New A/C systems present minor differences versus R-134a in service equipment, handling of the R-1234yf refrigerant, and a few extra minutes for enhanced leak detection steps. R-1234yf is otherwise similar to an R-134a system in performance and in repair procedures.

Refrigerant evolution

Chlorofluorocarbons (CFCs) are the basis of the refrigerant R-12 (popularly known as Freon) used in automotive air conditioning systems for decades up until the 1990s when growing evidence showed they reduced the size of the earth’s ozone layer. This ozone layer depletion allows increased amounts of harmful ultraviolet (UV) radiation from the sun to reach the earth’s surface.

According to the US EPA and European health agencies, increased UV radiation causes melanomas (skin cancer) and development of eye cataracts in humans, harms crop growth and marine ecosystems on which our food supply is based, and alters global biochemical feedback loops to negatively affect the concentrations of greenhouse gases that help maintain our atmosphere as we know it.

In the late 1990’s automakers worldwide replaced R-12 with R-134a, a refrigerant that offered less ozone depletion. However R-134a, like R-12, has a high Global Warming Potential (GWP) which is a measure of how much heat a greenhouse gas traps in the atmosphere.

Fearing that such trapped heat contributes to climate change, governments worldwide have endorsed a switch to R-1234yf, a new refrigerant that neither reduces ozone nor increases GWP. Another benefit: R-1234yf, if leaked into the atmosphere, has a 10-day lifetime, much shorter than the 13 year life of R-134a.

Nissan leaps in

Effective with the 2021 model year, all vehicles manufactured for sale in the US must have R-1234yf A/C systems. Nissan has engineered its new R-1234yf system to offer performance similar to that of the R-134a systems that it replaces, so the switch is seamless. The company began converting some of its US lineup beginning with the 2019 model year, two years ahead of the deadline. Although mechanical repair shops likely won’t face failures in these dependable Nissan A/C systems for years to come, collision repairers are seeing them already.

R-1234yf A/C system operation is similar to R-134a

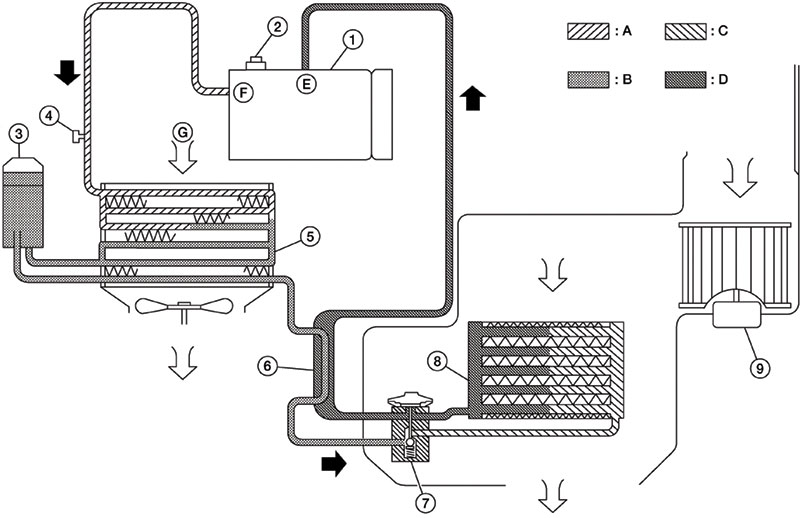

An R-1234yf system functions in basically the same manner as an R-134a system. Refrigerant and lubricant mix together and cycle from a compressor to a condenser to an evaporator and back, with visits to either an expansion valve and dryer or orifice tube and accumulator.

Refrigerant and lubricant capacities, operating pressures and temperatures, and Recover/Recycle/Re-charge (R/R/R) procedures are also generally familiar. With a few minor modifications, cooling performance of R-1234yf systems is comparable to that of R-134a.

A technician who is familiar with service procedures for R-134a will adapt quickly and easily to R-1234yf repair. You need to be EPA Section 609-certified to legally work on R-1234yf systems. The Mobile Air Conditioning Society and other providers have updated their Section 609 training to include procedures as specified in SAE Standard J2845 for working with R-1234yf.

A/C system differences

You cannot retrofit an existing A/C system to meet SAE specifications for R-1234yf. The R-1234yf A/C system features superior sealing, anti-spark versions of some components, different size or shaped service ports, and specific properties for handling the refrigerant, lubricant, and various chemicals it faces.

R-1234yf is a denser refrigerant than R-134a. Evaporators designed for use with R-1234yf feature more robust construction and superior sealing to ensure durability and leak resistance. To reduce risk of potential leaks or failures, a damaged R-1234yf system evaporator must be replaced rather than repaired. The replacement evaporator must meet SAE Standard J-2842.

