Harry, a long time veteran of the force, was nearing the finish line of his career. His retirement was fast approaching and, as such, he had been relegated to mostly desk duties. A ‘house mouse’ was the term for an officer who did not leave the station anymore, and that is exactly what Harry felt like.

So when the Chief stopped at Harry’s desk and asked if he would be interested in one final case, he jumped at the chance. Harry could tell by the look on the Chief’s face this would not be an easy one, though.

The victim, a 2006 Infiniti FX35, had already been investigated by several local precincts before being towed back to the witness’ residence. The witness had then attempted his own repairs before giving up, and the FX had been sitting for some time now. In fact, the vehicle had been sitting for so long that it had been classified as a cold case file.

This was not Harry’s first cold case. He knew what it would take to crack this one; long hours, working through lunch, coming in early to recheck test results. Harry knew the statistics. He knew that only 1% of cold cases ever got solved. Those were numbers that he simply could not accept. Numbers he refused to accept. But he also remembered what one of his first mentors on the force had told him, “The truth takes time.â€

Harry was OK with putting in the time, as long as he got to the truth.

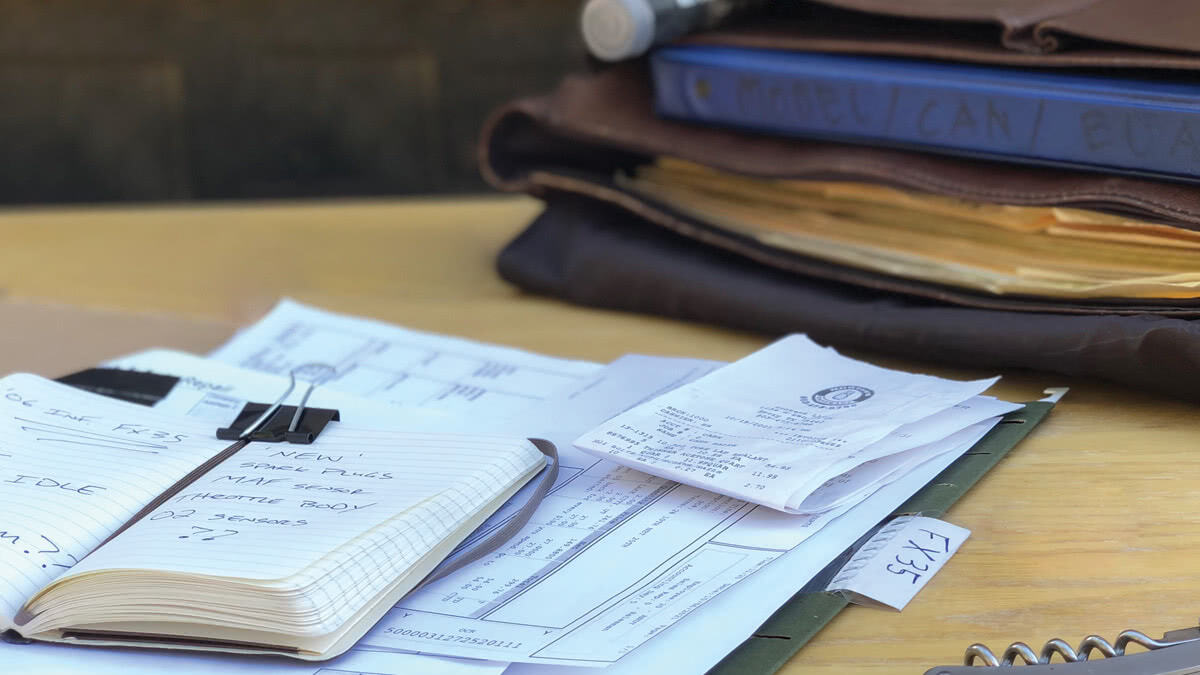

The case file was prodigious, stuffed full of repair orders, tow truck bills, and parts store receipts. There was not enough time to read it all before his shift ended, so he tossed the file in his briefcase to look at it later at home. That evening he read and re-read through the case file with the aid of an Old Frothingslosh or two and his favorite Dave Brubeck album.

When he was finished he had several pages of notes highlighting the key points of the case. They raised some questions that needed to be answered.

Harry was able to discern from the files that the mass air flow sensor, sparks plugs, throttle body, and oxygen sensors had all been replaced so far. The vehicle’s owner had been a “mechanic†thirty years ago and had attempted some of the repairs himself, specifically the spark plug replacement. Harry’s eyes rolled after reading this — another vigilante mechanic trying to take justice into his own hands. He had seen this many times over the years and it rarely ended well.

