The features of the M276 six-cylinder engine, with maintenance needs and procedures

Introduced to the United States in several models in the 2012 Model Year, the M276.9 6-cylinder naturally-aspirated engine was joined in Model Year 2015 by its dual-turbocharged brother M276.8. While our focus will be on the naturally-aspirated version, the turbo version is essentially the same engine and much of this information applies to both. Probably the most popular engine of all, there are millions of these engines on the road worldwide, many of them needing to visit your shop for maintenance and service.

Overview

The M276 is a gasoline direct-injection (DI) engine and, as mentioned, is offered in both naturally-aspirated and turbocharged versions. Further improvements in CO₂ emissions and engine noise, as well as modest increases in power and torque, were the goals for the design of this M272 replacement. Developed as part of the M270/274/276/278 family, many of the major systems of these engines are clearly similar to each other. Intake air and engine thermal management are especially new systems and the ECO Start/Stop function is standard equipment. Changing the angle of the crankcase V from 90° to 60° allowed for the elimination of the balance shaft.

In the United States, the M276 is a 3.5 liter engine with Homogeneous (DEH) combustion, while in most other markets the Stratified (DES) combustion version was delivered. DEH operation means that the fuel-air mixture is at lambda = 1 throughout the combustion chamber, while DES has lambda around 1 only in the vicinity of the spark plug. This lean-burn system reduces fuel consumption, with the disadvantage of increased NOx in the exhaust.

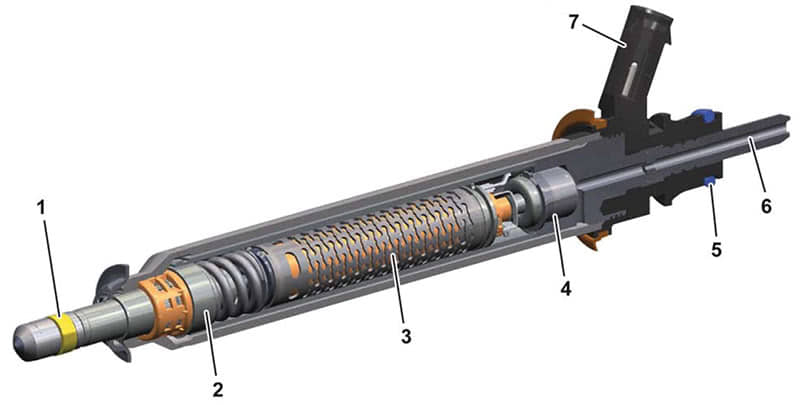

The Direct Injection (DI) system uses Piezoelectric fuel injectors for extremely fast and precise fuel delivery. The system is now a non-return high-pressure supply with two separate fuel rails. A high-pressure fuel pump delivers up to 200 Bar (nearly 3,000 psi) and is driven mechanically by three cams on the rear end of the right intake camshaft. The intake manifold has a switchover function to optimize the airflow into the engine. The cooling and oil circuits are carefully regulated and controlled for better efficiency.

