“Self-adaptation†is how M-B refers to fuel trim and that’s actually more descriptive. Regardless, understanding this electronic engine management feature will help you cure MIL-on complaints, failed emissions tests, etc.

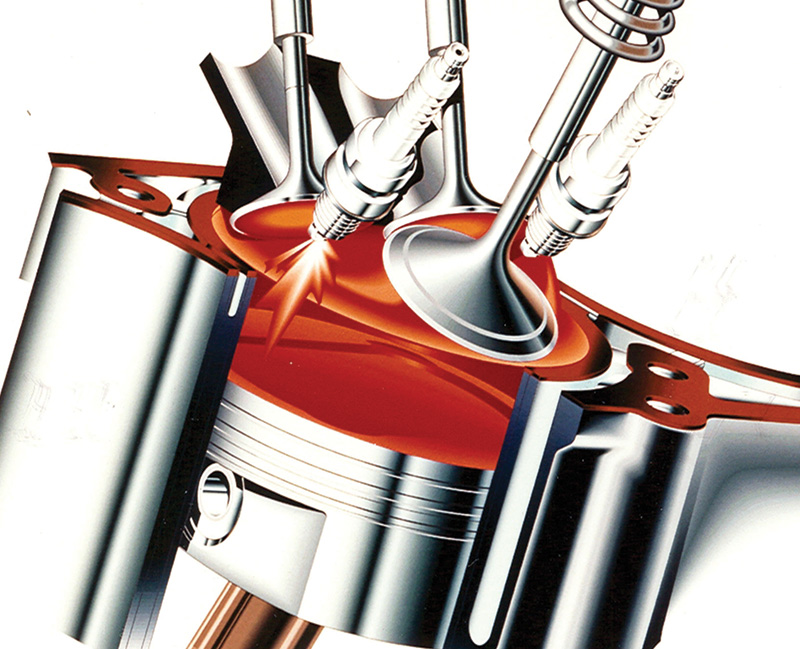

Three valves and two plugs per cylinder help make the M112/M113 engine efficient and clean-running, but the A/F ratio has to be right.

The dreaded “Check Engine†light.  Commonly referred to as the CEL, but more accurately called the MIL (Malfunction Indicator Lamp), its illumination is a source of anxiety for the owner of the vehicle. No one wants to get stuck during a grocery run, or while commuting to work, and that light in the cluster brings up all kinds of troubling uncertainties. Do I have to take care of the problem right away? Is it going to be expensive to fix? Will my car ever run right again?  For a technician, that indicator can also be a source of anxiety. Did I diagnose that fuel trim code properly? Have I replaced the right part? Is the light going to come on again? Here, we’ll take a look at how to properly diagnose a fuel trim code on a Mercedes-Benz vehicle. If you fix it right the first time, there will be less anxiety for everyone involved and more profit for your shop.

Continuous tune-up

Fuel trim is the fine tuning of the air/fuel ratio the engine control module (ME, or in standardized SAE J1930 terminology, PCM for Powertrain Control Module) does to compensate for any small deviations away from the ideal mixture. It is important that these calculations are as accurate as possible, to ensure a smooth running, smog-free engine.Â

How does the ME know how much fuel to inject? As you know, the basic formula for complete combustion calls for 14.7 parts of air to 1 part of fuel by weight, which is known as the stoichiometric ratio and is often represented by the Greek letter Lambda. In terms of fuel trim adjustments, ME will makes its calculations based on a post-combustion reading taken from the exhaust stream using the O2 sensors, or, in later models, A/F “wide-range†oxygen sensors. The amount the oxygen in the exhaust indicates whether the engine is running rich (too much fuel) or lean (not enough fuel). How can the readings be taken after combustion and still be used for calculating an accurate air/fuel mixture during combustion? This is a very important question.