The final repair order stated “ENGINE IDLING VERY HIGH – CHECK & ADVISE.†So that seemed like where he would need to start the investigation.

The next morning, after a debriefing with the station commander, it was time to go see the victim. Harry topped off his coffee mug and headed out to the impound lot. Luckily the Infiniti FX35 had just been dropped off the day before and was easily accessible at the front of the yard.

Harry had always started each investigation by checking the basics first; oil and coolant levels, battery condition, and a full system fault scan. He wasn’t about to change his process now, so he popped the victim’s hood and went over the basics. The fluid levels and battery were all good, but the oil did smell like it was fuel saturated. The aftermarket air intake tube and filter were red flags of which Harry made a mental note.

A full system scan was fruitless. The faults had been cleared, the monitors reset and any potential freeze frame data lost. Someone had been tampering with the evidence and poured bleach on this crime scene, washing away the clues.

Next, Harry went ahead and tried to start the SUV. Strangely the engine just cranked and cranked but would not start. There was nothing in the case file or his notes about a cranking no start condition. Was this new symptom related to the original issues or just a coincidence?

Harry didn’t put much stock in coincidences, not after this many years of unraveling crimes. There was almost always a connection. So what could be causing this no start? He asked a patrol officer to crank the engine over while running a few basic checks. Using a handheld COP ignition system tester, he quickly determined that the ignition coils were indeed firing.

There was no test port on the fuel rail of this VQ series engine, so Harry used an alternative method. With an exhaust gas analyzer in the tailpipe he had the officer crank over the engine again and there were well over 2000 ppm of hydrocarbons present. While this test did not confirm if the fuel pressure was within the manufacturer’s specifications, it was enough to show that the no start was not due to a lack of fuel.

Next, he decided to pull out a spark plug and have a look.

His suspicions were confirmed when he saw how wet and fouled the plug was. This engine was completely flooded out. Harry had some paperwork to finish up so he had a junior detective remove all the spark plugs, clean them, and squirt a little oil into each cylinder before reinstalling the plugs.

An hour or so later, Harry had his paperwork completed and headed back to the Infiniti. With the accelerator pedal held down to the floor to initiate Clear Flood Mode, he cranked the engine over again. This time it started sputtering after just a few cranks, and eventually the engine started with a cloud of smoke out the exhaust pipe. After the smoke cleared out, the engine was running well but the idle was very high at 1200 rpm.

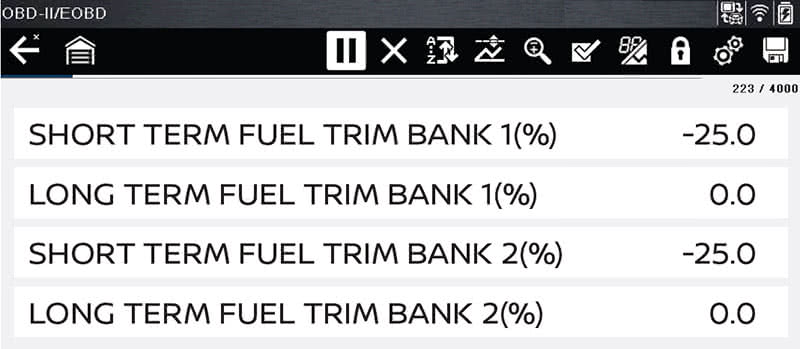

Harry’s initial feeling was that this engine had a large vacuum leak. The scan tool was still in the passenger seat, so he connected it back up to look for more clues. There still were no codes stored, but the live data was quite interesting. The short term fuel trims on both banks were maxxed out at -25%.

This data was a bit puzzling at first. The engine was running like it had a large vacuum leak, but the engine computer was subtracting as much fuel as it could with the short term trims. Harry was expecting to see positive fuel trim numbers indicating that fuel was being added to compensate for the additional unmetered air.

Could this FX35 be running rich and lean at the same time?

Despite the contradictory data, Harry went with his gut and hooked a smoke machine up to the air intake system to check for leaks. With the throttle body blocked off and the smoke machine connected into the brake booster hose, it didn’t take long for Harry to find a large air leak at the upper intake plenum.

The smoke appeared to be coming out from between the lower intake manifold and the upper plenum, right where the gasket should be. The plenum was going to need to come off for the investigation to continue any further.

