Multiple faults for several different systems on Subaru Crosstrek requires prioritizing and working through one at a time.

As Shrek cleverly stated in one of our beloved family movies, “Ogres are like onions. Onions have layers. Ogres have layers. You get it? We both have layers!â€

As Shrek is walking with Donkey through the farm lands on their way to save the princess, he is trying to make the point that ogres are more than they appear to be on the outside. This is true about so many things in life. People or situations are often more than they appear to be if we are willing to dig a little deeper.

Cars can be like onions too. Not that they smell bad and make your eyes water (though some do), but often they have layers — layers that have to be peeled away one at a time to determine what is really going on. This was certainly the case for a 2014 Subaru Crosstrek that came into the shop for diagnosis. It had layers, and many of them.

This particular Crosstrek was an XV Hybrid. Being the first go-around with Subaru’s version of a hybrid electric vehicle, it was time to hit the books and read through factory service information. There is no point in trying to diagnose a system without the proper understanding of how it operates.

The XV Hybrid was Subaru’s maiden production hybrid vehicle, and this first generation model was short lived from only 2014 to 2016. The design of the powertrain and battery systems on this hybrid are interesting to say the least.

There are three batteries in total: a 12V auxiliary battery, a 12V restart battery, and a 100V high-voltage battery pack.

The auxiliary battery operates the traditional 12V starter motor and all vehicle functions other than the Auto Start/Stop system.

The restart battery is a smaller battery located on the right side of the engine compartment and powers the automatic Start/Stop function along with the Integrated Starter/Generator.

The third battery is a nickel metal hydride pack located in the trunk of the vehicle. At 100 volts, this is a high-highvoltage battery even though the voltage is lower than many hybrids, and the range is considerably less as well.

The Integrated Starter Generator, or ISG, restarts the gasoline engine via the drive belt during an Auto Start/Stop event and when transitioning from hybrid operation to engine power. The ISG also recharges the restart battery and, under specific conditions, the auxiliary battery as well.

For the powertrain, a 2.0L gasoline engine is attached to the Lineartronicâ„¢ continuously variable transmission. The CVT transmission is also equipped with a hybrid electric motor, which operates together with the internal combustion engine in a variety of driving and charging modes. After reading about all of the different components on this hybrid vehicle, it seemed as if Mary Shelley1 was part of the design team.

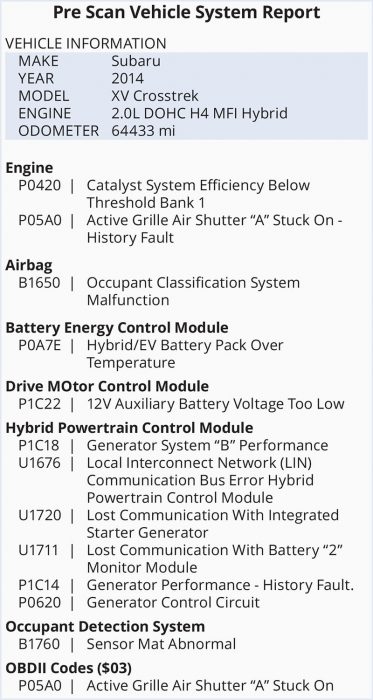

With thoughts of battery specifications, power flow diagrams, and high-voltage safety precautions, it was time to take a look at the Crosstrek. As with most diagnostics, the place to start is with a full vehicle fault scan and basic visual inspection. The scan results brought back numerous faults across most of the modules on the vehicle. This is where reading through the system operation paid off because there were faults for many hybrid components including the high-voltage battery, integrated starter/generator, and one of the 12V batteries. There were also faults for the active grille shutter, LIN data bus, and the occupant classification system, among others.

After the fault scan and basic checks were complete, it was time to create a plan of attack. This vehicle had multiple warning lights on: the Check Engine and airbag lights were on, as well as two hybrid warning messages. There were multiple faults for several different systems on the Crosstrek. The best approach in these situations is to prioritize the faults and then work through them one layer at a time.

