Maintenance procedures are not always as simple as you think.

Saying that Mercedes-Benz invented the automobile could be argued, but there’s no doubt that the Benz Patent Motor Car from 1886 holds the distinction as the world’s first internal combustion engine powered vehicle. Subsequently, Mercedes-Benz has been first to market with countless patents, inovations and new technologies. Automobiles have changed immensely over the past 136 years, but one thing has remained consistent: Maintenance. The Patent Motor Car and other early automobiles needed almost daily maintenance, from filling oiler caps and greasing joints to adjusting belts and lubricating chains. Thankfully today’s vehicles can be driven thousands of miles between required services, but they are still required.

Some shops make the mistake of looking at basic maintenance as a loss leader or a necessary evil to retain customers and sell more profitable service and repair work. These basic services need to be taken very seriously though. Maintenance messages that were not reset or oil level warnings in the information display after an oil service eat up valuable shop time and sour client relations. An over-tightened drain plug can easily crack or pull the threads out of an aluminum oil pan leading to costly warranty work. Rolling the o-ring of a cartridge type oil filter can cause a huge mess in the engine bay or worse, engine damage. All this to say there are many points at which basic maintenance errors can lead to costly damage. The easiest way to avoid these costly mistakes is to read through and follow factory service information, even for the simplest items like oil services, vehicle lifting points and installing air filters.

Oil Services

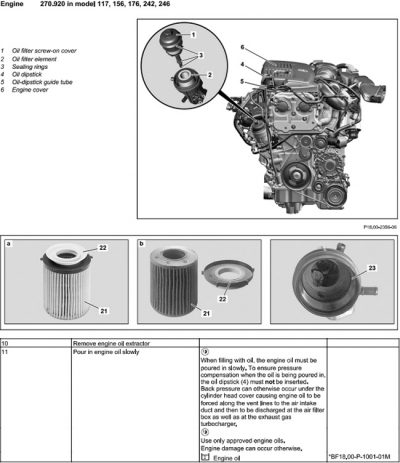

The first vehicle for consideration is a Polar White 2019 GLA250. This is the smallest SUV Mercedes-Benz offers and is equipped with a 2-liter turbocharged inline 4-cylinder, engine type 270.920, and can also be found in A-Class, B-Class and CLA-Class vehicles.

The vehicle was dropped off at the garage for regular scheduled maintenance and the service was assigned to an apprentice technician—a capable young man, but he was still rather inexperienced and green. This is common practice for the industry and for good reason; a shop cannot afford to have more experienced certified technicians performing oil services on a regular basis. Unfortunately, many younger techs are only given a few days or maybe a week of training and supervision before being set loose to sink or swim.

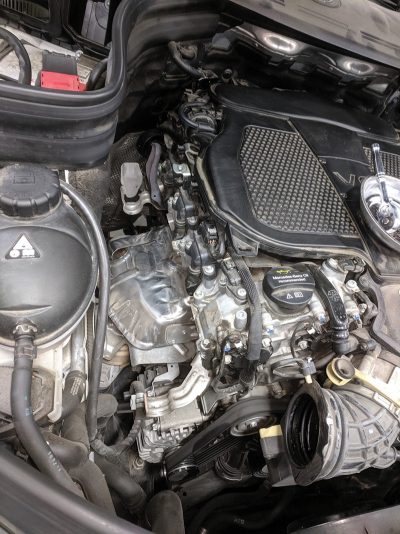

The technician raised the vehicle on the hoist and began draining the oil while performing an inspection of the undercarriage. Once the oil had finished draining the drain plug was tightened, under trays reinstalled and the SUV was lowered to the ground. A new cartridge oil filter was installed and at this point, the technician pulled down the overhead oil reel, reset the fluid counter and began pumping in 5.6 liters of 5w40 oil. After the oil was pumped in, the technician walked over to the oil sticker printer and printed out a windshield sticker. When he returned to the vehicle, he was confused and dismayed to see fresh oil steadily dripping out from under the left side of the vehicle. He quickly raised the vehicle back up and checked the drain plug; it was clean and dry. The engine hadn’t even been started yet and it really wasn’t clear where the oil was dripping from. Further inspection revealed the fresh oil was dripping out of the bottom of the air filter housing.

