With emissions and mpg both looming so large right now, you can’t have your customers driving around with the MIL on, but it’s not always so easy to find the cause of a fuel system glitch

Some of the most common driveability/emissions repairs we are asked to perform involve the engine’s fuel control system. This is not just because of gas mileage concerns and illuminated MILs (Malfunction Indicator Lamps), but also because more and more states have adopted some sort of emissions inspection program. Typically, if the MIL is on, the vehicle will not pass. Also, your customers don’t like seeing that warning light any more than they want to be burning extra gasoline. They know there’s a problem with the system, so they want it fixed, and who could blame them? So it becomes your job to identify the source of the malfunction and correct it. That may sound simple enough, but we know from experience that if the DTC (Diagnostic Trouble Code) that’s present is related to the fuel system, there are often many twists and turns in the trail that leads to the source of the trouble. What tools do we have to identify the problem?

First Things First

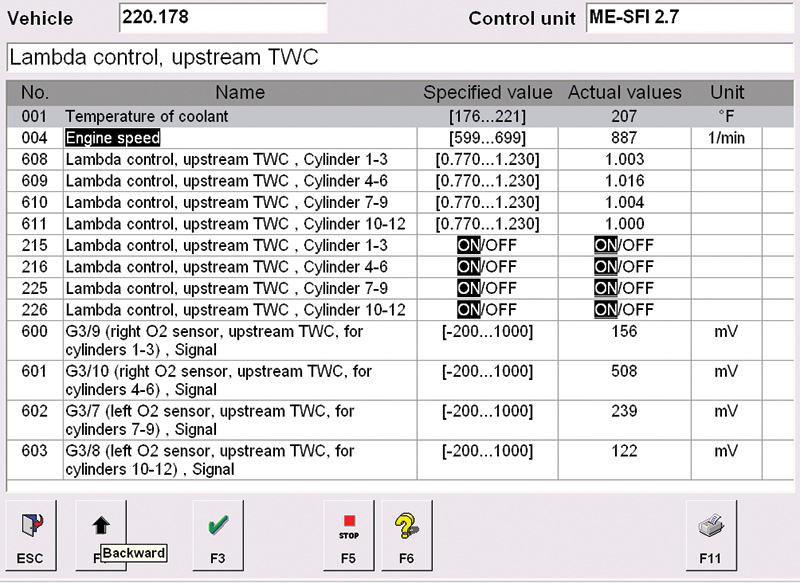

On this ’02 C320, you can see that the idle fuel adaptation is displayed in milliseconds and the part-load readings are split into two different rpm ranges, lower part load and upper part load. In this case, the injectors are pulsed .3 more due to a lean condition at idle.