Layer 1 ~ P1C22: Restart Battery

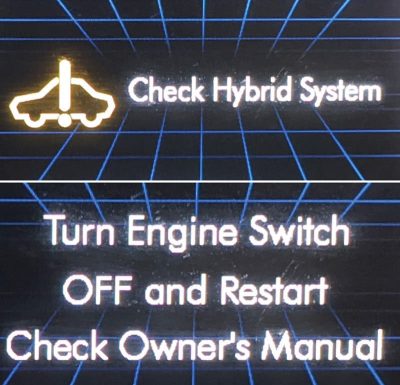

The first priority was to address the warning messages that finally got this Subaru in for repairs, beginning with the Check Hybrid System & Turn Engine Switch OFF and restart messages. The owner of the vehicle admitted that she had been ignoring the Check Engine light for months and the air bag light had come on a week ago. The hybrid messages, however, had her concerned enough to finally have the Crosstrek checked out.

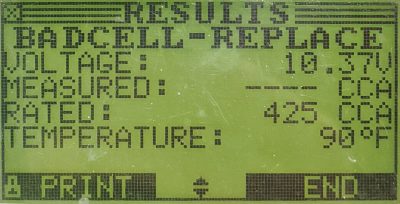

The P1C22 fault stated that the auxiliary battery voltage was low, so the logical place to start was testing both of the under-hood batteries. The auxiliary 12V battery tested OK, but the restart 12V battery on the right side of the engine compartment failed testing with a bad cell.

Despite the code description stating “12V auxiliary Battery Low Voltage,†this fault actually referred to the restart battery. This was most likely due to a discrepancy with the aftermarket scan tool being used. After calling a few of our local distributors, it was clear that this battery was going to have to come from Subaru. The dealership was called and we were stunned to find out the price of this little battery — over $700! Once the sticker shock wore off, the battery was ordered and installed.

There were several important installation notes for this battery listed in the replacement procedure. The battery sensor located on the negative terminal needs to be disconnected briefly to reset the learned memory. Furthermore, after the battery is installed, the ignition needs to be turned on for at least ten seconds before starting the engine and the brake pedal needs to be released. This allows for two things to occur: the initial testing of the electronic throttle valve and position learning of the brake

pedal stroke sensor.

With the restart battery issue resolved, it was time to move on to the second layer of this XV Crosstrek.

Layer 2 ~ P05A0: Active Grille Air Shutter

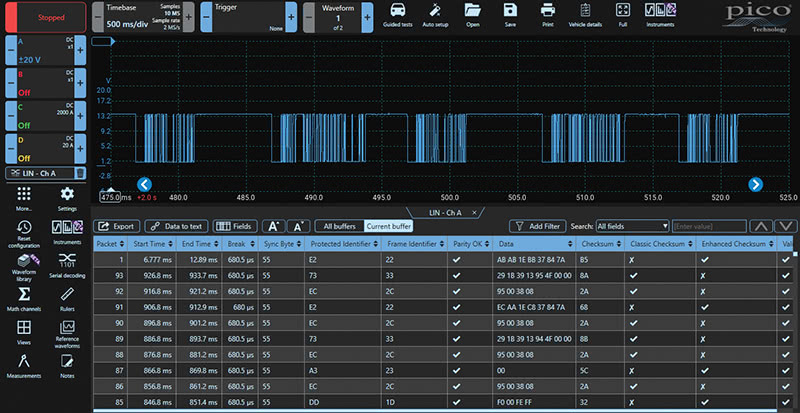

There were two faults in the engine control module that needed to be addressed. It was decided to save the catalytic converter fault for later, which left the P05A0 fault to be looked at. The research done at the beginning of the diagnosis paid off again when looking at the active grille air shutter system fault. The active grille air shutter communicates on a Local Interconnect Network, or LIN data bus. And there were several other components on the same LIN bus, including the integrated starter/generator, hybrid powertrain control module, and the restart battery sensor. This was also a newer generation LIN bus operating at a higher rate of 19.2K baud.