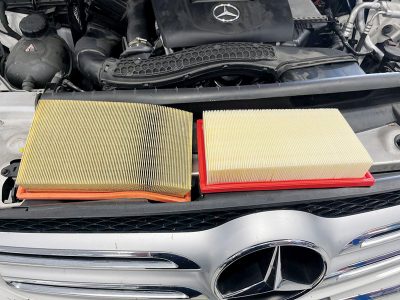

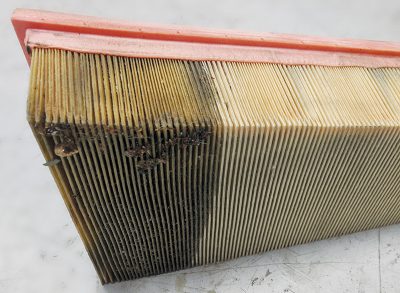

Now the technician was thoroughly confused and asked the foreman to take a look at the vehicle. Removing the air filter confirmed there was significant amount of oil soaking the air filter and pooling in the bottom of the air cleaner. The foreman decided to take a few minutes and read through the service information for this vehicle, and that is where everything became clear.

The Engine Oil and Oil Filter procedure clearly stated “When filling with oil, the engine oil must be poured in slowly. To ensure pressure compensation when the oil is being poured in, the oil dipstick must not be inserted. Backpressure can otherwise occur under the cylinder head cover causing engine oil to be forced along the vent lines to the air intake duct and then to be discharged at the air filter box as well as the exhaust gas turbocharger.”

So where did the technician go wrong? He was unfamiliar with this Mercedes-Benz engine and did not read through the Mercedes-Benz Workshop Information System (WIS) maintenance instructions before beginning the oil change. He had not pulled the dipstick up out of the tube, which as a side note, is good practice for any oil service as it serves as a visual indication that the engine needs oil and should not be started, and he pumped in the oil as fast as the overhead oil gun would pump, resulting in an oil bath air filter and an oil slick under the vehicle. To dig a little deeper, where did the shop go wrong? The shop had not created a standard practice where any time a new vehicle or unfamiliar engine is being serviced or repaired the first step is to consult the factory service information.

The cost of wasted oil at $12 a quart and a new $50 air filter adds up quickly, not to mention the lost production time to figure out what went wrong and to clean up the mess. All of this could have been avoided if the technician had simply read through the Engine Oil and Oil Filter Change procedure.

Air Filters

Air filter replacement is another basic service where costly errors can be made. To start with, a quality OE filter needs to be installed. Some aftermarket filters can adversely affect the air volume and air flow rate coming through the filter, resulting in air mass faults and performance issues. Always use factory air filters, or for price-sensitive customers, consider the Mercedes-Benz StarParts line of maintenance parts (a lower-cost alternative). Ask your dealer about them.

There are several issues to be aware of when replacing air filters on vehicles equipped with turbocharged diesel engines. The turbocharger system introduces additional components like intercoolers, charge air tubes and pressure sensors. Any of the components can cause drivability issues, limp modes and warning lights if not addressed properly. Often times, charge air pipes need to be loosened or even removed to gain access to an air filter. These are usually plastic pipes with clips or clamps holding them in place. Great care needs to be used when dealing with these plastic pipes to ensure they are not damaged. One specific area that needs to be paid close attention to are the charge air pipe seals. These are usually thick rubber seals that are used to seal two air pipes together, or used on the inlet of the turbocharger. Any time a charge air pipe is removed these seals need to be inspected and replaced if there is any sign of damage or deformation. Air leaks at these seals will quickly cause under-boost and air mass faults, but more importantly, a torn seal can damage the turbocharger. Damaged seals can get sucked into the turbocharger and cause catastrophic damage, as shown in the photo of a turbocharger from a Sprinter Van (note the new charge pipe seal which was unfortunately installed too late, after the damage had occurred).

Inspect the charge air pipe seals during every air filter replacement and if there is any question of the integrity of the seals, replace them. This is in the best interest of both the vehicle owner and the repair shop.

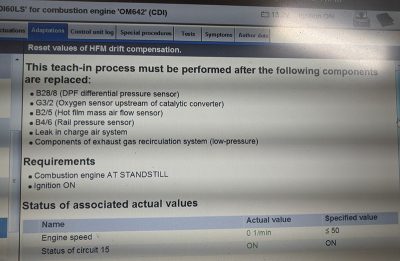

An additional note on air filter service is that some vehicles may require clearing an adaptation or an air filter monitor reset after a filter replacement. This is especially true for diesel engines and engines that use two mass air flow (MAF) sensors. For example, on the BlueTec 3.0 liter turbo diesel engine (OM642), if one of the mass air flow sensors is replaced due to contamination or damage the HFM Drift Compensation must also be performed, or Mass Air Flow faults will set. This is a teach-in procedure that balances the two Hot Film Mass Air Flow sensor signals together so the engine controller can properly interpret the data.

Another point to keep in mind is that when dealing with aftermarket scan tools you can’t always be sure that a reset or service function worked correctly. The option may be in the scan tool software, but there are cases where clicking on the reset button does not carry out the intended function. The best option of course is to use the Mercedes-Benz XENTRY Diagnosis System, but when that is not possible, one needs to test and verify that the scan tool being used correctly performed the reset.

