R-1234yf and Dynamic Oil Change Intervals

Environmental considerations are essential to Nissan’s research and development efforts. In order to reduce the harmful effects on the environment from inevitable refrigerant leakage, Nissan HVAC systems will incorporate a new HFO refrigerant called R-1234yf. Additionally, to reduce unnecessary oil changing, Nissan has introduced an intelligent oil control system to advise drivers on a suitable oil change interval based on their unique driving circumstances.

The evolution of refrigerants: CFCs to HFCs to HFOs

One of the major challenges for those of us in the automotive repair industry is to remain up to date with the constant changes in fluid chemistry, diagnostic procedures, and systems engineering. With the introduction of every new design, there is always the question: “Why the change?â€

These days, just about everyone knows that CFC (Chlorofluorocarbon) refrigerants were banned because they depleted the Earth’s ozone layer. The emergency phase-out of CFCs spurred a rapid transition to HFC (Hydrofluorocarbon) refrigerants that no longer contribute to ozone depletion.

However, HFCs still have high GWP (Global Warming Potential) partly because they remain suspended in the atmosphere for years. Even though R134 does not deplete the ozone, with a GWP of 1430, each unit will contribute the equivalent of 1,430 units of carbon dioxide to global climate change over its life in the atmosphere. For comparison, R12 has a GWP of 10,300 and an atmospheric lifespan of about 100 years! Considering it is inevitable that refrigerant in all types of systems will leak out, this is a significant problem.

Therefore, for the American markets, the EPA requires that all 2021 model year vehicles use refrigerants with low GWP. There will not be restrictions on the production or import of R134 itself, so older systems will not need conversion, and refrigerant canisters should remain easy to source.

Nissan will meet emissions requirements using HFO (Hydrofluoro-olefin) refrigerant R1234yf, also known as Opteon. The GWP for R1234yf is four (4.0), with an atmospheric lifespan of only a few days. Considering the similar performance and design characteristics to existing R134 systems, R1234yf is a logical upgrade.

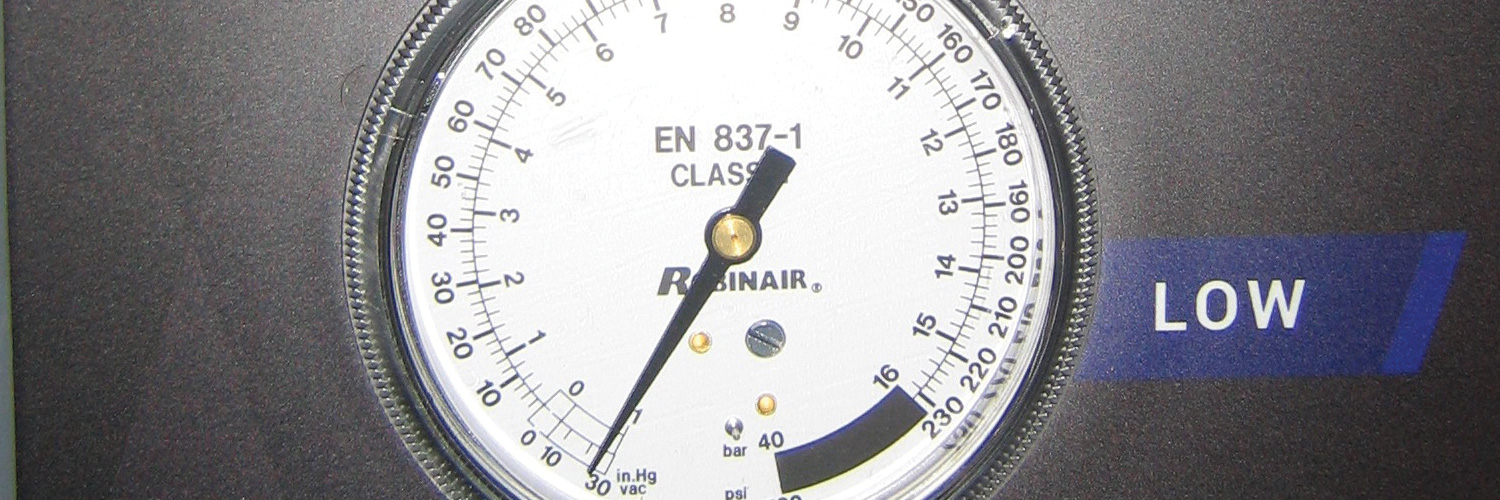

More similarities than differences

Despite using a new chemical, R1234yf systems will look familiar to anyone experienced in working with R134. The compressor-condenser-evaporator loop is conceptually identical. The service method using vacuum and recharge-by-weight equipment is the same. The refrigerant and oil capacities are similar. The cooling performance characteristics are nearly identical. If you are already EPA section 609-certified, no additional certification testing or updating is required to work with R1234yf. The operating pressure ranges are similar, as outlined in the chart below.

