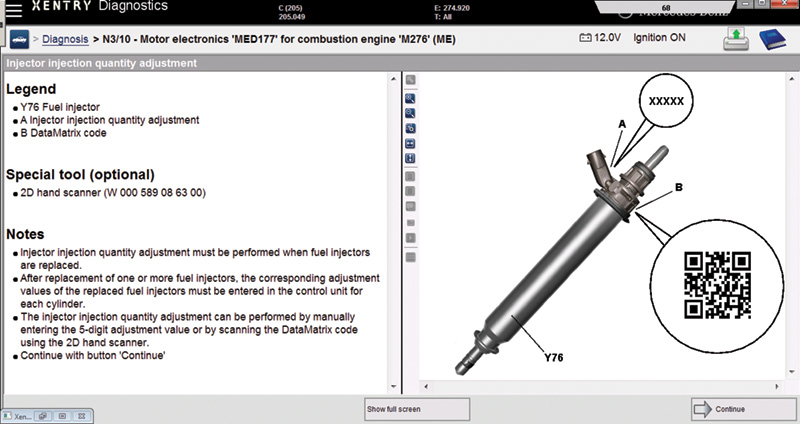

Programming isn’t just limited to software updates: Modern fuel injectors need to be married to the engine control unit in order to work right. For this you need the special 2D code scanner as well as XENTRY.

Marrying is when we link the component to the specific vehicle into which it is installed. We’ve had to do this for keys and engine control units since the development of the immobilizer and Drive Authorization Systems, but in 2018 we continue to see more and more systems that need to be married into the vehicle. In general, once married, there is no divorce: The control unit cannot be used in a different vehicle without problems.

There is also a fourth type of update (aside from XENTRY Diagnostics updates) we should consider, at least briefly: Firmware updates. Software refers to purely electronic data storage, while firmware means there is a hardware component involved. The typical example is a COMAND system, which uses a special workshop-only optical disk to update its operating software. This doesn’t mean a map data update for the navigation system, but the actual COMAND operating system itself. While you don’t need XENTRY Diagnostics for these kinds of updates, you do need the special workshop disk. Note that these disks are included with a XENTRY subscription and they come out every two months or so.

Lastly, don’t confuse any of this with the need for system Configuration. In these cases, we are only adjusting parameters within the control unit’s software to make sure it operates as it is supposed to in the vehicle it is installed in. A perfect example is a front power seat control unit: The exact same part is used for both the driver side and passenger side seat, so someone has to tell it which side it is installed on. If you don’t, it will not work correctly. You’ll need XENTRY for configuration, but unlike marrying if you later install the part into a different car you can change the configuration as needed.

STAR TekInfo remains as your best resource for the best possible repair and troubleshooting information available. Virtually anything you could ever need to do to a Mercedes-Benz is explained here…except software updates. For that, you’ll need XENTRY.

Let’s start with the easy one: reflashing to solve a problem. Your customer says that something isn’t working quite right, and you’ve found an LI Document on StarTekInfo that explains that the solution is to install new software. Here, we go into the control module’s Adaptations tab in XENTRY Diagnostics and select “Control Unit Programming.†The software leads you through the process.

A few comments on that process, so you not only know what to expect, but don’t accidentally “brick†the control unit (this refers to the effect of a faulty programming process: The control unit becomes as useful as a brick). The first point is that you really, really need to guarantee a good electrical power supply during the process. Not just a battery charger, but a good battery maintainer capable of several tens of amps, without the possibility of over-voltage. The next is to pay attention – really read and pay attention – to all the warnings and conditions that the software displays. So many times we’ve seen experienced technicians just click past the conditions and warnings page only to learn the hard way that they should’ve paid heed.

Once you start the process, you see a conditions page as we just mentioned — it might be spread over two pages. First, you have to log on to the update server using your assigned user ID and password. A page that is essentially asking “are you sure?†appears, and if you click “Continue,†the programming starts. The programming process can take several seconds to several minutes, depending on exactly which control unit you are programming. You’ll get a confirmation of success, or in rare cases, an error screen, with information on what you should do about it.

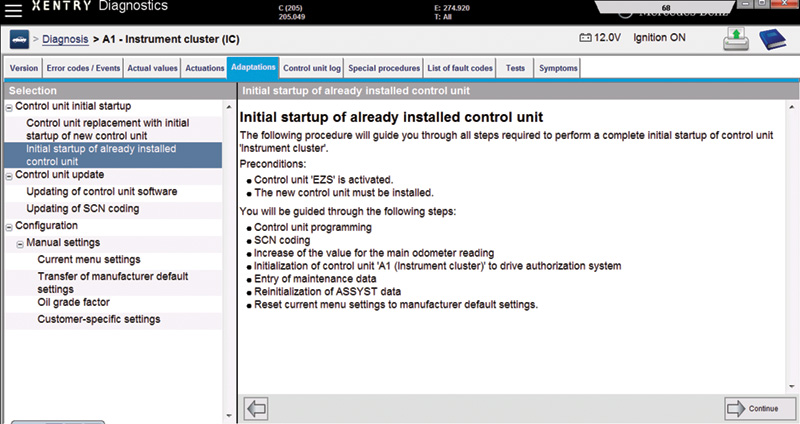

The process of programming a new control unit goes mostly the same, but you first pull all the programming from the original control unit if possible. This preserves any configuration settings and speeds up the process considerably. In this case, the menu selection is Initial Startup, and you usually have two choices: Transfer settings from the old control unit, or manually enter the settings. The latter is used when the old control unit is completely dead or cannot establish communications.

