Since the widespread adoption of continuously variable transmissions, there have been many misconceptions and misunderstandings among technicians. A large majority of technicians are hands-on learners. So, it is understandable that there is some disconnect when it comes to a transmission that they have never taken apart and actually seen how it operates.

However, technicians don’t need to have a great deal of experience rebuilding transmissions to correctly service, repair, and diagnose continuously variable transmissions. The key points are the same as when working on other systems on the vehicle: verify the concern, check the basics first, scan all modules present for faults, and review service information for component operation and technical bulletins. Continuously variable transmissions are here to stay, so it is imperative that shops are prepared to provide excellent service for the Nissan CVT vehicles that roll through the bay doors.

History

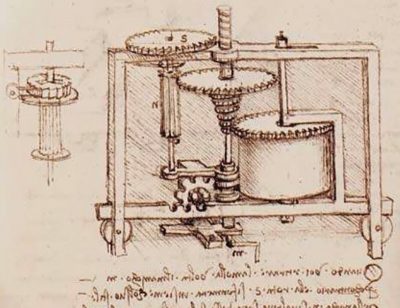

Incredibly, the concept for a continuously variable transmission dates back some five centuries, to Leonardo da Vinci. One of da Vinci’s legendary notebooks from 1490 contains a sketch of a stepless gearset able to transfer power from an input shaft to an output shaft. The gearset was in concept only, and never made it off the pages of his notebook. This was true of many of da Vinci’s inventions. His drawings were far ahead of their time, and it would be centuries before manufacturing capabilities caught up with his creativity.

The first working CVT wasn’t invented until almost 400 years later, and was originally used to power saws in lumber mills. Variations of the CVT transmission have since been used in motorcycles, snowmobiles, and all-terrain vehicles, as well as in multiple automotive applications.

Nissan originally delved into this technology 30 years ago with an optional CVT transmission on the 1992 Nissan March, also badged as the Nissan Micra. This vehicle was primarily sold in Latin American and Japanese markets. The 2003 Nissan Murano marked a significant shift for the auto manufacturer when they introduced XTRONIC CVT transmission technology.

Nissan’s commitment to increased fuel economy and reduced emissions has made CVTs the main transmission for a large part of their vehicle fleet. The next generation of CVT transmissions has gone through many design improvements which have further increased efficiency and reliability.

Operation

A Continuously Variable Transmission, or CVT, is still an automatic transmission, and as such it still uses many of the same components that a traditional automatic transmission uses. For example, the torque converter, valve body, final drive, and differential parts are all pretty much the same. The input and output sensors are also the same.

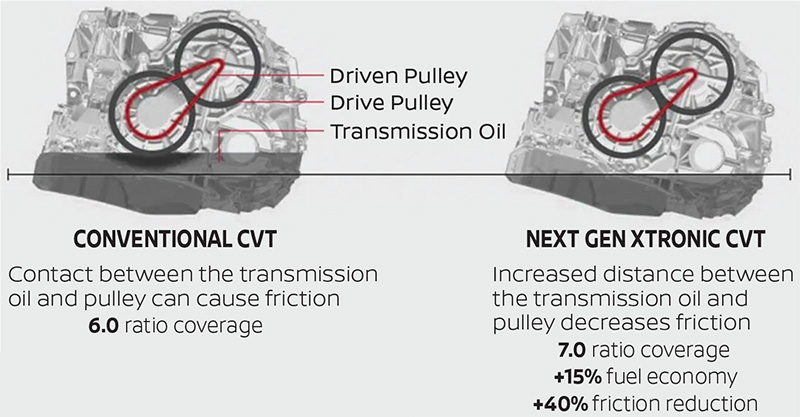

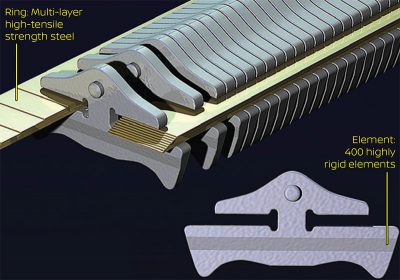

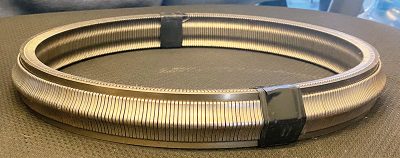

The big differences come into play with how power from the engine is transmitted through the transmission to the wheels. Instead of gearsets, bands, and clutch packs, Nissan’s XTRONIC CVT uses two pulleys and a flexible steel belt. The drive pulley, or primary pulley, is connected to the engine via the torque converter and flex plate. The driven pulley, or secondary pulley, is connected to the wheels via the differential and axles. The steel belt that runs on the pulleys is made up of over 400 pieces.