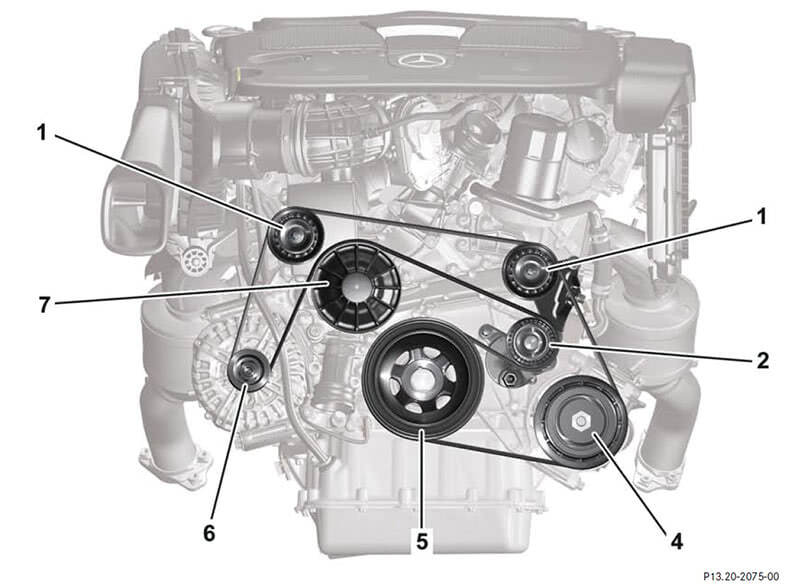

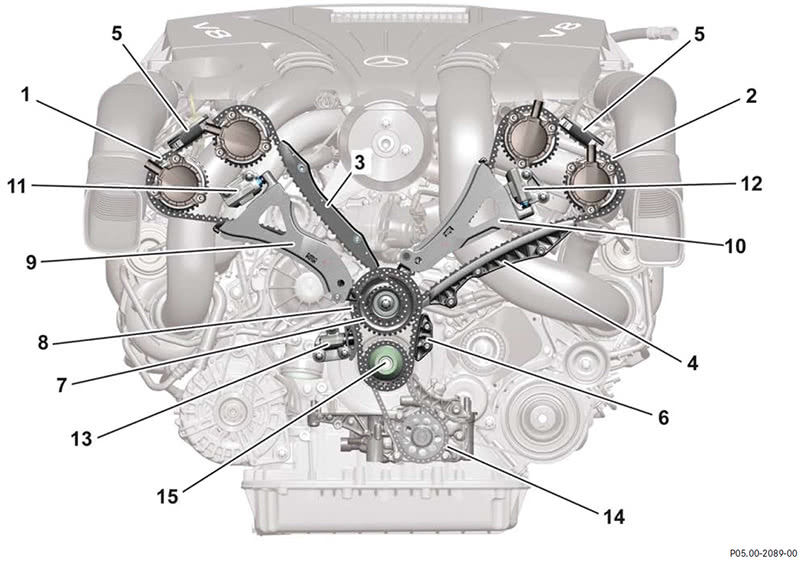

The crankcase and oil pans are made of die-cast aluminum with an open-deck crankcase and cast iron cylinder liners, with high-strength aluminum alloy cylinder heads. Two overhead camshafts, each with solenoid adjusters and driven by separate timing chains for each bank, actuate a total of four valves for each cylinder. An intermediate gear drives these two timing chains, with the oil pump driven by its own chain from the crankshaft, for a total of four chains.

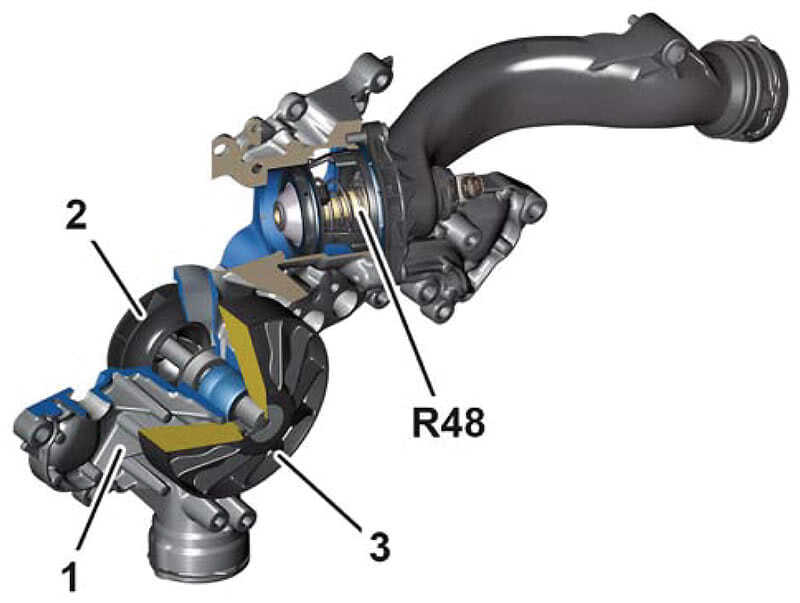

Thermal Management

Although the thermal management system is an important part of M276 operations, it has reduced relevance for maintenance and service. Suffice it to say that the ME-SFI control unit manages engine warm-up and heat, primarily as fuel economy, emissions and efficiency measures, and has ways to help reduce thermal load in an overheating situation, including control of the engine suction fan via PWM. Just a safety note concerning that fan: It can run up to 5 minutes after engine shutdown, so use caution under the hood during that time.

