In this first of a series of body service articles, we will cover collision equipment and tools to properly repair damage to Nissan and Infiniti vehicles.

Every day, more and more independent body shops are forming relationships with Nissan and their local Nissan and Infiniti dealerships to avail themselves of Genuine Nissan and Infiniti parts, service information and special service tools. The benefits of such a relationship are procuring parts that make it possible to return the vehicle exactly to its pre-accident condition, that are manufactured in the same factories with the same materials and processes as those installed on the assembly line, and that are backed by the same company that engineered and made the car in the first place. Also, this gives the independent access to the best possible, up-to-date service information, and tools that work perfectly.

Independent shops that purchase parts from Nissan and Infiniti dealers have found the arrangement to be the most cost-effective course. That’s not only because they are price-competitive (and the chance of getting the wrong part is almost nil), but more importantly because precision mounting holes save time, making the shop more profitable. Plus, the rapid delivery, ability to return parts, and local community attachment works out best for both parties. Add to all this the protection of Market Shield and the convenience of Collision Link, and you have an unbeatable combination.

Using the Nissan and Infiniti technical information websites

Taking full use of www.nissan-techinfo.com or www.infiniti-techinfo.com ensures getting the proper information to get the job done right, the first time and quickly. There’s no waiting for a call back from a third party information provider when time is of the essence.

Nissan also provides a way to obtain the special service tools that Nissan and Infiniti dealers use to service its vehicles. These special service tools can easily be procured via the TechMate website at www.nissantechmate.com.

Nissan and its dealers value these relationships with independent collision/body service shops and make it easy to obtain and use everything you need to properly service Nissan and Infiniti vehicles.

In this issue, we will look at the equipment and tools a modern body facility should have to function at optimum efficiency.

Proper Equipment and Tools

Nissan has a list of recommendations for its dealer collision and body repair facilities. Perhaps the list can be used as a guideline for independent facilities that already have a profitable relationship with their local Nissan or Infiniti dealer, or for those wishing to establish such a mutually-beneficial relationship.

The following outline is merely a list of the best practices in creating a top-notch body service facility for repairing modern cars and trucks, including Nissan and Infiniti vehicles.

General Workshop

Nissan lists these general workshop items as being standards for optimum results when performing body service:

- A dedicated paint mixing room with exhaust fume extraction that complies with local legislation. The lighting in the paint mixing room should be set to a minimum of 750 lux.

- Appropriate storage for hazardous materials and liquid waste.

- Lighting with a minimum of 70 foot-candles in the metal working area (measured at 36†above the floor surface), a minimum of 90 foot-candles in the paint shop, paint preparation areas, and detail shop.

- Color matching areas should have color-correct lighting.

- A high-pressure, high-volume compressed air system providing oil-free and moisture-free compressed air.

- An electrical diagnostic system and capability of diagnostic analysis for Nissan vehicle electrical systems.

- Personal protective equipment must be available to all employees.

Paint Shop Tools and Equipment

Here are guidelines for the painting & finishing areas:

- A paint spray booth that will meet at a minimum these specifications:

- Lighting at a minimum 100 foot candles at the center of the booth with upper and corner color-corrected fluorescent lamps.

- Air handling and heating requirements: Exhaust system to be capable of 125 ft/minute measured at the face of the vehicle shell and a minimum of 19,000 CFM.

- A heat supply system with direct-fired burners with a minimum of 1.5 MTBU capacity.

- Equipment designed, constructed and installed in accordance with the BOCA Building and Materials Codes, NFPA 33 and 70, OSHA and all applicable local, state, and federal codes.

- An adequate number of electric buffers and polishers.

- Painter suits and other protective safety gear suitable for use when mixing and applying the specified refinish materials.

- An enclosed paint gun cleaner.

- A solvent recycler that is compliant with local, state, and federal laws, and a compliant hazardous waste disposal system.

