There are many compelling reasons to perform glass replacement for your customers – and to use Genuine Mercedes-Benz Star-Marked replacement glass.

If you haven’t ventured into the world of glass replacement, now may be the time to branch out into a new way of producing profit for your shop and keeping your customers satisfied. It makes sense to maintain control in your relationships with your customers, rather than sending them down the road to a local glass shop, or farming out the work and realizing a smaller profit.

Turning customers away because you don’t offer glass replacement may make them think twice about returning to your shop, or give the impression that your services are limited. Customers want and expect full-range service to save them time and money.

Farming out the work lays some of the responsibility for any problems squarely on your shoulders. If there are leaks, cracks from improper installation, or incomplete cleanup, customers may return to you angry and with less trust in you and your shop. After all, you’re the one they expected to do the repair, and they will assume you did so.

One of the things you should always do is use Genuine Mercedes-Benz Star-Marked replacement glass for so many reasons. First, Genuine Mercedes-Benz replacement glass is made to the highest specifications at the same factory as the glass that goes into every new Mercedes-Benz vehicle. It is the right product, correctly made – it is Mercedes-Benz glass.

Genuine Mercedes-Benz Star-Marked replacement glass is your best choice to keep your customer’s vehicle original.

Additionally, all of the electrical connections and components for heating grids, antennas and rain sensors are of the highest quality, made to the same standards as the original glass – which it is.

While some metal, plastic or other replacement parts may meet most product specifications, glass is another story. It is literally in front of the customer’s eyes, rather than hidden under the hood. Any defects, such as less-than-perfect heater, antenna, or rain sensor grids, glass impurity, or variations in tinting will be easily spotted. Also, a piece of glass with improper curvature may result in leakage.

Genuine Mercedes-Benz Star-Marked Glass vs. Aftermarket

If you’re looking for important reasons to use Genuine Mercedes-Benz Star-Marked replacement glass over aftermarket, consider the following:

- Automotive glass is an important part of a vehicle’s structural integrity. Up to 30% of the torsional stiffness of a vehicle is a result of the strength of the windows. Mercedes-Benz uses continual testing procedures of glass components to ensure rigidity. Using Genuine Mercedes-Benz Star-Marked replacement glass, built with advanced glass technology, assures that the safety and quality designed into the vehicle is maintained. This advanced structural unity maintains roof rigidity to help protect occupants from unexpected dangers.

- Windshield tolerances are an important part of any replacement glass and Mercedes-Benz glass is manufactured to maximum accuracy based on the original design. Because Mercedes-Benz glass is fabricated to tighter quality specifications to perfectly match the sheet metal, there is less chance of water leaks and wind noise. Aftermarket glass, on the other hand, can be reverse-engineered. Therefore, the flush fit to exterior sheet metal could be at risk when using an aftermarket windshield. Choosing Mercedes-Benz glass ensures proper fitment, visual clarity, windshield wiper performance, and the overall integrity of the vehicle.

- Mercedes-Benz glass has integrated solar protection in the form of infrared reflective technology to provide UV protection and reduce heat load. This technology optimizes air conditioning performance and can improve fuel economy. Aftermarket variants often do not have the reflective technology.

- Mercedes-Benz glass and the attached moldings have been validated with exposure testing including UV (sun), chemical, temperature, tear and abrasion resistance (to survive events such as automatic car washes). Aftermarket windshields and moldings are often made with materials that do not meet Mercedes-Benz exposure tests.

-

Coating the glass with the correct primer will ensure a quality seal. Mercedes-Benz adhesives are designed to give the best results.

Mercedes-Benz glass has special acoustic-dampening technologies within the layering of the glass. Aftermarket products usually do not utilize this technology which may result in increased wind, road and engine noise in the vehicle’s cabin.

- Mercedes-Benz glass often incorporates various electrical components including rain sensors, antennae, and heating elements. Aftermarket glass often does not account for these complex Mercedes-Benz electrical components and may interfere with the vehicle’s electronic systems.

- Mercedes-Benz windshields ensure better wiper performance, while aftermarket glass may have a larger center contour.

- Mercedes-Benz ensures cleanly-ground edges, which not only increase worker safety during installation but also reduce the susceptibility to cracking.

The Correct Adhesives

The importance of using Genuine Mercedes-Benz adhesives with Genuine Mercedes-Benz Star-Marked replacement windshields cannot be over emphasized. Genuine Mercedes-Benz adhesives are thoroughly tested to result in optimal bonding and strength, ease of use and shorter drying times that lead to lower waiting times and higher customer satisfaction. Additionally, these products are tested to avoid conductivity problems for electronic components such as heater grids, antennas or rain sensors.