The description of operation explained that the active grille shutter has multiple functions and benefits. It is part of the aerodynamic design of the vehicle, and it works with the thermal management and climate control systems. When the grille is closed, the drag coefficient is lowered and the engine reaches operating temperatures quicker, which improves fuel economy and lowers emissions. The grille shutter can also help heat up the cabin faster and defrost the windshield more quickly.

After looking at the communication fault codes in the hybrid control module, it was clear that they were all related to the LIN bus that the grille shutter was on. A visual inspection of the active grille shutter revealed damage to the bumper and grille shutter. The owner of the vehicle confirmed that road debris had hit the front of her vehicle while driving on the freeway. The front bumper had been pushed back into the grille. This is one disadvantage of the active grille shutter; it is easily damaged by any type of front end collision.

The damage to the active grille had affected the LIN bus signals, causing all the communication faults along with the fault in the engine control module. The new grille shutter was ordered and installed. After clearing the fault codes, the Picoscope was connected and the LIN bus decoder (built into the software) was used to verify that the network was communicating correctly now. Serial decoding using a lab scope is a powerful tool that can quickly determine if all the data packets on a data bus are correct. With the new grille shutter connected, all the data packets on this Crosstrek’s LIN bus decoded correctly, so layer two was now diagnosed and repaired.

Layer 3 ~ P0A7E: Hybrid Battery Pack

There was also a fault in the Battery Energy Control Module, or BECM. This fault was for the hybrid battery pack being over temperature. Overheating is a serious issue that can permanently damage a battery pack. This code could be caused by several different things, including an inoperative battery pack cooling fan or a restricted air intake located in the left side C pillar trim.

Thankfully, in this case the over temperature fault did not indicate a serious problem. Research showed that Subaru had issued a service bulletin for this fault. (Click here to review the Subaru DTC P0A7E Service Bulletin.)

The bulletin describes the conditions in which the battery pack over temp fault can be set erroneously. The high-voltage battery naturally lets off heat after the vehicle is shut down, much like an internal combustion engine does. This heat soak period can inadvertently set the battery over temperature fault code. This is problematic, because once the fault is logged, the Auto Start/Stop and Regenerative Braking functions are suspended. The bulletin goes on to state that reprogramming files for the Battery Energy Control Unit are available to correct this issue.

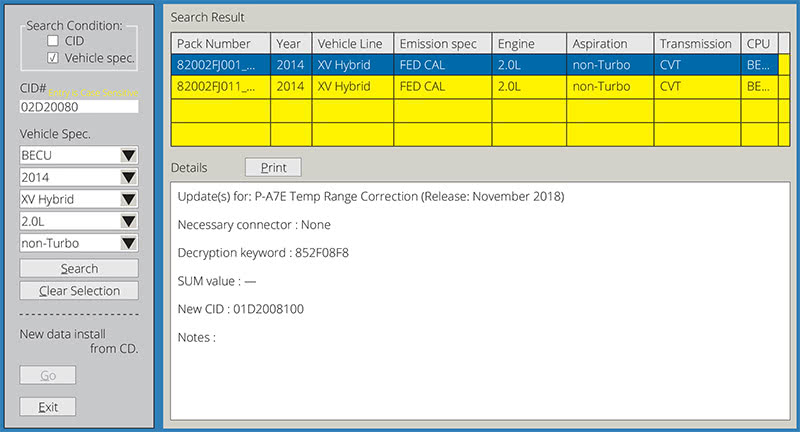

The Subaru reprogramming process is pretty straightforward. A copy of the J2534 reprogramming disc, an approved pass thru device, a battery charger, and a laptop are what is required. The J2534 disc can be ordered directly from Subaru, and includes all of the updated flash files as well as the FlashWrite program. Subaru releases a new disc four times a year. The FlashWrite software is easy to use, and the calibration IDs can be checked using the Reprogramming J2534 file chart that is available on Subaru’s Tech-info website.