There are steel ring packs and steel elements that make up the belt. The elements are lined up against each other and are held in place by the ring packs. There is a V-shaped taper to the sides of the elements, which fit into the conical shaped pulleys. The belt is referred to as a push belt. This is because as the belt rotates around the drive pulley, the elements stack up against each other, acting as a solid metal rod that pushes the driven pulley. The ring packs, also called loop packs, are made up of several layers of high tensile strength steel bands, or rings. The number of rings in the pack, in part, determines how much engine torque the CVT transmission can handle.

The real beauty of this technology is in the two pulleys on which the push belt rides. The width of these pulleys can be changed. This is accomplished through adjustable pulley sheaves and hydraulic pressure. The two pulley widths are adjusted in unison because even though the steel belt is flexible, it still remains one solid length. As the pulleys are hydraulically adjusted, the gear ratio between the drive pulley and the driven pulley changes.

Both of the two pulleys have a speed sensor that is monitoring a toothed ring on the edge of the pulley. The Transmission Control Module (TCM) monitors the speed of each pulley and verifies that the pulleys are operating as commanded. The TCM can set fault codes if the pulleys’ speeds are different than what is expected.

One of the big advantages of a continuously variable transmission is, as its name suggests, the ability to change through a continuous range of gears. This allows the engine to run at the optimal speed for fuel economy and emissions without being limited to a specific number of pre-set gear ratios.

A traditional 4 or 5 speed automatic transmission has toothed gears that engage together to create pre-determined gear ratios. There will typically be two under-driven gear ratios, a direct drive, and one or more over-driven ratios. This is clearly limiting, which is why manufacturers are building 7, 8, and even 9 speed automatic transmissions. A CVT transmission has a wide gear ratio range, and the transmission control module can request and maintain the correct ratio for the load conditions that are present.

The main disadvantage of CVTs is the limit to the amount of engine torque they can handle. Nissan has made significant advances in the technology though, becoming the first manufacturer to offer a CVT capable of handling up to a 3.5 liter engine displacement.

Service

There is some confusion related to the fluid in Nissan’s CVTs, and because of this the fluid is often overlooked. Some of the questions that arise are: At what mileage should the fluid be changed? Should it be changed at all? What fluid type should be used?

The fluid replacement procedure is straightforward and similar to an automatic transmission drain and fill. Drain the fluid from the drain plug. Fill the transmission with the initial fluid amount through the fill tube from above, or with the fluid charging pipe set from under the vehicle, depending on the model. Start the vehicle and shift through all the gears, holding for five seconds in each position. Monitor the transmission fluid temperature with the CONSULT III. The Fluid Temp data PID can be found under the Data Monitor tab. The temperature ranges will vary depending on the model and year.

When the correct fluid temperature has been reached, then the fluid level can be checked and adjusted if necessary. Some vehicles have a dipstick included, while later models have a cap on the dipstick tube. Nissan offers a special service tool dipstick for those vehicles. This tool would be a good investment for shops that routinely service Nissan vehicles. There is a technical bulletin which outlines the special tools and how to properly use them.

Nissan CVTs have two different fluid types. CVT fluid NS-2 is used prior to model year 2013, and is blue in color. Nissan switched to CVT fluid NS-3 for the 2013 model year and newer. NS-3 is green in color. The two fluids should not be mixed together, nor should any other transmission fluid be used in a CVT. Always confirm what type of CVT fluid is required for the vehicle being serviced, and always use genuine Nissan CVT fluid. In fact, genuine original equipment parts should always be used when serving and repairing CVTs.

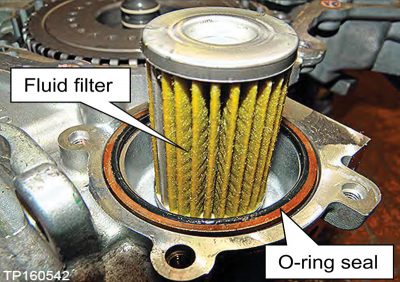

Depending on the model and year there are several options for transmission fluid filters. Many CVTs have an internal metal screen filter in the pan, while some also have an internal cartridge filter. The internal filters are not normally replaced when servicing the CVT fluid. There is also an external filter that is present on certain models.