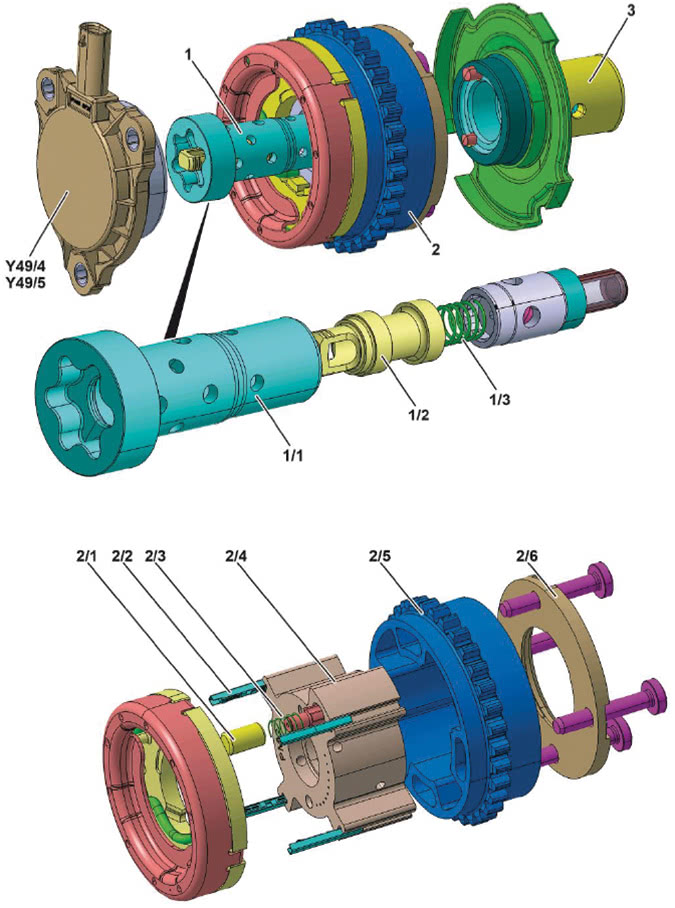

Variable Oil Pump

In contrast to the M272/M273 engines, the M276 (and M278) use a variable-flow oil pump, allowing oil flow to be regulated via a hydraulic control circuit. There is a high and a low pressure setting; at the low pressure setting, the piston cooling nozzles are deactivated through a special valve that requires a higher pressure to open. In addition to assisting with thermal management, the system allows a COâ‚‚ savings of around 2%.

Engine Ventilation

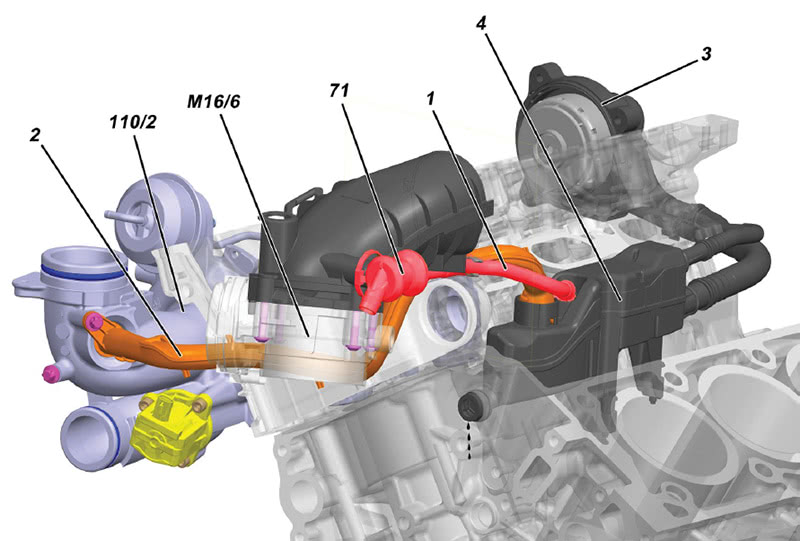

In the naturally-aspirated M276.9 (DEH), a crankcase vent line with restrictor and check valve is integrated between the air filter and left cylinder head. Only a single oil separator is used, the centrifuge located at the rear of the right cylinder head as with M272. Engine ventilation occurs via a vent line to the intake manifold, through a pressure-regulating valve.