If a refrigerant other than R-1234yf is added to the vehicle, that changes system pressures, reduces cooling efficiency, and ultimately causes damage to various components in the system. Out-of-specification pressures also lead to confusing readouts on scan tools and A/C service equipment, making diagnostic work more difficult.

To prevent accidental cross-contamination with different refrigerants, service ports on R-1234yf systems are sized differently than those of vehicles using R-134a. Without adapters, you cannot connect an R-1234yf fitting to a machine designed to recover or re-charge R-134a refrigerant, and vice versa.

A new Inline Heat Exchanger (IHX) helps boost the cooling effectiveness of R-1234yf up to 5 percent higher. This brings its performance up to a level comparable to that of R-134a systems. IHX technology features a tube-within-a-tube design. Liquid refrigerant from the condenser flows through the inside tube. Cooled refrigerant vapor from the evaporator flows through the outer tubing, drawing heat away from the liquid refrigerant.

In orifice tube systems the IHX is typically built into the accumulator. In a Thermal Expansion Valve (TXV) system such as that in the 2019 Altima, the IHX is a separate component. Note that the concentric chamber design is thicker than normal system tubing and makes temperature readings taken through the IHX unreliable.

Different lubricant and dye

Although most Nissan R-1234yf and R-134a systems use PolyAlkylene Glycol (PAG) oil, the formulation is different for each. Even when it is ISO 46 (the correct viscosity for R-1234yf lubricant), the PAG for R-134a cannot be used in R-1234yf systems. A universal or other PAG not made specifically for R-1234yf systems will result in the lubricant and refrigerant not mixing properly. This leads to poor lubrication, increased wear, and reduced service life of the compressor or other system components.

Review the lubricant type and quantity requirements in the Nissan electronic service manual. The 2019 Altima requires 40 ml (1.4 ounces) of PAG 46 for the swash plate compressor in its R-1234yf system.

Hybrid vehicles may use an A/C lubricant other than PAG. Refer to the Electronic Service Manual through www.nissan-techinfo.com for the specific PAG part number for the Nissan model in your bay.

Fluorescent (ultraviolet) leak detection dye that meets SAE Standard J2297 does not harm seals or affect lubricant performance. It works with either R-1234yf or R-134a systems.

A/C service equipment differences

The industry developed SAE Standard J2843 to set the performance requirements to recover/recycle/re-charge the new refrigerant. Equipment for use with R-1234yf must:

- Recover 95 percent of the refrigerant in the system, including any in tubing and hoses.

- Re-charge the system to within ½ ounce of the factory-specified volume of refrigerant.

- Include a built-in refrigerant identifier or have a USB port to allow connection of a free-standing identifier.

- Automatically discontinue operation if it detects incorrect or contaminated refrigerant.

- Prevent recharging if the machine detects a refrigerant leak.

To prevent moisture contamination, the machine shuts down after recovering 150 pounds of refrigerant, and will not run again until you replace its filter/dryer. Older machines for recovering and recycling R-134a are not compatible with R-1234yf systems.

There is, however, new R/R/R equipment that can service both refrigerants. These machines include built-in refrigerant identification technology. They automatically shut down if they detect the wrong refrigerant, or if the vehicle contains more than two percent of any contaminating gases. Refrigerant R/R/R equipment designed for use with both R-1234yf and R-134a is covered by SAE Standard J3030.

There are also new machines that are sold with fittings for R-134a, but also meet the SAE J2843 specification. They allow you to purchase a new machine today if you need one to continue servicing R-134a systems, and upgrade the fittings when you begin seeing enough R-1234yf vehicles to justify having a dedicated machine for working on the new refrigerant.

At over $600.00 per pound for R-1234yf, detecting even tiny leaks before you begin charging a system can be the difference between profitability and loss on the repair. Electronic leak detection equipment used with the new refrigerant must meet SAE Standard J2913. It can detect leaks as small as 0.15 ounces per year.

Refrigerant purity

Because R-1234yf is very expensive, and adapters are available that allow connecting new A/C systems to machines that charge them with non-approved refrigerant, safeguards are built into service equipment to reduce the incidence of accidental or intentional cross-contamination.

The equipment must have either built-in, or via USB connection, a refrigerant identifier or it cannot begin the recovery process. A built-in unit may offer slightly greater integration for reporting of results, but a portable unit is, well, portable. You can quickly move it and connect it to a vehicle in any bay.