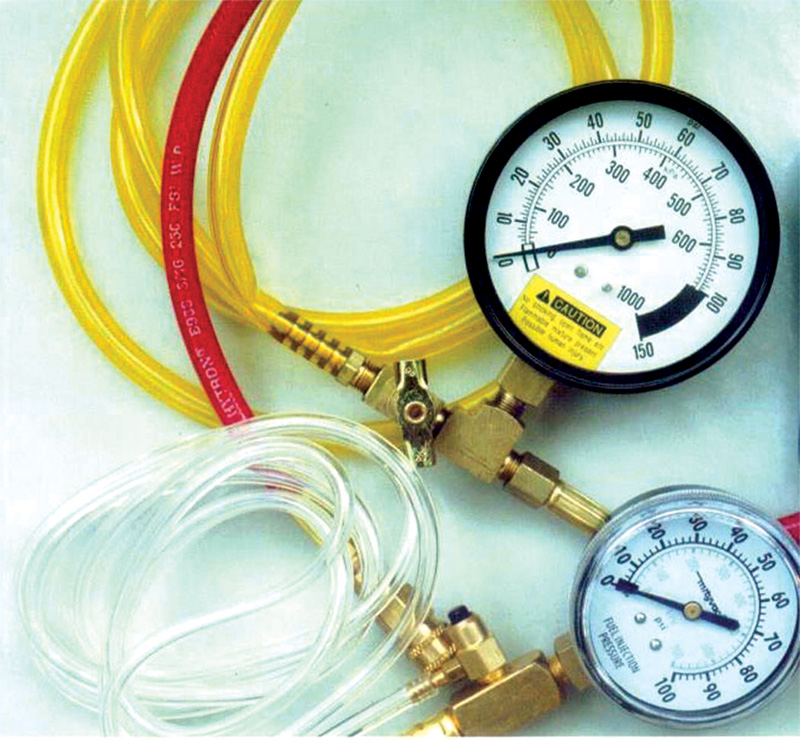

Since the fuel system is one of OBD II’s three continuous monitors, if a problem exists it is probably going to set a DTC. Of course, attend to the basics first, such as measuring fuel pressure and doing a visual check of electrical connections, wire integrity, hoses, etc. Then there are the many sensors and solenoids that determine how much fuel is actually injected. If you have an SDS, you will have access to the most comprehensive data available. For example, look at coolant temperature as the engine warms up to verify that the thermostat is keeping the coolant within the proper range. Typically, if the thermostat is opening too soon the PCM will flag a Code P0128. Engine speed and load signals determine the base pulse width, so have the largest affect on mixture formation. This is providing the Mercedes-Benz self-diagnostics have not found a problem with other input sensors.

This 12 cylinder breaks fuel trims down to two six-cylinder engines, then down further into two banks of three cylinders each. This is an overall Lambda reading. As you can see, each group of three cylinders is close to 1.00.

Feedback, Feedback, Feedback…

Believe it or not, the oxygen sensor arrived on the automotive scene over three decades ago. The PCM looks at the signal voltage it generates to tell if the mixture is rich or lean. If the signal indicates lean, the PCM will add fuel by increasing pulse width, and vicesa versa. You can see the fuel trim indication in the data stream. Mercedes-Benz breaks down these fuel trim numbers into two readings. The first is “Additive†fuel trim. This reading tells you what the PCM is doing to the mixture at idle and just off idle. In the SDS, it is also referred to as the “Idle†trim reading, and, on older systems, “lower part load.†If you see this number deviating from the center point, you should perform testing while the engine is at idle. If the problem is above idle and under vehicle load, you should look at the “upper part fuel trim,†or “Multiplicative†number. This represents fuel trims throughout the rpm range.

A Rose By Any Other Name

These numbers can be represented on several different scales. The SDS typically displays them as either a millisecond adaptation (ms), or in Lambda. If you’ll recall, Lambda is a scale based on stoichiometry, the ideal ratio of 14.7 parts air to 1 part fuel by weight. This is represented by the number 1.00. If the adaptation number is below this, the computer has seen a rich condition from the oxygen sensor, so is reducing fuel. If the number is above 1.00, the mixture was lean and the PCM is adding fuel. The ms scale is simple. This is how much time in milliseconds the injector is being held open or closed. A negative ms number means fuel is reduced. If it’s a positive number, then fuel is being added. You should compare Bank 1 and Bank 2 readings where applicable, but you can also tell if the engine has a problem at idle or at part throttle. Use this information to isolate the problem.

One Bank, Or Two

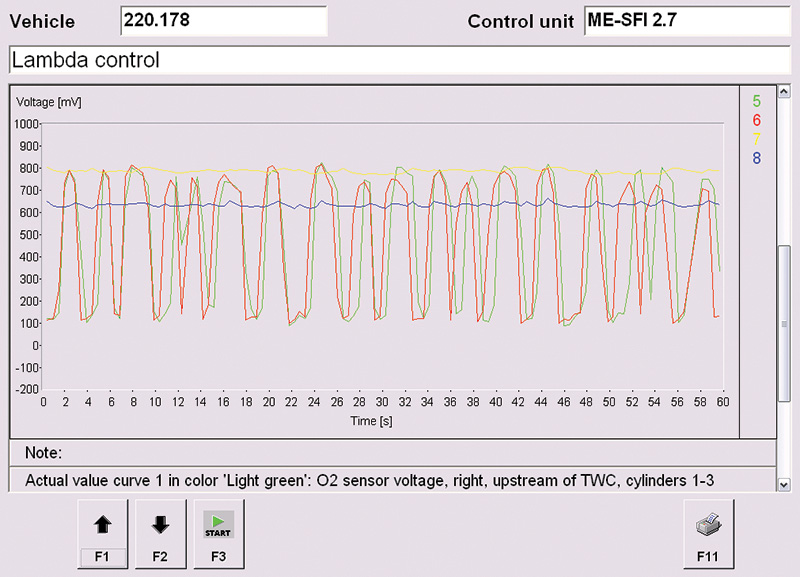

The accuracy of the feedback system is based on good O2 sensor readings. Here, you are looking at cylinders seven through 12, and two pre-TWC and two post-TWC O2 sensors. The red and green traces are the two front O2 sensors, which are switching normally.

