By Tom Nash

One of the hottest subjects in the automotive service industry is the use of nitrogen for filling tires. After initially being touted as the answer to prolonged tire life, safer handling and saving fuel, this service is now being scrutinized by some in the industry.

On one side, there are the manufacturers of nitrogen filling equipment who are promoting the service. On the other hand, some critics say that while it may be fine for large users, it doesn’t make financial sense for small facilities. Still others say that following the proper procedures for tire installation, maintenance and care with plain old air is just as relevant as ever.

The question we address here: Is nitrogen tire filling a good addition to your business, or is proper tire care and routine pressure inspection with air enough to outweigh the purchase and maintenance of an N2 program?

Of course, armed with a little knowledge and investigating the options on your own is the best way to make that decision.

The nitrogen system equipment manufacturing companies, many of whom have been providing nitrogen systems to the aviation, over-the-road, military and construction industries for years, are now seeking to make N2 the standard for the automotive industry.

Certainly, they are convinced that nitrogen is the wave of the future for cars and light trucks, based on their success in those other industries, and so are enthusiastically promoting their product as the answer to better, longer-lasting and safer tire inflation. They are excited about the prospect and are seeking market growth. There’s nothing wrong with that. But, problems can arise when the benefits are exaggerated and the value overstated, either by the equipment manufacturers or the repair facility. More on that later….

The key to proper tire inflation and the tire’s ability to keep pressure lies in more than just blowing nitrogen or air into a tire. The right tire for the vehicle must be installed, plus the mounting and balancing must be performed correctly. The air (or nitrogen) must be dry and filled to the correct pressure; the valve stems must be seated and sealed correctly and the valves must be tightened properly and free of debris. If any of these standards are not met, it doesn’t matter whether there’s air, nitrogen, oxygen or spaghetti sauce inside the tires.

Who’s Using Nitrogen — and Why?

Nitrogen has been used to fill tires in the trucking, construction, military and fleet industries for several years. The main reason has been the durability of tires (we’re not talking 75-buck rubber here!), but also for safety and better mileage. The cost savings of the huge number of vehicles, tires and fuel — plus the insurance premium savings — can add up to some pretty hefty figures.

The aviation industry has used N2 in planes for safety, durability and reliability under extreme temperature variations. The tires on a passenger jet flying at 30,000 ft. may be exposed to temps of -30 deg. F., then have to land on a scorching 130 deg. F. tarmac runway. There’s just no tolerance allowed for under-inflated tires in such situations.

NASCAR uses bottled N2 for convenience — as does the Formula 1 Series— for safety, durability, fire retardation (N2 doesn’t fuel combustion like the oxygen in air does) and reliability under temperature extremes.

Recently, many chain service facilities (mostly tire stores) have chosen to use N2 for tire filling. Oddly, their business is to replace worn tires, but the service fees for N2 filling and the customer’s need to return for check-ups, rather than go elsewhere, helps increase the facility’s bottom line. Customers returning for tire inspections and rotations can also be made aware of any other needed services.

Some new car dealerships, many of whom sell high-end vehicles equipped with Tire Pressure Monitoring Systems (TPMS), are making it available to their customers as a way to help avoid generating TPMS diagnostic trouble codes, which — in some models — may put the vehicle into a “limp home†mode. It also adds a touch of high technology to the service experience.

Nitrogen Generation

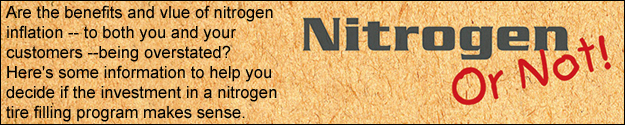

A nitrogen generator contains many hollow fiber tubes lined with a special membrane that allows the smaller oxygen molecules and other gases to escape, but the larger nitrogen molecules travel through to a holding tank (courtesy Get Nitrogen Institute).

