48-volts and some seriously cool technology get wrapped into the Mercedes-Benz EQ Boost system, and techs beware: There’s lots to learn.

Many of us have entered the world of hybrid and high-voltage EV repair in one way or another over the last few years. Our learning curve on things medium and high voltage, in general, has begun.

The leap toward all-electric vehicles is accelerating at a staggering pace. Mercedes-Benz is all-in with the recent introduction and roll-out of its EQ lineup of vehicles, along with a commitment to a 100% electric lineup by the end of this decade. The all-electric platform, known as EQ, the EQ Power series of full hybrid and plug in cars, and now the mild-hybrid solution, EQ Boost.

EQ Boost is a 48-volt light hybrid system, which boosts the combustion engine with up to 21 additional horsepower when needed, much like the ERS-K and ERS-H systems in Formula 1.

The relatively new (to the industry) 48-volt technology is creeping into dealer service bays and independent repair shops everywhere. It’s the latest trend. Why? 48-volt technology is fast becoming the industry’s preferred method for light electrification—and to an extent, hybridization of the traditional ICE-only (Internal Combustion Engine) equipped vehicle. The big advantage is that for a given power, both motors and wiring can be about a quarter the size of the 12-volt equivalent, saving money and, more importantly, weight.

Mild hybrids are nothing new. Many manufacturers including Mercedes-Benz have recently jumped on the 48-volt bandwagon and for good reason. This is because 48-volt power brings huge benefits to not only fuel economy and emissions reductions, which are significant, but also, 48-volts provides an acceptable level of energy and current supply for the modern vehicle’s high-load electronic options and drive by wire systems.

Back in 1995 into the 2000 model year, we remember an industry-wide discussion on movement toward a standardized 42-volt system to augment the 12-volt system. This approach, both the voltage chosen, and the (looking at it now) shortsightedness of redundant electrical systems caused manufacturers to decide to shelve the idea. Your author anecdotally remembers Mercedes-Benz to be one of the leaders in pushing back on this change, thankfully.

But over the last several years, especially with the addition of multiple modules, more high current-consuming options, and autonomous drive-by-wire systems such as electric power steering, high current 3 phase fuel pumps, electric pumps and motors have in totality for all intents and purposes maxed out the 12-volt topology.

In addition to the increase in high-current-consuming systems and electronics, most manufacturers have at the same time been making engines smaller and more efficient to remain emissions compliant.

Consider the size of a vehicle like an E-Class or S-Class, formerly powered by the big, (heavy) powerful high-displacement V6 and V8 engine. Today, due to the trend of smaller more efficient turbocharged gas-direct injected powerplants, in Europe and elsewhere (including now in the US), the same sized vehicles are now powered by a 2.0 Liter turbo or a charge injected 3.0L inline 6 cylinder with even more horsepower than the old “powerful†engines.

So here as well, technicians can agree that as the electrical load has necessarily increased over the years, the resulting increases of parasitic losses from compressors, belts, coolant pumps and alternators in the smaller, more efficient engines have also been an engineering challenge with respect to electrical load limits of the 12V system. So what to do?

EQ Boost: The 48-volt Answer

By deploying a 48-volt topology, Mercedes-Benz now has a platform that can supply all of the voltage and current needed for today’s high-current consumers, but also leaves plenty of room for expansion. In addition to providing a boost to engine power, the system can power electric coolant pumps, electric superchargers, E-ACTIVE BODY CONTROL and many other systems.

The EQ Boost 48-volt system officially makes the vehicle a “Mild Hybrid,†which by definition means that the electric motor cannot directly power the wheels, but Mercedes-Benz has even pushed the envelope on the mild hybrid designation, with their Sailing Mode and engine decoupling scheme.

The Mercedes-Benz EQ Boost system is an engineering masterpiece, where others only dabble. In typical Mercedes-Benz form, engineers have taken the 48-volt concept to incredible levels of sophistication, function and innovation.

For example, you’ll notice virtually no turbo lag in models equipped with EQ Boost. Why? Because the ISG’s 184 lb-ft of torque can be activated almost instantly, which provides immediate and forceful “oomph†directly into the drivetrain. Additional charge air from an electric compressor (similar to a supercharger) in some models also helps reduce turbo lag.

Between the ISG and the Electric Auxiliary Compressor (EAC), sufficient drive power can be added to the system during the time it takes for the turbo to spool up. The EAC essentially fills the gap of time it takes for the turbo to spool up. This supercharged-turbocharged scheme provides an instantaneous and smooth acceleration characteristic not found in other vehicles.