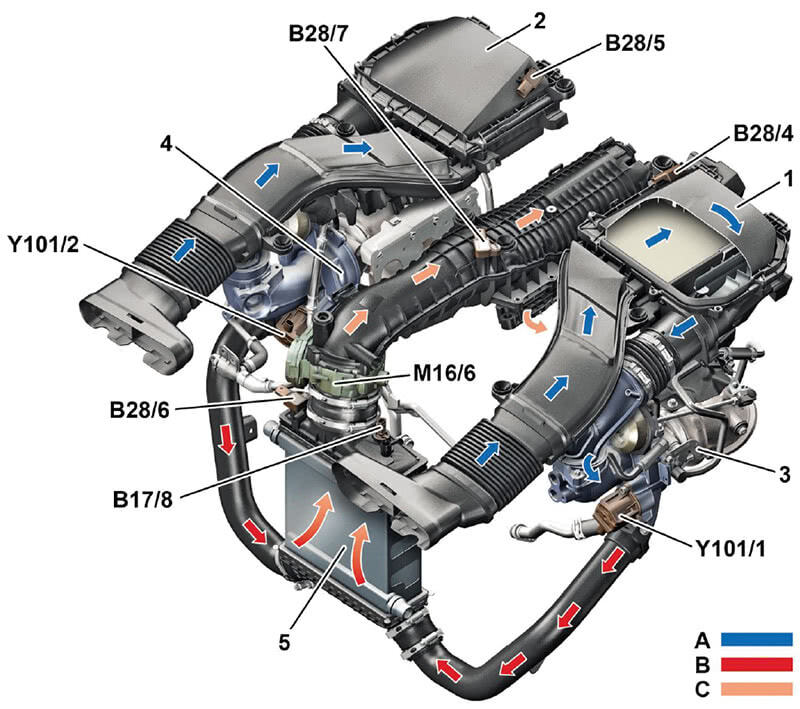

In the turbocharged M276.8 (DEH LA) there are two oil separators, an extremely fine separator located at the inner engine V, and again a single centrifuge at the right rear. Two lines transport blowby gases to the extremely fine separator, and from there the gases are led to either the charge air distributor downstream of the throttle valve or to the induction point upstream of the right turbocharger.

Chain Drive and Camshaft Adjustment

As mentioned previously, this engine uses a total of four chains in the engine timing and oil pump drive system. The goal here was to improve engine noise and endurance while reducing friction. A short chain goes from the crankshaft to the intermediate gear at a ratio of 1:1.33. The two camshaft chains are then driven by this intermediate gear at a ratio of 1:1.5. All three chains are tensioned by hydraulic chain tensioners. As with earlier engines, another short chain from the crankshaft is used to drive the oil pump.

Since the camshaft adjustment system is very similar to other engines, we won’t discuss it further. WIS has a GF document describing the function in detail

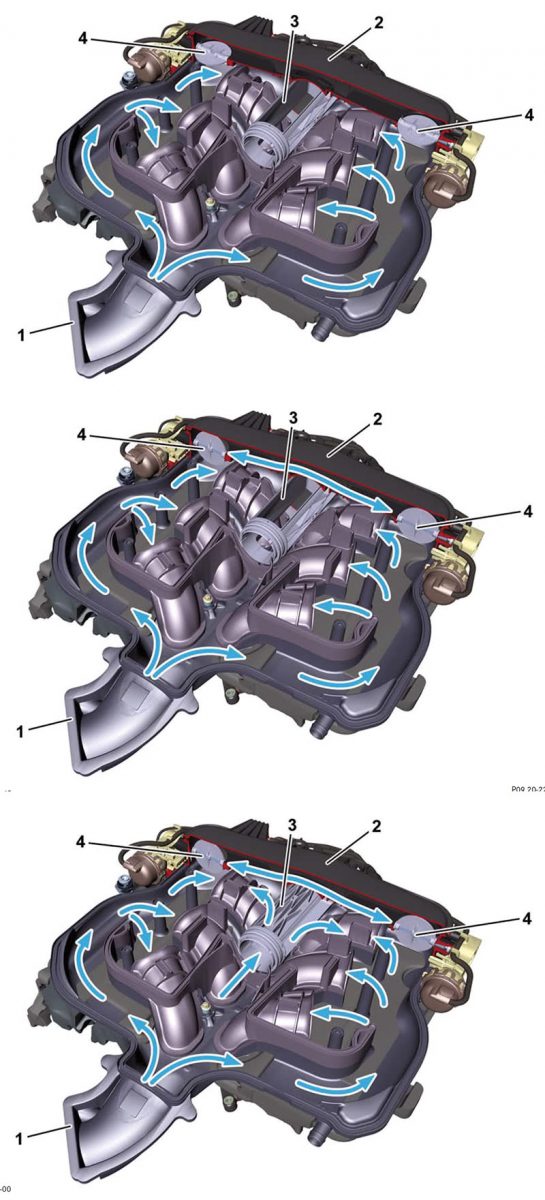

Engine Air Supply

To help engine efficiency, an air intake path needs to have a low resistance to air flow, yet maintain favorable flow conditions under all possible circumstances. Intake air is passed through a relatively large air filter to minimize flow resistance and is delivered to the intake manifold. There, depending on operating condition, the length of the intake ducts is varied so the engine torque curve can be optimized. Two resonance flaps, a central resonance chamber and a selector drum accomplish the varying duct lengths. Of course, the entire system is controlled by the ME control unit.

