One technological advance that’s largely unsung is computer-controlled suspension. Mercedes-Benz’s Active Body Control (ABC) is a sophisticated system that deserves your attention (and we’ll throw in a peek at Semi-Active Suspension, too).

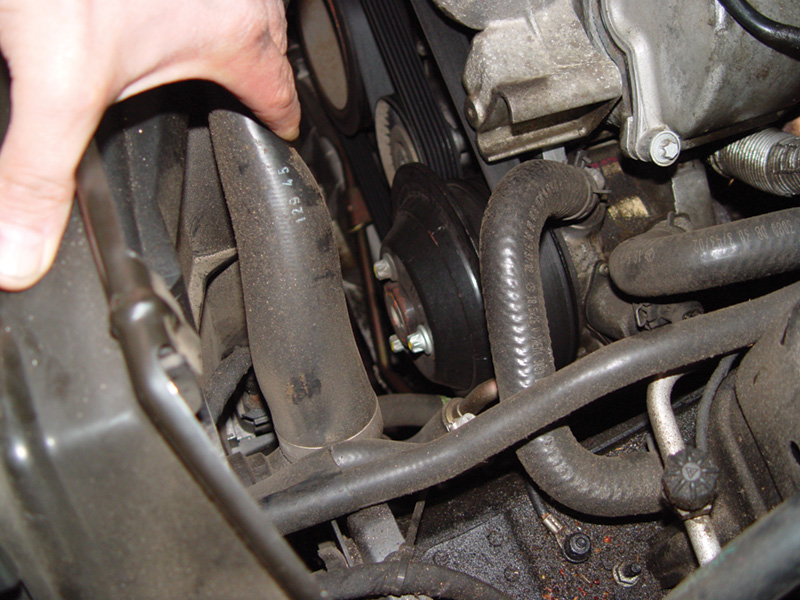

The hydraulic pressure of the ABC system is provided by a belt-driven pump, the same one that feeds the power steering system. It will be damaged if allowed to run dry for over four seconds, so make sure the fluid is up to the proper level and that the reservoir filters are not clogged.

The suspension system is often considered the personality of a vehicle. A soft suspension gives a compliant, comfortable ride, but doesn’t provide enough road feedback for sporty driving. A taut suspension is well suited for motoring fun, but may not be very comfortable on rough roads. Mercedes-Benz engineers believe in the use of creative technology to provide a combination of the two. With electronics, they can change ride heights, suspension stiffness, body roll, etc. The two main systems the company offers are Active Body Control (ABC) and Semi-Active Suspension (SAS). ABC is hydraulic, whereas SAS is pneumatic, using air springs, but also incorporates ADS II, which controls the vehicle’s dampening hydraulically. Of course, it’s very important for proper diagnosis and repair to be able to know for sure what the vehicle you’re working on is equipped with.

Certain models, such as the early 230 chassis SL-Class, use the ABC hydraulic system, which controls ride height. With its built-in intelligence, if the driver has selected a high setting, it will be overridden whenever the vehicle exceeds 68mph — the body will descend to its lowest position for optimum center-of-gravity and handling.

You’ll find a screen in the banjo bolt of the pressure feed line. It protects the system by blocking debris. It should be removed and cleaned whenever service work is done to prevent pressure drop in the system.

SAS can be found on later chassis, such as the 211 E-Class. It is an evolution of the older Airmatic system found in the 220 chassis S-Class. It still uses pneumatics, but now it has two-chamber struts. Dampening is controlled by decreasing or increasing the air volume through opening either one or two chambers in the air spring. The ADS II hydraulic system provide four levels of dampening control that the driver can select with a switch mounted in the LCP (Lower Control Panel).

The ABC hydraulics operate at over 2,900 psi, so it is important to reduce this pressure to safe levels before attempting repairs. With any Airmatic or SAS system, you should also relieve the pressure before starting any suspension work to prevent damage to the components. It will also make reassembly much easier because a collapsed strut can be positioned more easily than an inflated one. The SDS is used to safely reduce this pressure. With ABC, pressure is generated by a belt-driven hydraulic pump (the same one that provides psi to the power steering). A return-flow solenoid controls fluid being drawn in from the reservoir. There are two levels on the dipstick, one for high suspension levels, and the other for low. The return lines for both the power steering and ABC reservoirs have filters in them, which should be replaced any time the system is opened and refilled with new fluid.

The return-flow filter is mounted in the reservoir. While you’re visiting your Mercedes-Benz parts dealer, you should pick up these filters and at least four liters of hydraulic fluid. This will protect your work and give components the longest possible service life.