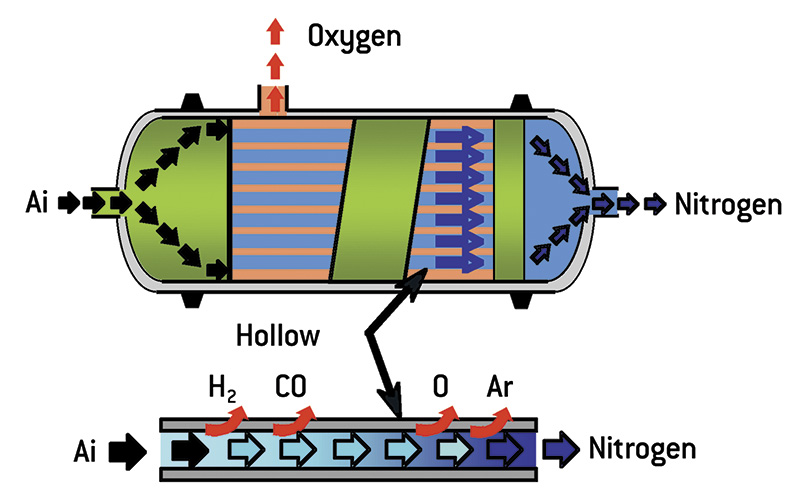

Nitrogen makes up 78% of the air we breathe. At 21%, oxygen is the second most common element in air. Together, they make up about 99% of the air, the rest being small amounts of other gases. Nitrogen molecules are larger than those of oxygen. It’s a fact that the smaller molecules of oxygen permeate tire material more easily and cause faster degradation of the tire structure.

N2 tire filling systems extract the nitrogen from the shop’s compressed air via a special membrane that allows the smaller oxygen molecules and other gases to pass through, but traps the larger nitrogen molecules. This process is called membrane permeation. The pure — or nearly pure — nitrogen is then stored in a tank for use.

N2 Equipment

There are different types, sizes and capabilities of nitrogen filling systems. Large, stationary units are used in mass service facilities, such as fleet shops and high-volume car and light truck dealers. Smaller systems – which won’t be used constantly – may prove more sensible for independent repair shops.

With a need to fill dozens of tires each day, tire stores require N2 units with large storage tanks and multiple hoses.

Among the companies offering the large systems is Parker Hannifin Corporation. It has been manufacturing N2 systems for over 20 years and claims to have sold over 10,000 units. It also offers portable units for fleet road service.

Branick Industries is another major supplier to the tire industry. It offers several sizes and styles of stationary and portable N2 units, The company has supplied the nearly 500 Costco Tire Stores.

Portable units with lower capacities may be best suited for the average independent repair shop (courtesy RTI).

Champion, well known for compressors, is also player in the mass service arena. The company currently makes three sizes of N2 units, ranging from light to medium-duty use.

These three companies are part of, and are endorsed by, the “Get Nitrogen Institute,†an association formed to promote the use of N2 in passenger cars and light trucks. A spokesman for the industry informs MT that more manufactures may join soon.

Ingersoll-Rand also makes larger systems suitable for fleet/tire store use. Models vary by the size of storage tanks and the number of hose outlets.

Other companies make smaller units for independent shops, dealers and tire facilities. RTI Technologies, makers of A/C handling, fluid exchange equipment, etc., offers N2 units for dealer/fleet use, as well as smaller units for independent shops.

Vacula Automotive Products offers stationary and portable models ranging from light- to heavy-duty.

Many other companies that make and sell equipment for the aftermarket are offering N2 systems, and still others are testing the waters. Several should have systems available soon. Look for the jobber trucks (Snap-on, Matco and Mac Tools) to offer such equipment eventually.

With any unit, the price will vary by tank capacity and included accessories. Prices range from $3,500 to $7,000 for light/medium duty units, while systems suitable for fleets and large tires stores may reach $15,000.

The key to getting the best bang for your buck is choosing a durable, quality-built unit that is easily serviceable and has good parts availability. Beware of companies that aren’t well known in the industry. Any hot piece of equipment is going to have new companies trying to get on the bandwagon to make money. Thoroughly research any N2 systems you are considering and ask for references from other shops that are using the product. Ask about warranties and after-sale service. Best advice: Stick with the names you know.

What’s the Real Value?

So what’s the truth about the benefits of nitrogen tire filling, and what’s also true of plain air?

Nitrogen molecules, being larger than air molecules, leak out of tires three to four times more slowly than air (courtesy RTI).

