Even though there are almost 15 years’ worth of OBD II-compliant vehicles out there, EVAP system failures still often stump technicians. Let’s look at some techniques that’ll help you avoid that.

Evaporative emission systems have been installed on all cars sold in the U.S. since 1971. The concept is certainly simple enough:    Since venting the gas tank (and long ago the carburetor’s float bowl) directly into the atmosphere would make up a large percentage of a vehicle’s HC emissions, there was a need to contain and dispose of these fumes. The solution that was universally adopted was to store them in a charcoal canister, draw in fresh air, and feed this mixture into the engine to be burned.

Monitored

But this elegant simplicity disappeared with the advent of OBD II, which makes EVAP a monitored system. That means that as the vehicle is driven an electronic control unit tests the system’s operation. In this case it’s looking for leaks in the components that store, route, and control fuel vapor. An OBD II requirement is that the system must be able to determine if there is a    small leak (no more than .020 in. in diameter), or a large one (.040 in. and up).

Now, there are many different ways for a tech to check for leaks, but there are only two methods of electronically monitoring for them. You can generate pressure and look for a pressure drop (pressure decay). Or, you can pull the system into a vacuum and see if it holds (vacuum decay). Volkswagen uses the positive pressure method.

A breather line connects the fuel tank to the charcoal canister. This carries vapors from the tank during refueling. Canisters themselves are mounted in various locations according to space and proximity to the fuel tank. They contain activated charcoal as their storage medium. Another line on the canister is routed to the intake manifold, and is connected to a canister purge solenoid. This solenoid is duty-cycle-controlled by the Powertrain Control Module (PCM). When the computer feels it is necessary, it pulses the solenoid and allows fuel vapors from the canister to be drawn into the intake manifold to be burned. While the engine is idling, cycling is on and off, but may be pulsed on more with increased engine rpm and load. On most front- and four-wheel drive models, the solenoid is mounted on the passenger side of the engine compartment on the air filter housing.

Pumped up

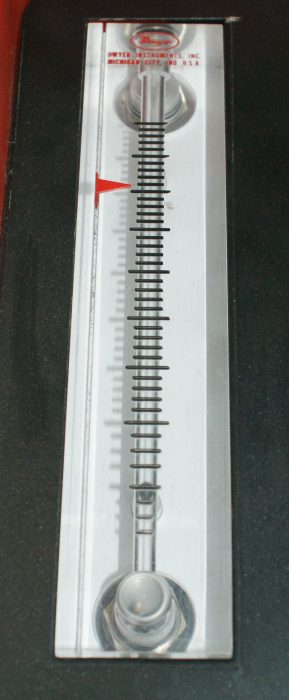

Volkswagen uses a Leak Detection Pump (LDP) to perform the pressure decay leak detection method. The way an LDP functions is simpler than it sounds. Manifold vacuum is applied to the upper chamber of the pump. A solenoid is pulsed on and off allowing and restricting this vacuum source to the upper chamber. This raises and lowers a diaphragm in the LDP that has opposing spring pressure applied to it. This up-and-down action generates a positive pressure in the bottom of the LDP. The pressure is at maximum when the spring can no longer overcome the pressure in the system. This pressure is applied to the fuel storage components. A pressure switch monitors how long it takes to build pressure, and whether or not the pressure is maintained over a period of time. If the pressure is maintained, then there is no leak. If the switch changes states within this specific time then a pressure loss must have occurred. The PCM will run the LDP again and retest.

This EVAP system is usually not intrusive to customers. The only indication they’ll ever have that there is a problem is an illuminated MIL (Malfunction Indicator Lamp) with a Generic code somewhere in the P044X range. Here a VAG 5054 would give you factory-specific codes that would narrow down the possibilities in a more cost-effective way. In any event, it is sometimes a difficult task to sell jobs to customers when there are no perceived problems with their vehicles. You have to let them know that this is an emissions-compliance issue, and in many states these days there is an OBD II inspection process. The vehicle will not pass if the code is active and the MIL is on.

Measuring blocks

You have a few different options when you are actually going to do a diagnosis. First, if you have a VAG 5054 scan tool you can observe data in “read measuring blocks,†address number 08. For most vehicles built in the past 10 years, you would look at data block 070 and 071. Block 070 tells you the status of the purge solenoid and if it is working properly. Data block 071 lets you know if the leak monitor passed or failed the last time it was run. If you actually want to test the system, you can clear the codes and enter into “basic settings†address 04. You can enter the same measuring block numbers 070 and 071, but here you will run the tests if the conditions are right. With the engine running at operating temperature, entering 070 starts the canister purge solenoid test to check purge flow. With 070 the LPD is activated and the system will test itself for a leak.

Look in field 4 after the test is complete to see if the system is okay or not. This can help during diagnostics as well. While the LPD is running the PCM is measuring how long it takes to fill the system. This time will vary with fuel level. This is why the EVAP monitor does not run unless the tank is between ¼ to ¾ full. If the LDP needs to cycle on again, or it takes too long to build pressure, then there must be a leak. Using the VAG 5054 you can block off the line leading from the LDP to the canister. This action takes most of the fuel storage system out of the equation. If the test passes, you now know the LDP is working and the leak must be after this point.

You should now block the line leading to the canister from the fuel tank and run the same 071 test in basic settings. If the test fails, you know the problem is somewhere between where you first blocked it off and the current block-off point. Check the lines into and out of the canister and the canister itself. It is sometimes difficult to use a smoke machine to test for cracks in plastic parts such as the charcoal canister. Simply apply a soapy water solution to the plastic part and look for air bubbles just as you would look for a leak in a tire. If the system passes the next test, keep blocking hoses farther away from the LDP. When the system finally fails the basic settings 071 test, you know the leak is between the current point and the last point you blocked off.

Smoke it

Another way to pinpoint a leak is to use a smoke machine. It’s such a simple device we wonder why we didn’t think of it first. Burn oil, then apply light pressure and plug it into a system. If you see smoke, you have found the leak. Nitrogen works the best for the necessary pressure, and is really the only safe choice because shop air would create a fire hazard. Your smoke machine needs to be rated for EVAP systems that operate at 0.25 psi. We’re dealing with inches of water when it comes to EVAP systems. The best place to start smoking the system is at the inlet of the canister purge solenoid coming from the canister. This should permeate throughout the entire system after a few minutes. You know the system is full if you remove the gas cap and smoke comes out. Secure the cap and start looking at hose connections and lines.

There is the possibility of an internal leak. During the leak test the canister purge solenoid is closed. If it is not properly sealed, or stays stuck open, the manifold vacuum on the other side will drop the pressure in the system. You will not see smoke because it is passing through the purge solenoid and entering the intake manifold. A stuck-open solenoid will constantly draw fuel vapors from the canister. Engine management will react to this un-metered air and will increase additive fuel trim. This is the first place you should look if you pulled two codes from the PCM, one for purge flow/leak and a second for a lean condition, P0171 and P0174. You may get lucky if you start the engine and remove the tank side of the purge solenoid hose. You should hear a pulsing vacuum leak. If the sound is steady, the solenoid is stuck open. Try tapping on the solenoid and see if it starts working again. If it does, it still must be replaced. You can verify your repair with basic settings again and see if it passes the block 071 test.

EVAP problems can be difficult to diagnose. Sticking solenoids and LDP switches can be intermittent. With the proper tools like a smoke machine, however, you should be able to find most problems. Sometimes a soapy water solution will lead you to a crack in plastic parts. Having a VAG 5054 or equivalent may help you find the problem and lets you test to find out if your repair actually fixed the vehicle. Knowing how a system works is half the battle!

Download PDF

0 Comments