Pattern recognition

Fuel trim has to be thought of as an overall trend. The ME is not looking at each individual cylinder to make adjustments in fuel trim, but rather at the big picture. It will help to remember this during our diagnostic process. Also keep in mind that there is a limit to how much the ME can adapt. If you’re old enough to remember carburetors, you could compare this to the limited idle mixture screws that were mandated in the 1970s to reduce exhaust emissions. Turning them in or out as far as they would go had only a small effect on the idle mixture, and couldn’t make up for such things as a major vacuum leak, or a heavy float.

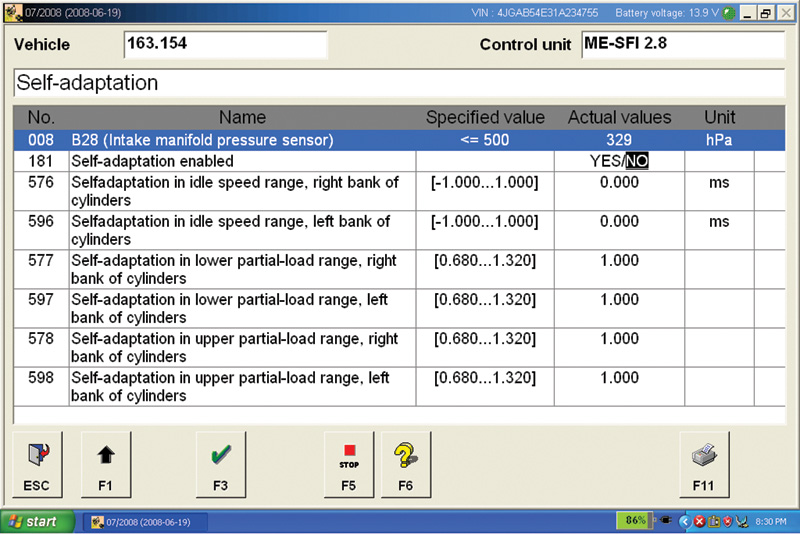

There’s only so far the ME can adapt in either direction of increasing or decreasing injector pulse width, hence fuel quantity, before it reaches its limits. For Mercedes-Benz, this is called Enrichment Limit, or Enleanment Limit. Although these values may be shown in different ways depending on the model, it is commonly displayed as a number between -1.000 and +1.000 when everything is okay, and outside of that range (in either direction) when something is wrong. The more positive the number, the more fuel ME is adding, and vice versa.

For the most accurate diagnosis, it helps to have the factory scan tool, which is called the Star Diagnosis System (SDS), or the Diagnostic Assistance System (DAS), or XENTRY for newer models (for the purposes of this article, we will be using DAS). Just having the tool is not enough, however. DAS will provide you with a whole lot of information, but it’s up to you to decide what to do with it. For our example here we will be using a 2001 ML 320 with the V6 M112 engine. The M112 and its V8 sister the M113 share many design features: single overhead cams, three valves and two plugs per cylinder, sequential fuel injection under the control of ME SFI, and a Hot-Film Air Mass Sensor (also known as the MAF for Mass Air Flow). The M112/M113 engine family was standard in most Mercedes-Benz cars and SUVs from 1998-2006. Fuel trim fault codes are fairly common with these engines, so there’s a good chance you will see one of these cases roll into you shop pretty soon.

Before we begin, let’s mention that we are assuming the O2 sensors have been checked and are operating correctly. If you suspect a lazy or failing O2 sensor, DAS has some nice features that will help you determine if it (or they) need to be replaced (perhaps we will tackle that topic in a future article). For now, let’s assume all these critical sensors are functioning properly.

