There are many issues that can arise in the HVAC system, and new regulations to be aware of. Let us dissect the HVAC acronym and take a closer look at each of the letters individually.

HVAC is a very familiar acronym for Heating, Ventilation and Air Conditioning. From the condenser to the rear heater core (if equipped), this acronym covers a wide variety of components all working together to heat, cool, dehumidify, filter and deodorize the cabin air for the driver and any passengers in a vehicle. Due to all the components in the HVAC system, there are many issues that can arise and new regulations to be aware of. Let us dissect the HVAC acronym and take a closer look at each of the letters individually.

Heating

Depending on the region of the country, a working heater can vary in importance. When heat is needed though, it has to work. There are several common reasons for poor heat output, including low coolant level, a restriction in the system, or a blend door problem.

Low Coolant Level

A low coolant level will often cause low heating concerns due to the heater core developing an air pocket. The low heat output may be present before an overheating concern as the level becomes lower in the system.

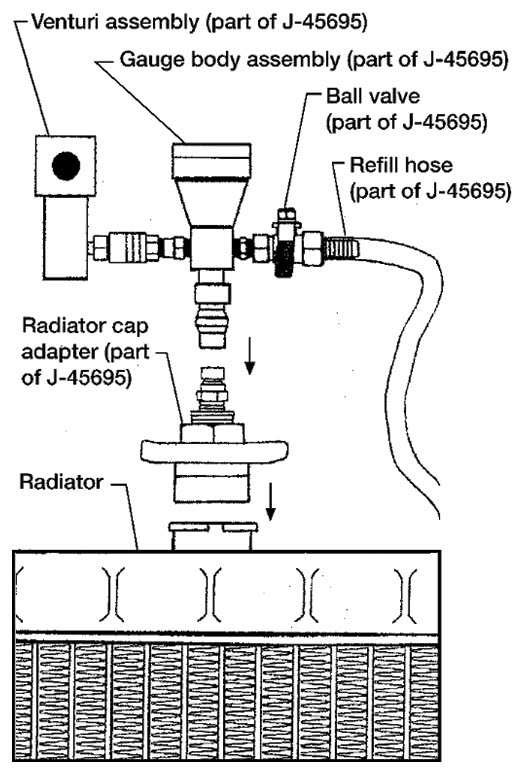

Air in the heater core doesn’t have to be from a leak in the cooling system though; it may be present from a recent repair. The cooling system needs to be properly bled to remove any air that can become trapped. The best method, and the one Nissan recommends, is to use a vacuum filing device. These may be stand-alone units, or part of a coolant exchange machine. Simply filling the system and running the engine until the thermostat opens is not sufficient to remove all the air.

Certain models and engine designs are more prone to trapping air, so always refer to service information and check for applicable Technical Bulletins for the correct refilling method. The Coolant Refill Tool, J-45695-A, is available through Nissan’s Tech·Mate website. The tool is made by Bosch Automotive Service Solutions, so it may also be available from aftermarket sources.

The reason for a coolant leak needs to be investigated to determine if the cause was age related or if there is an underlying issue that also needs to be addressed. Was the leak from ‘natural causes,’ i.e. rubber or plastic fatigue from normal use? Or is there possibly a bracket out of place from a minor collision that rubbed through the leaking component? These questions need to be answered to prevent a future comeback and potential warranty issue.

One example of an underlying issue is electrolysis. Electrolysis is generally caused by coolant that has become more conductive for various reasons, or poor grounding of the engine block or other components. Improperly installed aftermarket electronic parts can also add to the problem. If suspected, an electrolysis issue needs to be addressed along with any necessary cooling system repairs; failure to do so will likely result in repeat component failures.

Electrolysis can be tested with a digital volt meter. Place the negative lead on the negative battery terminal and touch the tip of the positive lead into the coolant, either in the radiator or the expansion tank. Use care to not touch anything metal with the positive lead. A reading above 100 millivolts indicates an issue. This test can also be done with the engine running and someone in the driver’s seat turning on and off electrical components to see if the readings increase, indicating a potential ground path issue for that component. The most likely components would be blower motors, cooling fans, headlights and other higher load devices.

