These rugged trucks have aged well, with old plastic parts and a few TSBs needing your attention.

The phrase “Out with old and in with the new” doesn’t always apply to automobiles. Supply shortages, electronic chip shortages, and economic concerns have the automotive market in a state of flux. With the average age of the vehicles on the road hovering around 12 years, there are just as many “old” cars on the road as new ones.

The new and used pickup markets remain strong, with trucks being as popular as they have ever been. Perhaps Kip Moore explained it the best when he sang, “There‘s something ‘bout a truck.†There is certainly something ‘bout the Nissan Frontier. This pickup has been a great seller for Nissan and has a loyal following among owners.

Initially introduced in the U.S. under the Frontier name badge in 1997, this pickup truck is celebrating its 25th anniversary this year. Surprisingly, throughout those 25 years, the Frontier has only seen three generations.

The first generation was a compact pickup offered from 1997 to 2004. It was a simple yet capable truck, with roots going back to earlier Nissan and Datsun pickups like the Hardbody, Navara, and the 720.

Clocking in at 15 years, the second generation has been the longest-produced version of the pickup, from 2005 to 2021. During the second generation, the truck moved up a class to a mid-sized pickup, using some design aspects from the full sized Titan. The engine was upgraded from the 3.3L V-6 to the 4.0L V-6, and the interior received some much needed updates.

While the Frontier has never been overly stylish, it has checked all the boxes a pickup truck should: reliable, tough, workhorse. Nissan may have been going on the adage, “If it ain’t broke don’t fix it,” by sticking with the second generation for so long, but that is no longer the case.

The New

The third generation Frontier has been totally redesigned, and debuted in 2022 as a stand-alone model for the North American market. Initial reviews have been overwhelming positive for the new and improved pickup. The heart of the new Frontier is the 3.8L V-6 that first appeared in the 2020 Frontier.

The VQ38DD engine features a slightly smaller displacement than the 4.0L VQ40 series engines that had been standard equipment for so many years, but it boasts fifty more horsepower than its predecessor. The VQ38DD engine also features direct fuel injection, referred to as NEO-Di, and electronic variable intake camshaft timing, denoted by the acronym eVTC. The exhaust camshafts use the traditional hydraulically-controlled variable valve timing.

The nine speed transmission is also a large step forward from the previous transmissions. The new Frontier also has all the Advanced Driver Assistance Systems available as part of the Nissan Intelligent Mobilityâ„¢ package, including Intelligent Cruise Control, Lane Departure Warning, Blind Spot Monitoring, and the new Intelligent Around View® Monitor with Off-Road Mode which, as Nissan puts it, will allow off roaders to “scrape by without leaving a scrape.” A redesigned interior with the latest tech and creature comforts rounds out the list of improvements.

Since this new generation hasn’t been on the road for long, there is limited service data and technical reports at this time. One Technical Bulletin worth noting, however, is NTB21-100A.

This bulletin explains the operation of the wireless phone charging pad, which is one of the new tech features. The charging pad will only operate when all the doors are closed and will discontinue charging when a door is opened. It is important for technicians to be aware of how these new technologies function, in order to sort out valid customer concerns from normal behavior. Staying on top of all the new features being released with every model year can be a monumental task, but being aware of how these technologies work can save hours of trying to diagnose a system that is operating as designed.