Out of range

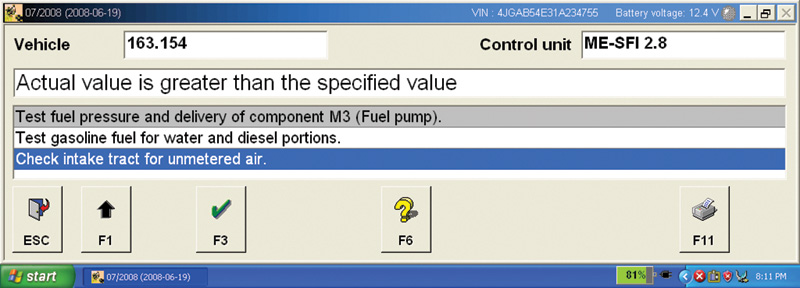

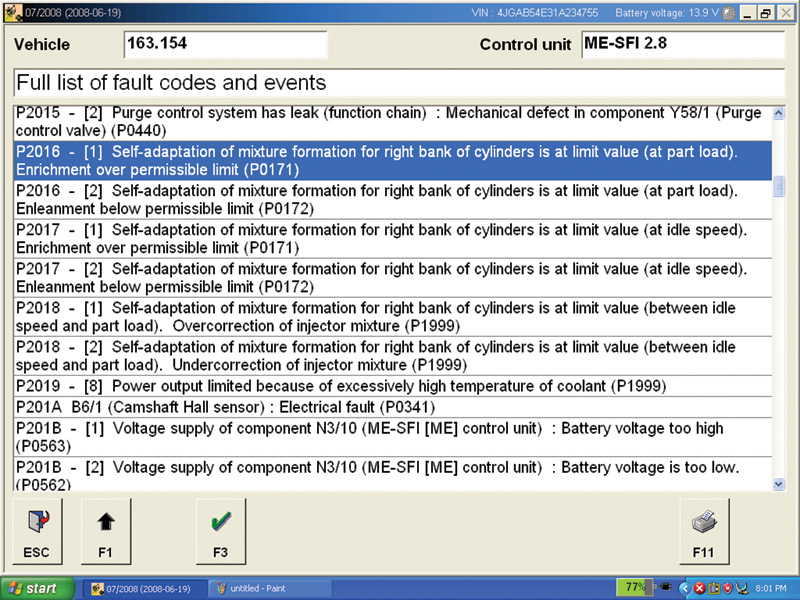

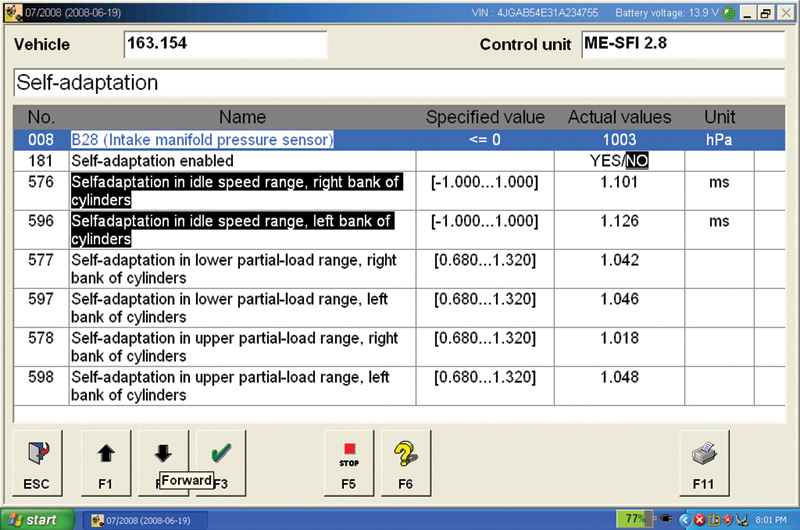

Here’s the scenario: A vehicle comes in with the MIL on. You do the basic scan for fault codes (short test) and you come up with what’s highlighted in Figure 2.

What does “Enrichment over permissible limit†mean exactly? Simply that the ME cannot increase the duration of the pulse width, hence the amount of fuel injected, any further. This is the most common fuel trim code in an M112/M113, enrichment over the limit either at idle speed or part throttle. So, we know the engine is running lean and the ME cannot add enough fuel to make it back to the 14.7:1 ratio (Figure 3).

