Struts are integral to most Nissan suspension designs. Let’s explore the basic methods of testing and inspecting their operation on the road and in the bay, and what to tell your customers.

Aftermarket struts are often used in place of Genuine Nissan parts because some people believe they offer equal performance, better availability, and lower cost. The fact is that aftermarket units are reverse-engineered from factory struts. The aftermarket manufacturers focus on fitment, but lack the resources to put in the internal testing hours to produce an identically-performing shock absorber. It is likely that the internals of an aftermarket strut are based on vehicle weight and target dampening, but not on rigorous lab and track testing with original Nissan equipment. Can you imagine an aftermarket strut companies seriously testing their products on every single vehicle they claim to support? You will find that the cost of Genuine Nissan struts is not prohibitive, and they are well-stocked at most local Nissan dealerships. We’ll discuss the importance of choosing the right part for the job, as well as how to test and inspect for different types of strut wear.

Aftermarket struts are often used in place of Genuine Nissan parts because some people believe they offer equal performance, better availability, and lower cost. The fact is that aftermarket units are reverse-engineered from factory struts. The aftermarket manufacturers focus on fitment, but lack the resources to put in the internal testing hours to produce an identically-performing shock absorber. It is likely that the internals of an aftermarket strut are based on vehicle weight and target dampening, but not on rigorous lab and track testing with original Nissan equipment. Can you imagine an aftermarket strut companies seriously testing their products on every single vehicle they claim to support? You will find that the cost of Genuine Nissan struts is not prohibitive, and they are well-stocked at most local Nissan dealerships. We’ll discuss the importance of choosing the right part for the job, as well as how to test and inspect for different types of strut wear.

Shocks – Struts – What’s the Difference?

Frequently, people refer to shocks and struts interchangeably, but this is not really accurate. It’s one of those situations where all struts are shock absorbers, but not all shocks are struts. To be clear, let’s compare similarities. Both shocks and struts are functionally for ride quality and safety. When driving over dips or rough terrain, all vehicles’ springs will want to expand and contract until they run out of energy. A shock absorber’s compression and rebound behavior will slow the spring oscillation down, allowing the vehicle to come to rest faster after a bump. Also, when a shock absorber compresses, it resists the vehicle’s downward motion and effectively cushions the cabin. From a safety perspective, properly functioning shocks will keep the tires in constant contact with the road when cornering or on uneven surfaces. The difference between shocks and struts is the hardware. A strut cannot be removed from the vehicle without affecting the suspension geometry. It is literally part of the structure of the car. If you remove a strut, the body will rest on the wheel. The strut is also part of an assembly where the shock absorbing portion is within a metal housing that also serves as the spring seat. The spring is partially compressed (pre-loaded) and held in place by a top mount that is secured to the top of the shock piston. A firm stopper, often called a “bump stop,†is used to protect the shock portion from over-traveling and becoming stressed. The bump stop and piston are protected from road debris with a flexible rubber or plastic boot. When doing the repair, it’s important to use Genuine Nissan parts for accurate fitment, performance specifications, and the highest quality available.

The Phone Call

Every Genuine Nissan strut is marked from the factory with the part number and the Nissan logo. Do right by your customer, and install a replacement Genuine Nissan strut to restore ride quality.

More often than not, the customer phone call will begin with, “How much for struts on my Nissan?†Many suspension and alignment shops will recommend replacement struts on nearly every vehicle that arrives. As a Nissan specialist, you need to identify your customers’ original concern, and steer them towards the decision that is best for their car. Replacing Genuine Nissan struts with aftermarket replacements at 50,000 miles would be a mistake, but one that happens all too often. There are marketing campaigns out there from major aftermarket strut manufacturers that promote unnecessary “preventive†strut replacement. A Genuine Nissan strut with 50k on it is likely to perform better than a new aftermarket replacement, so judge each vehicle through functional testing. First, find out whether something caused the customer to head to the tire shop for service, or whether the tire shop suggested strut replacement after an inspection. You can find out quickly if the customer is bothered by a clattering or clunking noise over bumps: common descriptions you’ll hear that suggest worn-out strut components. What about a “teeter-totter†feeling when going over a sloped speed bump? Does the stuff in a customer’s trunk seem to jump up and crash around? Ask if the car seems like a boat, because many people associate a boat with a soft, wallowing ride. A little time on the phone will get the customer into your shop for the next step of the process.

The Initial Inspection

A visual inspection might reveal the presence of an aftermarket “spring saver.†Do you suspect Nissan has an equivalent part? Not likely. Replace worn out springs as necessary during strut work.