When dealing with an engine with two banks, compare the fuel trims from one to the other. If you have a problem with only one bank, focus on that side’s O2 sensor. Once you have isolated the problem bank, use the Additive and Multiplicative fuel trims to determine if it occurs at idle or part throttle. If the problem is at idle, you need to perform additional testing. If you have a lean condition and a P0171/4, check for vacuum leaks. This can easily be done with a smoke machine, but keep in mind that the oil is being burned, which can contaminate the MAF element, so remove the MAF first. If you have a rich condition, you may have a leaking injector. If the problem is with both banks, you should look at sensors that affect both. A lean condition can still be a vacuum leak, but it can also be low MAF output. At this time you may want to start looking at the MAF.

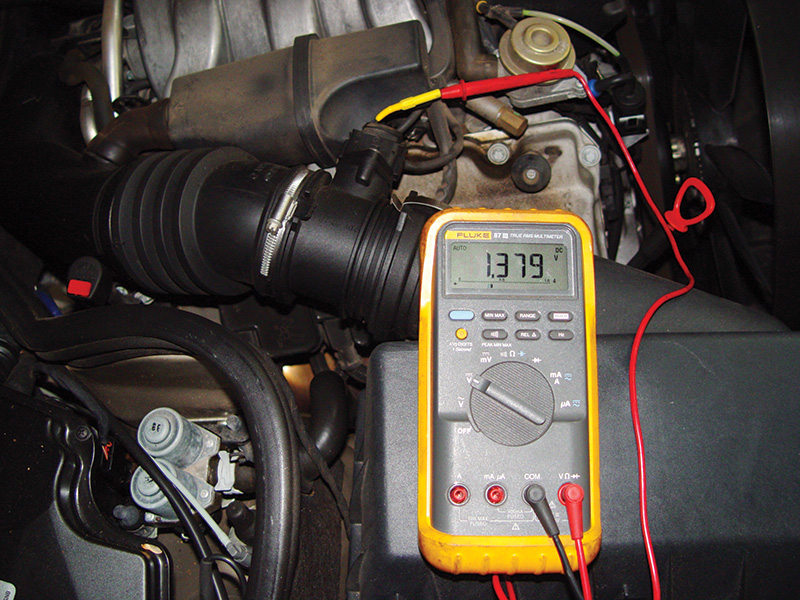

This is the MAF signal reading on an E320 at idle. You should see between 1.3 and 1.4 volts. If your reading is higher or lower than this, you probably have fuel trim codes. If this is severe enough, you may also be facing a drivability problem.

Problems Over The Road

With a quality DMM (Digital Multi-Meter) you can measure signal voltage using the MAX/MIN feature. While recording, accelerate to WOT and see what your maximum voltage is. A good MAF should read over 4.0V. If not, you probably have a fuel trim code with high Multiplicative readings.

Small problems like a vacuum leak usually do not affect the fuel trim much above idle. An injector with a weak return spring can still cause a rich condition, but it probably won’t if it is only leaking. If dealing with a lean condition at higher rpm, the MAF should be at the top on your list of suspects. Also, you may have a fuel delivery problem. Check fuel volume as well as fuel pressure, particularly with return-less systems. All of these fuel trim numbers are based on O2 sensors that are working well and promptly. They should be able to switch rich-lean-rich at least once a second. Then, race the engine and you should see a sudden rich condition, a result of acceleration enrichment (as would’ve been provided by the accelerator pump in a carburetor — remember those?). If yes, you have a good O2 sensor. If you have multiple codes, try clearing them, then clear out fuel adaptations. Let the engine idle for five minutes and look at the idle (Additive) fuel numbers. Follow this with a short road test and look at the part throttle (Multiplicative) numbers to see if it looks like codes will set again.

Of course, there are many causes of fuel trim codes, but using your SDS and fuel trim numbers should help reduce your diagnostic time. It also leads to accurate diagnosis and satisfied customers.

0 Comments