As a side note, in the M276.9 turbocharged engine, the intake manifold system is different. Rather than having a variable intake duct system, it is more conventional with a fixed system of intake ducts and, of course, a pair of turbochargers.

Fuel Injection

The Piezoelectric fuel injectors allow for very precise fuel delivery, again to help manage fuel economy and emissions. The fuel feed line to each injector is sealed at the high-pressure end by an O-ring, while the seal between the fuel injector and cylinder head is a Teflon ring. Any time an injector is removed, it is absolutely critical that instructions in the Mercedes-Benz Workshop Information System (WIS) for reinstallation are followed closely, particularly concerning the use of the special tools (such as W278 589 00 33 00) for this job, to ensure a leak-free installation. All seals and the hold-down spring must always be replaced. Never use a slide hammer, since the rail is soldered, and both the rail and injector will be damaged.

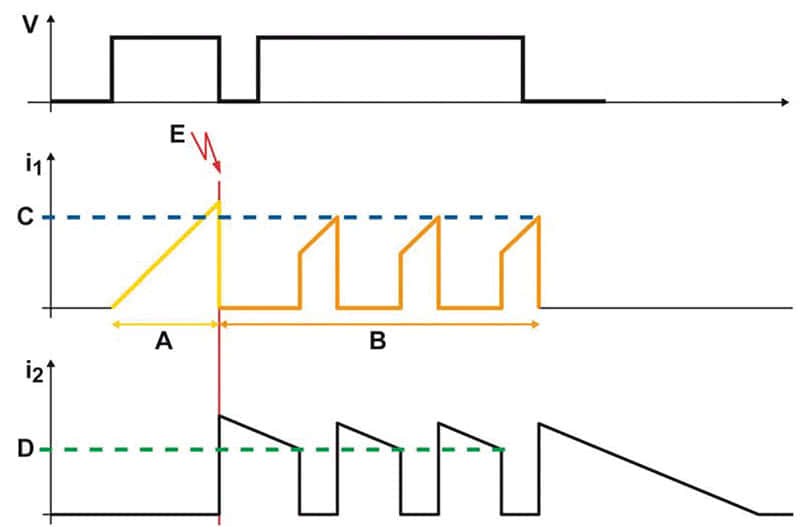

During operation, the injectors operate at voltages between 125 volts and 160 volts and a current of up to 8 amperes, which can be lethal if contacted by the body. Never expose yourself to these voltages by, for example, attempting to measure them directly as opposed to using a contact-free current clamp. If the ignition must be switched on, do not touch any part of the system or testing instruments/probes while energized. Accidentally shorting either injector control wire to ground will damage the ME, and accidentally reversing the polarity of the wires will damage the injector. There is a 220 kΩ discharge resistor in parallel with each injector, and this value can be measured at the fuel injector electrical connections.

The injectors themselves are fragile, as the piezoelectric elements are similar to thin glass. Never apply a voltage to a piezo injector, as it will be damaged. Dropping an injector or subjecting one to any kind of shock (such as a hammer blow) will destroy it, requiring replacement. Any contamination of either end of the fuel injector will also damage it, so always use clean protective caps at every removal.

Lastly, the high-pressure side of the fuel system (which includes the injectors) can remain at over 200 Bar (3,000 psi) for a very long time after the engine is switched off. Use extreme care in depressurizing the system prior to repair work to avoid having fuel penetrate your skin under pressure, which can be fatal.

Ignition

In a conventional engine, the ignition system generates a single pulse for the spark plug to ignite the combustion mixture. The M27x family of engines operates in both single-spark and multi-spark modes. Initially the same as a single-spark cycle, in a multi-spark cycle the ignition coil energy is not fully discharged, but is recharged in the interim so it can again provide enough energy for additional sparks. These multiple sparks allow for a slower yet more complete combustion, increasing fuel efficiency while reducing emissions and engine noise, particularly after a cold start and during the warm-up phase.

Each spark plug has its own coil. The spark plugs are connected to the coil by a short boot. The ME controls each coil through individual direct connections. The ignition coils also deliver diagnosis information back to the ME through the same wire.