Not to mention that the EQ Boost system can be matched to either the 2.0L 4 cylinder, the new beltless 3.0L inline 6 or the torquey 4.0L V8 powerplants, using essentially the same production parts, a smart idea for production and cost control.

The EQ Boost system also does some neat out-of-the-box tricks with the 48-volt topology that are groundbreaking in concept in the form of the E-ACTIVE BODY CONTROL system. More on that later.

Let’s take a basic look at the 48-volt EQ Boost system from a technician’s point of view and discuss what to expect during the diagnosis and repair of this system. We must first look at some electrical differences in voltage potential and available current as compared to a 12V system that we are used to analyzing, to understand why a 48V platform was chosen.

Ok, so why did the greater industry choose 48-volts? Simple: 48-volts provides enough energy for high voltage-like punch and current, yet it remains under the 60 Volt “High Voltage†safety standard for Direct Current (DC), above which cables become much larger and need heavy insulation and shielding schemes.

48-volts is lower than the high voltage standard and is therefore much more cost effective and easier to package into multiple platforms. Plus, the battery is far smaller and lighter than in a high voltage hybrid or EV application where it’s typically hundreds of volts.

The shift to 48V also facilitates multiple high-current chassis support systems, which typically depend heavily on charge pumps, capacitors, and transformers in the 12V platforms. This means with 48V supply, the wires, components, capacitors and other parts can be made much smaller, consume less current and run more efficiently in general.

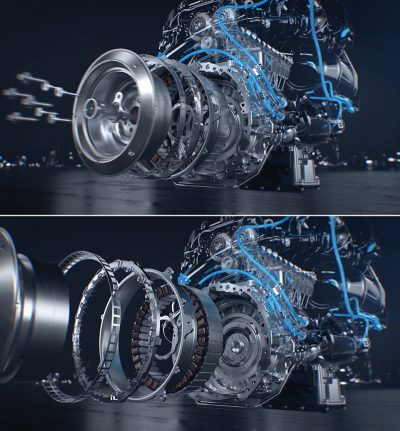

Because the 48-volt vehicles are relatively new technology for us in the service bays, we will look at some basics of 48-volt systems, and dive into the Integrated Starter Generator, or ISG to see how it works, because along with the battery and the control electronics, the ISG (Integrated Starter Generator) is the heart of the 48V system.

48V is exactly 4 times the potential (and therefore, available current) of the 12V system. Ohms law for linear DC dictates that at the same load (resistance), 4X the potential = 4X the available current.

12-volts/2.5 Ohm load resistance = 4.8 amps

48-volts/2.5 Ohm load resistance = 19.2 amps, or 4X available current.

But if we used all 19.2 amps to run that same motor (Load) for example, the 4X current would quickly burn out the motor and windings due to overspeed and overheated windings, as that motor was designed with circuit wire and windings to run at 12V and 4.8 amps, or 57.6 watts.

It is also known that if we adjust the resistance of the load in relation to the increase in voltage, the same work can be done with less current, which means less wear and heat on components and lighter, thinner gauge wiring may be used where applicable.

Example

At 12V, the 2.5 Ohm load running at 4.8 amps will consume 57.6 watts of power, P (power in watts) = I (current) times E (voltage).

At 48V, that 2.5 Ohm load running at the same 4.8 amps would try to consume 230.4 watts.

So, if we take that (required) 57.6 watt fuel pump and apply basic physical law calculations at 12V and then at 48V, we get the following:

P (watts) = 57.6 divided by 12V = 4.8 amps, whereas a fuel pump consuming the same 57.6 watts in the 48-volt example works out to run on only 1.2 amps of current to do the same work.

P (watts) =57.6 divided by 48V = 1.2 amps. More voltage means that higher current loads for traditional 12V systems can be run with less current and therefore, smaller wires. Same 57.6W load, but far less taxing on the supply system, load device and wiring.

In fact, if we consider that the industry’s migration to PWM power controls have taken motor efficiencies and longevity up by an estimated 37% in a 12V system, what can this new 48V technology add in not only combustion engine boost efficiency but in parts longevity?