These products are also available from your local Mercedes-Benz Wholesale Parts Dealer. For more information, or to locate a dealer, log onto www.MBWholesaleParts.com.

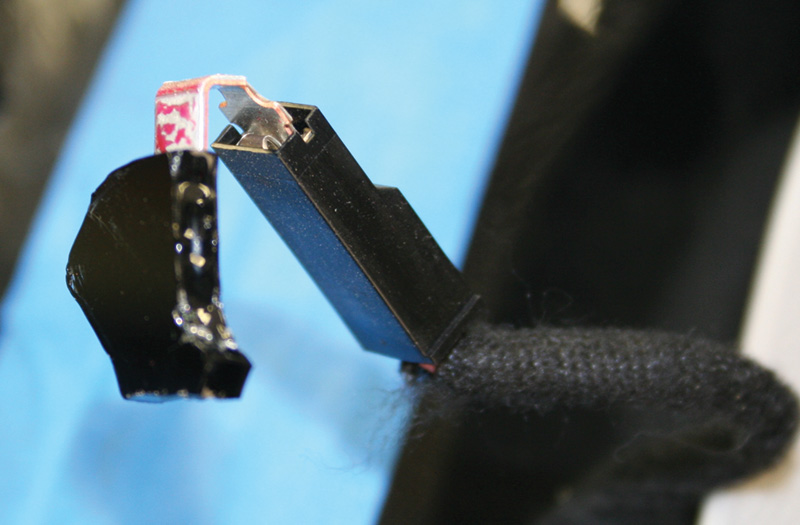

Electric Connectors

Properly functioning electrical and electronic connectors for heater grids, rain sensors and antennae are of prime importance. If the connectors on the glass are not of optimum quality and properly placed, problems can occur in the operation of the sensors or grids.

Genuine Mercedes-Benz Star-Marked replacement glass is always 100% correct in the quality of grids and sensors. Aftermarket glass, being reverse-engineered, may not be so.

Of course, the care in removal, handling and reattachment of the vehicle-mounted connectors can have a great bearing on the success of component operation, so always follow the specific repair information instructions for the vehicle you are servicing.

Set the glass properly the first time. Today’s quick-curing sealers don’t allow much forgiveness.

Glass Service Tips

Here are some handy tips for glass replacement service:

-

Take note of the windshield when a vehicle arrives in your shop for any service. Look for chips or emerging cracks that will only spread as the vehicle is driven. Mention to the customer that you can replace the glass with Genuine Mercedes-Benz Star-Marked glass so the vehicle stays as originally designed. This will enhance the vehicle’s resale or trade-in value.

- Always use the correct adhesive for the sealing area. The specified products may be different for the replacement glass surface and the metal mounting area.

- Always use the required urethane sealing product. Using other than the correct product can result in leaks, cracks or loss of structural integrity.

- When replacing rear glass, be sure to carefully remove the wiper arm to avoid damage.

- Install glass with sealer in the correct location quickly. Once installed, it should not be moved. Affix with tape in a few spots to secure until sealer is set.

- Nothing irks customers more than getting their vehiclex back and finding pieces of glass left from the replacement service. Always clean all glass shards from the vehicle to maintain your relationship with your customers.

- Always refer to the specific service information for the vehicle you are servicing. This information is available at www.startekinfo.com.

- Training information is available on the Mercedes-Benz USA Technical Training website at www.mercedestechstore.com.

- On the site, you can download electronic files, or print sheets of service information.

- More information about Genuine Mercedes-Benz parts, plus why you and your customer should use them, is available at

www.mbusa.com/mercedes/service_and_parts/genuine_parts.

Contact your local Mercedes-Benz Wholesale Parts Dealer for information on any Genuine Mercedes-Benz Star-Marked replacement glass or adhesive products.

Neat, Damage-Free Glass Removal

You can get relief from this anxiety and confidence that you’re using the Mercedes-Benz-approved technique in the form of the Roll Out tool, available from Reliable Automotive Equipment, Inc. (www.raeservice.com). Manufactured by Wielander + Schill, this is more a system than a single tool. Its main components are two double suction cup and winch assemblies that are affixed to the inside of the windshield or window, a ratchet, cutting wire, insertion needles, and an interior protection kit. The basic concept is to use the winches to draw the wire through the seal all around the perimeter, which leaves a neat, clean cut with no debris. The kit is expensive, and other methods may be faster, but we think once you try it you’ll be sold on the idea.  |

0 Comments