With all the modern conveniences found in Mercedes-Benz vehicles, it’s no wonder they also have a technologically-advanced power distribution system. The Dual Battery system helps manage this symphony of electronics.

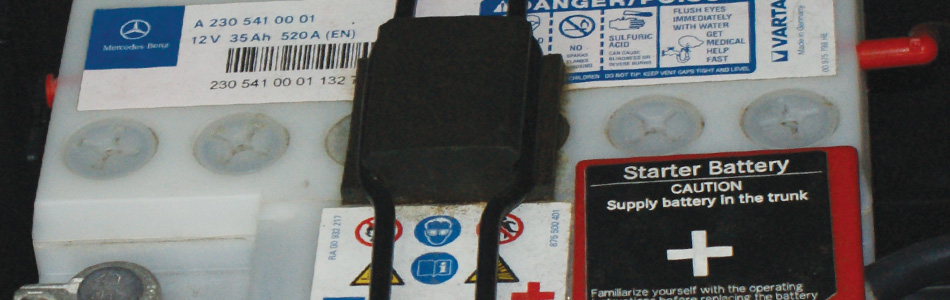

If you see a relatively large conventional lead acid battery (clear case), it is for starting. All jump starting should be done here, and you should load test it in the conventional way. This battery requires maintenance, so check the electrolyte level and specific gravity.

Technology does not come without consequences. Mercedes-Benz vehicles are some of the most technologically advanced on the planet. The features that separate them from ordinary vehicles are very often the computer systems that control almost everything from the powertrain and chassis to body and HVAC, and all of them require a stable source of electrical power. As this situation evolved, changes had to be made to the conventional charging and power supply systems to keep pace with electrical demands. What most people do not know about their charging systems is that not much charging is going on at idle. The alternator is simply not spinning fast enough to make any appreciable current. The real charging takes place on the highway. Even then it is more of a trickle charge than a big boost since much of what’s generated is being used up by big consumers as you drive.

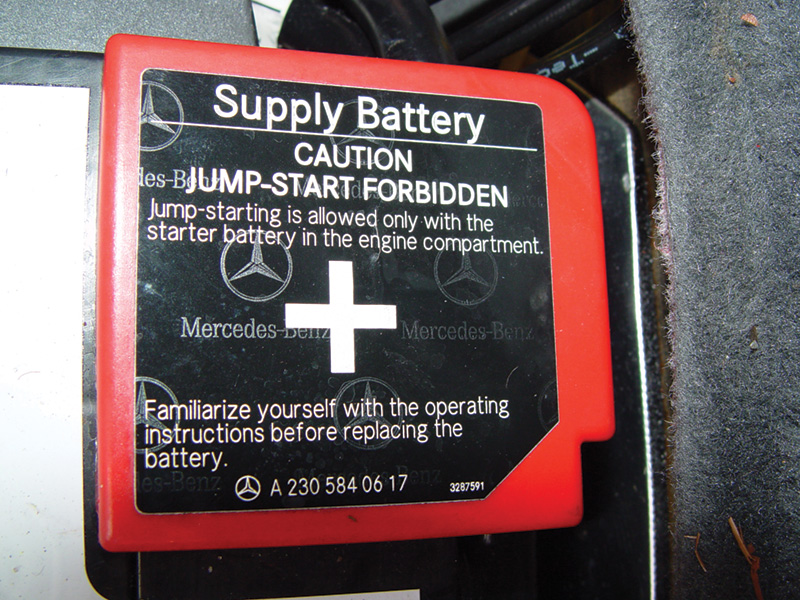

Don’t discard the systems battery’s positive post cover as it carries the warning not to jump start the vehicle from this post. Also, these VRLA/AGM batteries should not be charged as you would a conventional unit. Use low current over a longer period of time, or simply use a charger specifically designed to handle AGMs.

Generally, current draw is much less on a sunny day than on a cold night with rain when the blower motor, headlights, and wipers add to the load. The alternator has to supply stable current and voltage under these varying conditions, so Mercedes-Benz developed a dual-battery system that increases power storage capacity to provide a safety margin — one battery starts the engine and the other supplies the rest of the vehicle. They can be isolated from each other when the extra capacity isn’t needed, and combined under heavy electrical loads. Also, non-essential electrical consumers can be shut off if the total load exceeds the system’s capabilities. As with any other feedback system, a control unit is necessary to monitor the electrical load and make the necessary changes, such as tapping into or isolating the additional battery.