| R-134a | R-1234yf | |||

| Ambient temp: | Low (psi) | High (psi) | Low (psi) | High (psi) |

| 77F | 37-45 | 135-165 | 28-35 | 144-176 |

| 86F | 42-52 | 153-187 | 32-39 | 159-194 |

| 95F | 47-58 | 168-206 | 38-46 | 209-255 |

| 104F | 51-63 | 181-222 | 44-54 | 237-290 |

|

2018 Altima (R134) and 2019 Altima (R1234yf) AC high/low pressures. Information for operating pressures can be found using the ESM (Electronic Service Manual) through www.nissan-techinfo.com. Choose the “Trouble Diagnosis†button if given the option, and then VENTILATION, HEATER, AND AC > HEATER AND AIR CONDITIONING > BASIC INSPECTION > PERFORMANCE TEST > Inspection. |

||||

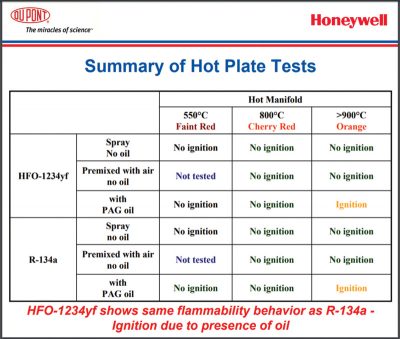

In terms of safety and handling, R1234yf has an equivalent toxicity rating and similar acute toxicity levels to R134. However, R1234yf is considered a mildly flammable gas of the lowest classification (ASHRAE A2L). While direct open fire in a closed environment might cause ignition to R1234yf, the most common automotive scenario of a high pressure leak onto a hot exhaust manifold showed no greater risk of ignition than R134.

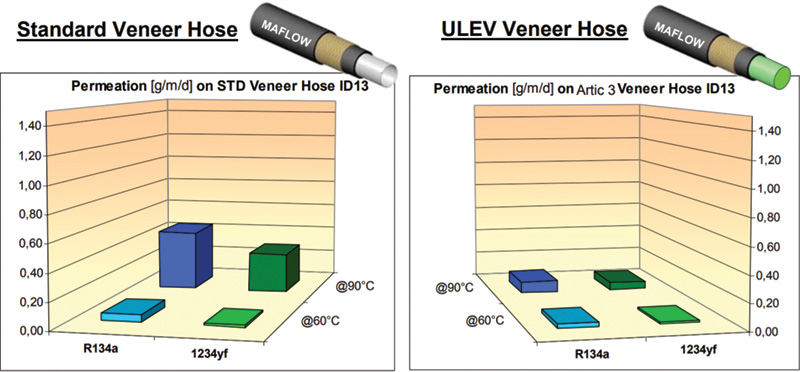

Given equivalent gas concentration, R1234yf has a slower rate of seepage through HVAC hoses than does R134.

Practical differences between R134 and R1234yf

At a glance, these are the important differences between R134 and R1234yf refrigerants:

- The oil is not compatible.

- The recovery, recycle, and recharge machine is not compatible.

- Leak detection dyes are not compatible.

- The service fittings are not the same.

Admittedly, the first thing you might notice when servicing an R1234yf system is that your R134 machine fittings don’t connect! This is precisely to prevent accidental contamination.

Compressors use PAG-46 oil specially formulated for HFO-1234yf. This can be purchased directly from Nissan using the part number “VC100yf,†or through appropriate vendors of high quality lubricants. Some PAG oils for R1234yf are backwards-compatible with R134 systems. The reverse is not true. Even when a PAG oil is ISO46 (the correct viscosity), if it is not formulated specifically to work with HFOs, it will harm the system. When placed in “universal†or a non-R1234yf oil, the lower solubility of the refrigerant results in larger immiscible regions and improper vaporization. This behavior affects the oil circulation, resulting in insufficient compressor lubrication and lower thermal transferability. (Read more specifics from the UN’s Energy Learning program here https://bit.ly/2tLbiNQ).

Likewise, dyes for R134 oils are different than dyes made for R1234yf oils. Dyes made for R1234yf are not backwards compatible with R134. Do not interchange leak detection dyes. (A complete leak detection kit compatible with R1234yf can be found on nissantechmate.com, search for “J-43926â€.)

Reference the vehicle’s service manual for the specific amount of oil needed during repair procedures. Compressor oil capacity is similar between R134 (2018 Altima: 120 ml) and R1234yf (2019 Altima: 120 ml). Test results indicate mechanical wear tendencies inside compressors using R1234yf oil are comparable to those using traditional R134 oil.

