by Steve Campbell

Most modern kits are designed to be bolt-on or clamp-on, but welding the joints provides the optimum seal and durability.

Most full-service shops can easily handle exhaust replacements. The task commonly requires only basic hand tools, although a lift, an air chisel and a torch obviously make the job easier. But a vehicle that needs new mufflers and pipes anyway is the perfect candidate for a performance upgrade—and practically every vehicle on the road today stands to benefit from the change, bringing diversity and broader service options to mainstream customers.

“Recent research indicates that performance exhaust systems remain one of the top-selling products in the performance category,†says Marc Cloutier, sales and marketing manager for MBRP Inc., a leading manufacturer of performance exhaust products. “Shop owners who offer these products and accessories are positioning themselves to meet consumer demand. The benefits include increasing revenue and creating a larger customer base as well as expanding knowledge and expertise about the products in this category and how they can uniquely meet the needs of a customer.â€

In fact, the most difficult element of the entire procedure is likely to be removing the old system, as most technicians know. “If you get a vehicle in that is 20 years old and has a buildup of rust and corrosion, the removal of the old system is going to take a while,†says Scott Stutler, national sales manager for DynoMax. “Once that’s out of the way, though, the installation of the aftermarket system is basically just sliding in replacement parts and is pretty quick. All of our kits are designed to be easy for a do-it-yourselfer, so they are bolt-on or clamp-on kits. I recommend welding the joints for best results, but they’re going to hold up just fine with what comes in the box.â€

Being able to articulate the improvements available through a performance exhaust system may be the most effective sales tool at the shop’s disposal. Customers who understand the longevity and durability benefits first may see horsepower gains as a bonus, and those who appreciate increased drivability as well as enhanced appearance should be aware that a better-breathing exhaust is one of the most effective steps in the

performance progression.

Exhaust replacement commonly requires only basic hand tools, though a lift obviously makes the job easier. But a vehicle that needs new mufflers and pipes anyway is the perfect candidate for a performance upgrade.

According to Lawson Mollica, marketing manager for AEM/DC Sports, the points to emphasize when discussing performance exhaust options are proper engineering and manufacturing standards. “The systems are tuned specifically for a given application to reduce restriction and increase performance,†he explains, “And the exhaust is manufactured from material that is superior to OEM exhaust material. The sound of the exhaust note is improved, and the systems improve vehicle looks through polished canisters and stylish exhaust tips.â€

O.E. mufflers are designed for an average consumer, so the focus is on sound reduction rather than performance. Most original-equipment mufflers utilize baffles and chambers to quiet the exhaust, and the spent gases must flow through this maze inside the muffler before finally exiting at the back of the vehicle. Most specialty-equipment manufacturers use more advanced technologies to not only control sound volume, but also reduce backpressure. Freeing up exhaust flow is a key to increasing engine performance.

Performance systems are designed for specific applications. They reduce backpressure for increased performance while providing a tuned exhaust note.

MagnaFlow Performance Exhaust, for instance, designed its muffler to utilize a straight-through stainless core that contains tiny perforations. “The exhaust gases pass directly through the muffler without slowing, allowing a reduction in backpressure,†says Tanya Jacquot, PR/media relations manager for Magnaflow. “The perforations in the core allow the sound to be absorbed by the special sound-absorbent packing in the muffler. This packing will not deteriorate over time like the fiberglass of years past and actually hardens when heated to last a lifetime. MagnaFlow’s stainless-steel mufflers and cat-back systems use high-quality materials, are manufactured to ISO standards and are all backed by a lifetime warranty.â€

Flowmaster, another of the major names in performance exhaust, touts its directional-flow muffler design. “Our product was patented 25 years ago next year on sound-cancellation physics,†explains Phil Smith, technical service and product specialist for Flowmaster. “There is no packing material or artificial fillers. We utilize the sound energy—the pressure waves, frequencies and sound waves—to extract the exhaust, and that really sets us apart in the industry.â€

Where original equipment exhaust systems are designed mainly to attenuate sound and keep high-volume costs in check, performance systems utilize materials, engineering and manufacturing processes that produce optimum flow.