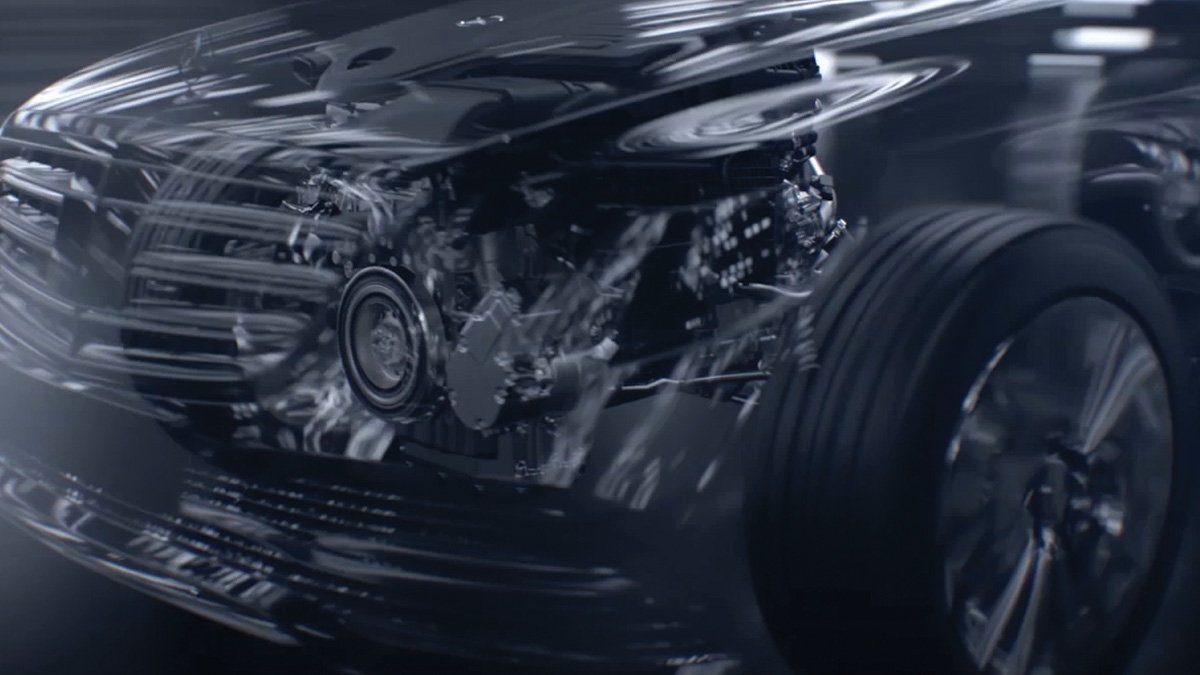

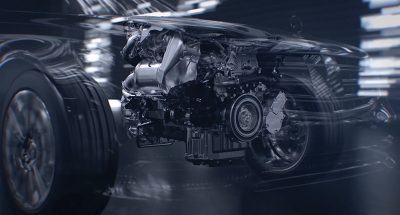

The Mercedes EQ Boost system, set up for the 2.0L 4-cylinder turbo and 3.0L inline “beltless†turbocharged 6-cylinder now found in multiple carlines, is known in terms of electrification as P1 topology. This means the Integrated Starter Generator is mounted in the bell housing area on the crankshaft, between the engine and the 9-speed transmission.

This powerful 48-volt 6-phase motor replaces both the engine starter and the 12V alternator. The 48-volt EQ Boost system uses a 0.9 kWh 48-volt Lithium-Ion battery, which is much smaller and lighter than the 300-volt to 800-volt high voltage batteries found in Full Hybrids, Plug-in Hybrids (EQ Power) and EVs (EQ Series).

Testing the ISG 48-volt Motor

Although the 48-volt designation implies that the system is not considered “High-Voltage,†technicians are warned that there may be dangerous voltages within the system. Despite the supply being at a nominal 48-volts, Mercedes-Benz advises that higher voltages, exceeding the 60-volt contact limit, may exist under certain conditions. This means that it is never safe to try to monitor voltages or signals in the 48-volt system using conventional test techniques such as a voltmeter or oscilloscope.

Please don’t take this lightly. Contact with a high enough voltage can be fatal.

According to the Mercedes-Benz Workshop Information System document SN00.00-P-0063-15A (48V on-board electrical system safety guidelines), it is strictly prohibited to work on an active 48-volt on-board electrical system.

ALL testing of the ISG must be performed through the XENTRY Diagnosis System. It’s not that Mercedes-Benz wants to restrict access to diagnosis, but purely for your safety. As you surely know, you can get your own XENTRY system if you want one; just visit startekinfo.com, pick the application (e.g., Passenger Cars) and click into the Workshop Resources menu for all the details.