The real benefit of nitrogen filling can be best described as “stabilization of inflation.†If the tires have no defect or damage that could result in deflation and are properly mounted and sealed, nitrogen filling can give better results than plain air. Among these are:

- Slower loss of pressure. Because pure nitrogen molecules are larger than those of air, leakage or permeation of tire materials is three to four times slower.

- Better resistance to temperature changes than air, which contracts and expands more under heat variances.

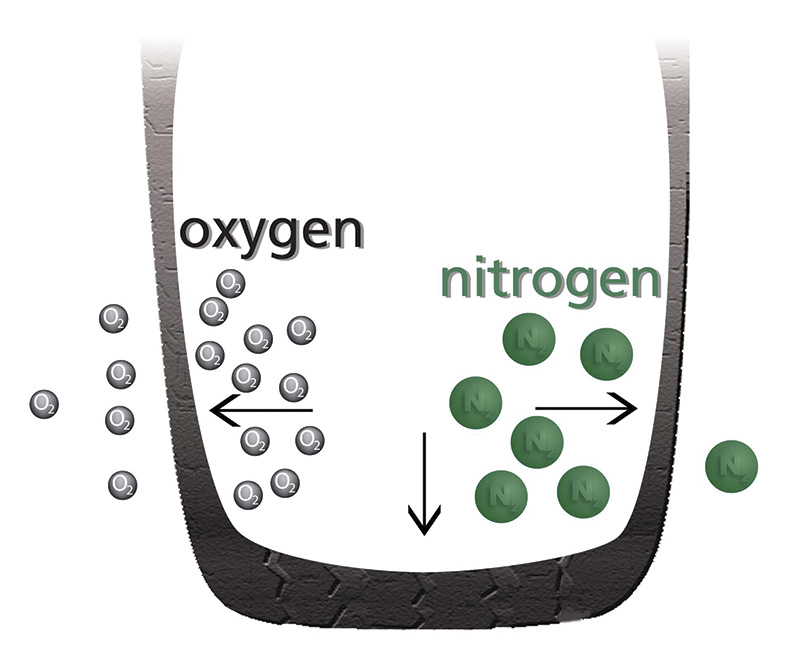

- Less corrosion of wheel interiors. Nitrogen not only does not promote oxidation, it’s also dryer than air.

- Fewer valve stem leaks due to rim corrosion.

Many of the features touted about nitrogen use, however, are just as applicable to plain air — again assuming that the tires are in excellent shape, properly mounted, sealed and inflated:

- Safer handling and braking. Proper inflation means a better “footprint†to present the correct, engineered-in contact area to the road surface.

- Better mileage than experienced with improperly inflated tires.

- Longer tire life.

- Fewer TPMS false alarms.

Small bits of corrosion from wheels can prevent valves from seating properly, leading to loss of tire pressure. Unlike air, nitrogen doesn’t carry moisture or promote oxidation (courtesy of Get Nitrogen Institute).

Getting Into the N2 Business

First, you must have clean, dry air. The presence of excess water or oil in the shop air system will cause problems for the N2 generator membrane, leading to sooner-than-expected replacement. Before buying an N2 unit, make sure your shop air system is in good shape.

A nitrogen purity tester can quickly and accurately read the composition of what a tire contains to determine if air has been accidentally added (courtesy of RTI).

You’ll need:

- A nitrogen generator with storage tank.

- Training for sales and service personnel. Your staff must be familiar enough with the situation to speak intelligently with customers and answer their questions accurately.

- A warranty on the unit. Most equipment companies offer a warranty on both the equipment and the membrane.

- A service program on the equipment. Make sure you can get quality service performed quickly.

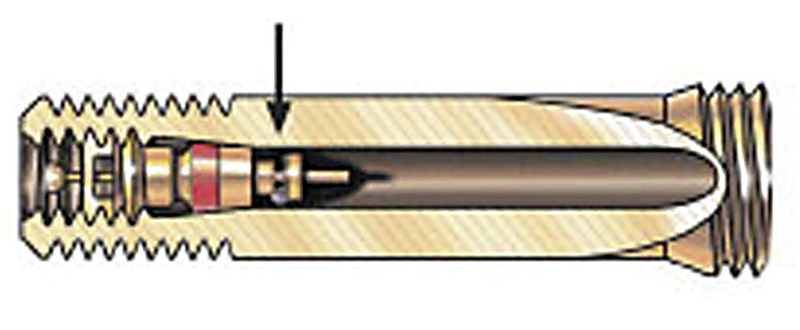

Accurate tightening of the valve core is critical to maintaining proper tire inflation, which is especially critical with TPMS (courtesy of Vacula).