To address an electrolysis issue there are several options. First, the coolant should be serviced and new OEM coolant with the correct mixture should be added. There are some aftermarket solutions like a radiator cap with an anode attached. Adding a supplemental ground wire to one of the heater core pipes using a hose clamp and a ground lead is also an option.

Electrolysis may not be a common situation, but it should remain in the back of a technician’s mind as a possibility, especially when dealing with a heater core leak.

Restriction in the System

Look out for tell-tale signs of a potential restriction; the most obvious being gold or copper colored stop leak flakes in the coolant reservoir or top of the radiator.

These flakes would be welcomed if panning for gold, but in a cooling system they are a cause for concern. While sealant additives may temporarily stop a coolant seep or leak, they also do an excellent job of plugging the thin capillary-like tubes inside of a heater core. Cleaning the heater core by back flushing or with a cooling system exchange machine may restore the heat performance, but often heater core replacement is the best option. The sealant may also be masking a major issue like a damaged head gasket.

Sealant is not the only thing that can clog up a heater core though. Mixing coolant types and using low quality coolants can lead to gelling of the coolant. The different chemical make-ups of the coolant can react with each other, causing the coolant to coagulate. This condition can quickly clog a heater core or restrict a radiator. Always use the recommended OE coolant type and distilled water to avoid issues with gelling.

Ventilation

The ventilation system is often the most overlooked part of the HVAC acronym. This is due to the majority of the system being inaccessible inside the dashboard. Until there is a problem, like a leak in the evaporator core or a rodent nest in the air ducts, it is easy to take this system for granted. Here are several points to remember when working with ventilation components.

Start by cleaning the cowl of any leaves or other debris that may have built up, as this is where fresh outside air gets into the passenger cabin.

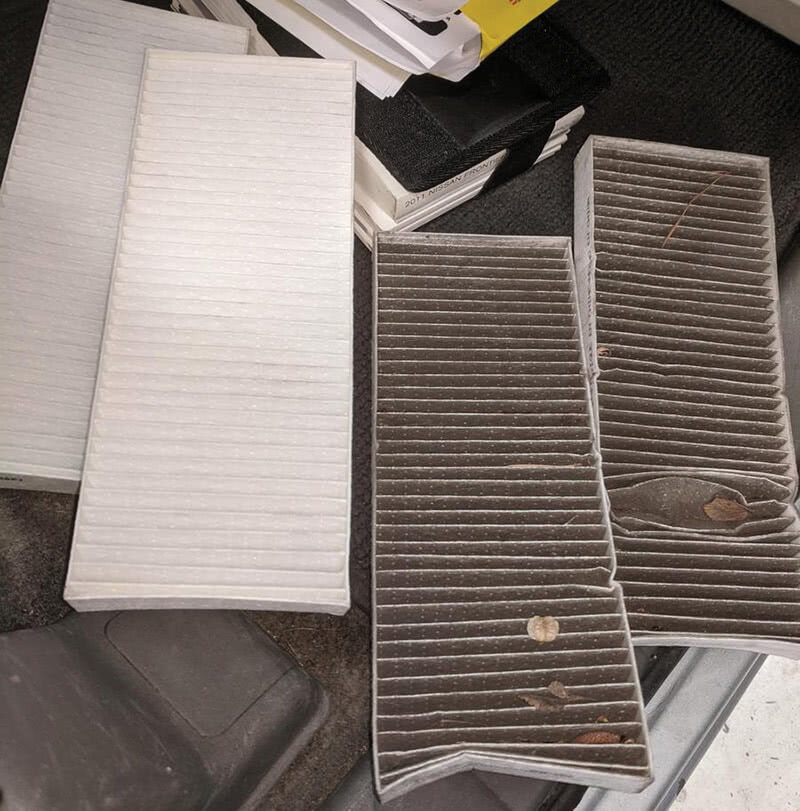

The cabin filter (or filters depending on the model) is the most familiar ventilation part. Nissan recommends a replacement interval of 15K miles for most models. If the last service mileage is unknown, most cabin filters can be accessed easily enough to visually inspect them. For proper fitment and filtration it is best to use OE Nissan filters.