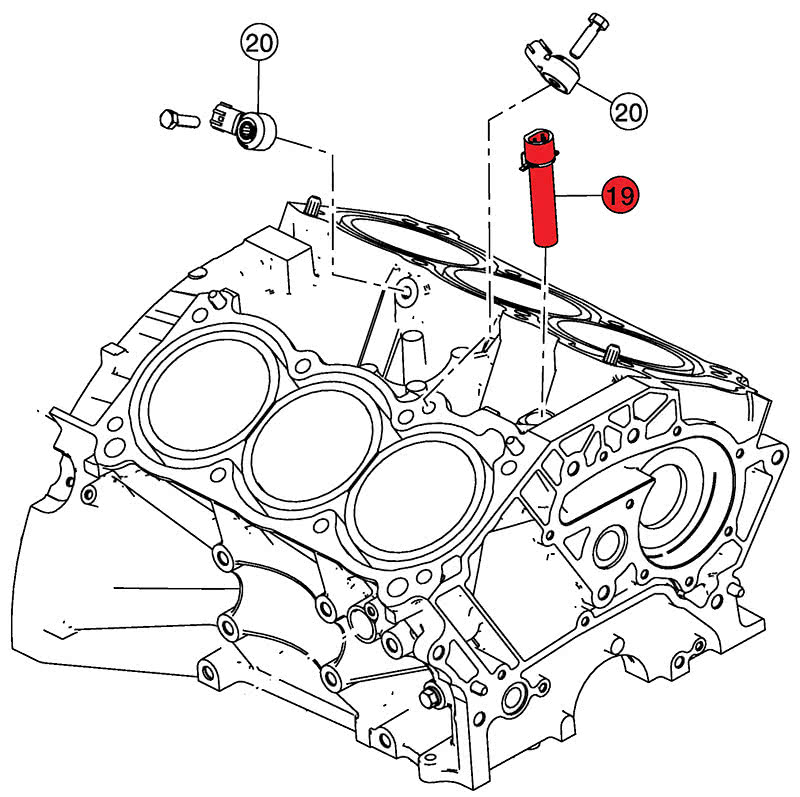

Another interesting item found while reviewing service information is an engine block heater in the valley of the engine. This optional coolant heater is shown on the parts diagram for the engine, and will undoubtedly have an additional set of wires for rodents to chew on, along with the two knock sensors under the intake manifold (more on that later). It is not clear which vehicles will have the coolant heater installed, but it may be intended for cold climate regions.

Nissan has clear blueprints for the future, and it is for a fleet of electric vehicles. There have been reports that the auto maker plans to cease almost all new gasoline engine research and development to focus primarily on electric vehicles for all their major markets. The only exception to that plan is the North American pickup truck market, where the Frontier remains popular.

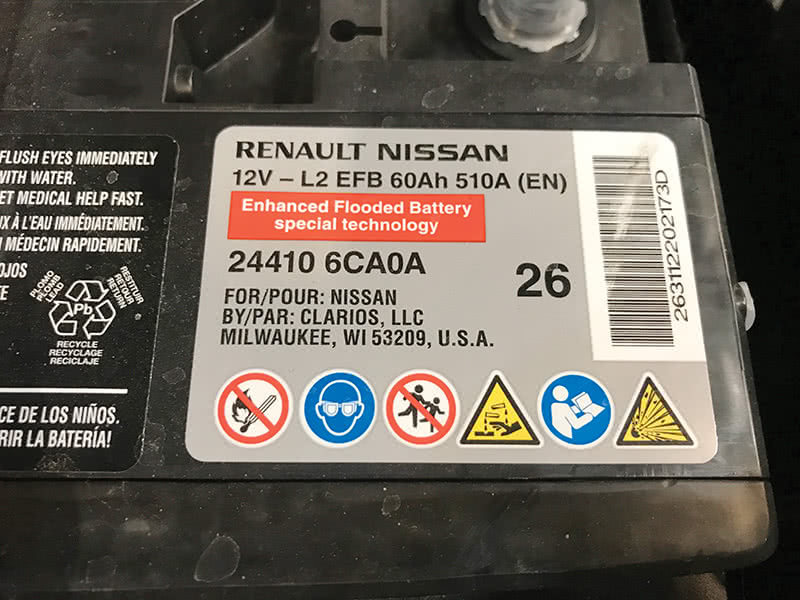

Nissan is expanding their partnership with Renault and working together on battery technology, including the Holy Grail of solid state batteries to achieve this EV future. The now infamous Carlo Ghosn, a former chairman of both Nissan and Renault, originally brokered the partnership 20 years ago. The battery alliance is designed to help both companies reach their EV goals.

Nissan’ s commitment to the Frontier means it will be with us well into the future, and their EV focus may mean there will be an electric version of the Frontier in the future.

The Old

The reliability and longevity of the Frontier are two main reasons there are so many of these trucks still on the road. Combine those with the fact that the Xterra shares many powertrain and driveline components with the Frontier, and most independent repair shops will see a steady diet of these vehicles coming through their bay doors. Here are some common issues that have been seen on the Frontier throughout the years.

Plastic Components

While not unique to Frontiers, there have been issues with plastic components under the hood, especially on higher mileage vehicles. More specifically, there are issues with the plastic valve covers with integrated spark plug tube seals, and the heater hose assembly on the passenger’s side of the firewall. The extreme conditions under the hood take their toll on these plastic parts.

The plastic heater hose assembly can fail without warning and should be replaced at the first sign of seeping. In fact, the author installed a new factory engine in a Frontier at a very hefty price tag due to the plastic heater pipe failing and causing a catastrophic overheat condition.

The spark plug tube seals are a non-serviceable part of the valve cover, so if there is any oil in the spark plug tubes, the valve covers need to be replaced. Nissan offers complete valve cover assemblies at a reasonable cost, making replacement the superior alternative to resealing. Also be sure to replace the crankcase breather hoses that go between the valve covers. These hoses become hardened over time and usually cannot be reused.

Replacing aged plastic components really should be looked at as normal preventive maintenance, and replacing them before they fail will save costly repairs down the road.

Engine Valley

The valley of the V-6 engine is a very inviting place for rodents to get warm and build a nest. When there are knock sensor fault codes stored on a Frontier, it is quite common to find a nest under the intake manifold and a damaged knock sensor wiring harness.