The initial startup instruction screen for an Instrument Cluster. After fulfilling the preconditions, the system guides you through the seven steps required to correctly install this new cluster in the car. The programming and SCN coding requires an online connection to the Daimler servers. Note the other programming possibilities at the left: Besides initial startup, there’s a software update, SCN coding, and manual configuration.

If you do go with the automatic transfer of settings, remember that you can’t shut down or otherwise interrupt the diagnosis session once you have pulled the data from the old control unit, since if you do that information gets lost. If this does happen, just install the old unit, start from the beginning again, and learn the lesson.

Marrying control units is only needed in certain systems. In every case, when you get to the Adaptations tab in XENTRY Diagnostics for that control unit, you will see a menu entry for the process. If you start with the procedure listed first, and work your way down the list, you will always perform all the processes needed by that control unit. The designers of XENTRY, logical as they tend to be, did this exactly because these processes might be new to someone, and so they wanted to make it as easy as possible to do everything correctly, and in the correct order, every time.

The caveat for marriage – in control units as well as in life – is to be sure you’re okay with the situation becoming permanent. Before marriage, you can verify that the new control unit really does fix the problem, but in general only for a limited number of times. If you find the problem isn’t fixed, you can remove the control unit before making it permanent, which usually means you are able to install it in a different car. But once you’ve confirmed the marriage, the control unit is permanently and irrevocably tied to that specific VIN, and cannot be unmarried for use in a different car.

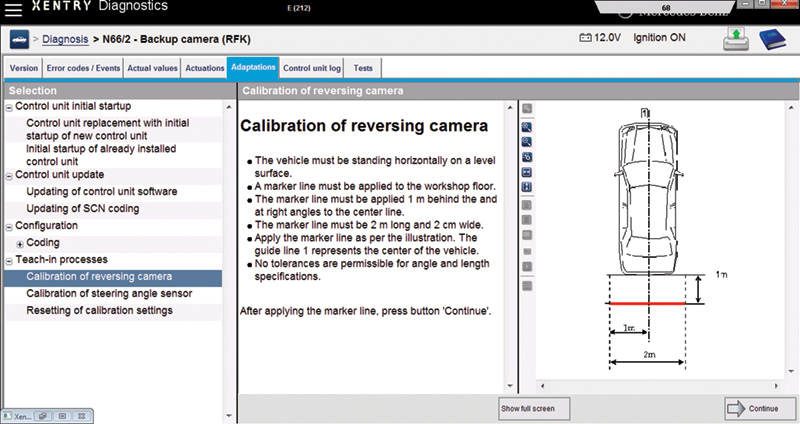

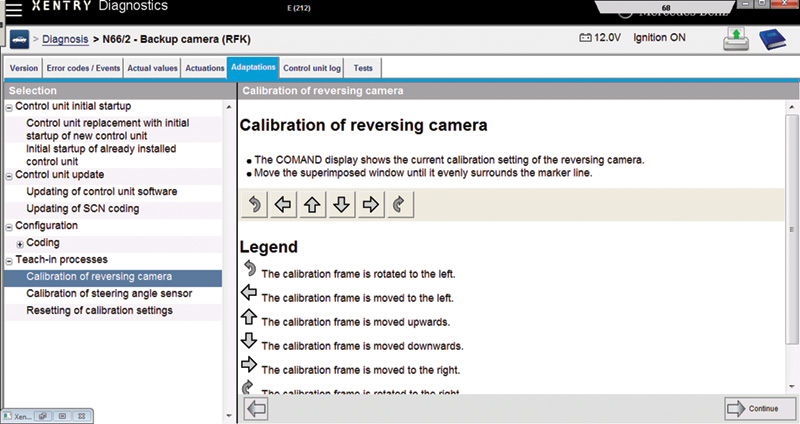

Not all calibrations need special equipment. Here we see the XENTRY instructions for reversing camera calibration: A line of tape carefully placed behind the rear bumper.

It always amazes us to see used control units that require marriage up for sale on those online market websites. A used engine control unit, just like a used key, is only worth the scrap value of its materials. It is not possible to erase its programming and use it in your car. That being said, some online companies claim they can reset the programming.

