by Kerry Jonsson

There are hundreds of diagnostic trouble codes (DTCs) that an engine management system can use to alert the technician as to where it has found trouble. All too often, we give credit to the OBD II system for being able to pinpoint the problem for us. If we see a MAF (Mass Air Flow) sensor code, we put in a new MAF. If we see an oxygen sensor code (no matter which one it is), we put in a fresh O2 sensor — if we see an air/fuel mixture code reading too rich or too lean, well, we often put in a new sensor anyway.

At least we did this until customers started coming back, usually with the same code. We realized we did not fix the problem and that we were going to have to dig a little deeper. The code that got us here is the infamous P0171, which means the fuel system is running on the lean side of the stoichiometric air/fuel ratio. Now, we are starting to look at the factory flow chart. “Yeah, that’s it,†and, “That will tell us the problem†are our famous last words.

If you’ve ever looked at the flow chart for a typical P0171, you’ve seen that it essentially says to check everything that affects the fuel system. In the case of this 2000 Toyota Echo (not a very popular vehicle in the United States), the flow chart has us “checking†the following:

|

That’s a pretty extensive list. Considering that the problem is “always in the last place you look,” this could be a fairly long diagnosis. Some of the tests are easily performed, such as that for fuel pressure. Other tests are a little more time-consuming, like checking injector flow. We’re not advocating trying shortcuts to reduce your diagnostic time. We are promoting a diagnostic procedure that may be to your benefit. Everyone has his or her own way of doing things, and this is not meant to say that what has worked for you all these years is wrong. Here at Master Technician magazine, we would just like you to consider some additional testing methods that others in the field have had some measure of success with. In the long run, we feel this will help all of us. Let’s take advantage of all the information the vehicle has compiled while flagging the code.

First Things First

First, you probably pulled codes (DTCs) to see if they told you anything, but really the first step before that is the old visual, hands-on inspection. Simply getting in the vehicle, starting the engine and observing the way it runs should be an even earlier preliminary (note the odometer reading while you’re at it — our editor got burned in the diagnosis of a pristine Mercedes that actually had almost 300K on it because he assumed it was a low-mileage vehicle — no amount of driveability work can fix a skipped timing chain). If you have an engine noise, misfiring or surging, you need to fix that first. DTCs can help, but getting a P0300 code for a misfire does not tell us what’s wrong, it just gives us the news. Most of the time, with a P0171, the vehicle runs fine. The sophisticated electronics in the fuel system are very often capable of detecting a fault long before it becomes a drivability issue. This is not always the case as some components can fail rather abruptly and cause both a drivability problem and a fault code, but for the purpose of this article we’ll go with the scenario of the vehicle running okay.

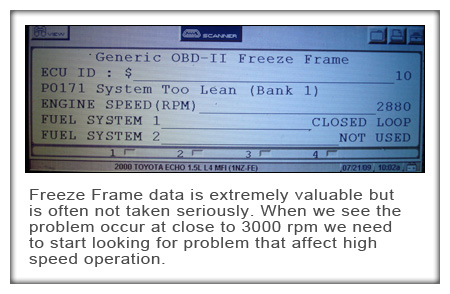

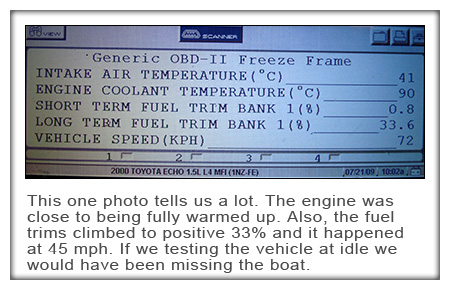

As we mentioned earlier, individual techs have their own ways of doing things. Here we will just try to add some different test steps to help shorten the diagnostic process. A good idea at this point would be to check the freeze frame data in the Generic OBD II protocol. We know that factory data is often updated faster, but it is wise to try to see under what “conditions†the code was set, which may save time. Freeze Frame data is in Generic functions mode $02. This information pertains to what the vehicle was doing at the time the DTC set. If we evaluate this data, it might tell us where to look. Using this 2000 Toyota Echo as our example, we see the DTC flagged at 2,880 rpm. If we scroll down our Freeze Frame, we can also determine that the code set at 90 deg. C, long-term fuel trim was 33% positive (trying to richen a lean mixture), and the vehicle was traveling at 72 kph, or 45 mph. Keep in mind that it takes the PCM a few seconds to collect the Freeze Frame data after the code flags. Any sudden changes such as throttle position or engine rpm may be different. However, it is safe to assume that coolant temperature and long-term fuel trim could not have changed that radically while the Freeze Frame was being recorded.

