Catalytic converters have been all over the news lately, but not because of the fact that they are incredible devices that can literally change the molecules of the exhaust gases and convert toxins into less harmful byproducts, such as water vapor (steam) and carbon dioxide.

Catalytic converters have been in the news lately because all around the world they are getting stolen at an alarming rate.

The wave of thefts around the U.S. and in many countries around the world has increased, mainly because of the price of the precious metals that are used in the modern three-way catalyst.

Metals that are most commonly used in converters are platinum (Pt), palladium (Pd) and rhodium (Rh).

The current price of rhodium is the main reason that they are so sought after by thieves around the world.

Converter theft is not very common when it comes to Volvos, though, because later Volvos have most of their catalysts installed up near, or as part of, the exhaust manifold. This makes them very difficult to remove from the car without a lift and some special tools.

Testing

Accurate testing is very important when condemning a Volvo catalytic converter because it can be easy to misdiagnose and you could unnecessarily replace a very expensive part or parts. Just because the car stored a code PO420 or PO430 does not mean it’s time to replace the cats.

There are a lot of different methods and schools of thought out there on converter testing; some testing methods are more accurate than others, depending on who you ask.

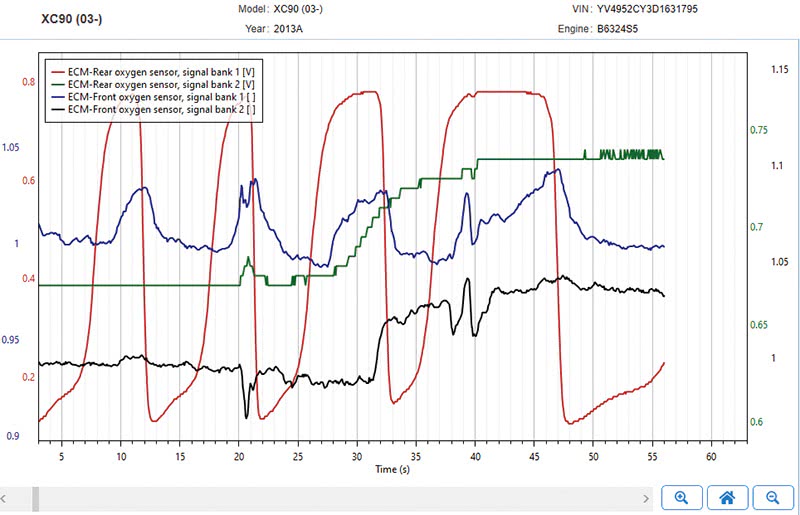

Here is how most Volvos perform self diagnostics on their catalytic converters…

Three-Way Catalytic Converter (TWC) Diagnosis

The three-way catalytic converter stores oxygen from the exhaust gases and uses it to make toxic gases more environmentally friendly. The catalytic converter is a three-way converter in which HC (hydrocarbons) and CO (carbon monoxide) are oxidized and NOx (nitrous oxide) is reduced.

As the three-way catalytic converter ages, its ability to store oxygen is reduced. The conversion capacity of the three-way catalytic converter is reduced and unburned residue is released. To reduce the environmentally damaging emissions, the Engine Control Module (ECM) checks the efficiency of the three-way catalytic converter. In brief, this check is carried out as follows:

To be able to check the catalytic converter, two sensors are used.

One heated oxygen sensor is located in front of the catalytic converter in the engine compartment (front heated oxygen sensor), and a heated oxygen sensor is located after the catalytic converter in the engine compartment (rear heated oxygen sensor).

After the rear heated oxygen sensor, there is another catalytic converter located at the front end of the propeller shaft tunnel under the vehicle’s floor. However, this catalytic converter is not monitored.

The main function of the heated oxygen sensors is to measure the oxygen content in the exhaust so that the engine control module can maintain the fuel/air mixture at around lambda=1. This mixture allows for optimum catalytic conversion.

To evaluate the efficiency of the three-way catalytic converter, one uses a deviation added to the lambda signal.

In practice this means that catalytic converter diagnosis starts within 20 minutes after engine start (time varies depending on market).

The process is as follows:

A deviation is added to the lambda signal and the engine control module is allowed to correct this.

The deviation switches between positive and negative values so that the fuel/air mixture switches between rich and lean.

A counter registers the number of switches occurring while the diagnosis is taking place.

If the center and rear heated oxygen sensors register a large number of switches exceeding a parameter, a diagnostic trouble code for catalytic converter efficiency will be stored.

If the parameter is not exceeded, the three-way catalytic converter is deemed to be operating properly.

The costs of new catalytic converters these days are steep and getting steeper, so accurate testing is critical, because you don’t want to be the technician that recommends cat replacement to “fix” a customer issue and a few weeks later and a few thousand dollars later, the customer comes back into the shop with the same problem.