Maintenance

Vehicles equipped with the M276 engine are equipped with the Mercedes-Benz ASSYST PLUS system. As always, check the owner’s maintenance booklet or the maintenance sheet in WIS or STAR TekInfo for the most accurate information, but in general these engines need an oil and filter change every 10,000 miles (or one year), using the well-known A and B service rotation. The engine oil dipstick is used to check the oil level.

As with virtually every vehicle, the maintenance sheet also calls for engine air filter replacement (every 50,000 miles or 5 years) and fuel filter and coolant replacement at 120,000 miles (or 12 years). Check the maintenance sheet for a complete rundown of all the required maintenance points.

Service Notes

Aside from those already mentioned, a few service tips might help save some time.

As always, use only Mercedes-Benz approved oils that are of the correct viscosity for expected local conditions and approval type for the engine. M276 uses MB-Approval 229.5 oils. The M276 engine generally requires only 6.5 liters of oil when the filter is changed, somewhat less than many other engines. Some variants, particularly the AMGs, do use the usual 8+ liters, so be sure to check.

Note that there is an official resource on the web to provide the details of approved oils and other operating fluids, so you can find the correct brand and product for your needs. Since the February 2022 split of Daimler AG into Daimler Truck AG and Mercedes-Benz Group AG, the MB BeVo website, which previously provided these details, has been replaced by the Mercedes-Benz Operating Fluids website, found at operatingfluids.mercedes-benz.com.

When checking ignition angles, the only possibility is to use XENTRY Diagnostics or possibly some factory-compatible aftermarket diagnostic readers. The ignition angle cannot be measured with conventional tools and equipment. The M276 uses pressed-on tone wheels for the camshaft adjuster system, and if you get a customer complaint of hard starting, rough running and poor performance, check the tone wheels for looseness.

Use only genuine Mercedes-Benz spark plugs. Aftermarket plugs are not always indexed, meaning the electrode gap needs to be facing a specific direction. Install incorrectly indexed plugs and the M276 will, as with the other Direct Injection engines from Mercedes-Benz, suffer from melted or cracked pistons from incorrect combustion patterns. If you haven’t read the article on spark plugs in the March 2021 issue of StarTuned, now is the time to go look at it. Also note that special tool W278 589 00 09 00 is strongly recommended for removing the 14 mm 12-point-hex spark plugs.

Connected in parallel with the ME’s piezo actuator module is a 200 Ohm discharge resistor. This value can be measured on the injector plug after disconnecting it from the injector. Be absolutely certain the ignition is off and the key is in your pocket, since this connector carries dangerous voltages when the ignition is on.

It probably goes without saying, but we’ll say it anyway: All work around the fuel system must be surgically clean, since even the slightest speck of dust can ruin the system. When working on the injectors and fuel rail, the stainless steel lines can be reused as long as they pass the test as specified in WIS (AR07.03-P-1010-03MM), which measures the length of the connection point. This is one place where using an accurate torque wrench will save you considerable problems. We’ve been able to reuse the high pressure fuel lines several times by being careful with the torque, and seen lines rendered useless after a single tightening. At over 200 Bar, you don’t want a leak, so if you’re not sure, replace it.

If you hear a complaint of poor performance, especially at high engine load or speed, check the fuel pressure after the high-pressure fuel pump, specifically at high volume delivery. Poor maintenance or inferior oil quality have been known to affect engine internal lubrication, and the special lobes on the camshaft that drives the high-pressure fuel pump may have worn, decreasing pump volume capacity.

Before you commit to any sort of internal engine work, be sure to carefully reference the relevant WIS work instructions. The M276 family of engines use quite a few more special tools for many internal operations, and some of these tools can get expensive. Your dealer might be helpful in either exploring what’s involved or perhaps loaning you the tools needed, but be aware that without these tools you’re just looking for trouble.

Lastly, we have seen a couple of these engines with a misfire condition and oil-fouled spark plugs. The engine breather system can allow oil ingestion into the intake manifold, and, in severe cases, can cause fouling. Just replacing or cleaning the plugs isn’t enough: Check the breather system to find where oil is getting in to prevent a rapid comeback for the same issue.

We hope you found this article about the M276 engine informative and practical. We covered some of the newer systems and functions, and offered some of the more common service tips we’ve come across in our work. As always, Mercedes-Benz USA recognizes your value to the brand and our mutual customers, and provides considerable information that is available to both dealers and workshops like yours to advance the goal of satisfied customers. Be sure to take advantage of that!

0 Comments