When diagnosing electrical problems, the more you know about modern power distribution systems the faster you will find the problem. Rapidly changing technology has revolutionized how power is applied.

If you see a large auxiliary battery on an earlier dual-battery system, it’s for starting. The battery in the rear powers the main system. A white case tells you it’s not an AGM battery, but the regular lead-acid type.

While the 12-volt automotive battery is still the electrical storage device of choice for all non-hybrid vehicles, the similarities in late-model electrical systems to those of the past stop there. Mercedes-Benz still used conventional lead-acid batteries in the last few years, so you can continue to follow traditional testing methods. But Mercedes-Benz has also introduced a dual-battery system that uses the AGM/VRLA battery (Absorbent Glass Mat/Valve Regulated Lead Acid). You need to be able to identify the differences between the two so that you can properly recharge and test each different type. Having two batteries to deal with also poses some questions. For example, does one battery do one thing while the other does something else? These newer vehicles draw significant current with the key on and the engine off, and even while the engine is running electrical loads from computer control units, blower motors, auxiliary coolant pumps, wipers, defrosters, heated seats and steering wheels, etc. can exceed what the alternator can provide at idle. Adding a second battery provides the extra electrical storage capacity needed.

This rear-mounted battery is the main electrical power supply in some newer systems. A black case tells you it is an AGM battery. Read the warning on the red cover and look for the letters “VRLA†to confirm. You’ll need a special battery tester to check this one.

Know What You’re Working On

This auxiliary battery has seen better days. It should supply 12.6 to 12.8 volts when properly charged. This one can no longer hold a charge. The black case tells you to check if it is an AGM type. In this case, it is. Using an OEM battery is the safest way to repair the problem and prevent false alarms in the future.

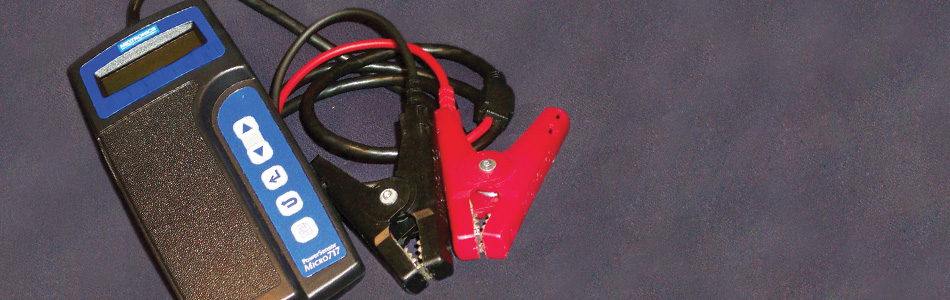

Starting with modern chassis like the 211, there’s a main battery mounted on the passenger side of the spare tire. It is of the AGM type, which means you need to use different methods to recharge and test it. In recent years, you’ve been told to rapidly charge lead-acid batteries. While AGMs can be charged with conventional equipment, they require a low charge rate. Fast charging will damage the internal parts of the battery. We also cannot use typical testing methods such as applying an electrical load with a carbon pile, or checking specific gravity. Mercedes-Benz recommends the use of the Midtronics MCR 717 battery tester or equivalent. It applies a specific AC voltage to the battery and monitors the responding current flow. Many new battery charger/testers are available and have selections for AGM batteries, so it’s okay to use them. Look for and read the red protective battery positive terminal cap and it will warm you if it is an AGM.

Power Flow

The rear-mounted battery is the main power supply of the vehicle — it powers the rear pre-fuse box. There are large high-current fuses of 150 and 200 amps that bolt down, and blade-type fuses in the box, which power up the front and rear SAMs. This is necessary since the SAM modules provide “wake up†signals for other systems. It also supplies battery voltage to the interior fuse box. There is a second pre-fuse box mounted in the passenger side foot-well under the carpet. It has a high-capacity capacitor installed in it, so be careful with tools in the area. Since electrical loads can exceed the main battery in the trunk, there is an auxiliary battery mounted under the hood, typically on the passenger side of the firewall. This battery is always grounded, but is not always connected to the vehicle on the power feed side. It is cut in through an auxiliary relay.

