Whether it’s the government mandating higher fuel economy standards, or customers demanding greater performance and smooth shifting, Mercedes-Benz has always risen to the challenge. For almost a decade, 7G-Tronic transmissions have been an important part of that response, so they are starting to require service. Here’s what you need to know.

Even though we don’t think much about it, the automatic transmission is present in something like 95% of the vehicles sold in the United States. Spirited drivers enjoy being in control of the revs as they go through turns and relish the driving experience, but this was mostly limited to those who knew how to engage a clutch. That is, until sophisticated electronically-controlled automatic gearboxes from Mercedes-Benz arrived, providing the ability to manually shift gears to everyone.

Older automatics lost horsepower through the fluid coupling of the torque converter, which also reduced fuel mileage. Mercedes-Benz engineers made great strides in fuel efficiency and putting power to the ground when they designed the 7 G-Tronic transmission, which made its debut in the 2004 model year and has since been installed in more and more models. They are getting close to 10 years old, and have accumulated some serious mileage. To give them an even longer service life, they are going to need some maintenance, and in this these transmissions are unique. We should all know their special requirements for our customers’ good and our profitability.

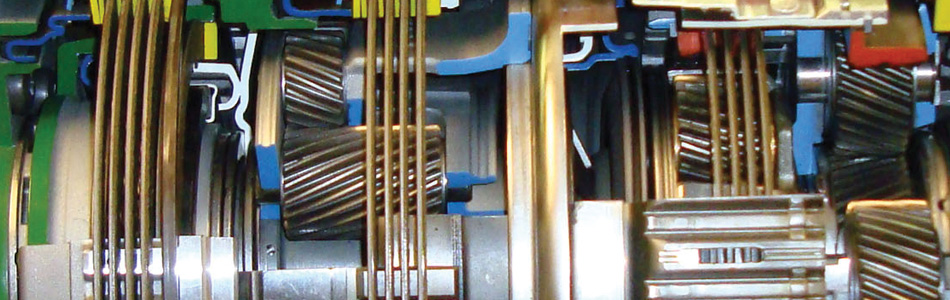

This new gearbox’s service designation is 722.9, which is the next evolution from the earlier and more mechanical 722.6 model transmission. The reason it is called the 7G-Tronic is because it has seven forward gear ratios. This could be achieved because the transmission is completely computer-controlled. While older models (211, 205, etc.) have mechanical linkage that controls the same shift pawl that the ISM does, later versions dispense with this. Instead, the Electronic Selector Module (ESM) sends the gear position signal over the powertrain CAN (CAN-C), and it makes its way to the 7G-Tronic control unit mounted in the transmission valve body. In the case of the 221 Chassis S-Class, the gear position input comes from the Gear Selector Switch mounted in the Steering Column Module. Either way, it is a CAN input to the Electronic Transmission Control unit (ETC) and the Intelligent Servo Module (ISM). The ISM is mounted on the side of the transmission and controls a mechanical motor that moves a shift pawl in the transmission. By having the ETC control unit mounted inside the valve body, Mercedes-Benz has reduced the number of wires into and out of the transmission, thereby reducing complexity. This, however, prevents a technician from electrical testing of individual components inside the transmission.

