Since 1996, OBD II regulations have required that the fuel supply system be checked for leaks as small as .020 in. As fuel is used, air must be allowed into the tank to prevent a vacuum from forming. But how do we help prevent fuel vapors from escaping?

Under the Clean Air Act of 1970, all ‘71 and newer model cars sold in this country were required to have an evaporative emissions system that prevented raw gasoline vapors from the tank (and, in those days, from the carburetor fuel bowl) from escaping into our precious atmosphere. In a typical early EVAP set-up, these vapors were routed to a charcoal canister via small-diameter hoses, where they were stored. When the engine was running off-idle, ported vacuum near the throttle plates would draw them into the intake manifold so that they would get burned in the combustion process.

About a decade later when closed-loop electronic engine management was phased in, the PCM controlled a vacuum solenoid that would purge the charcoal canister at the most opportune moment for performance.

When OBD II regulations were instituted in 1996, everything changed. The Society of Automotive Engineers (SAE) proposed a means of addressing the concerns of escaping fuel vapors. Raw fuel (hydrocarbons, aka HC) could get into the atmosphere because of a leak in the EVAP system, or because it was overwhelmed. The EPA wanted these potential emissions to be eliminated by a protocol that could check for leaks. Early attempts at compliance were dubbed non-enhanced systems with minimal capacity. Enhanced systems are capable of finding large leaks (.040 in., or larger), or small leaks (down to .020 in.).

EVAP Leak Monitor 101

There are two different ways to determine if there is a leak in the system: pressure decay and vacuum decay. With pressure decay, a small amount of air pressure is generated and applied to the EVAP. Of course, the system is vented as it absorbs fresh air into the canister to mix with the gasoline vapors. This venting needs to be closed to check for a leak. All EVAPs have a canister purge solenoid that opens and allows the vapors in the canister to be drawn into the engine. In a pressure decay system, this solenoid is closed to seal one end. The other end of the solenoid seals the vented canister side. Next, a sensor or switch indicates the pressure in the now sealed system. If the pressure is maintained in the EVAP, it must not be leaking and therefore passes the EVAP monitor. If the sensor or switch indicates that pressure is lost, the PCM looks at how long it took to drop and calculates if it is a large leak or a small leak. If this happens twice, the PCM flags a code.

On the vacuum-decay type, the EVAP system is pulled into a vacuum. A computer-controlled solenoid closes the vented half of the system, and the canister purge solenoid is pulsed to pull the system into a vacuum. The solenoid is then closed, and the system is completely sealed on both ends. If the vacuum is maintained, no leak is present. If vacuum is lost, there must be a leak. Once again, the amount of vacuum lost over time is used by the PCM to calculate if it is a large or a small leak. Either a pressure-sensitive switch, or a fuel tank pressure sensor determines this. This test is referred to as the EVAP monitor. In order for the PCM to run the monitor, certain conditions have to be met. One of the primary concerns is fuel level. Although the purge solenoid is operated all the time to purge vapors in the canister, the overall EVAP leak test is only run when the fuel level is between one-half and three-quarters of a tank. This means the PCM needs to know how much gas is in the tank.

EVAP Monitor

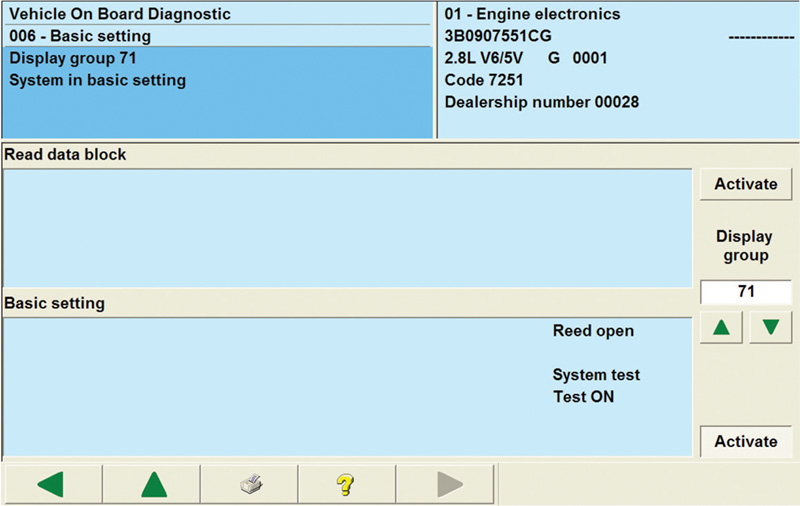

This information can be a direct input to the PCM, or it may come in on a CAN network from the instrument cluster if the fuel gauge is wired directly into the cluster. Either way, if you have codes for a fuel level sensor you may have some difficulty getting the EVAP monitor to run. If you have a VAS 5052 or equivalent, you can force the monitor to run to completion. Also, if you have a leak the fact that you can run the test should be considered in your diagnosis. If you enter basic settings, you can get all non-continuous monitors to run (non-continuous monitors do not run all the time). The first time the test runs and fails, a pending DTC is set. The second time the system fails the monitor, it flags a DTC and the MIL (Malfunction Indicator Lamp) is illuminated. Continuous monitors run whenever the ignition key is on and will flag a code immediately if a failure is present. A problem with the electrical circuits of the EVAP system will flag a code. Remember, leak codes require two trips to flag a permanent code.