Design differences notwithstanding, stainless steel has become the material of choice among many performance exhaust manufacturers, but there are various grades of stainless used, each with benefits and drawbacks. “For example, T304 stainless steel provides true rust-proof qualities perfect for customers looking for show quality, or who just want the best of the best,†Cloutier says. “T409 stainless steel is one of the most common material grades used due to its ability to resist rusting. Though it will display surface rusting, it will last for an extremely long time without rusting through. Finally, there is mild steel, usually coated with some rust-inhibiting product, most commonly a mixture of aluminum and silica. Unfortunately, when that coating is chipped or scratched, the exposed mild steel will begin to rust. This may be satisfactory for customers who do not require a system to last beyond two or three years.â€

“A system that uses mild-steel piping coupled with a stainless exhaust may cost less than a full stainless-steel system,†Mollica adds, “But the customer should be made aware that the corrosion properties of a mild steel system are not as good, so it will not last as long.â€

Manufacturing methods are equally important to how an exhaust system functions. While cost reduction and noise abatement are primary concerns for the designers of stock exhaust, maximizing flow is critical for performance products.

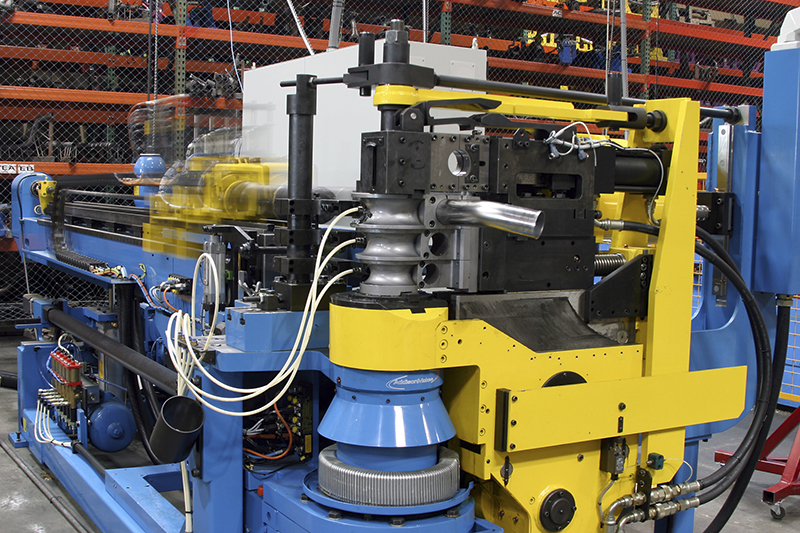

“The crush-bent tubing in most O.E. exhaust systems is restrictive because that method actually crushes or ovalizes the pipe at the bend, resulting in a 20% size reduction and reduced exhaust flow,†says Jacquot. “We use only mandrel-bent tubing in our cat-back systems. Mandrel-bent tubing is bent from the inside, allowing the tubing to maintain its shape throughout the bend and preserving the flow.â€

Modern performance exhaust systems are manufactured from materials that are, in most cases, superior to O.E.M. materials. The result is greater durability and longevity in addition to better appearance.

Performance exhaust manufacturers also concentrate on maintaining pipe diameter to optimize flow. “Many exhaust systems have variable pipe diameter, especially in the muffler,†Cloutier explains. “Larger-diameter pipe assists in more rapid release of hot exhaust gases, but where that diameter changes, exhaust flow is constricted. Straight-through mufflers are designed to maximize exhaust flow compared with stock baffle-muffler designs that are more focused on sound attenuation.â€

Sound is a point of pride with many performance enthusiasts, some of whom search extensively for just the right exhaust tone. To that end, several manufacturers offer exhaust-note samples in the form of MP3 or other electronic files on their web sites. On the other hand, exhaust noise has come under the scrutiny of many states’ legislators, who have attempted to regulate the matter with varying degrees of success. The Specialty Equipment Market Association (SEMA) has devoted significant time and effort to ensuring that such legislation is fair and not based solely on the subjective opinion of a law-enforcement officer on the street. The association has offered wording for legislation that a number of states have adopted. In part, it says that “…no person shall modify the exhaust system of a motor vehicle in a manner so that the exhaust system emits in excess of 95 decibels as measured by the Society Of Automotive Engineers Standard J1169 (May 1998).†Consumers should be made aware of local ordinances regarding exhaust noise, and their preferences for noise versus performance gains should be a crucial element in determining a proper system.

Much has also been made of potential fuel-economy gains that may result from the replacement of an O.E. exhaust with a performance system. While most experts agree that performance exhaust may indeed have the potential to improve fuel economy, human nature might be a mitigating factor.

“The reality is that individual driving styles and even the terrain that is covered—as well as weather and temperatures, too, for that matter—can affect average fuel economy no matter what system is on the vehicle,†says Ed “Blake†Burgy, automotive product manager for Corsa Exhaust. “If the customer has a ‘heavy foot’ while enjoying the new sound and performance of his exhaust system, his fuel economy might even go down.† It’s probably best, therefore, to minimize the expectation of better economy rather than later trying to explain to a customer that he’s been having too much fun.