Interpretation and Isolation

What does this data tell us? Well, for one, the vehicle was almost fully warmed up. Number two, the problem happened at speed, not at idle. Finally, with the long-term fuel trim being 33%, this is a significant lean condition. Most American and Asian vehicles will flag codes at around +/- 10%, but each manufacturer can be different.

The first thing the flow chart has us look at is the air induction system. Remember, we are looking for a lean condition. The only way we could have a lean condition caused by the air induction system would be a vacuum leak. The vacuum leak could be external, such as a bad intake gasket, or it could also be internal, such as a stuck-open EGR valve. One fact we need to keep in mind is that a vacuum leak will have a greater effect at idle than at 3,000 rpm. We’re only using the following numbers to illustrate an example of relative air flow, and they are not meant to represent actual engine air flow. Let’s assume our vacuum leak flows at a rate of one gallon of air per minute. When the vehicle is idling, it takes in 10 gallons of air per minute; a one gallon air leak would be 10% percent of total air flow, leaning out the mixture. At 3,000 rpm, an engine will intake 100 gallon per minute. So, that same vacuum leak would only affect the mixture by 1%, not 10%. Our conclusion should be that looking for a vacuum leak will probably not lead to the cause of the code since the problem is occurring off idle. The same set of conditions applies to an exhaust leak. The greater the air flow the less effect.

An easy way to test for a lean condition at idle or at speed is to evaluate the fuel trim numbers, especially the long-term fuel trim. Since the vehicle has already been driven, you are going to have the fuel trim numbers of the past few miles. While this information should be recorded, we also should clear it out and start from scratch. Now, on some vehicles clearing codes resets the fuel trim numbers to 0, but not in this case. This Toyota Echo did not reset the fuel trim numbers to zero, so we disconnected the battery. It was safe to do on this vehicle. Be careful with other vehicles as you may lose other adaptations such as electronic throttle, idle and transmission shifting. Try unplugging the PCM, or removing its key-off power supply for a few minutes instead.

Now that the fuel trims are set to 0, just let the engine idle for five to 10 minutes and see if the trims change. If they go up, you may have a vacuum leak. If they stay at 0, there is no problem at this point. If they go down, look at what can cause a rich condition. You can now drive the vehicle down the road and record the fuel trims at the same vehicle speed you observed in the freeze frame. If the number is still high, we need to look at what can cause a lean condition at higher rpm. In our case of the Echo, the fuel trims stayed 0 at idle, but returned to 33% after a road test.

Taking Action

Fuel pressure definitely needs to be tested. Fuel pressure testing can and will be an article on its own, so for the sake of time we’ll simply say look at the fuel pressure going down the road and then accelerate hard. The drop in vacuum should increase the fuel pressure due to the action of the regulator. On returnless systems, the fuel pressure will not increase, but certainly should not drop. That would mean that under heavy demand the pump is not up to the task. Once again in the case of the Toyota Echo, fuel pressure was within specifications. We need to look deeper.

Checking injector flow is possible, but time-consuming. Some manufacturers build an injector flow rate test into their self-diagnostic capabilities. You can also perform what is known as a fuel contribution test. Here you set up your exhaust gas analyzer (yes, get the dust off of it) and while looking at an undiluted sample before the catalytic converter, you monitor HC and short each spark plug one a time. Each time we short a spark plug the HC will increase from the misfiring cylinder. If injector flow rates are equal, then the HC should increase equally for all injectors. If not, we have a flow problem. Before we resort to these more time-consuming measures, however, we should look at easier components to test, such as the MAF.