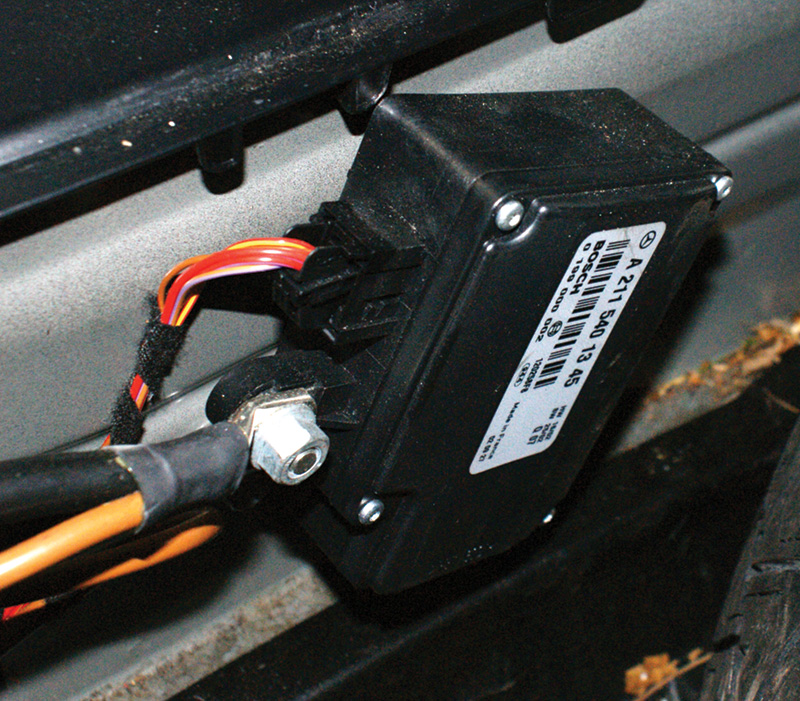

The battery control module, pictured here, monitors the rear battery voltage, the front battery voltage, and alternator output through the body CAN B. You can talk to it with your SDS unit and program it if it needs to be replaced.

Who Pulls Whose Chain

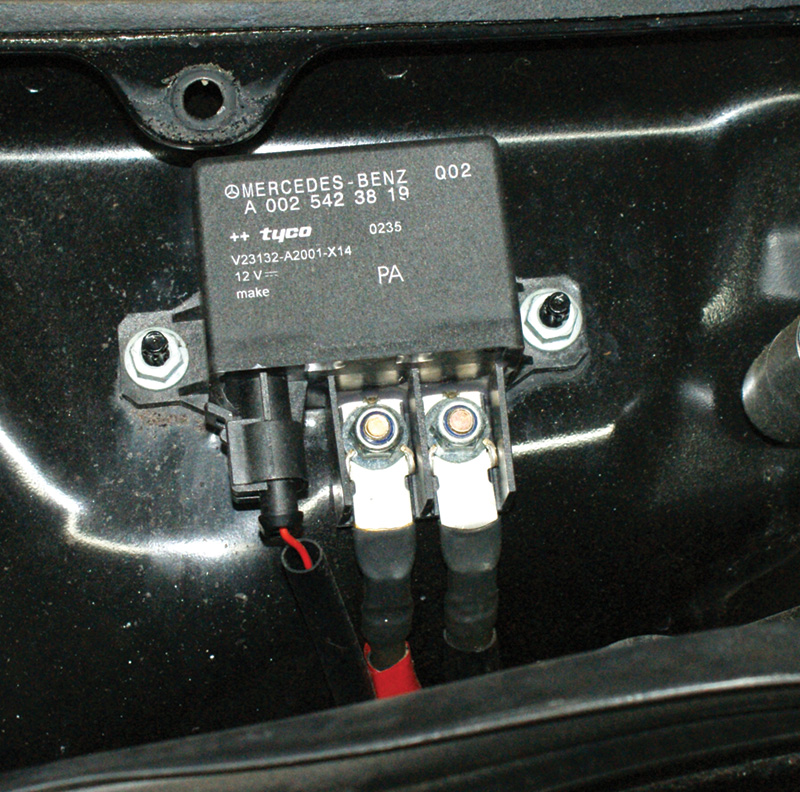

On the 211 chassis, the relay is mounted under plastic covers at the base of the windshield. With a paid subscription to www.startekinfo.com, you can look up component locations with Starfinder for your particular model. When extra electrical current is needed, the relay is turned on. The auxiliary battery supply voltage is applied through a 150-amp fuse to the front pre-fuse box. This battery is also an AGM, so the same rules apply for charging and testing as for the main battery. The relay is operated by a Battery Control Module, which is mounted by the main battery in the trunk. The module activates the auxiliary battery relay in two cases:Â First, to recharge the auxiliary battery, and, second, to connect the auxiliary battery when system voltage is low. The control module looks at the voltage of both batteries and the alternator output through a CAN. You can access this control unit with your SDS and retrieve DTCs.

This is the auxiliary battery relay. It turns on to allow the auxiliary battery to charge and, if system voltage is low, to add current under heavier loads. It is not on all the time, so do not expect the auxiliary battery to always indicate charging voltage.

Warnings

If the battery control module detects a fault, you’ll see a message in the instrument cluster warning the driver. The problem can be no charging, low voltage, or overcharging. If the voltage is just low, the warning message tells you to cut off accessories. The module is also in control of a cut-off relay that interrupts power to the auxiliary cigar lighter/power supply sockets to help reduce electrical loads. The control unit can also request that consumers be shut down according to its preprogrammed priorities. There are two stages of power reduction. If both stages do not bring up system voltage, then the auxiliary battery relay is energized (connecting the auxiliary battery to the front pre-fuse box) and the red warning message is displayed on the dash. In this case, you will need to check the condition of both batteries with your tester, and alternator output to see what is causing the problem. Remember, before condemning any component, make sure the system is not being shut off due to excessive electrical load. Pull and clear codes after a Quick Test and see if it starts working again.

A Known Quantity

The alternator can be tested as any other alternator, but you need to make sure the batteries are in at least adequate shape for testing. If the batteries need replacement, make sure you get the AGM type that meets the specifications of the originals. If not, you may get false warning messages in the cluster and improper charging and activation of the auxiliary battery. Using OEM batteries is the best way to avoid this. The specifications are printed on both the front and rear batteries. Also, Battery Control Modules are reprogrammable and your SDS will prompt you if updated software is available.

0 Comments