Thankfully, Nissan sells the knock sensor wiring as a sub harness to the main engine harness, making replacement easy and cost effective. It is strongly recommended to replace both knock sensors at the same time even if there was only a fault for one bank and not the other. Only use OE Nissan knock sensors, as aftermarket sensors are known to cause issues, and a fault code could return after a short time. Also, be sure to torque the sensors to the correct specification (normally around 20 ft-lbs). Improper torque can damage the sensors or cause them to read incorrectly.

Knock sensor fault codes will not always illuminate the Check Engine light, but a failing sensor can cause driveability issues, so do not overlook these hidden components. Knock sensors can cause low power complaints due to retarded timing, and they can also affect transmission operation.

No Start Conditions

At some point in a Frontier’s life cycle it may suffer from a no start condition, usually of the cranking no start variety. The most common no start issues are related to ignition components or a timing belt that was overdue for replacement.

The first generation Frontier had a distributor ignition system, so a worn distributor rotor and cap were a good place to start looking for problems. At higher mileages the distributor was also prone to failures. (View the Ignition Coil Spark Test video below.)

Second generation Frontiers got an upgrade to a Coil On Plug (COP) ignition system. These systems have been relatively problem free, requiring spark plug maintenance every 105K miles, and the occasional ignition coil replacement. The most important point to note about the COP systems is to use OE Nissan parts, specifically OE ignition coils. Aftermarket ignition coils with lower quality internal components can cause multiple driveability issues, including misfires, hard starts, or even a no start.

The recommended replacement interval for the timing belt on the 3.3L VG33 engine is 105,000 miles or 72 months. The timing belt should be changed earlier than that on the VG33ER supercharged version. When a timing belt fails, it usually happens at the crank sprocket, with multiple teeth tearing off of the belt.

This engine is considered an interference engine, meaning the valves and pistons share space inside the combustion chamber and can contact each other. Luckily, when a belt breaks on one of these vehicles, the engine is usually fine with no valve train damage. The sound of an engine cranking abnormally fast is a strong indication that the timing belt has been compromised. An easy way to see if the belt is broken is to remove the distributor cap and see if the distributor rotor is turning when the engine is cranked over. This test will indicate if the camshafts are turning with the crankshaft or not.

No Start Case Study

One such no start presented on an early second generation 2005 Frontier equipped with the V-6 engine and a manual transmission. This truck had an intermittent no crank, no start condition, however. The owner of the truck had called and requested a quote on a new starter because the tow truck driver had smacked it with a hammer and gotten the engine to start (and we all know how much tow truck drivers love to take out some aggression on an unsuspecting starter motor). The service writer explained that he would really like to see the truck before quoting a new starter motor, so the owner agreed and dropped off her pickup.

During the client interview, the owner stated that she had not been driving the truck much since COVID-19 hit, and when she did drive the vehicle it had intermittently not started for her. Sometimes the truck would not start for twenty minutes or more, and she had called a tow truck several times. She also revealed that she had accidentally bumped the cargo lamp switch on the left side of the dash before and drained the battery overnight, but she didn’t think that what happening now. The tow truck driver had tapped the starter repeatedly until the truck finally started the last time it had acted up.

The technician looking at the Frontier tested the battery and charging system, and both passed testing. A lab scope was used to check the starter motor health and nothing unusual was found in the current waveform. For the better part of a day, the truck started fine and no issues could be found. Finally, after repeated attempts, the engine would not start. There was no click or any sounds at all, but the dash lights were on and there was power to all the accessories.

Further testing showed that there was no power getting to the starter motor solenoid, and in fact, there was no power going through the clutch pedal position switch. The client was called and informed of the findings. She authorized the replacement of the clutch inhibit switch. The new clutch pedal position switch was ordered, and when it arrived the technician crawled his way up under the dash to install it. While changing out the switch, the technician noticed the rubber bumper that the position switch contacted was split down the middle.

This small part, called a clutch pedal rubber stopper grommet, is a press fit into the clutch pedal, and it was really what was causing the intermittent no crank. The broken half of the grommet would not fully depress the clutch pedal switch, creating a no start. Thankfully the local Nissan dealership had one of the rubber grommets in stock, and the Frontier was still able to go home at the end of the day.

While this was not an overly complicated diagnosis, it highlights the importance of taking the time to collect all the information and not jumping to any conclusions. A second or even third conversation with a customer may be needed to get to the bottom of an issue.

The cargo light switch was a red herring, and while it had drained the battery down in the past, it was not what was causing the current issue. The tow truck driver banging on the starter motor was also fake news. It was merely coincidence that the vehicle started after tapping the starter multiple times. The clutch pedal position switch hitting the half of the rubber bumper that was still intact was the real issue; a rubber bump stop has a list price of $9.52. It would have been easy to just sell a new starter motor and release the truck only to have it come back again in a few days.

By Jordan Hill

0 Comments