Fluid Life Monitor

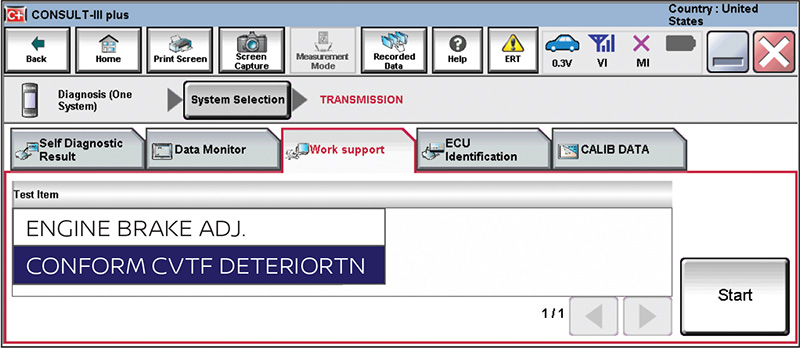

Nissan CVTs use a fluid life monitor system. This is a software based monitor that is part of the TCM programming. Nissan engineers created the fluid life monitor based on an algorithm that includes current mileage, the conditions the vehicle is driven under, the number of cold starts, the number of hot starts, and other factors. It is not just simply based on miles driven, but on a rather complex equation. After the fluid has been serviced, it is necessary to clear the fluid life monitor. This is done by connecting the CONSULT III, selecting the transmission control module, and then selecting the Work Support tab. Once on the Work Support screen, select Conform CVTF Deteriortn and then click Start.

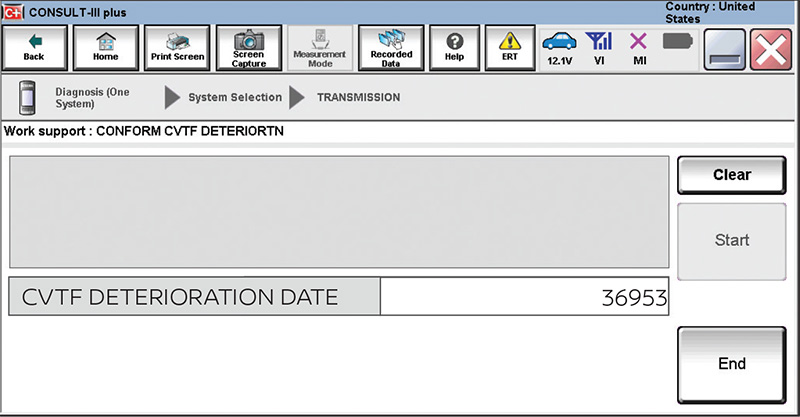

The next screen shows the deterioration number and has a Clear button that needs to be clicked to complete the reset. Resetting the deterioration data clears the fluid monitor memory, signaling to the TCM that the fluid has been replaced and to adjust strategies accordingly. The fluid monitor reset is the final step when servicing a CVT. It is often overlooked, but needs to be completed in order to keep the transmission operating correctly and prevent premature wear.

The fluid deterioration replacement number is 210000. This number does not refer to mileage, but rather to the number of times the CVT fluid has exceeded 90 degrees C. However field research shows failure of CVT components before the 210000 deterioration number is reached. This would indicate that the fluid deterioration monitor is not the only indication of when the fluid should be replaced. The fluid should be visually inspected and driving conditions should also be considered. If the vehicle is used for towing or driven in mountainous terrain, the fluid should be replaced more frequently.

| Fluid status | Conceivable cause | Required operation |

|---|---|---|

| Varnished (viscous varnish state) | CVT fluid becomes degraded due to high temperatures. | Replace the CVT fluid and check the CVT main unit and the vehicle for malfunctions (wire harness, cooler pipes, etc.) |

| Milky white or cloudy | Water in the fluid | Replace the CVT fluid and check for places where water is getting in. |

| Large amount of metal powder mixed in | Unusual wear of sliding parts within CVT | Replace the CVT fluid and check for improper operation of the CVT. |

Repair

Before any repairs are performed on CVTs, always read through service information fully for any special procedures or special service tools that may be required, and for any applicable Technical Service Bulletins. Nissan has issued several service bulletins related to CVT testing and repairs.

There have been some noise concerns related to CVT transmissions. Some of these concerns are warranted, while many others are not and the transmission can easily be misdiagnosed for a noise issue. There is a technical service bulletin from Nissan addressing some of these concerns.