Programming of the Battery Energy Control Unit went smoothly on the Crosstrek. The Calibration File was updated and the fault code cleared from the BECU, and one more layer of this XV was resolved.

Layer 4 ~ B1760: Sensor Mat

There were two faults related to the air bag light. The B1650 fault in the air bag module simply stated that there was a malfunction with the Occupant Classification System. This was a “finger pointing†fault code that pointed to the Occupant Detection Control Module (ODCM) for further information. The B1670 fault was for the passenger seat sensor mat having an abnormal reading.

Further research revealed there was a technical service bulletin for this fault also. Service Bulletin 07-134-18 expressly states that, before performing fault code diagnostics or replacing any components, the passenger seat cushion needs to be checked for moisture from a spilled beverage or a window being inadvertently left open. A damp seat cushion can cause a false reading of the sensor mat and set the fault code. (Click here to review the Subaru Fault Code B1760 Service Bulletin.)

While the seat cushion did not feel damp to the touch, the vehicle owner confirmed that she had accidently left the windows down while there had been a light rain a few days earlier. This was enough information to confirm that the seat cushion had likely gotten wet and needed to be completely dried out.

The bulletin explains that the best way of drying the seat is with natural air. After reading through the procedure, the vehicle was parked in direct sunlight with the windows down slightly. Then, with the engine running with the A/C turned on at room temperature, the blower was set on maximum speed, and the vents were aimed to direct air flow at the seat cushion.

If the passengers’ seat cushion is found wet or displays any staining, dry the seat cushion completely using natural air. Parking the vehicle in a sunny spot with windows slightly open is recommended.

To speed the drying time, it is recommended to use the vehicle’s Air Conditioner function:

- Park the vehicle in open area or use exhaust ventilation equipment

- Set the parking brake and start the engine

- Turn the A/C ON, set the blower fan to MAX, then direct airflow from the vents at the seat cushion

- Set A/C temperature to a comfortable room temperature (full heat is not required).

CAUTION: The occupant detection sensor mat is a sensitive part. Use of a Hair Dryer or Heat Gun to dry the seat cushion is not allowed.

The bulletin strongly states that heat guns or hair dryers should not be used to speed up the drying process, as this could damage the occupant detection sensor mat. The bulletin also notes that, if the fault returns after completely drying the seat cushion, further diagnostic steps would be required. This was not necessary on this Crosstrek though; drying the cushion took care of the fault code and the SRS light did not turn back on.

Layer 5 ~ P0420: Catalytic Converter

The fifth and final layer of this Crosstrek was the P0420 catalyst efficiency fault code. This was the second fault stored in the engine control module not addressed originally.

Surprisingly, the owner’s manual was still in the glove box, and it confirmed that the catalytic converter was covered under the Emissions Extended Defect Warranty for 8 years or 80,000 miles. This 2014 Subaru only had 64,433 miles on the odometer, so it would still be covered. It’s always a good idea to check for any applicable warranties on vehicles that are in the shop. Many hybrid and low emission vehicles have extended warranties covering a variety of components.

There were no service bulletins for the P0420 fault, and the fuel trim and oxygen sensor data all looked good. At that point it was in the owner’s best interest to recommend the final layer of this Crosstrek be taken care of at the local dealership.

Altogether, the XV was in the shop for a week waiting for parts to be delivered and the repairs completed. Then it was sent to the Subaru dealership to have the catalyst efficiency fault addressed under the extended emissions warranty.

This hybrid Crosstrek highlights the importance of unraveling a multiple issue vehicle one layer at a time. This will help avoid replacing unnecessary parts and prevent a car from coming back repeatedly. Reading through service information before getting knee deep on a vehicle is also crucially important. Sometimes seemly unrelated issues are connected, and starting with a clear understanding of system operation will save valuable time. Peeling back layers one at time works for the simplest of issues to the most ogreish vehicles.

0 Comments