Spark Plugs

Next up is spark plug replacement, which will require veering away from diesel engines back to gasoline powered vehicles. Firstly, do not assume replacement intervals; be sure to check service information for each specific vehicle. The spark plug replacement interval, commonly at 100k miles or more, has been shortened on many of the newer models to 60k or even 45k miles, as in the following case of a 2015 GLK350 that was brought into the repair facility for maintenance just before the odometer hit 50k miles.

The spark plug replacement procedure on this SUV requires the air cleaner assembly be removed on the right bank and the engine control module (N3/10) repositioned to gain access to the left bank. The job has a standard book time of 2.7 hours.

There is a specialty socket for the spark plugs on the 3.5L V6 engine (276.957) installed in this GLK350. The special service tool is a thin walled 14 mm 12 point socket; the Mercedes-Benz part number for the socket is W278 589 00 09 00. Attempting to remove the spark plugs with the incorrect socket can result in the tool becoming lodged in the cylinder head or damage to the spark plug, making it more difficult to remove.

Select the correct spark plugs based on the vehicle application and always use genuine Mercedes-Benz plugs. Many aftermarket spark plugs can cause performance issues, and in some cases, lead to misfires due their electrodes being misaligned. See the March 2021 issue of StarTuned for the details.

Be sure to torque the spark plugs to the correct amount, which is 23 Nm in the case of this GLK350 SUV. Over-torqueing the plugs can weaken or crack the porcelain insulator. This may not cause an issue immediately, but the vehicle will likely be back in a few days or weeks with a misfire complaint.

The final detail of applying spark plug connector grease to the inside of each ignition coil boot can also be found in service information. The grease (part number A 002 989 80 51 09) aids with reinstalling the coil boots and will help prevent damage to the boots when they are removed again at the next service interval.

Batteries

Between AGM and flooded (liquid acid) starter batteries and whether a battery registration is required, there can be a lot of variables when it is time to replace the battery on a Mercedes-Benz.

Many batteries have a 4-digit date code stamped on the negative terminal or on an adhesive label making it easy to determine the age of the battery. Make sure to confirm if the vehicle requires an AGM battery or not before recommending a battery replacement. Misquoting the battery will greatly change the estimate price and installing the incorrect battery type in a vehicle can cause serious issues with the charging, starting and other electrical systems, not to mention vehicle and passenger safety. Also, most batteries have a vent hose that must be reinstalled on the new battery, along with a plug for the vent hole on the other end of the battery cover. Missing this could cause significant corrosion or allow hydrogen gas to reach dangerous levels.

Some battery replacements require a scan tool function to communicate to the engine controller, charging system or other module that a new battery has been installed. This can vary by year and model, so consult service information closely to determine if a battery registration is required. The battery replacement procedure for a 2018 C300 states, “Confirm battery change in front SAM control unit in the Actuations menu item.”

Under a separate heading it goes on to say, “Due to technical modifications in the energy management system, it is essential to reset the charge throughput of the starter battery using XENTRY DAS each time the starter battery is replaced. Replacement of the starter battery is confirmed in the SAM control unit (N10) in the ‘Actuations’ menu item.”

Service Bulletins

Finally, be sure to check for any service bulletins (Known in the XENTRY Portal as Local Information Bulletins or “LIs”) that may affect the specific Mercedes-Benz vehicle being serviced. Bulletins are an excellent resource when faced with an unfamiliar vehicle or problem, and there are plenty of bulletins related to maintenance work and service parts. The LI search feature lets you narrow the list of bulletins to those that are related to the complaint or task at hand.

For example, bulletin LI00.20-P-069865 relates to an error with the ASSYST PLUS active service system, in which the remaining mileage and next service date are incorrect. There is updated software for the instrument cluster to deal with this problem. In a case like this, looking for related technical bulletins could save a technician’s and client’s time when the normal service reminder reset is not working correctly.

Other bulletins make note of specific service parts to be aware of like T-B-54.15/254. This bulletin covers a type of fuse that Mercedes-Benz uses which has silver plated contacts, denoted by the letter “S” after the fuse amperage rating.

There is a great deal of knowledge to be gained by reading through the technical bulletins for the vehicles that come into the shop. Daily workload may not allow for this, but during downtime this is a good practice. A best practice is to scan all the newest bulletins once every couple of weeks.

Vehicle maintenance is as old as the automobile itself, and it is here to stay. Even with the push to full-electric vehicles there will still be service needed for final drive units, battery cooling systems and braking systems. By following factory service information, using OE parts and making sure all their technicians are properly trained a shop can limit costly errors and maintain strong customer relations.

0 Comments