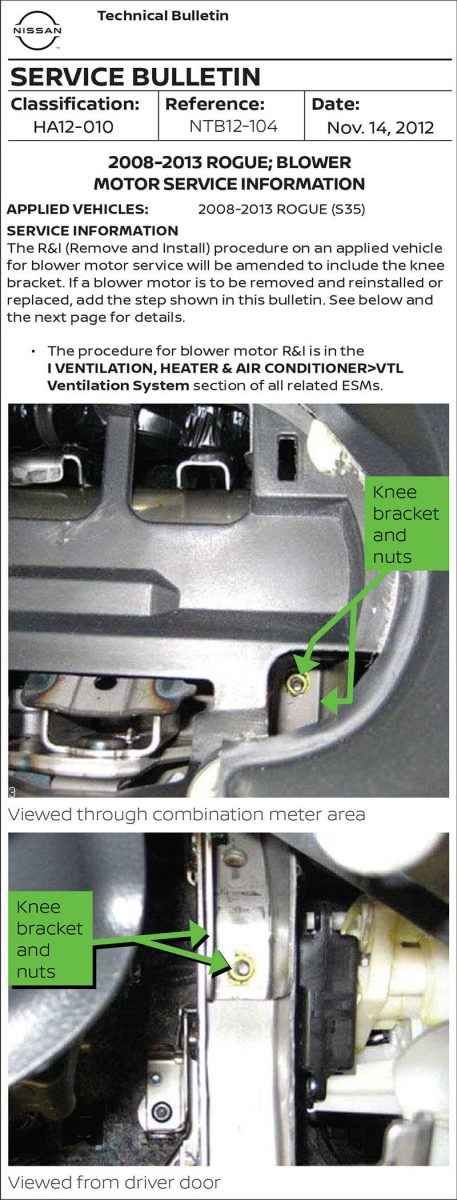

Blower motors are another familiar part of the ventilation system. Improvements in design and operation have resulted in longer lifespans for blower motors, and replacement is not as common as it once was. When a blower motor does need to be replaced, the 2008—2013 Rogue presents unique challenges, as indicated by the 2.4 hour labor time. Instead of being accessed below the glove box, the motor is located high up on the driver’s side of the blower case. It requires the removal of the brake pedal and accelerator pedal along with several other components. The original repair instructions omitted a step, so Technical Bulletin NTB12-104 was released as a correction to the Electronic Service Manual.

It is also important to note that the motor and blower cage are assembled as a balanced pair and should not be serviced individually.