After all the bolts were removed, he lifted the plenum off to inspect further. Harry found the gasket was bent over onto itself and not sealing the upper plenum. He also found the lower intake bolts were loose and not properly torqued.

Harry was confident he knew how the gasket got so badly brutalized. A follow-up interview with the witness confirmed that he had removed the upper intake plenum to replace the spark plugs; another vigilante repair gone wrong.

The next step on this vehicle would be to replace the plenum gasket and properly torque the lower intake manifold. That would have to wait until the next day though. Harry was beat. He dropped off the parts requisition forms with the dispatch officer and headed home for the night.

The next morning, the new plenum gasket was waiting for Harry when he arrived at the station. The gasket was installed and all the bolts were torqued to factory specification. A second smoke test showed that no further air leaks were present. Harry started the SUV, and the idle had dropped from 1200 to 900. This was still too high, but was a large improvement from what Harry had started with.

With the scan tool connected, he rechecked the live data. The fuel trims were unchanged; both banks were still maxxed out at -25%. This didn’t surprise the veteran detective though. He had repaired a lean condition with the intake gasket. Now he needed to unravel the rich condition.

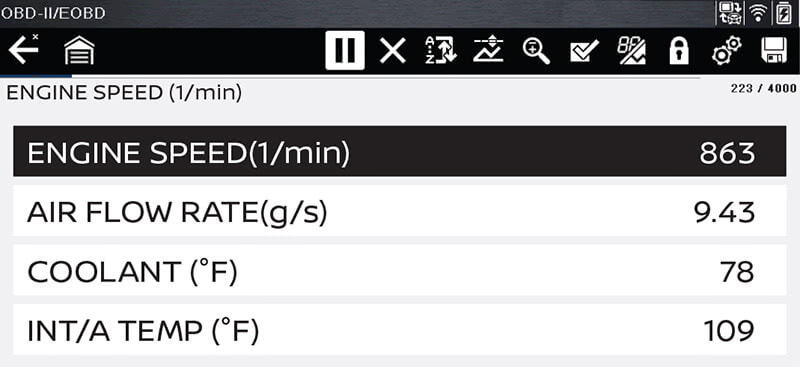

Harry switched his focus to the mass air flow data next. He noticed something unusual right away. The Intake Air Temperature data PID was at 109 degrees Fahrenheit, but the engine had only been running a few minutes and the ambient air temperature was below 80 degrees F. Service information stated that the IAT Sensor was integrated into the MAF sensor on this application.

He also noted that the MAF sensor was reading 9.43 grams/second at idle, which was too high of a reading, even with an elevated idle. This would explain why the engine computer was over-fueling the engine.

Long ago at the academy, Harry had been taught a quick method to calculate an engine’s expected air intake volume. It was a simple equation, but it still held true after all these years. There should be about one gram per second for each liter of engine displacement at 500 rpm. So Harry would expect this 3.5 liter VQ35DE engine to be reading 6.0 – 6.1 grams per second at 863 rpm.

Closer inspection of the mass air flow sensor revealed it was an aftermarket part with no brand name marking of any kind. Harry knew the MAF sensor reading was a critically important input for the engine management system, since all of the lookup tables in the engine control module were based on the air volume being measured correctly. The only choice for this important of a sensor was an OE part from the Infiniti dealer.

The MAF sensor connector (next page) was also new and had been spliced into the harness. Harry pulled up a wiring schematic to confirm that the new pigtail connector had been wired to the correct pins. Thankfully the wiring was OK and all the pins were in their correct positions. The clues all pointed to a faulty mass air flow sensor that would need to be replaced. Harry also really wanted to get rid of the aftermarket air intake tube, but that wasn’t his call to make.

The new OE mass air flow sensor was ordered from the dealership and was delivered later that day. He installed the sensor and cleared the fuel trim memory before starting the engine again. This time the fuel trims were completely normal, fluctuating between -5% and +5%.