Don’t be “that guy,” you know, the technician that gets out a generic scan tool to check for codes stored in the ECM and any time the infamous PO420 code comes up, they automatically sell their customer a new catalytic converter.

Volvo’s Diagnostic Trouble Code Information For ECM-P042000

Condition: The ECM checks the efficiency of catalytic converter (bank 1) by switching between rich and lean fuel/air mixture. When the changeover is made, the signal from the rear heated oxygen sensor (HOâ‚‚S) is checked and the time taken for the probe to switch is noted.

The DTC is stored if the ECM registers that the rear heated oxygen sensor (HOâ‚‚S) switches too quickly, and this is interpreted as poor catalytic converter efficiency.

The diagnostic trouble code can be diagnosed with the engine at operating temperature, approximately 15 minutes after the engine has first been started if the vehicle is driven (normal road load) at about 45-55 mph for 30-40 seconds.

Substitute value

- Nothing

Possible source

- Air leak in the exhaust system

- Damaged front heated oxygen sensor (bank 1)

- Damaged front catalytic converter (bank 1)

In a perfect world, where your customers’ cars are meticulously maintained and repairs are done as soon as they are needed, the catalytic converter should last for the life of the vehicle.

Of course, we don’t live in a perfect world and a lot of customers are not the best at staying on top of their car’s service needs.

How many times has one of your customers come into the shop with an illuminated Check Engine light, and when asked how long it has been on, they say something like, “I don’t know,” or the ever popular “a few weeks,” which often translates to “over a month.”

The standard OBD II fault code setting parameters most ECM trouble codes are anything that can cause the car to emit 1 ½ times the acceptable tail pipe emissions for that car’s year and engine size.

What can out of control fuel trim or unregulated emissions do to the average catalytic converter?

Well, it usually depend on how much and how long the problem is ignored by the driver.

Volvo catalytic converters are engineered to reduce exhaust emissions for the life of the vehicle and should perform well even when the car has passed the 100K mile mark.

The care and feeding of your customer’s Volvo is very important to the lifespan of their car’s catalytic converters.

How Many Miles Should a Catalytic Converter Last? 50K? 100K? 200K?

This is probably a very popular question among customers that are facing the cost of catalytic converter replacement at your shop.

The best way to answer this question is to say, “It depends.” The failure of the catalyst has very little to do with mileage and more to do with the way the car was serviced and repaired, or not repaired, in a lot of cases.

The most common cause of premature cat failure is due to ignition misfires, poor fuel control, or fuel, oil, or coolant contamination.

Excess heat, unburned fuel, and excess oxygen all can damage the cat in a very short time.

Also, in rare cases, the cat’s substrate can be damaged by impact from the customer going off road or the exhaust hitting something like a speed bump.

In the case of impact, you can usually hear the broken pieces of the converter’s substrate rattling around inside.

Have You Ever Seen Early Volvo Catalytic Converter No Code Failure Diagnosis (1998-2000 Volvo S/V/C/XC 70 Series)?

Yes, there are more than a few of these cars left on the road today.

You may still run into one of these early Volvos with this problem, especially if your shop is in a state that requires enhanced emissions testing.

In states like California, the standard smog test includes checking the car’s ECM to see if all or most of the emissions monitors have been completed.

As most technicians know, it can be difficult to perform the correct drive cycles to run all the monitors, especially in cities with a lot of traffic.

These early Volvos can be extremely difficult to clear all the emissions monitors in the ECM, unless you have access to a closed race track for two days straight.

But in some cases these 1998—2000 Volvo S/V/C 70 models can be almost impossible to set the monitors on.

Most likely, when you get one of these cars in your shop and check to see what monitors have run after hundreds of miles driven by your customer and maybe you, you will see that all monitors have run, except for the one for the oxygen sensor and the one for the catalyst.

And guess what? There are no stored trouble codes and no pending codes stored for either the Oâ‚‚ sensors or the cat.

The reason is the order in which this series of Volvo runs its emissions monitors and the setting criteria for the trouble codes for this car’s catalytic converter.

Yes, you could drive one of these Volvos to the moon and back and probably never get that cat monitor to run.

So if you get a 1998—2000 Volvo S/V/C 70 in your shop that has no Check Engine light on, no stored pending codes or freeze data that just won’t complete the monitors for the cat or the O₂ sensors, try the following:

Run the engine up to operating temp with a scan tool connected and monitor the front and rear oxygen sensors.

You can also use an oscilloscope to graph the sensor readings for a better comparison.

Hook up a scan tool like VIDA and bring up live data for the front and rear Oâ‚‚ sensors.

Start the engine and run the engine until the car reaches operating temperature.