At the base of the windshield under a protective cover is the auxiliary relay. This connects the auxiliary battery to the system either to supply voltage or receive charging current for the auxiliary battery.

There are two variations of the dual-battery system you will find on Mercedes-Benz vehicles. You can tell them apart by the size of the battery under the hood. The larger conventional lead-acid battery is on the late 1990s/early 2000s system. The smaller motorcycle-type battery is used on the early to late 2000s. The early system uses the conventional battery mainly for the starter if the other trunk-mounted battery is low. It can also supply current when vehicle demands are high. This is the only battery you should jump start the engine from. It is known as the “starter†battery and the red warning tag over the positive battery post lets us know that. The larger battery mounted in the trunk is known as the “systems†battery. It supplies power to the accessory and ignition switch-on functions. You should never attempt the jump start the vehicle from this battery.

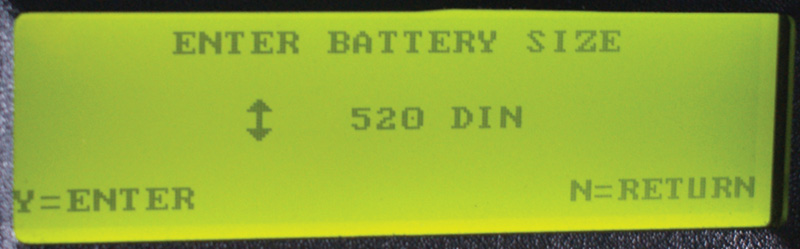

Read the label on the battery and you may see some ratings you are not used to. For instance, Ah stands for Ampere Hours and DIN is Deutsches Industrie Norm, the European equivalent of SAE. You are probably accustomed to looking for the cold cranking amp reading. This is one difficulty in finding a non-OEM replacement.

On the later system, a smaller (motorcycle-sized) battery is mounted underneath the cabin air filter. It is of the VRLA (Valve Regulated Lead Acid) type, and uses AGM (Active Glass Mat) construction. It is usually in a black case and the label identifies the battery type and specifications. This battery is a sealed unit, but if internal pressure increases to a predetermined point a relief valve opens. AGM batteries use absorbent glass mat to hold the electrolyte against the internal plates. They need to be charged at a very low level over long periods, or with the AGM settings on your charger. The larger systems battery found on both the older and newer variations are also of the VRLA type. This is one reason replacement batteries should be OEM from your Mercedes-Benz parts supplier. The rest of the system is designed to work with this type of battery, and any substitutions can lead to trouble codes and poor performance.

The early system (with the conventional starter battery) has a Vehicle Power Supply control module. It manages the charging of both batteries with two relays. One is the cut off relay, and the second is called the isolation relay. The cut off relay disconnects the starter battery from the rest of the charging system when it is in the relaxed state. When the systems battery drops below 10.8 volts, the cut off relay is energized and the starter battery voltage is added to the overall system. It is also energized to allow the charging system to charge the starter battery. The isolation relay is normally closed and provides voltage to the accessory power sockets. When voltage is low, the relay is energized opening the voltage supply circuit to the accessory sockets. Through CAN messages to the SAM module, other accessory consumers such as seat heaters are shut off to reduce the electrical load.

The later system works slightly differently. The under-hood battery is an auxiliary battery, not a starter battery. A Battery Control Module (BCM) monitors the available battery voltage at start up and during heavy electrical loads. It is critical that you do not connect vehicle accessories directly to this battery as the BCM will not measure these electrical loads. Always attach accessories through one of the fuse circuits in the pre-fuse boxes. The control unit still controls two relays. The cut off relay still interrupts electrical consumers if battery voltage is too low, but now we have the auxiliary battery relay that simply adds an additional power source to meet the demands of the vehicle. You can look at data with your SDS since the control modules are integrated into the car’s CAN network. Remember, substitute batteries were not made to work with the vehicle’s battery control units and you may set codes or cause premature failures. To test these VRLA batteries you will need a tester with an appropriate setting. The Miditronics 717 is one tool that Mercedes-Benz approves for testing these batteries. Knowing how a system works and properly repairing it properly is what Mercedes-Benz wants for your customers and your business. Â

Â

When using an AGM battery tester, you will have to enter the specifications of the battery. You may have to change the units you are measuring with to make sure the tester performs the correct test.

0 Comments