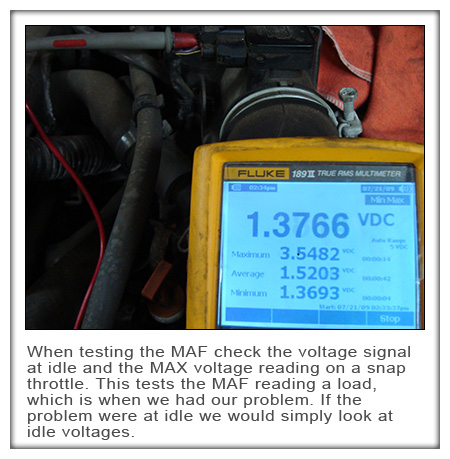

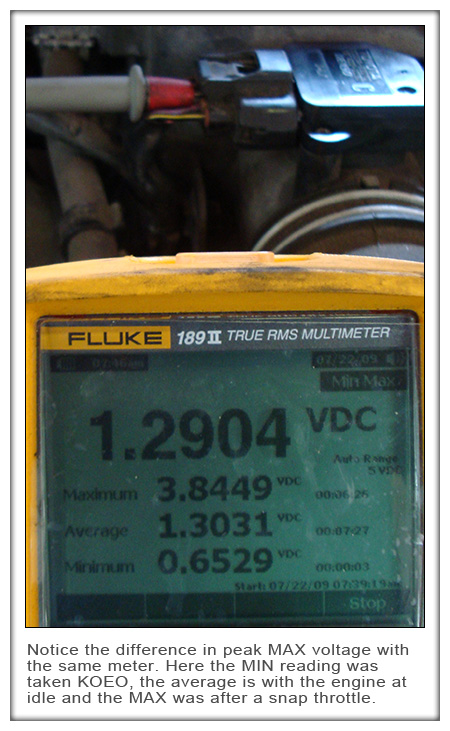

Looking at the Toyota flow chart, you see that MAF testing revolves around checking the power, ground and voltage signal. The signal they expect you to see is 1.1 to 1.5 volts. That’s a pretty big swing and we believe if we saw 1.1 or 1.5 volts, something here is broken. Observing vehicles that are running fine you will see approximately 1.3 volts +/- .1. This we would consider a normal reading. Keep in mind that different locales have different barometric pressures, different air temperatures throughout the year, and different humidity levels, so check out what the voltages are for your conditions. Use our numbers as a ball-park. On our Toyota, we observed about 1.3 volts and the fuel trims were stable and below 1%. According to the flowchart, this MAF passes the test. But remember our problem is at 45 mph when our long-term fuel trim returned to 33%. We need to test the MAF throughout the rpm range. One way we can accomplish this is under a severe load. Snap the throttle, bring the rpm to at least 3,000-4,000, and watch the maximum voltage measured during this snap throttle. You will need a multi-meter capable of recording a MAX/MIN value. Just as important is knowing the sample rate of your meter. The Fluke 88 automotive meter is capable of a 100 ms sample rate. The less-common Fluke 87 is capable of the same 100 ms sample rate, but also has a Peak MAX/MIN feature capable of a 1 ms sample rate. If you were to use these meters, you would have different voltage readings for each one. The rule of thumb here is “know your meter†and test some known-good vehicles. In our case, this Echo had a MAX reading of approximately 3.5 volts. This is low relative to our experience on known-good vehicles in our locale. After installing a new MAF, we performed the same test and saw our voltage reading change to approximately 3.8 volts. This may not seem like much, but .3 of a volt is a big deal when it comes to MAF readings.

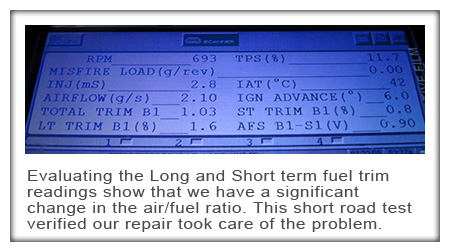

The Proof Is In The Pudding

After a road test, we monitored the fuel trim readings at around 45 mph and recorded that the long-term fuel trim was down to below 2%. Plus or minus 5% are acceptable readings. When you are closing in on 10% is where you start flagging codes. With a reading just above 1%, we have the confidence to return the vehicle to the customer knowing it was fixed. We hope you found this article useful and continue to support Master Technician so we can continue to support you.

Thanks for your inquiry abujin. Per Kerry, our contributing editor:

“I arrived at these numbers looking at new MAF’s that I tested after I installed it and I also tested good units that kept the fuel trim number very close to 0%. I hope that answers the question. “

Good basic training. Would like to have known more about where he obtained readings for” known good in our locale”

helped a lot

VERY GOOD