That doesn’t mean that XENTRY tests everything; instead, the XENTRY guided test routines may have you checking for specific signals and voltages, processing Diagnostic Trouble Codes, and even making microOhm measurements (using a commercially available microOhm meter) with the ISG removed from the vehicle.

Referring again to WIS document SN00.00-P-0063-15A, the 48-volt system must be deactivated before working on any components. Refer to the work instructions (again, in WIS) for the specific task at hand for details. In general, the 48-volt system can be deactivated by putting the 12-volt electrical system out of operation, by disconnecting the main battery (G1) ground line. Wait at least 10 seconds for the energy to dissipate, and of course you must ensure there are no external power sources (e.g., battery maintainer) connected.

The bottom line is that these systems can be dangerous, so please read the appropriate documentation and follow the safety instructions. Anything else is just crazy.

The Rest of the System

Within the EQ Boost system, not only is the ISG powered by the 48-volt module, but so are several other high-current consumers. For example, the EQ Boost equipped models incorporate an electric coolant pump, an electric air conditioning compressor and supports the suspension and other systems as well.

The EQ Boost system has allowed for the deletion of all belt-driven accessories, providing load relief to the mechanical engine, leading to the super-cool and futuristic looking “beltless†engine.

Mercedes-Benz has also incorporated the E-ACTIVE BODY CONTROL (EABC) into the 48-volt scheme and has been able to design the suspension motors to capture electricity during suspension rebound to convert back to voltage that recharges the 48-volt battery. That’s right… hit some bumps, recharge your battery. (Should we test on some washboard dirt roads?)

When one looks at the totality of this advanced system, and what the engineers have been able to do with EQ Boost, it is quite amazing. This system is capable of providing ultra-smooth start-stop operation. So smooth in fact, the driver can hardly feel it occurring. This is because the crankshaft mounted ISG can be ramped up to idle speed very quickly and smoothly using PWM power control.

At any engine speed, the electric motor can be made to match engine RPM to boost crankshaft power, decouple and glide (Sailing Mode), and the system can also provide light electric boost to the crankshaft with the engine OFF. This means that during coasting and traffic creep conditions, this system can shut off the internal combustion engine earlier, which increases fuel economy and decreases emissions even more than traditional start-stop.

Mercedes-Benz states the ISG produces about 21 HP of boost to the crankshaft when applied. Regenerative functions occur during sailing mode, as well as deceleration, and don’t forget, they’ve even captured regenerative energy from the suspension system. Wow. These technologies will help Mercedes-Benz to continue to meet stringent EPA fuel mileage rules coming into 2025, when the CAFE average needs to be at 54.5 MPG.

On another note, one major (unsung) industry issue on the repair and service side is the wear to traditional timing chains with the start-stop system. In many carlines, this is a real problem with the 12-volt-starter-equipped vehicles with start-stop technology. The constant on and off “shock†of that engine shutting off and the 12-volt starter engaging the flywheel for restarts has proven destructive to engine timing chains and has been a silent issue in repair shops for years. But no more.

Beefier timing chains and the smooth ramp up to idle speeds provided by the EQ Boost ISG will all but eliminate this issue, another great hidden benefit of the Mercedes-Benz EQ Boost 48-volt system.

There are many manufacturers deploying 48-volt systems, but Mercedes-Benz seems to have utilized this technology in an almost symphonic fashion. It will be awesome to see where the engineers take this platform from here.

Technicians preparing to work on EQ Boost systems should study the applicable electrical knowledge necessary to understand the system. There is quite a bit of integration with, and differences from, the 12-volt systems we are used to diagnosing.

The 48-volt platforms will be with us for some time, and Mercedes-Benz has made huge investments and technical strides in deploying EQ Boost, so we will be servicing these vehicles for years to come.

Will the ICE be pretty much entirely phased out by 2035 as some predict? In July 2021, Daimler AG announced that they will offer only electric vehicles (EVs) as of 2030. While that’s still several years away, and anything can happen in the meantime, but there’s your proverbial line in the sand.

So what does the future hold for the automotive service industry? Will we become changers of wiper blades and tires? We can’t predict the future, but we can guarantee that big changes are coming, and pretty soon. But all that’s up to you young technicians to solve, as many of us “fossilized†older techs and operators will be well retired by then… we hope.

0 Comments