Being Prepared

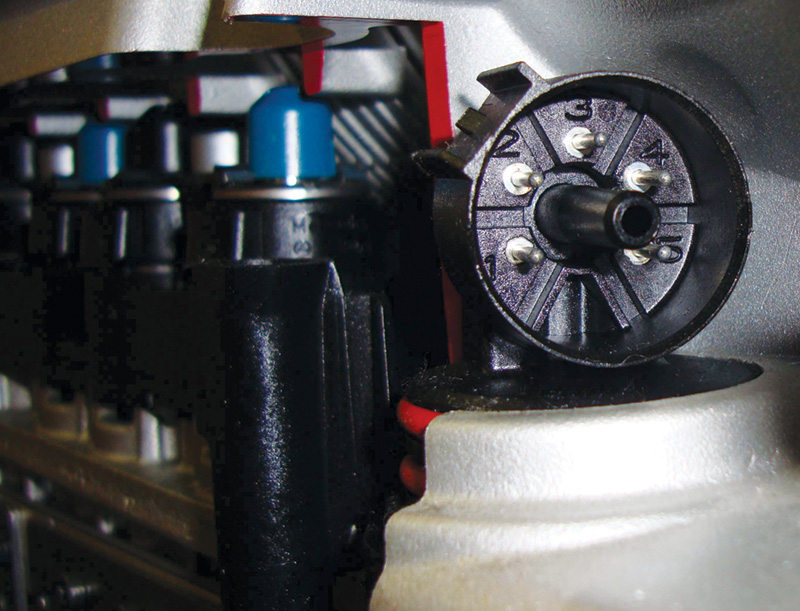

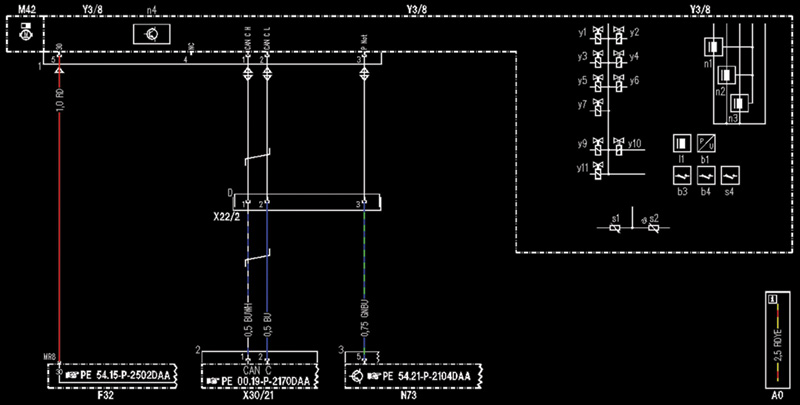

With the ETC unit moved inside the transmission, wiring to and from the control unit has been reduced. This connector is for the later 724.2 and 725 transmissions. Pins #1 and #2 are the CAN C lines and voltage is supplied on pin #5. Pin #3 is the wake-up signal from the EIS and lets the ETC unit know the key has been turned on or off.

As a result of most of the electronics being moved inside the transmission, diagnostics are handled by the Mercedes-Benz scan tool SDS/XENTRY, or equivalent. If you have made the investment in an SDS, you are rewarded with a significant amount of information and control. Before you can view this data, you need to verify communication with the ETC control unit on the C CAN. There is a six-pin connector on the 722.9 transmission connecting the control unit to the harness of the vehicle. The next generation 724.2 and 725 transmissions have a five-pin connector. Only four wires are used to connect the ETC control unit to the rest of the car. This helps reduce wiring complexity and streamlines the diagnostic process. Typically with the 722.9 transmission, pins #1 and #2 are the CAN C wires. The front SAM supplies power to pin #4 of the control unit, and pin #5 provides the ground. The best way to get an accurate wiring diagram for the vehicle you are working on is with a paid subscription to www.startekinfo.com. Verify that the connector is not full of transmission fluid — it is possible for it to leak. Once you have established communication, you can move on to the next step of the diagnosis.