Manufacturing processes also ensure a better-quality product. Mandrel bending, in which the curve is formed using internal pressure rather than external crushing, provides better flow characteristics by eliminating diameter reduction.

Some consumers also worry that the addition of a performance exhaust might create problems with emissions or computer equipment. In the case of cat-back performance systems, however, there is little chance that a problem might occur.

“The computers are so sophisticated today that they should be able to adjust themselves,†said Flowmaster’s Smith. “There are times when some vehicles with earlier computers can be a little slow, where you might have to disconnect the battery cables and leave them off for a period of time and then reinstall them to give the computer a fresh start. But in most instances, there shouldn’t be any kind of additional tuning or outlay of expense for someone to adjust the computer.â€

If the factory catalyst and/or any associated sensors are moved or modified, however, there is a risk to the vehicle’s performance that may compromise the factory warranty, says Jason Snyder, national sales manager for Edelbrock Corp. “Otherwise, your rights as a consumer allow you to install aftermarket specialty and replacement parts,†he explains, noting that SEMA’s web site offers insight into consumer rights (see www.sema.org/warranty). “SEMA does a great job of explaining the Magnuson-Moss Warranty Act, which gives consumers protection against warranty denial due to the installation of an aftermarket component,†Snyder said.

Every manufacturer we spoke with offered the same basic advice: Read the instructions that come with the kit and make an inventory of the parts to be sure that nothing is missing to deliver a well-executed installation.

Installation of performance systems is a straightforward process, but every manufacturer we spoke with offered the same basic advice: Read the instructions that come with the kit and make an inventory of the parts to be sure that nothing is missing. Most also recommended that kits be installed from front to back, keeping clamps and fasteners slightly loose to allow parts to be maneuvered into position prior to final tightening. A multi-purpose spray lubricant can be helpful in adjusting hangers in their rubber isolators, and a Sawzall or chain cutter may come in handy when removing a particularly corroded or rusted original system. As noted earlier, some also recommend welding joints to ensure the best possible seal, or at least having the customer return two or three days after the installation to allow the technician to check that nothing has loosened or slipped out of alignment. That extra service can build customer confidence as well as ensure a return visit.

Indeed, upgrading exhaust can be a shop’s primary step in becoming involved with a wide range of performance equipment. As customers learn about and become comfortable with the abundant possibilities, they may be encouraged to opt for other modifications.

“Performance exhaust is an excellent segue for any shop to get into the performance market because there are so many up-sell opportunities,†says Stutler. “The consumer’s top three performance-enhancing modifications are an air intake, computer tuning and performance exhaust. Any shop should be selling those three together. But intakes and tuners are just one piece of that. If a guy can install a performance exhaust system, he can install a tonneau cover, a set of side bars, a brush guard or even a set of window vent visors. To take it a step further, he could certainly upsell a set of headers as an added performance benefit to go with a cat-back exhaust. He could also get into interior accessories.â€

Virtually any type of car or truck—gas- or diesel-powered, naturally aspirated or forced induction, carbureted or fuel injected—can benefit from a performance exhaust system.

High-quality point-of-sale displays can encourage the customer to ask the shop salespeople for information about performance products. Shops should take advantage of these types of materials when they are available from manufacturers.

All of the manufacturers also agreed that carrying a basic exhaust inventory is a smart idea. Because consumers tend to upgrade on impulse after finding that they need to replace a rusted or damaged O.E. system, it’s best to have on hand at least those components that can be used on the shop’s most common vehicle mix. Most of the manufacturers also offer an assortment of point-of-sale displays ranging from simple brochures to more complex panel and stand-up exhibits that may be set up in a shop’s showroom or waiting area.

“These point-of-sale displays are high-quality pieces that are designed to be silent salesmen and encourage the customer to ask the shop salespeople for the additional information they need to make their buying decision,†says Burgy.

Even with such promotional materials available, however, the counterperson, technician or sales team has the greatest potential for educating customers to the benefits of upgrading an exhaust system.

“Always take the time to ask the customer a few questions about the vehicle and what they want to achieve by purchasing a system,†Cloutier advises. “By identifying the major goals of the customer and the primary applications of the vehicle, the shop owner is in a position to make an educated recommendation regarding exhaust and any additional accessories or other performance systems that might serve to meet the goals. By doing so, the shop owner enhances the customer experience and increases revenue potential. Improving the customer experience keeps customers coming back. This allows the shop owner to grow those relationships, increasing opportunities for future sales and opportunities for referrals from happy customers.â€

0 Comments