The second step of reversing camera calibration: Use the screen buttons to adjust the image on the COMAND display until it looks right. Not difficult, but impossible without XENTRY.

Recalibrating control units or sensors is a different kind of process – two processes, actually. One is simply version-coding the control unit so it knows what kind of car it is in. The other is actually recalibrating a system or sensor so it can operate properly. Mercedes-Benz has a list of various control units and their recalibration needs, which we’ve reproduced here. We have been cautioned that it is a moving target, and so the table might be incomplete, particularly for very new and very old models, but by and large it is a good quick reference to see if you need to do something to finalize the repair. Just because there are no MILs lit doesn’t mean every system is happy.

For version-coding, you go in with XENTRY and just follow the menu to set all the settings. Most of the answers are straightforward, such as if the car has automatic transmission or is left-hand drive. In some cases you may need to refer to the data card to see if the car has a particular option code or not.

In some cases, particularly the emissions-relevant systems, you use a Software Calibration Number, or SCN. These SCNs are built to prevent tampering with the settings. For these, you once again have to log on to the servers, which transfer the data behind the scenes. Many systems can have their software updated but if they don’t have a valid SCN, it won’t work. Transferring the SCN from the old control unit to a brand new one saves time by (usually) eliminating the need to log on to the update server.

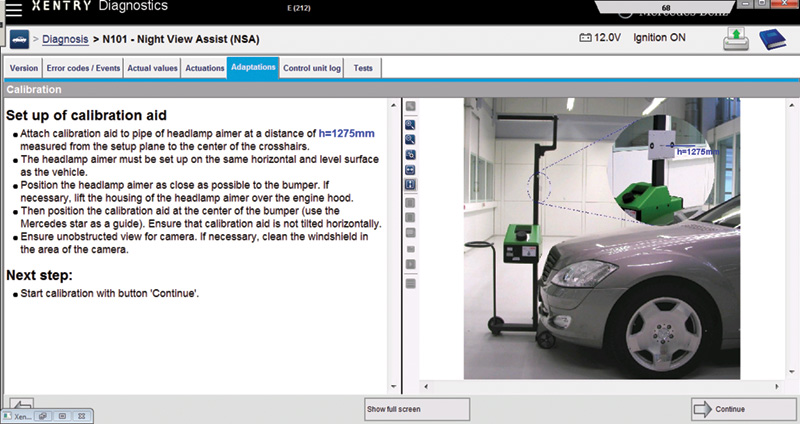

To calibrate a Night View Assist camera, which uses infrared light to display an image on the instrument cluster display, you need both a headlight aimer and the special calibration target. The XENTRY software walks you through every step of the procedure.

The Calibration procedures for the many systems and sensors vary wildly. Some may only require that the technician perform some simple actions – the calibration of AIRMATIC has you press buttons on a XENTRY screen until the indicator for each wheel strut turns green – or may have you use a special tool such as a camera calibration target.

Almost all cameras need a calibration target, the exceptions being some of the older rear-view cameras. The surround-view (360-degree) cameras, the mono and stereo multi-function cameras, and newer rear-view cameras in systems that display guidance lines all need target-based calibration. In each case, the XENTRY system guides you through the process, giving you the part number of the target, where it is to be positioned, and what to do with the XENTRY system to set the calibration. Failing to perform the calibration means the system will either not work at all, or will work improperly. We can’t stress this enough: Be sure to calibrate when needed, for your customer’s safety and your own liability.

Most of these targets are relatively inexpensive, but even $100 is a lot if you only use it once a year. Because we buy a lot of parts from our local dealer – not to mention we’re all old friends – we have a good relationship with them, and can borrow or rent almost any tool they have. And be aware that Mercedes-Benz requires dealers to have all these calibration tools as a condition of being a dealer.

Just a note for our collision industry friends: This all applies to you, too. If you’ve replaced the windshield, or removed the radar sensor by the radiator, the system needs to be recalibrated. As we mentioned before, just because there are no warning lights doesn’t mean everything is fine.

We hope this short article was helpful. As the technology in Mercedes-Benz cars advances, so will the demands upon the workshop. Dealers know this and invest tens of thousands each year in new tools and equipment. Soon to be gone are the days when you, as an independent Mercedes-Benz workshop, could get away with not having an OEM diagnostic unit, or skating by with a Chinese knock-off unit of perhaps questionable legality.

More recently, reputable automotive supplier companies have been offering diagnosis tools that claim to do everything the OEM tool does. We’re not saying they don’t live up to their promises, but we will say that you get what you pay for. If you’re considering one of these units, find out what the software updates cost, and if you get access to those critically-important control unit update servers and StarTekinfo. Once you add up all the extra hidden costs, you might find that MBUSA is actually offering a pretty sweet deal. In any case, “times they are a changing,†so don’t get left in the dust.

Download PDF 〉

0 Comments