If the identifier detects more than two percent of a gas other than R-1234yf in the system the machine automatically shuts down the recovery process to prevent contaminating your shop supply of refrigerant. You need a separate recovery-only machine to continue working in these situations. The machine extracts refrigerant from the vehicle and deposits it into a tank for disposal.

Portable recovery-only equipment for R-134a is not suitable for R-1234yf. Some newer recovery-only machines can be used with both refrigerant types. Whether a dedicated R-1234yf or dual refrigerant unit, recovery-only equipment must meet SAE Standard J2843.

Be wary of small (8 ounce or less) cans of R-1234yf intended for consumer use. They may contain sealers and other additives that are not Nissan-approved. If detected, these chemicals can shut down your recovery process.

Service procedure differences

Like with R-134a, the best practice first step in R-1234yf service is to identify the type of refrigerant in the system. The difference is that refrigerant identification is legally required and automatically initiated by software in R-1234yf service equipment.

Once the R-1234yf has been identified and verified at least 98 percent pure, the A/C service equipment automatically recovers the refrigerant and oil. The technician can pause the process to remove and replace components.

You can re-charge an empty system with the old method of using gauges, a scale, and a vacuum pump, but you could be fined by the EPA for doing this with R-1234yf. You charge an R-1234yf system only after it passes an approximately two-minute vacuum decay test, followed by an evaporator leak test. If it doesn’t hold vacuum, you must find and repair the leak(s) and repeat the test before the machine can charge the system.

If the machine sees no vacuum loss, it injects 15 percent of the total factory-specified refrigerant charge into the system, then prompts the technician to conduct an evaporator leak test. The test is uncomplicated but adds time. Turn the blower on “Low,†direct the airflow to the floor, insert a leak detector probe into the center floor duct and watch for leaks. If the vehicle has a dual evaporator system you must also leak test the rear unit. Input the “leak/no leak found†result into your R/R/R machine.

Repair any leaks and re-test. Once the leak detector gives the green light, hit “Continue†and the R/R/R machine automatically inputs the remaining 85 percent of the refrigerant charge into the system.

Leak detection during the 15 percent pre-charge step saves your shop the loss of a large quantity of R-1234yf, which is many times more expensive than R-134a. It also saves the customer money and helps protect the environment.

Industry experts suggest that service providers increase the labor time of the average A/C repair estimate by 0.25 hours when working on R-1234yf systems.

If an incorrect or contaminated refrigerant is detected, many R-1234yf A/C system components must be replaced rather than repaired. Modern thin-tube evaporator designs are difficult to flush, and not repairable to the more robust leak resistance specifications of an R-1234yf system. Hose assemblies containing inline filters or mufflers cannot be flushed. Accumulators or receiver dryers and orifice tubes must be replaced.

Lubricant for electric compressors

If you use an R/R/R machine that is capable of switching between R-1234yf and R-134a, you must add oil in a separate step when charging vehicles with electric compressors. These systems require a dielectric (non-conductive) lubricant such as PolyOl Ester (POE).

A/C lubricant circulates around the windings in an electric compressor. Use of PAG, which is not dielectric, can allow electricity to be conducted by the oil through the compressor windings to its case. This can cause the A/C system to seize up or fail. It also poses an electric shock risk to the technician.

It is a good idea to have a separate injector for each type — PAG or POE — of lubricant so they do not get mixed together. An incorrect oil can cause compressor seizure or damage an entire A/C system.

Safe handling and storage of R-1234yf

Requirements for safe handling and storage of R-1234yf include:

- No smoking around refrigerant or during A/C service.

- Storage away from direct sunlight and temperatures greater than 125 degrees F (52 degrees C).

- Storage away from potential spark sources.

- Storage where refrigerant containers are protected from potential damage and exposure to corrosive liquids or gases.

Identifier hose contamination

If A/C system oil gets into the sensitive electronics in a refrigerant identifier it will damage the tool. There are several truck A/C systems with an under-cab low side service port that has an above-average potential to introduce excessive oil into the identifier’s sampling hose. After using your refrigerant identifier on a truck with this under-cab low side service port, inspect the identifier’s sampling hose for oil contamination. If you find oil contamination, replace the hose.

An A/C system air concentration of 10 percent or more could also indicate the presence of oil contamination in the identifier’s sampling hose. Replace the hose.

R-1234yf training, OEM procedures, and the right tools

Get EPA Section 609 certified if you are not already. Refer to your Nissan electronic service manual (ESM) for repair procedures specific to the vehicle on which you are working. Use the Nissan recommended tools for R-1234yf diagnosis and repair. Do those three things and you will find that servicing R-1234yf systems is not so different after all.

Download PDF

0 Comments