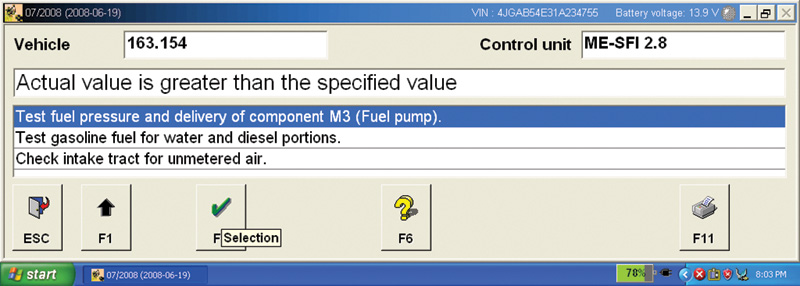

Why is the ME adding so much fuel? DAS leads you down a diagnostic path starting with Figure 4.

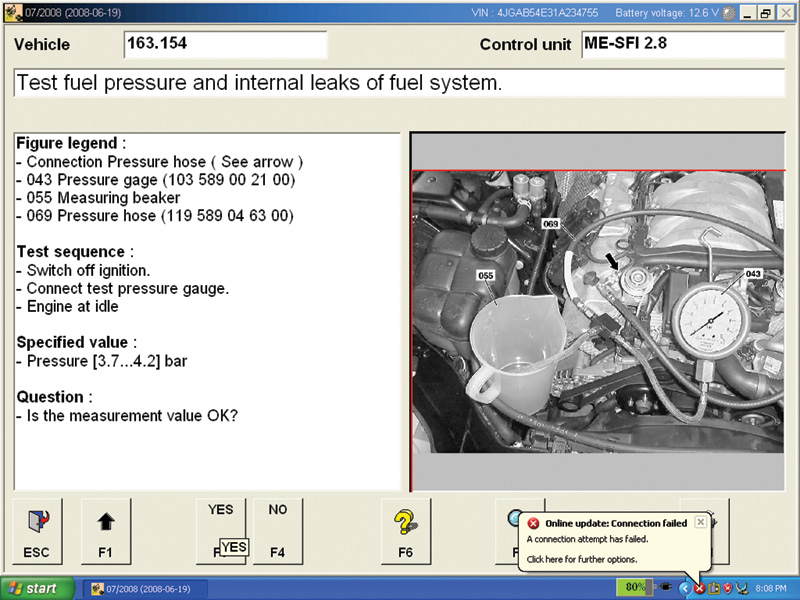

First, let’s see if it’s a fuel problem. Bear in mind that it’s not enough just to check fuel pressure. Quantity matters as well. DAS first has you check for adequate fuel pressure and internal leaks (Figure 5).

Bar and volume

Figure 7: DAS shows more than a liter of gasoline to the fuel pump in 30 seconds, so continue on with diagnosis.

Install a fuel pressure gauge and run the engine at idle. The pressure should be 3.7-4.2 Bar. Turn the engine off and leave gauge connected. After 30 minutes, the pressure in the rail should still be greater than 2.5 Bar. Anything lower than that might indicate a leaking injector (or, perhaps a leak upstream). In our case, the fuel pressure remained above 2.5 Bar, so we continued to follow the prescribed procedure (Figure 6).