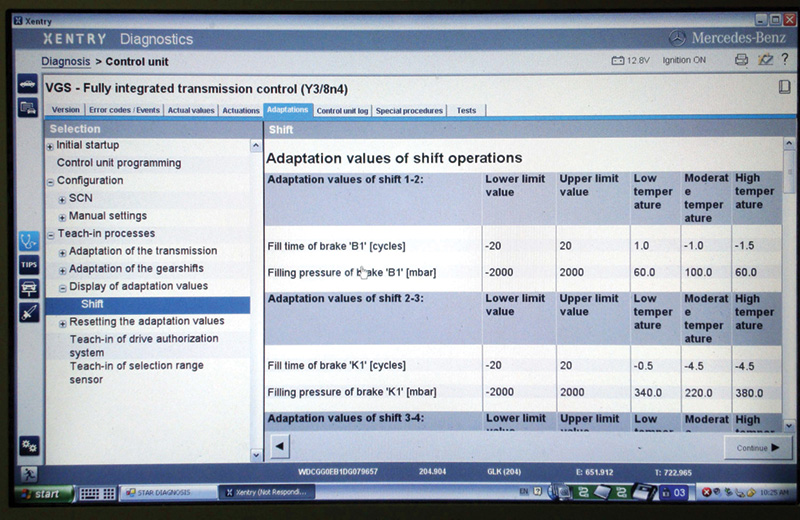

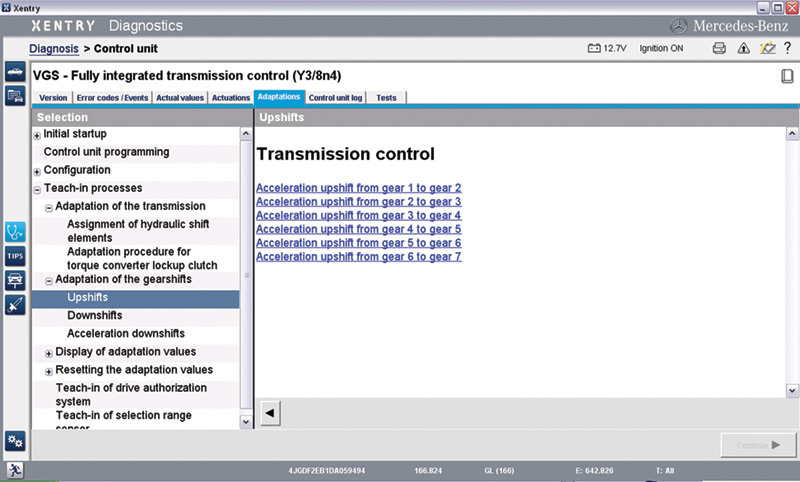

As you probably know, the self-diagnostic capabilities of Mercedes-Benz control units are comprehensive. You should first look at any self-diagnostic trouble codes or events flagged by the ETC unit. You can also use bi-directional controls such as “Actuations†or “Tests.†If the customer complaint has to do with unusual shifting, you can view “Adaptations.†As the vehicle is driven, the ETC unit monitors the input, intermediate, and output shaft speed sensors. By comparing the three it can determine if the clutches are slipping and make changes to the pressure control to maintain smooth shifting. As the transmission clutches wear, the ETC unit can keep pace with these changes and provide seamless shifting. You can view these changes and see if any severe adjustments are being made. This can let you know if the transmission has reached a point where it is going to require service. As clutch material wears away, it travels throughout the gearbox suspended in the transmission fluid. If this material builds up in the torque converter clutch, shift, or pressure control solenoids it can cause shift concerns. It can also get trapped in the valve body, causing pistons to stick.

With a paid subscription to www.startekinfo.com, you can view a wiring diagram for the ETC unit. Here we have the 724.2 showing the power supply, CAN C, and wake-up signal. The transmission body itself forms the ground for all the electrical components.

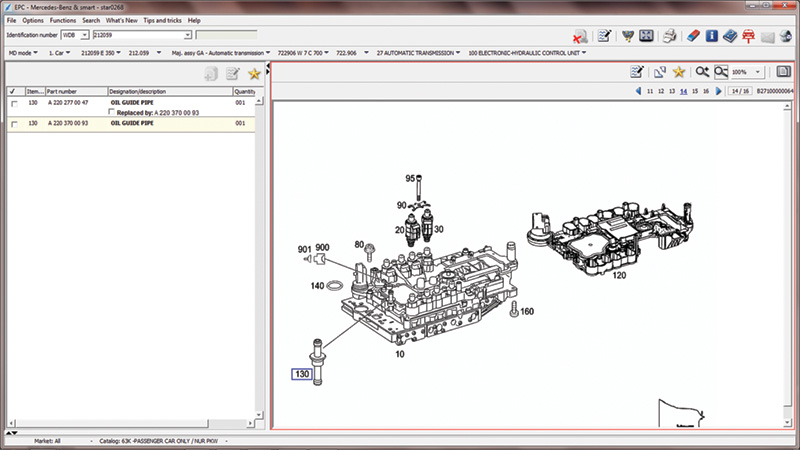

Looking at Mercedes-Benz EPC will give you an idea of components inside the transmission. Here, we have highlighted the oil guide pipe. It supplies fluid pressure to Brake B3. If there is a leak here, it can cause problems with starting — Neutral, 1st and Reverse all need B3.

Next Step?

As with any other transmission problem, you should first check the fluid level and look for any obvious leaks. This was typically done with a special tool dipstick on the 722.6 transmission. The procedures for checking the fluid level on the 7G-Tronic is a little different. On these units, the overflow method is used to determine and provide the correct fluid level. The transmission needs to be under certain specific conditions before the fluid can be checked. Since fluid volume will change with temperature, you need to have the transmission between 104 and 113 deg. F. (40 to 45 deg. C), so you are going to have to warm up the vehicle. While it is safer to go on a test drive and run the transmission through all of its gears, you can duplicate this by running the vehicle on the lift or a dynamometer. Either way, this purges the air from all of the channels in the transmission and fills the torque converter. The torque converter will drain back once you stop the engine, so the fluid level is checked with the engine running. There is a standpipe in the transmission pan that has a specific height. When you remove the inner plug of this standpipe, a small amount of fluid should flow out. If not, the level is too low and fluid needs to be added through this opening.

If the transmission fluid looks or smells burned, it should be replaced. While this may correct some overall transmission performance issues, keep in mind that it will not reduce the tens of thousands of miles of use that have caused internal components of the transmission to wear out. Dropping the pan and changing the fluid and filter will only replace between five and six liters. The torque converter and cooler lines by themselves hold between four and five liters, so you are only changing a little over half the fluid. If you have the equipment to perform a fluid exchange, keep in mind that you are going to need approximately 10 liters. It is also recommended that you flush out the cooler lines specifically as clutch material and other debris may have been deposited there and can damage a new or remanufactured transmission.

There are now recommended service intervals for the 722.9 and later transmissions, somewhere around the 70,000-mile mark. This includes the transmission fluid and filter mounted in the pan. Information for the specific vehicle can be obtained from the Maintenance Section of the Owner’s Manual, or at www.startekinfo.com. You should also check technical service bulletins to see if there are any changes for the specific model and year you are working on.