If you have the time, a road test with the customer aboard will put the two of you on the same page regarding the problem. At five mph, brake quickly and observe the nose dip, then watch for continued bouncing. During the drive, you should listen for knocking noises in both turning directions, and when the wheel and suspension is traveling over gentle dips or bumps. Once back from the road test, jounce the customer’s Nissan by pressing down with all your weight on one of the bumpers. Observe the rebound behavior of the vehicle. Good quality struts that are not worn out will dip once, rebound, and stabilize after that single bump. You should not be able to easily “rock†the car into a wavy motion. The more the car moves as though it were on top of bed springs, the more worn out the actual shock absorber components are. These basic checks can be performed without committing the customer to the repair, and can provide an informed opinion about whether strut performance is degraded. However, it may be necessary to recommend further investigation to evaluate the condition of the other components of the strut assembly, or to pinpoint a noise.

Further In-Depth Inspection and Road Testing

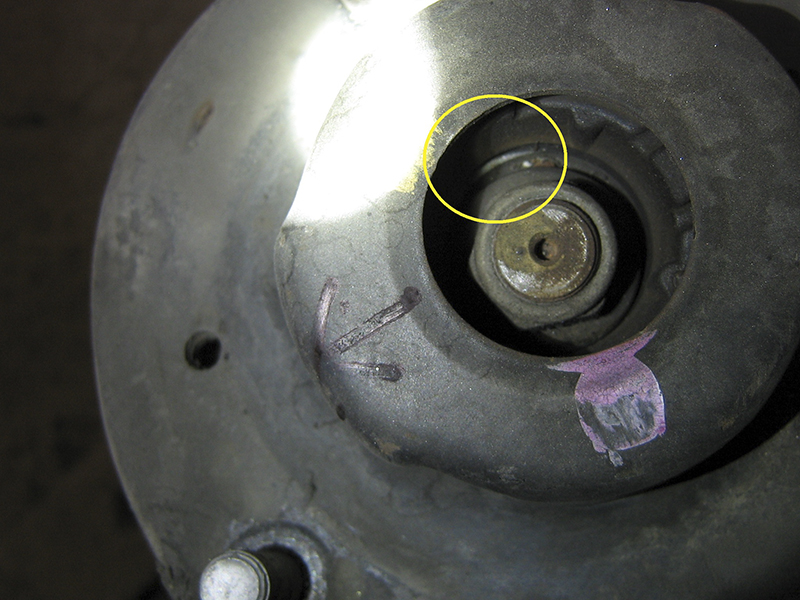

A careful visual examination will tell you a lot, such as how excessive motion has worn a “clean†spot on this strut top, which can be identified from under the hood.

The strut top mount can wear out. Check if the strut top’s bearing is seizing, which you may feel as binding, stiffness, or a “notchy†steering sensation. You may also hear a chirp or similar noise. By design, the strut assembly must rotate with the turning of the suspension, and the strut top bearing allows the strut, spring and seat to rotate without moving the entirety of the metal top mount. If you suspect the noise is coming from the strut, confirm this by feeling the top mount for vibration while a helper turns the steering wheel. Second, the rubber portion of the strut top mount will weaken, just like a motor mount. When this happens, the top of the strut piston can clatter against the metal of the surrounding mount. Inspect for cracking and tearing near the bearing. It is just as easy to replace the strut top mount during strut reassembly, so pay close attention to the condition of the top mount when determining a strut repair.

Avoid having to use zip-ties and other poor methods to secure a replacement boot by getting a Genuine Nissan boot and bump stop.

When it comes time for repair, use Genuine Nissan parts. Because you wouldn’t choose the cheapest, low-quality parts for the customer’s Nissan wheel bearings, for example, you also shouldn’t choose the lowest quality strut top mount. Aftermarket strut top mounts will often use inferior materials in the rubber that will tear again. If the vehicle is on a lift, you can inspect the struts for evidence of fluid leaks. Hydraulic fluid within the shock or strut is necessary for generating dampening force. At first, small amounts of seepage may not have any noticeable effect on the ride quality or strut performance. However, when a substantial amount has leaked out, the customer’s car will have an uncomfortable ride. For example, if the left strut is firm and working properly, but the right strut has leaked, unequal dampening force occurs. This means the vehicle will rebound at different rates from left to right, creating a “sea sickening boat ride†experience.

If the strut boots have torn, dirt and debris can enter the piston area, damaging the seal and causing the strut to leak prematurely. This is no different than steering rack boots that tear, causing premature inner tie rod end failure. When replacing the struts, inspect the condition of the dust boots at the same time. Using a good quality boot from Nissan will guarantee secure fitment and long life. Most aftermarket boot kits are “one size fits all†and will require more labor on your part to get the boot to cooperate with the strut. Squeeze the boots to find out if the bump stops are broken. A broken stop can be caused by repeated bottoming-out, which is an indicator that the strut or spring is worn out. The bump stop is designed for when the suspension travel is greater than the normal operational range of the strut. This may occur when the customer hits a pothole or other major drop that puts the full weight of the vehicle downwards against the strut piston. A missing or broken bump stop is likely to cause a new replacement strut to fail prematurely. Struts keep the tires in contact with the road. Imbalanced tires coupled with bad or weak struts can cause erratic tread patterns. Typically, a tread pattern called “cupping†will develop, and can be felt by running your palm across the surface of the tire. A cupped tire will have a “hedgehog†looking profile. There are no real safety concerns regarding cupped tires, but they will cause a high degree of road noise and may introduce wander or drift.