Bulletin number NTB16-109b is titled Information to Prevent CVT Replacement Due to Misdiagnosis of Noise, and it is applicable to all Nissan vehicles equipped with a CVT transmission. The bulletin outlines how many of the noises that CVT transmissions make are normal and, unless the noise is combined with a shifting concern or fault code, repairs should not be recommended. The bulletin also stresses that CVTs operate and sound differently when there is no load on them. A CVT will sound much louder when lifted on a hoist and the wheels are off of the ground.

Just because a CVT transmission operates differently, remember that the rest of the car is still the same. When dealing with a noise concern, check the basics first before jumping to conclusions about the transmission. The first step is to duplicate the noise. Asking the owner of the vehicle the right questions is often critical to being able to duplicate a noise concern. It may also require going on a road test with the owner.

Another question to address with the owner is whether this is their first vehicle with a CVT transmission. If so, they may simply be unfamiliar with how they sound and feel. For clunking concerns, verify the engine and transmission mounts, along with steering and suspension components. For rotational noises, check wheel bearings, drive axles, and U-joints or C-V joints in the driveshaft for AWD models.

The usual suspects for rattle noise should be checked first also, like exhaust heat shields. A set of chassis ears can be helpful in determining the origin of a noise complaint. A noise and vibration analyzer can also be very useful in pinpointing a noise. PicoScope offers an NVH kit which uses an accelerometer sensor and connects to the vehicle OBD port. The software can then analyze all the frequencies during a road test and help to determine which component or system a noise or vibration is coming from.

There are two technical bulletins related to judder complaints and a P17F0 or P17F1 fault code on newer CVTs with a V6 engine. A judder is described as a shake or shudder, and can have single or multiple bumps or vibrations. Bulletin NTB17-039M is over 100 pages long and covers valve body replacement and CVT chain inspection in great detail. The second bulletin, NTB15-014, covers software reprogramming for the P17F0 and P17F1 fault codes.

Programming

Perhaps the most confusion with CVTs is related to programming and relearning. There are several different programming procedures based on which components need to be replaced to repair the vehicle. The following are two repair scenarios and their required programming steps.

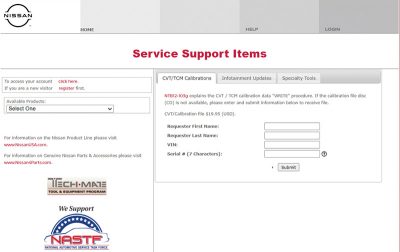

CVT Transmission or Valve Body Replacement – The individual characteristics of each solenoid in the valve body is measured during manufacturing. This calibration data is programmed into the transmission control module. When either the transmission assembly or the valve body is replaced, the old calibration data needs to be erased from the TCM and the new calibration data needs to be written in its place. This calibration data will be included on a compact disc with the new replacement part. If the CD is lost or damaged, the calibration data can be purchased through the Nissan Tech Info website, on the Service Support Items page.

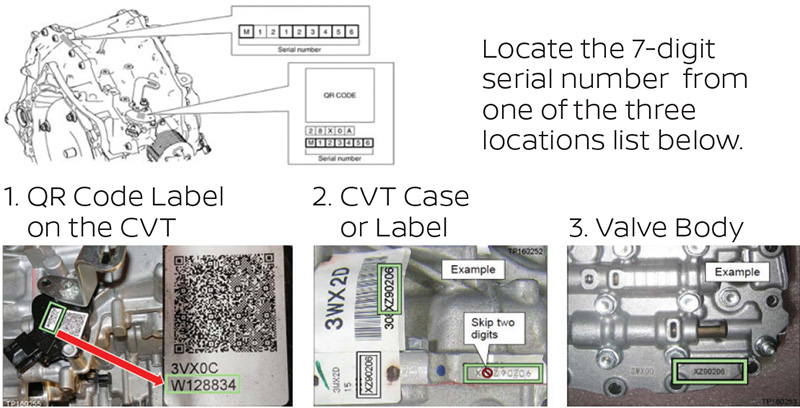

The transmission serial number is needed to retrieve the calibration data. The serial number can be found in several locations depending on the transmission.

Transmission Control Module Replacement – Before installing a new TCM, the calibration data for the valve body needs to be saved out of the old TCM. Then, after installing the TCM, the saved calibration data can be written to the new module. If the calibration data cannot be retrieved from the old TCM, the data can be retrieved through the Nissan website as previously described.

In situations where both the transmission assembly and the transmission control module are replaced, the transmission should be replaced first and then the control module. These programming and relearning procedures should be performed with the CONSULT III for best results. Nissan has provided additional programming information and step by step tutorials in several technical bulletins.

By Jordan Hill

0 Comments