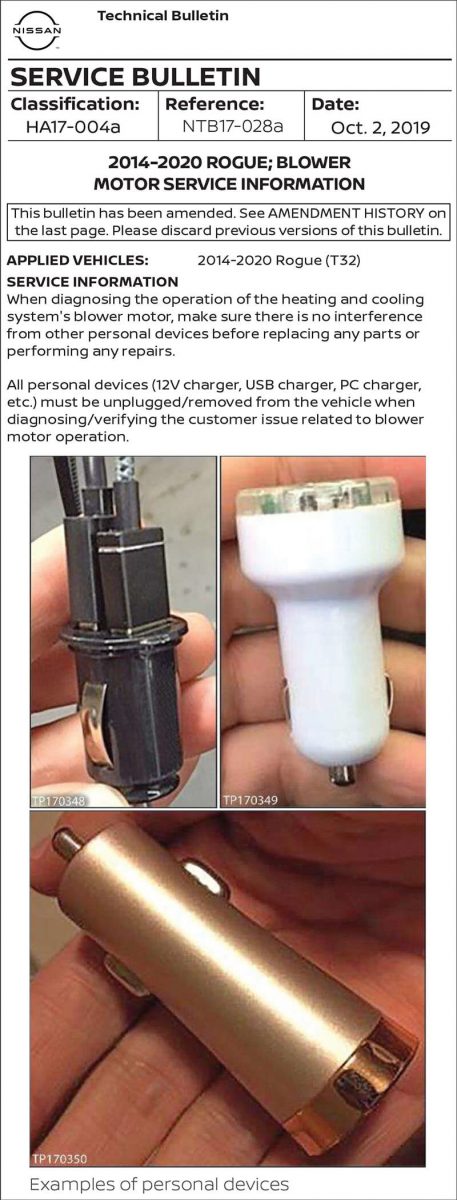

There is also a bulletin for the blower motor on 2014—2020 Nissan Rogues. This bulletin is related to diagnostics, however. The TSB states that any aftermarket chargers or other devices need to be unplugged when diagnosing a blower related concern. Specific examples of interference caused by personal devices are not detailed in the bulletin, but it underlines the value of checking aftermarket devices and keeping an open mind for seemingly unrelated causes when performing diagnostics.

Both of these service bulletins are a good reminder to always review service information before repairs or diagnostics. This is a valuable habit to maintain, as procedures can be revised and pattern failures identified over time.

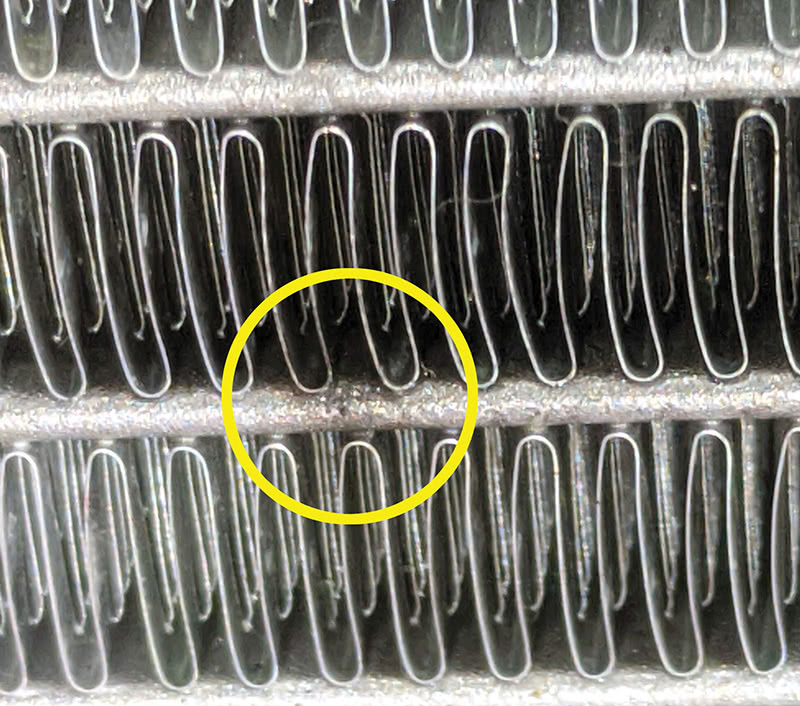

One final thought before moving on the final two letters of HVAC. Ventilation doesn’t only apply to the passenger compartment. The radiator and condenser also need to be able to breathe properly. Any restrictions in front of the condenser or between the condenser and the radiator can cause poor air conditioning performance, engine overheating, or both.

Air Conditioning

Air conditioning systems have been standard equipment on vehicles for decades now, and during the summer months A/C service is routine. The most significant recent change in A/C systems is the introduction of the new refrigerant, HFO-1234yf.

The Environmental Protection Agency identified several acceptable substitute refrigerants through their Significant New Alternatives Policy. The SNAP program researches ozone-depleting substances across many industries and sectors. The EPA has mandated that R-134a could no longer be used in Motor Vehicle Air Conditioners (MVACs) after 2021.

That mandate for alternative refrigerant compliance has passed. Nissan’s adoption of the policy started with the Altima in 2019 and has continued over the last three years, with all 2022 Nissan and Infiniti models using HFO-1234yf refrigerant.