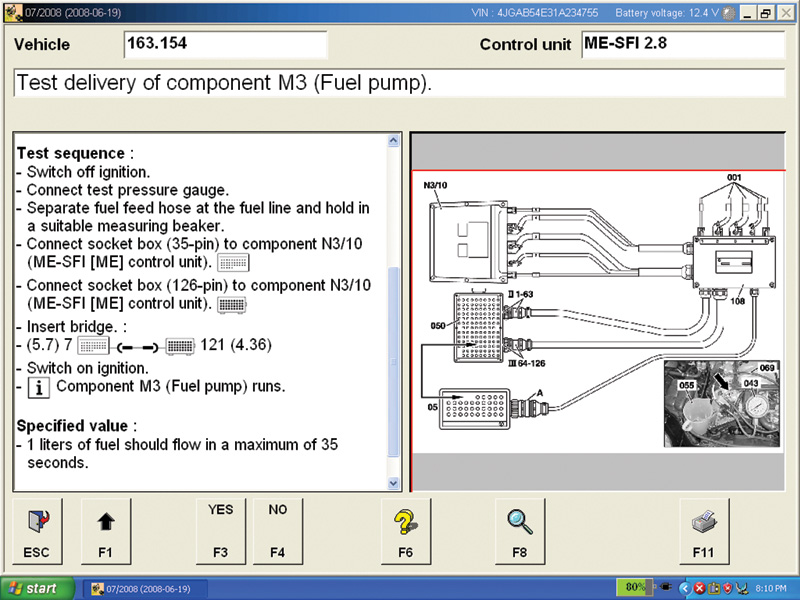

Here DAS is having us check the amount of gasoline the fuel pump (M3) delivers. One liter should be delivered in less than 35 seconds. If not, check for restrictions in the fuel pump circuit such as a clogged filter or crimped line. We were getting more than a liter in 30 seconds, so we continued on the diagnostic path (Figure 7).

We knew there was no diesel or water in the fuel because we looked at the fuel sample taken on the previous test. At this point, DAS suspects unmetered air. In other words, air entering the intake tract downstream of the Air Mass Sensor, thus not measured by it, or accounted for by the ME. Two things are possible:

- There is a leak in the duct between the Air Mass Sensor and the throttle body admitting “false air,†or an ordinary vacuum leak in a hose or joint.

- The Air Mass Sensor is not sending accurate signals to the ME.

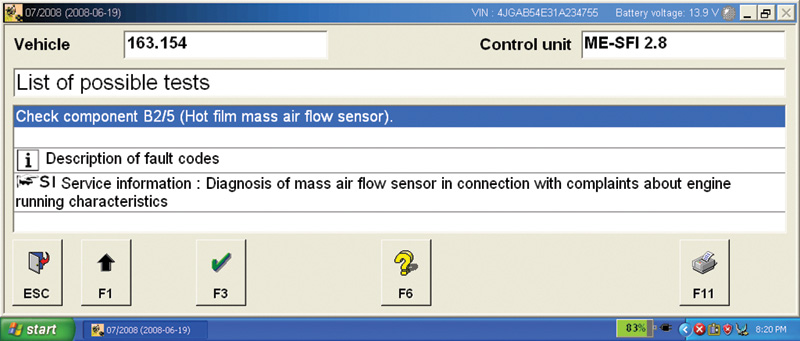

How do you find out which? Smoke testing the intake and EVAP systems for any possible leaks is a good start. Once you are absolutely sure there are no intake leaks, then you can suspect the Air Mass sensor. How do you test it? DAS helps with that too. If there is no direct fault code for this crucial sensor, the easiest way to do this is to find the “List of possible tests†menu (Figure 9) inside the ME using DAS.

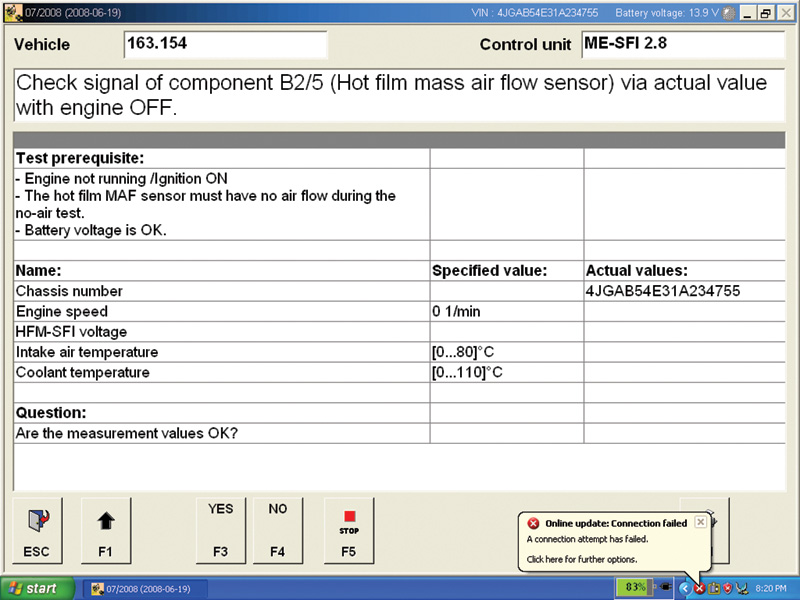

From there you can get to the screen where you can check the data from the Air Mass Sensor (Figure 10).