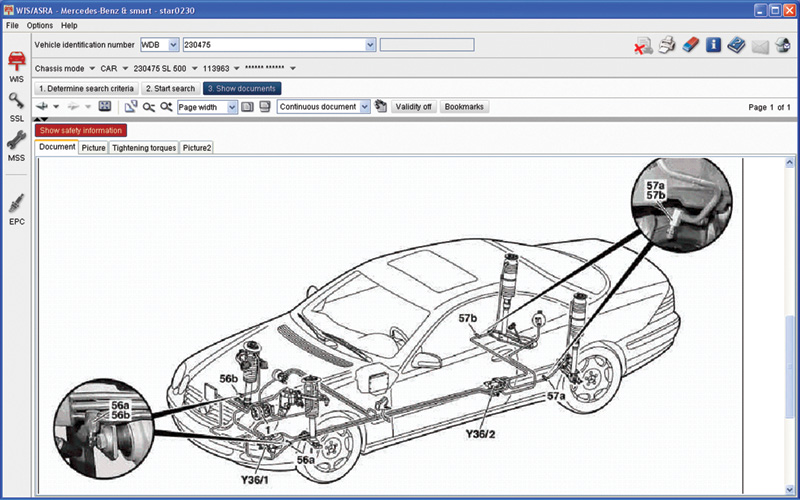

As an example, in the 230 chassis ABC fluid pressure is routed to a pressure supply valve unit mounted behind the driver’s side front tire in the fender. It controls the pressure applied to the front and rear axle valve units. The front valve unit is mounted in the front driver’s side fender. It controls both front corners individually. The rear unit is mounted in the driver’s side rear fender in front of the wheel, and controls the rear corners individually. A reservoir mounted in each valve stores pressure until the pump replenishes the supply. When opening the system, you should know that there are four bleed screws, one in each corner, which you can open to let the fluid drain before removing lines. Crack the screws open slowly to prevent spillage. Your SDS unit can also be used to relieve fluid pressure. Support the vehicle so the pressure loss does not allow the chassis to drop. Union and banjo fittings are used to connect metal lines. Push-lock fittings are used on rubber lines. Push the plastic lock rings in evenly while you pull the line out to prevent damage to the connection.

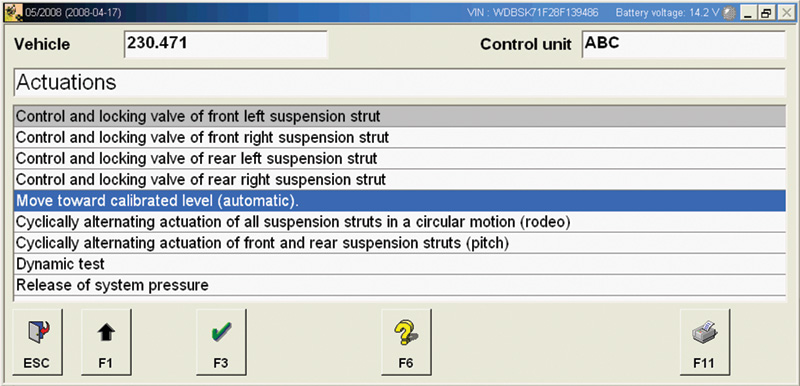

Using your SDS, you can control each corner. Move to the calibrated position and perform a “Dynamic Test†(Rodeo mode). Selecting “Release System Pressure†will also allow you to start disconnecting lines for repair.

With your paid subscription to Startekinfo you can review all of the safety procedures before attempting a repair. You can also look up locations of the bleed screws to depressurize the system so you can start work.

You can read all of the safety precautions in WIS with a paid subscription to www.startekinfo.com. The ABC control unit monitors fluid temperature and pressure, and controls solenoid operation. With your SDS, you can look at this data, and under “Actuations†you can manually control each corner of the vehicle as well as engage the “Rodeo†mode where all four corners are raised and lowered. This allows you to completely test the system and check for any potential trouble codes and leaks. If you’ve opened any connections, you’ll need to refill the system and purge it of any air. Once again, Startekinfo provides this step-by-step procedure. This will prevent the reservoir from running dry and damaging the pump. The system should always be allowed to sit for 10 minutes to allow fluid to return to the reservoir for an accurate fluid level reading. After purging air and testing with your SDS, you can confidently return the vehicle to the customer knowing the system will perform as it’s supposed to.

0 Comments