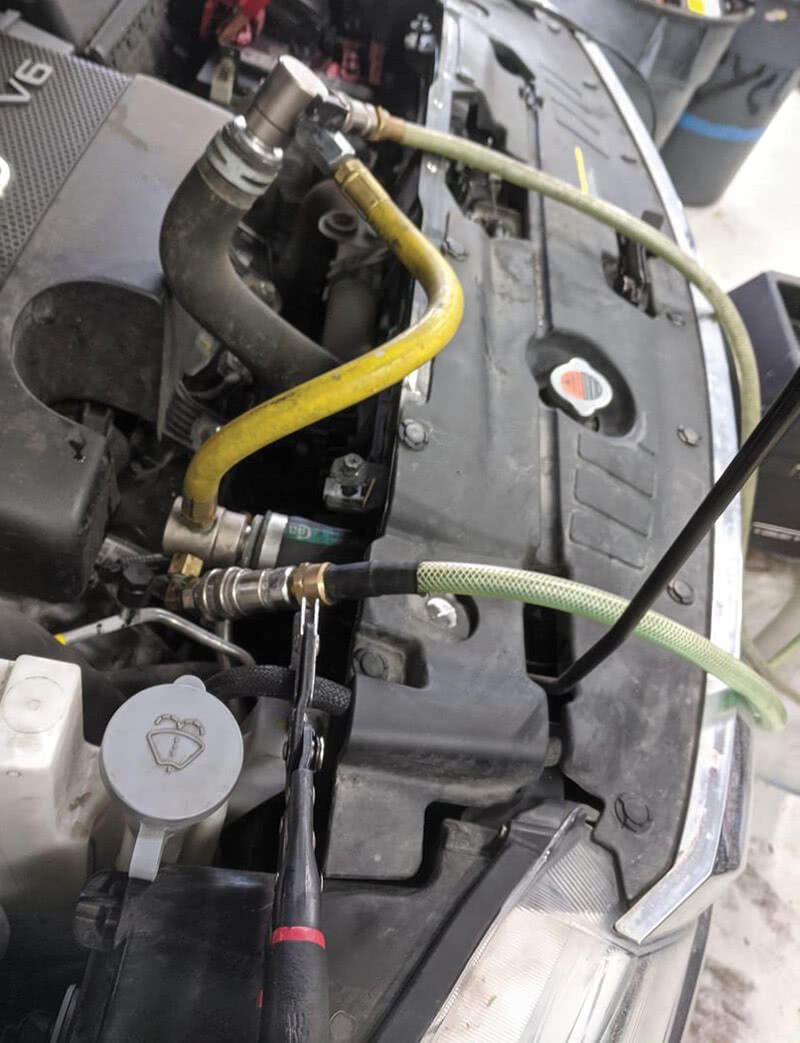

So where to begin with this new refrigerant? The under-hood label is always a great place to start when servicing an A/C system. Several key pieces of information are on that label, including the type and amount of refrigerant and the type of oil the system requires. The under-hood label has been redesigned for HFO-1234yf (also referred to as R-1234yf). The new label contains much of the same information, but the layout is different than that on the R-134a label.

Checking this label is even more crucial during transitional model years where either refrigerant could have been used. If the under-hood label is missing, the refrigerant type may also be indicated on the service port caps.

Many independent facilities have been hesitant to purchase the equipment required for the new systems, but as some of these vehicles are reaching the three year mark and coming out of factory warranty, now is the time. Shop owners or managers are strongly recommended to research all their options before purchasing any new equipment. Nissan lists the J-52405 Recovery, Recycle, and Recharge (RRR) A/C service machine as an essential tool on the Tech·Mate website.

Purchasing a new A/C machine may not be practical or feasible for some smaller repair shops, but there other options. Collision facilities are the first sector of the independent automotive market to see the latest vehicle technology, and they have been dealing with HFO-1234yf for years now. Some collision centers will recharge an A/C system as a sublet repair for local garages. There may also be a mobile refrigerant operator in the area that can perform recovery and recharge services on-site. Using any of these options makes it imperative to confirm what refrigerant is present in the Nissan being serviced before quoting a job or starting a repair.

Another thing to consider is the increased costs associated with the new refrigerant. The recharge process is longer and requires a technician to be present at the machine. This is in contrast to the ‘set it and forget it’ routine with many R-134a machines that can automatically pull a vacuum on the system, perform a leak check, inject dye, and recharge the system. R-1234yf refrigerant and necessary PAG oil are considerably more expensive than their previous counterparts.