By using XENTRY, you can view the adaptations the ETC unit has made to improve shifting for this particular unit. The scale is in millibar (mbar) and shows how much pressure needs to be added to improve the shift. The more pressure that needs to be added means the more there are sticking components or worn clutches.

Correcting Shifting Concerns

SDS/XENTRY software provides a way to improve shift quality on transmissions that have the proper level of good transmission fluid. Some of us in the aftermarket industry have the notion that we should clear the codes and the adaptations and then go on a road test to see what returns. Clearing the adaptations is what is needed for a new or remanufactured transmission. This erases any shifting strategy that may have been learned from a worn and slipping unit. If you do not clear the adaptations, the fresh transmission will shift as if the old slipping unit is still in place. This can cause premature wear in the new unit, and shift quality will not be smooth. By the same token, if you clear the adaptations with the old unit in the vehicle, the ETC will use a shift pattern as if the transmission clutches are new. This will make the transmission slip even more until the control unit relearns to adapt to the slipping shifts. This could take weeks and will probably cause more damage than good. SDS/XENTRY software has provisions to allow you to adapt each shift. You can go into “Adaptation of the Gearshifts†and select only the gear shift you want to correct.

The ETC control unit will go into a learn mode and quickly learn what it needs to do to correct only the shift you are having a problem with. While in this mode, have someone else drive the vehicle so you can watch the scan tool. Follow the directions, which will direct the driver to stay within driving parameters such as throttle position, vehicle speed, and engine load. Perform these adaptations three to five times. If you have still not corrected the shifting concern, you can try repeating the process again three to five times.

There are software limits within which the ETC unit can correct a shift concern. If you have not fixed the problem at this point, the unit is going to need mechanical service or replacement. You and the customer are going to have to make a value judgment to determine if the problem is only in the ETC/valve body unit, or the mechanical transmission itself, and what course of action you are going to take. You need to look at the overall mileage on the unit to see if it is worthwhile to only replace the valve body/ETC unit, or if it makes sense to install a reman or new transmission. Mercedes-Benz offers a cost-competitive replacement unit. Remember, the torque converter is available separately.

With XENTRY software, you can force the ETC into learn mode and adapt each shift one at a time to try to correct a shifting problem. You should have someone else drive the vehicle, allowing you to follow the one-screen instructions in a safe manner. Adaptations cannot be performed until the transmission is up to normal operating temperature.

Big Picture

If the customer has decided that he or she is going to invest in a new or remanufactured transmission, you need to know the process in order to complete the job effectively. Number One, aluminum bolts are used to mount the transmission and should not be reused. Purchase new bolts and torque them to specs. You already know you are going to need approximately 10 liters of Mercedes-Benz transmission fluid in order to maintain the warranty. Aftermarket fluid has not been tested by Mercedes-Benz for its lubricity or thermal characteristics and will void the warranty if there is a premature failure.

You cannot install a used transmission since the original unit has been programmed to the vehicle, and cannot be programmed to another vehicle. Only a new control unit can be installed and programmed to the vehicle. There are several steps to this process with the factory SDS/XENTRY system. First, you need to program the new ETC control unit to the specifications of the vehicle. With the new software installed, you can then request SCN coding from the Mercedes-Benz service website with XENTRY. XENTRY Connect will return the SCN software coding file, and it will only work on the vehicle for which you have requested it. Once you have installed the SCN coding, you then need to “learn†the control unit to the Drive Authorization System (DAS).

The ETC and ISM modules give current gear position to all of the other control units on the C CAN. This includes those that are a part of the Drive Authorization System (DAS), and, since it is involved in starting the car, it is part of the Theft Related Parts (TRP) program. The owner of the vehicle will need to supply proof of identity and proof of ownership before parts can be purchased. The new ETC control unit is going to need to be “learned†into the DAS system. Finally, the transmission control unit has a Selection Range Sensor built into it. This gives the gear position to the ETC control unit. This sensor needs to be matched to the ISM to coordinate shift inputs and outputs. They must match or the transmission will remain in limp-home mode. Depending on the type of failure the ETC has picked up, it will go into various limp-home modes. Individual shifts can be bypassed if there is a problem with a single solenoid, but major electrical failures put the transmission into sixth gear allowing it to be driven in for service. Vehicles equipped with this transmission should not be flat towed over 30mph, and it is best to have them flat-bedded to prevent further transmission damage.

Being armed with the proper procedures and factory-backed O.E. replacement parts makes Mercedes-Benz a partner in the service you provide to your customers. How can you get a better partner than that? This relationship helps you provide the level of service that keeps your customers coming back.Â

0 Comments