Be aware that R1234yf systems are still highly susceptible to moisture contamination, and the PAG oils for this refrigerant are hygroscopic. Take care during service and repairs to limit exposure as you would when working with an R134 system.

Cooling performance

For testing purposes, when an R134 system is flushed and filled with R1234yf without making any modifications, the performance output remains within 5 percent depending on the compressor. Typically, R1234yf is less performing. Therefore, with minor component optimizations, R1234yf performance can be improved to the expectations for R134.

One such component is an internal heat exchanger (IHX), which is often found in stationary A/C systems but is less common in automotive applications. An IHX improves the performance of any refrigerant system, and is not unique to or required by an R1234yf design. The exchanger has two pipes or chambers: a smaller one that passes through a larger.

On the 2019 Altima, the IHX is bolted to the thermal expansion valve. As warm liquid refrigerant from the condenser enters the smaller chamber en route to the TXV, cold vaporized refrigerant exits the evaporator into the surrounding larger chamber. Heat transfers from the liquid into the gas, reducing the temperature of the liquid further below the condensation point. When this “sub-cooled†liquid refrigerant evaporates, it will take more energy (heat) to boil since its temperature is lower than it would have been without the exchanger. Thus, vent temperatures are reduced.

Drawbacks

For most of us, the real drawback is the equipment and procurement cost required to support the new refrigerant. A gram of R1234yf at the time of writing is about 15 times more expensive than R134. Considering it’s 350 times better than R134 for the environment, and that, without dramatic efforts to curb climate change, nobody will be around to complain, it’s a necessary inconvenience. Furthermore, as more vehicle manufacturers get on board with R1234yf, more chemical producers will compete on pricing to meet demands. By the time R1234yf systems need regular maintenance and repairs, the associated costs may be less.

Purchasing a new recovery, recycle, and recharge machine is another major investment in shop equipment. You can find the officially recommended Nissan-approved machine on nissantechmate.com. Search for “J-52405.â€

The future is R1234yf. Prepare and certify for it

Nissan has made an informed engineering decision when transitioning away from R134 to R1234yf. According to ALLDATA, among 28 different auto makers, 48 percent of new car models shown in 2017 already have switched to R1234yf. That number is growing to meet environmental regulations. While other refrigerant systems may meet those regulations, for automotive applications, the clear winner is R1234yf. Be aware that in order to purchase the refrigerant at wholesale volume (more than 2 lbs), you or a technician at your shop must have section 609 certification.

Reducing waste oil with intelligent oil change intervals

The processes of oil extraction, production, refinement, delivery, and recycling come at a great price to this planet. When oil is drained from an engine before its functional lifespan has ended, it is effectively wasted oil. According to a California Air Resources Board study, 83 percent of surveyed drivers qualify under “severe operating conditions†in their owners’ manuals, and yet still 73 percent of all drivers were changing their oil more frequently than the manufacturer recommendation. (From a mechanic’s perspective, this surprises me!) Nevertheless, it means that good oil is being wasted.

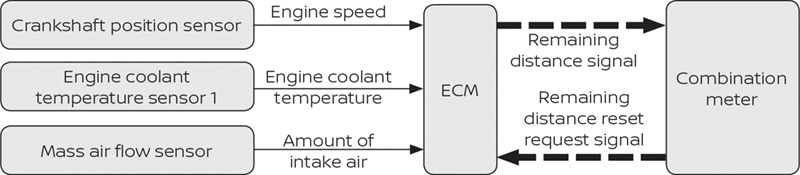

On Nissans equipped with OCS (Oil Control System), the ECM monitors the deterioration state of the engine oil. This is achieved by calculating the engine load, coolant temperature, and engine speed based on signals from the MAF sensor, ECT, and crank position sensor.

When OCS data indicates that the mileage is approaching the recommended calculated oil change interval, an alert is displayed on the driver information screen. The alert appears during the first IGN ON at around 1000 miles before due, then again around 600 miles, then five more times at 60 mile intervals from 300. Once the recommended change is reached, the alert language changes to indicate that the service is due every IGN ON.

Working with the Engine Oil Data

As a technician, whenever you perform an oil change, you must manually reset the OCS data. The reset procedure is outlined in the Electronic Service Manual.

Conversely, after replacing the ECM, it is necessary to do an oil change since the OCS data will be lost!

No substitute for a human

You may have noticed that there is no oil level sensor input to the ECM’s oil deterioration calculation. That means the oil change interval calculation cannot factor any accelerated oil deterioration due to reduced oil volume. In a perfect world, all our customers would be regularly checking and topping their engine oil. In the real world, we all know how many of our customers actually do this. The OCS change recommendation should be another tool in the arsenal of responsible vehicle maintenance, but it is no substitute for the humble dipstick.

0 Comments