Then there are the costs of a new refrigerant machine, dye injector, leak detectors and refrigerant identifiers. The increased technician time, higher cost of refrigerant and oil, and the new equipment costs add up to shops charging higher fees. Some shops have reported needing to charge as much as double the cost of an R-134a evacuate and recharge service to remain profitable with the new refrigerant.

Internal Heat Exchanger

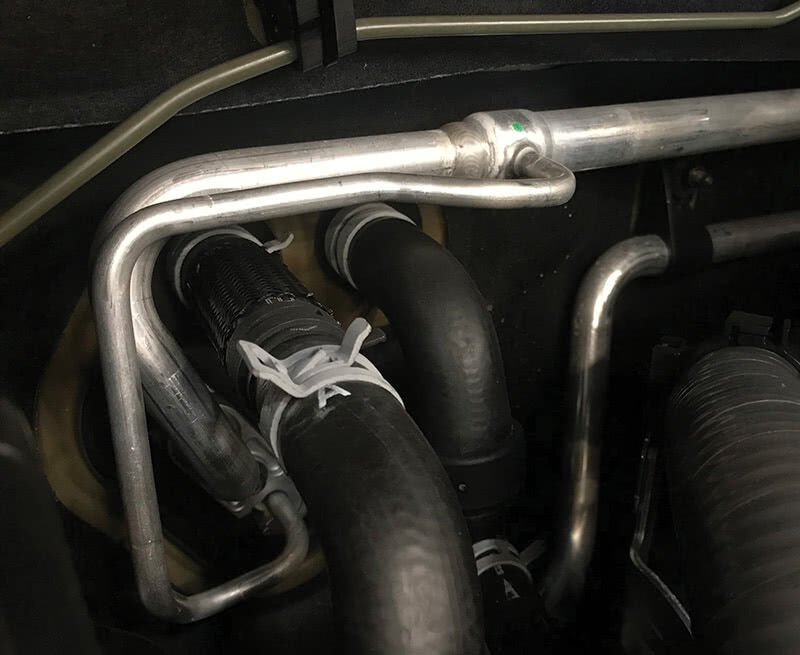

Often when vehicle technology changes are made for safety or environmental reasons there is a sacrifice of performance. This is true with the transition to R-1234yf refrigerant. The heat quotient of this new refrigerant is marginally lower than that of R-134a, which in turn is lower than R-12. The loss of heat quotient needs to be compensated for elsewhere in the system; enter the Internal Heat Exchanger or IHX for short. The IHX can also be referred to as a Suction Line Heat Exchanger (SLHX) and is located between the evaporator and compressor.

The IHX is a liquid-to-vapor heat exchanger, with the high side line (liquid) being molded into a section of the low side line (vapor). Heat from the liquid refrigerant in the high side line is transferred to the vapor in the low side line, creating sub cooling of the refrigerant before entering the expansion valve and evaporator.

Nothing needs to be done differently in regards to the IHX, other than the high side and low side lines will be replaced as one assembly. Technicians do need to be aware when looking under the hood though, as the pipe assembly looks different.

609 Certification

Now is also a good time for technicians to make sure they have their Section 609 Certification. This EPA certification replaces the 608 certification and covers the new HFO-1234yf refrigerant. The certification is required for any technician who is servicing air conditioning systems, and in order to purchase small sized refrigerant containers.

The test is relatively easy and inexpensive, and is available through the Automotive Service Excellence (ASE) web page or the Mobile Air Climate Systems Association (MACS) website.

Two For One

The 2009—2020 Nissan 370Z and the 2008—2013 Infiniti G37 have a unique radiator and condenser design. Both parts are molded into one unit and are serviced as one part. These are not the most common everyday vehicles, but it is important to be aware of the unique design when quoting a repair. Recovering and recharging an R-1234yf system will significantly affect the cost of a radiator replacement.

Remember that the HVAC system is very interconnected and one failing part can have an effect on many other components. Keep an open mind and follow a logical process to diagnose all the parts of the HVAC system effectively and efficiently.

By Jordan Hill

Great tech site!

Thanks Doy! We appreciate your feedback.