Hot film

The important data here is the “HFM-SFI voltage.†This is the signal back to ME that tells it just how much air is coming through the throttle body. An aside on how a Hot Film Air Mass Sensor works is appropriate here. Basically, a film element is heated to a given temperature inside the sensor housing. As air passes over this element, it has a cooling effect. The ME watches how much voltage is needed to maintain the calibrated temperature, and extrapolates from that and the intake air temperature sensor signal the actual mass of the air entering the engine. This is a much more precise reading than could be obtained with an old-fashioned VAF (Vane Air Flow — a flap rotating in the air flow and turning a variable resistor), which couldn’t actually “weigh†the air.

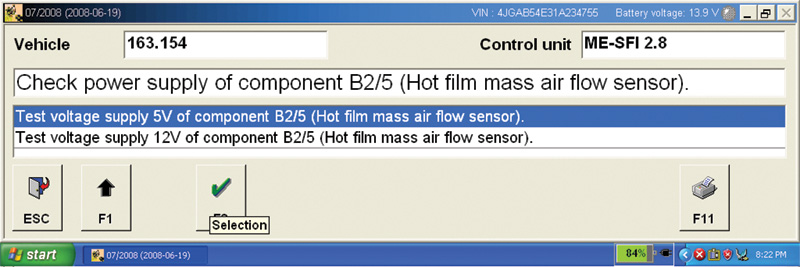

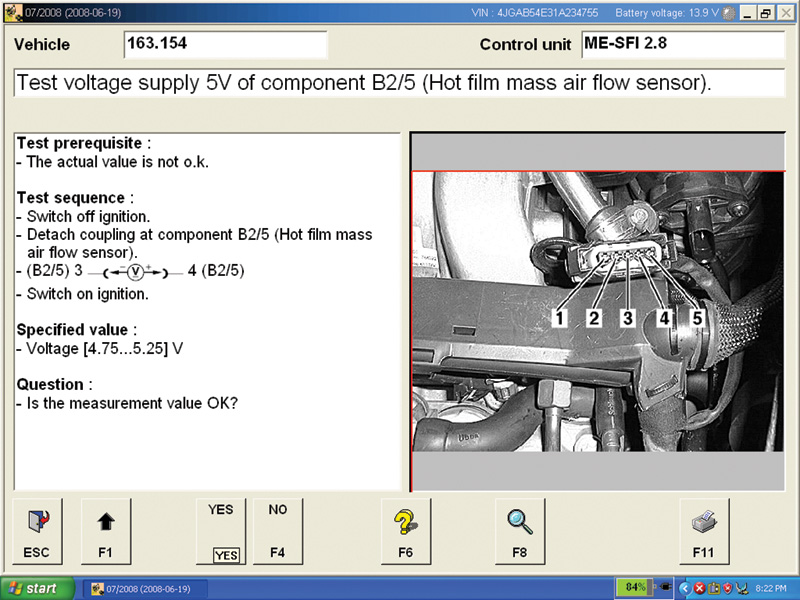

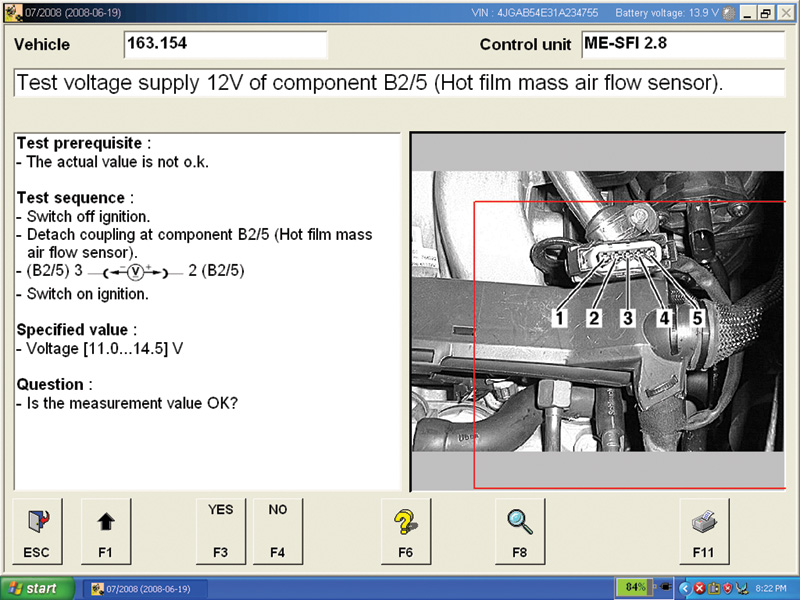

If this voltage is off either in partial load or idle conditions, there will be a fault with self-adaptation. A problem with the Air Mass Sensor or its connections or wiring is probably the most common source of a fuel trim code in the M112/M113 engine, but how do we prove it? There are two voltages we must check first (Figure 11). DAS has us check the 5V reference and the 12V supply to the Air Mass Sensor (Figures 12 and 13).

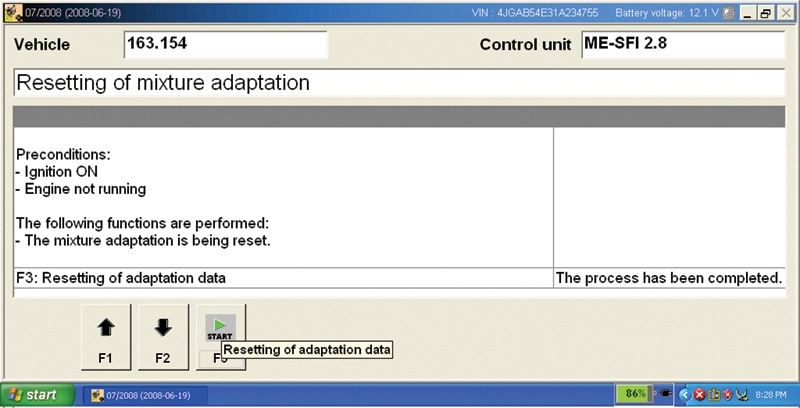