Metal Shop Tools and Equipment

The following is list of suggested metal shop equipment and tools:

-

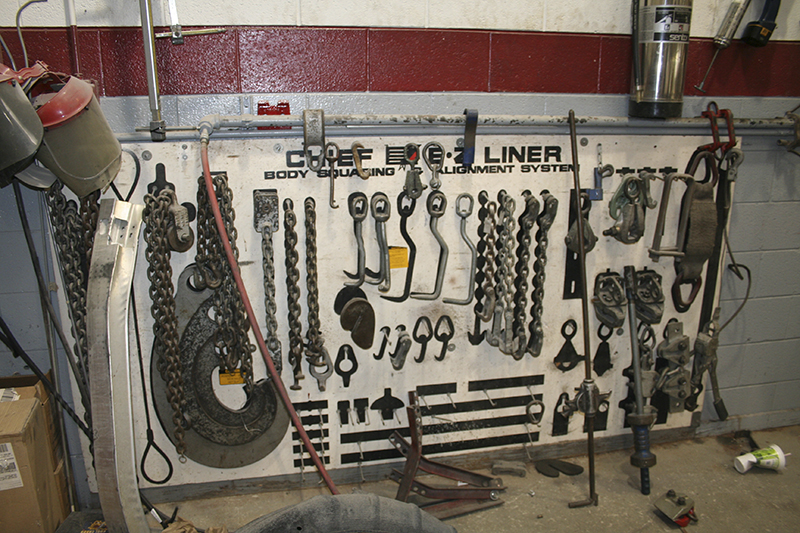

- A three-dimensional electronic measuring, and/or fixture system with an anchoring and straightening rack or bench to allow 360° pulling and access to Nissan body dimensions data for damage analysis and repair.

- All the necessary anchoring and pulling accessories including clamps, fixtures, and chains.

- A squeeze-type resistance spot welder (STRSW) capable of welding high and ultra-high strength steels. Machines in this category will generally produce a minimum of 9,000 amps with a minimum of 600 p.s.i. squeeze force at the electrodes and have manual or automatic settings for steel types and coatings. The facility wiring must be capable of supplying adequate power to the machine as specified to produce acceptable welds. Test welds using the same metal type and thickness of the vehicle being repaired can be produced and be destructively tested to verify the machine and facility wiring capability and performance.

- A MIG welder capable of producing 140 amps output.

- An induction heater to provide flameless heat when controlled heating is required. A heat monitoring system or a non-contact thermometer is also required.

- Fire-retardant welding blankets (a minimum of two per each GMA and STRSW machine).

- A masking paper and tape and welding spark paper dispenser.

- A mobile fuel retrieval system.

- An R134a refrigerant recharging/recovery/recycling station and, at least one technician certified to operate this equipment.

- An A/C leak detection tool (sniffer-type).

- Portable hydraulic rams with 4 and 10-ton kits.

-

Pressure-feed corrosion protection material application equipment that has wand attachments for applying anti-corrosion materials inside body cavities with a 360° spray pattern.

-

A dent-pulling stud welder for steel and aluminum panels.

- A battery charger with start and boost capability.

-

An R134 refrigerant recharging/recovery/recycling station helps you meet regulations, saves time and holds down costs.

An adequate number of hydraulic floor jacks, jack stands and ramps to allow vehicles with low ground clearance to be loaded onto lifting equipment without damaging the vehicle.

- A caulking/sealer applicator gun kit.

- A heat gun.

- A coolant pressure tester, manual or electronic pressure test system.

- A spot sand/media blaster hand-held tool for small area blasting.

- Plastic welding and adhesive repair equipment for plastic/urethane parts.

- A headlight alignment system.

Resources

The best source for obtaining many of these Nissan-Approved items is the Nissan Techmate website at www.nissantechmate.com.

The TechMate website can also be accessed through the Nissan and Infiniti Technical Information websites at www.nissan-techinfo.com and www.infiniti-techinfo.com, without having to purchase a subscription or logging on.

Here’s a list of Nissan-approved suppliers. Many more companies also offer excellent equipment and tools for body service:

Bench Aligning Systems

- Blackhawk Equipment

- CAR-O-LINER Company

- Chief Automotive Technologies Inc.

Paint Booths and Accessories

Vacuum Sanding Equipment

Air Compressor Systems, Air Dryers and Accessories

- Champion

Curtis-Toledo

0 Comments