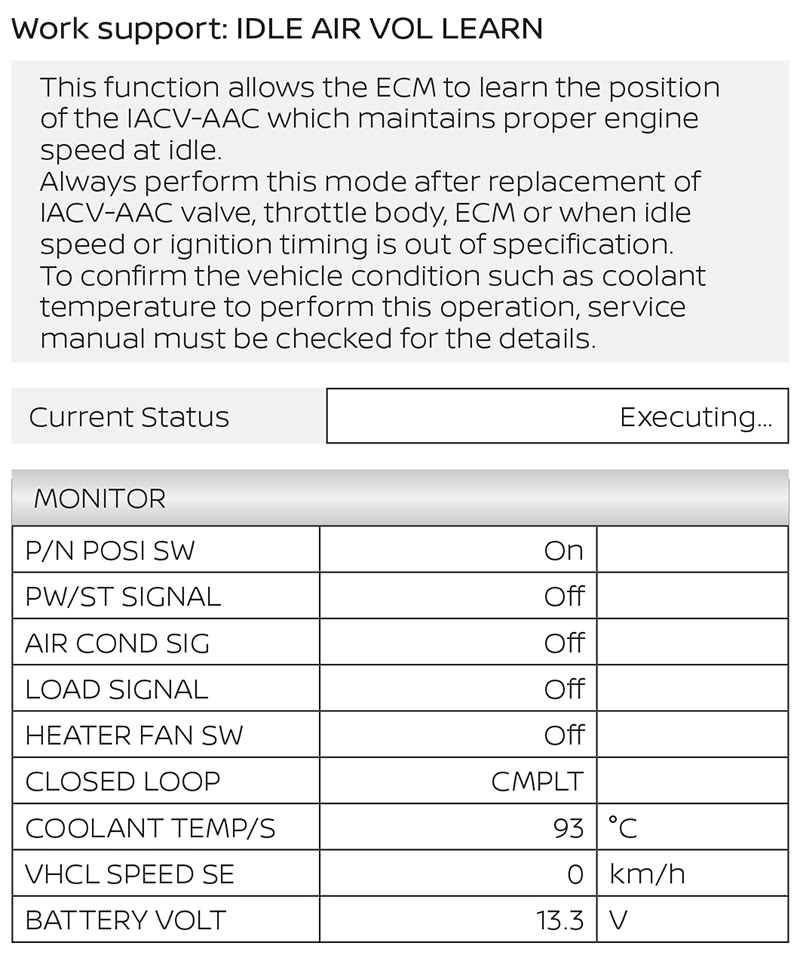

After an extended road test, the short term fuel trims were still normal and the long term trims were compensating as expected. However, during the drive the Check Engine Light had come on with a P0507 fault listed. The description for the fault was “Idle Control System – RPM too high.â€

Harry paused for a minute to recap the investigation so far. He had made some good progress on the case. The flooded engine had been cleared out, a large vacuum leak had been found and repaired, and the defective aftermarket mass air flow sensor was replaced with a quality OE part. The fuel trims were well within the acceptable range now.