Rev the engine up to 2,500 rpm. You can do this in the shop with the transmission in Park.

In most cases, you will see that the front and rear Oâ‚‚ sensors are mirroring each other even though the car will not set a cat efficiency code. Yes, this car needs a new catalytic converter.

Once the cat is replaced, guess what? This car that your customer or you have been spending way too much time driving to set monitors will easily complete all the emission monitors in two trips.

Case Study: Common Volvo Catalytic Converter Misdiagnosis (2007-2013 Volvos With 3.2L N/A Engines) XC90/S80/V70/XC70

Which came first, the chicken or the egg?

This age-old question is meant to make you think of the possibilities. Well, when it comes to Volvo catalytic converter diagnostics, keep this old question in mind.

There have been a lot of these Volvos that have had their cats replaced unnecessarily due to rushed diagnostic procedures along with the ever popular “jumping to conclusions.”

Volvos can be daunting for the technician that only works on Volvos once in a blue moon, especially if they only have access to generic scan tools and generic repair information.

You may have had one of these Volvos come through your shop, usually because the Check Engine light has come on.

These cars usually seem to not display any other issues for the customer other than the dash warning light being illuminated.

In the case of the Volvos in this case study, the ECM will usually store a Catalyst Efficiency code like PO420 or PO430.

Some shops will see a car with these codes that has over 100K on it and automatically assume that the catalytic converter or converters are “worn out.”

Possibly, but this is not always the case; testing is needed to determine the real cause of these codes.

What tests do you prefer?

The old faithful test for most technicians is the standard comparison of the upstream and downstream oxygen sensor signals to see if the sensors are mirroring each other.

In most cases this test is effective, but could a damaged, shorted, contaminated sensor give a false reading? You bet!

False signals are a common cause of “jumping to conclusions.”

Before condemning a cat, make sure to do the proper testing.

Think Outside the Box

Here are some examples of some newer tools that can be useful when diagnosing catalyst problems.

FLIR or Forward Imaging InfraRed

The use of thermal imagining is a relatively new tool in the modern technician’s arsenal of testing equipment.

If you are one of those technicians that likes to test the temperature difference between the inlet and the outlet of a catalytic converter to see how it’s performing using a direct or indirect thermometer, try using a FLIR gun or FLIR camera attachment for your phone.

Using FLIR you will be able to see the catalyst warm up and be able to capture the image of the cat to compare to other similar cars that are performing normally.

Using thermal imaging is not an exact science, but the more you use it, the better you will be able to easily spot potential problems.

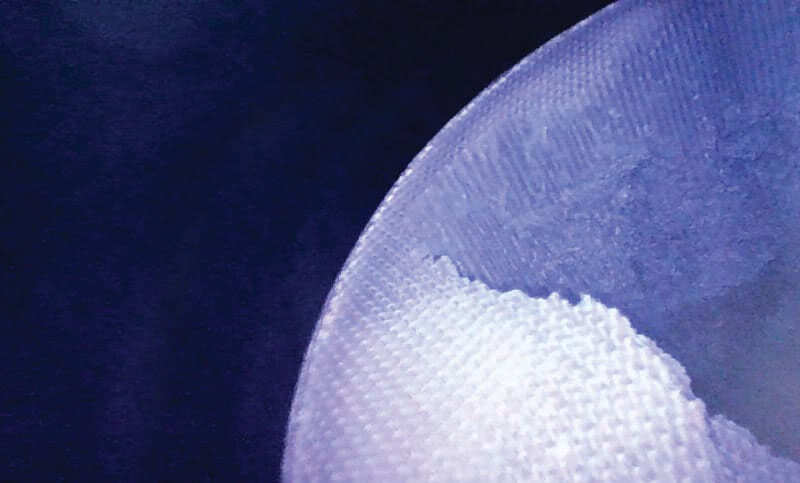

In the old days, the only way to see if the inside of a catalytic converter was physically damaged was to unbolt it and use a flashlight to peek inside, and that’s not possible if the cat had a long pipe on one or both ends.

In some cases, you might be able to see part of the stratus of the cat by removing one of the oxygen sensors and peering through the hole.

Both of these methods take time and can have mixed results.

But luckily for the modern automobile technician, there is a better option.

Endoscopic cameras used to be only used in hospitals and they used to be very expensive. But today you can get a decent endoscopic inspection camera that uses your cell phone as the display for about $20.

Of course, you get what you pay for with tools, but you don’t have to spend a lot to get a good, clear look inside tight spaces like a combustion chamber or a catalytic converter housing.

You can usually remove an oxygen sensor and fish the camera probe all the way to the face of the catalytic converter’s core to inspect it and capture images that you can show your customer to show the damage.

0 Comments