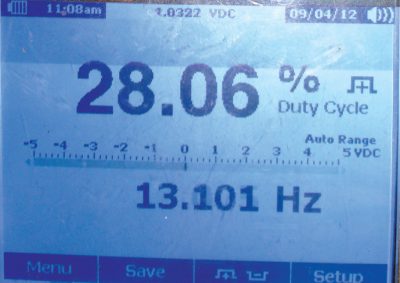

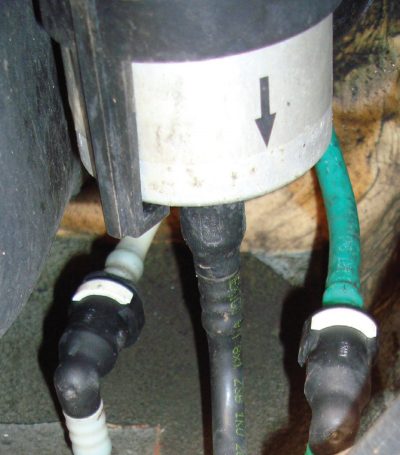

Starting in late 1995, Volkswagen vehicles used the pressure decay method to determine if the system had a leak greater than .020 or .040 in. The second component in the EVAP working with the canister purge solenoid was the Leak Detection Pump (LDP), the purpose of which was to pressurize the system. It is two components molded into one. One is the solenoid that controls the vacuum supply to the pump, and the other is the switch that reacts to the vacuum in the system. When the LDP is not energized, it is the fresh air vent to the canister. When the system is energized, the solenoid is pulsed on and off. This allows manifold vacuum into the upper chamber of the LDP causing a diaphragm inside to lift against a spring. When the solenoid is pulsed off the diaphragm returns and forces slightly pressurized air through a reed valve into the EVAP system, which causes the pressure sensitive switch to close and send a voltage signal back to the PCM. The computer evaluates how long this switch stays closed in response to pressure in the system and determines if there is a leak, and if it is small or large.

The Smoking Gun

If the self-diagnostics have determined that there is a leak, you are going to have to find it, and there are a few different approaches. We’re sure you’ve heard of smoke detection. In this case, lightly pressurized air and visible smoke is pumped into the test port of the EVAP system. Often, smoke machines used for EVAP have a nitrogen tank to supply the pressure. This is considered safer than using shop air, which would create a flammable mixture. As the smoke fills the system and builds pressure it will escape through any leaks. With the vehicle on your lift, go over all of the hoses with a strong light looking for smoke. Most smoke machines have a flow meter, which can be used to see if you still have flow when you close the fresh-air vent.

As mentioned earlier, on Volkswagen vehicles from the late 1990s you can select Basic Setting data block 71 to run the test. If the system passes, the monitor will show it as completed. This can also be used as a diagnostic tool. If you have a VAS 5052 or equivalent, you can command the EVAP test by simply clearing any DTCs and running the monitor in Basic Setting data block 71, and you can do this multiple times. Each time, you can remove and plug off another part of the system.

Start with the components and hoses farthest away from the LDP.

For example, suppose you have code for a large leak. You enter Basic Setting, select block 71, run the test, and it fails. You then block off the canister purge solenoid and rerun the test. If it passes now, you can conclude that the canister purge solenoid is not closing all the way and is allowing EVAP air to leak into the intake manifold while the PCM is trying to perform a leak test.

New and Improved

Newer Volkswagen models, such as the 2011 Volkswagen Routan, use a system called Natural Vacuum Leak Detection (NLVD). The heart of this is the Evaporative System Integrity Monitor (ESIM), which is mounted directly on the canister. It contains mechanical components, so its position is critical (brackets are used when the canister is mounted at an angle). The ESIM comprises a housing, cover, a pressure-sensitive diaphragm and switch, and two check valves attached to two different weights. One weighted check valve reacts to pressure and the other reacts to vacuum. The diaphragm/ switch in turn reacts to the pressure or vacuum inside the EVAP system and sends a signal to the PCM. This system is an improvement on earlier NVLD systems since it no longer needs a solenoid. During refueling, the air that was in the gas tank becomes pressurized. When the pressure exceeds five inches of water, the large check valve is forced open and the fuel vapors are sent to the canister. While the vehicle is running, the fuel is heated by ambient conditions and expands. As the fuel cools, it contracts and the EVAP system draws a vacuum.

The natural vacuum created causes the diaphragm to be pulled in and closes the switch. This lets the PCM know the system is in a slight vacuum. After a calibrated amount of vacuum (about one inch of water) has been achieved, the small check valve opens and allows fresh air in to mix with the vapors in the canister. With atmospheric pressure being the same inside and outside the canister, both weighted check valves are closed, sealing the system. The PCM evaluates how long it takes the cooling of fuel to pull the system into a vacuum. If it takes too long, then there must be a leak. The PCM is only watching the switch condition, so the test is considered nonintrusive. If this test is failed, the PCM performs an intrusive test. During the next cold start, it pulses the purge solenoid and draws the EVAP system into a vacuum. It then monitors how long it takes for the switch to open. If it opens quickly, there must be a large leak. If it takes slightly longer, there must be a small leak. The PCM also evaluates leaks in the purge hose to the manifold. For 30 seconds after the engine is shut off, the purge solenoid is kept open. This should eliminate any vacuum built up in the system and the PCM verifies that the switch in the ESIM is open.

In Closing

Understanding how EVAP systems work is the key element in diagnosis, and will help you troubleshoot nagging EVAP leak codes faster and with more accuracy. It is also important to learn about future EVAP monitor testing to prepare for when newer vehicles start showing up at your shop. Your continuing education through your Volkswagen dealer and

TechConnect will help you along the way.

0 Comments