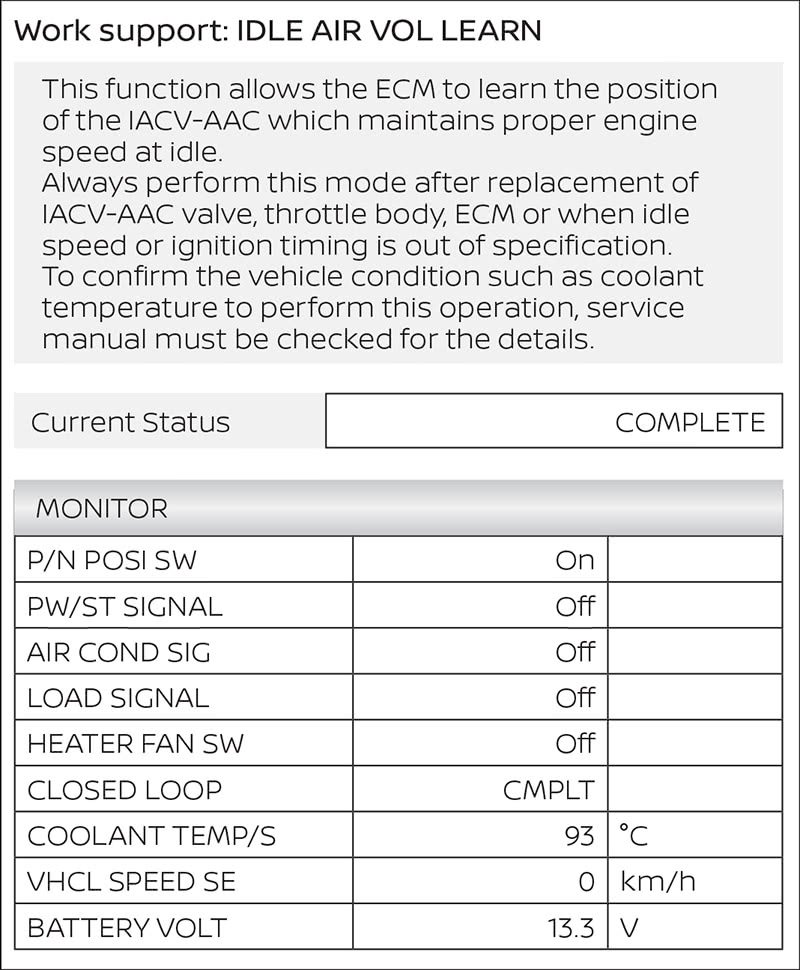

But despite all this good work, the investigation had stalled. The engine was still idling too high and was now setting a P0507 fault. The Idle Air Volume Learn function would initiate, but it would get stuck while ‘EXECUTING’ and not complete the relearn. Harry had cleaned the throttle body and tried the relearn again, but it still failed to complete. He even installed the original throttle body on the vehicle, because it had been replaced with an aftermarket part by one of the other shops that originally looked at the high idle concern. The original throttle body did not change the results though.

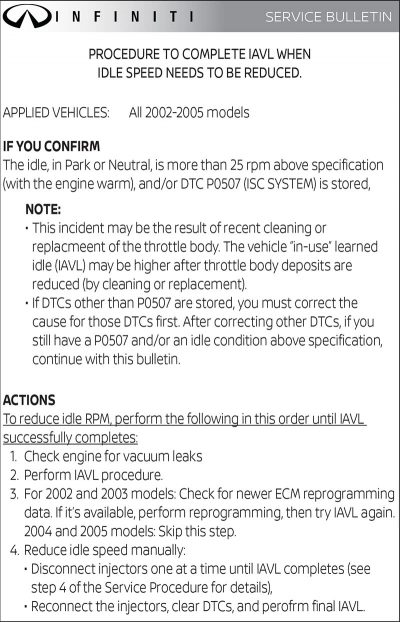

The effects of this FX were really wearing on Harry. He needed one more breakthrough to tie up this final loose end of the case. After several hours of racking his brain, Harry remembered an All Points Bulletin that came across his desk sometime in the past. He dug through the piles of pages and files on his desk and in the drawers. Finally, the search paid off and Harry located the APB he was looking for.

Disconnecting the injectors was an interesting way of forcing the idle rpm low enough for the relearn to run and complete, but unfortunately it was not an option for Harry. The engine design made this impractical. The fuel injectors were under the intake and were completely inaccessible. There had to be another way.

Harry put out a call for help over the wire, and heard back from a Nissan dealer detective who had done hundreds of idle relearns on Nissan products. He said that some relearns go through on the first try and some take several tries. Then there are a few that require getting creative to get the relearn completed. He explained that if the engine speed is too high, the reset will not initiate because all of the enabling criteria have not been met.

Depending on the engine design he would disconnect injectors, unplug the MAF sensor, or even restrict airflow to the air filter in order to lower the rpm enough to allow the relearn to run. Then, once the relearn had completed, it would need to be run a second time with all components plugged back in and operating normally.

Harry thanked the detective profusely for the valuable tips and headed back out to the ailing SUV. The exposed aftermarket air filter would make it quite easy to partially restrict the air flow with a shop rag. With the rag in place, the engine lagged and the engine speed dropped. To Harry’s relief, the Idle Air Volume Learn ran and completed! He ran it a second time without restricting the air filter and the relearn completed again. The engine was now idling exactly where it should be and Harry knew that this case was closed.

Harry was not sure if he was ready for retirement, but this was a satisfying ending at least. The case had a bit of everything from defective parts, to misdiagnoses and poor quality repairs. The victim suffered from a cranking no start, both lean and rich conditions, and a high idle concern. In the end Harry had closed a cold case for the department and brought closure to another victim. This was one for his memoirs if he ever got around to writing them.

By Jordan Hill

“So Harry would expect this 3.5 liter VQ35DE engine to be reading 6.0 – 6.1 grams per second at 863 rpm.”

I think that would still be too high at idle, I would expect to see closer to half that.

Also wanted to add that I have had some sucess in getting the idle speed down low enough to complete idle air learn by restricting fuel line (when possible). Trans needs to be warmed up too.

Nice read. A lot of useful insights.