If either of these voltages is off, there’s a problem with the ME itself, or the wiring between the sensor and the ME. Chase this down. If both of these readings are good, either there’s a bad contact in the connector to the sensor, or the sensor itself is faulty (you did positively rule out an air/vacuum leak, right?). A quick way to double-check this is to reset the adaptation data in the ME. First, clean the contacts in the Air Mass Sensor connector using the special electrical kit, or any good contact cleaner— be careful because the contacts are tiny and delicate. Then, using DAS, access the ME’s Adaptation Menu and select “Resetting of mixture adaptation†(Figure 14). Once you’ve reset the adaptation, everything goes back to the zero position (Figure 15).

Drive the car, or run it at idle. If the Air Mass Sensor is bad, you will almost immediately see the adaptation data creep back to the limit. If it does, you can feel confident about replacing the sensor (again, make sure you’ve ruled out air/vacuum leaks!). Protect the new one by making sure it stays clean— install a new air filter element as well, and make sure there are no other contaminants getting into the intake tube.

While here we concentrated on a lean condition code, the same principles apply to a rich code, but instead of being paranoid about intake leaks, you would be trying to find where the extra fuel is coming from (bad/leaking injector?). Lean or rich, DAS gives you the information and the step-by-step procedures you need to find the fault. Happy hunting.Â

0 Comments