These nice N2 valve stem caps (or, cheap green plastic) clearly indicate the content of the tire to help avoid accidental contamination (courtesy RTI).

If you purchase a nitrogen generator unit, you should also have the following:

- An N2 purity tester. These devices quickly and accurately measure the nitrogen content of the tire fill. This is important to determine if air has been added. Tires that vary in N2 percentage will react differently under temperature and driving conditions. TPMS systems will read these differences and store a code if the variance is severe.

- A valve stem torque wrench. Doesn’t sound important? Think again. Proper valve stem torque is critical to TPMS systems. New torque standards have recently been issued by the Tire and Rim Association (TRA), changing from 1.5- 4 in.-lbs to 3-5 in.-lbs. These tools are calibrated for accurate tightening. Vacula Automotive Products makes a good one. Others may be available from your suppliers.

- Customer information, signs and point-of-sale brochures. To interest, educate and initially inform customers, there’s nothing like good old POS brochures.

- Green hose. All units come with hoses, but reaching away from the unit requires an extension hose. A green-colored hose — usually available from the equipment maker or hose reel makers – indicates the N2 application. Do not mix with other hoses in the shop, as contamination may occur in tires.

- N2 valve stem caps. It’s really important to install valve stem caps that indicate the tire is filled with nitrogen to avoid having the customer or any service facility adding air. Caps are usually available from the equipment makers at low cost.

- Tire Check Reminder Stickers. Just like oil change stickers, these are invaluable for reminding customers to return for a check of their tires.

What to Charge

Typically, tire stores and OE dealers don’t charge for N2 filling in new tire purchases, but may for refills and definitely do for fill exchange service in tires that have been on the road for a while. Independent shops need to price the service to cover the cost of the equipment and labor, which is typically from $4.00 to $10.00 per tire. You should check what your competition is charging and then decide on price.

No Specific Promises

As mentioned earlier, some equipment manufacturers, service facilities and tire stores are making claims that with nitrogen the tires will last a certain number of miles longer, or that the customer will gain a certain number of mpg. Don’t put yourself in the position of having to defend promises of improved mileage.

Customers can be pretty shrewd. If you promise better mileage from N2-filled tires without explaining how the mileage is gained, someone will surely track his mileage and return with a complaint if his expectations (based on what you promised him) aren’t realized. Never state a certain number of miles per gallon – only “better†mileage. The same thing goes for handling and tire wear. Truly, all other factors being equal — rim seal, balancing, valve stem seating, valve tightness and pressure — the tire will remain inflated to the proper psi longer and the overall results will be better. Customers need to be told about all the variables that affect tire inflation, and that nitrogen also leaks out of tires – but at a much slower rate.

Don’t make promises for conditions that are out of your control. The customer has a responsibility to monitor the tires after leaving your shop — or at least to return so you can inspect them.

Lastly, never, ever, tell a customer that a dangerous handling or braking situation could occur if N2 isn’t used. Scare tactics for selling brake work and other automotive repair went out the window when the State Attorneys General agreed to prosecute such practices. You are much better off to educate the customer about the benefits of N2 with brochures and by answering their questions honestly. You don’t need an angry customer or bad publicity.

The choice to purchase nitrogen tire filling equipment — like any other major purchase — is a serious one. We hope we’ve offered a bit of information to help you on your way to making your choice.

Some Websites for Nitrogen Tire Filling Information:

Get Nitrogen Institute: www.getnitrogen.org

Parker- Hannifin: https://www.parker.com/

Branick: www.branick.com

Champion (division of Gardner Denver):Â www.gardnerdenver.com

Ingersoll-Rand: www.irtools.com

RTI Industries: www.rtitech.com

Vacula Automotive Products: www.vacula.com

0 Comments