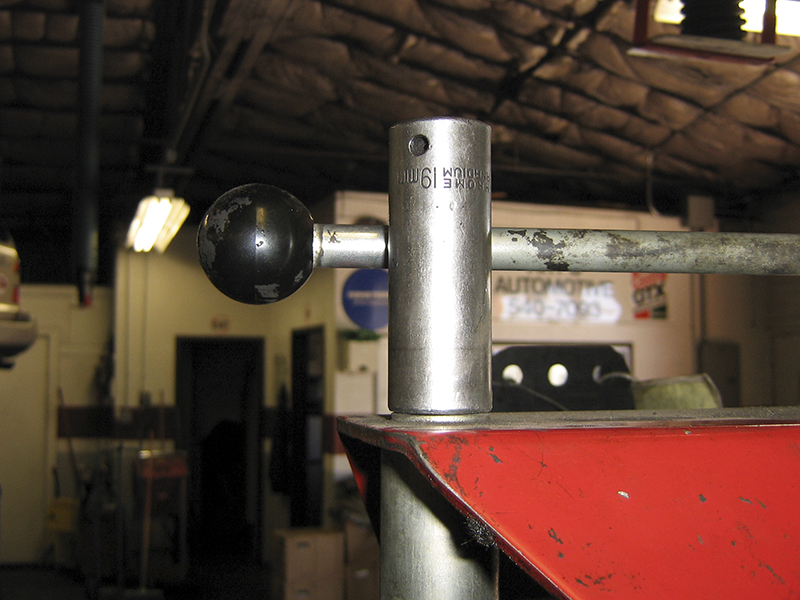

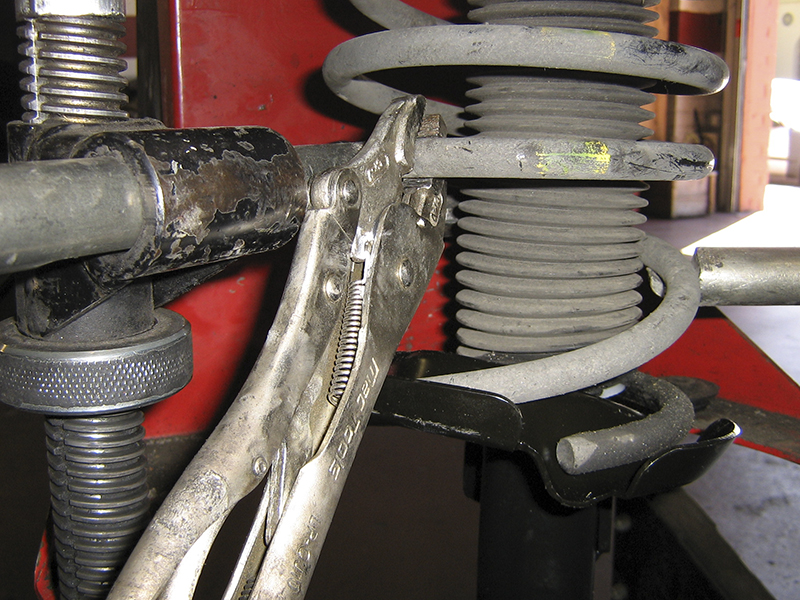

On this spring compressing tool, a socket can provide an additional level of safety. It can act as a catch to prevent the winch from unwinding too quickly.

Struts and Alignment Considerations

Because struts are integral to the suspension, they can create adverse alignment issues. On all Nissan vehicles with suspension struts, those struts serve as the structure for the wheels’ camber angle and typically cannot be adjusted. This is another reason to utilize Genuine Nissan struts, as they are perfectly matched to the rest of the suspension geometry, you will not affect the vehicle’s original engineering by installing an aftermarket strut company’s attempt at duplication. Some technicians may argue that an alignment is unnecessary after strut replacement, but let’s explore why you should recommend one for your Nissan customers. The first angle that must be adjusted during a routine alignment is camber, specifically at the rear. If you replace front or rear struts, you will necessarily change the camber, and by changing the camber you will likewise change the toe. Errors or variations can occur when reinstalling the eccentric bolts, even if you attempt to mark the original location. Like many things in the automotive repair industry, it’s better to do the job right than to do the job over again.

Make a Difference for the Customer

This Nissan has premature wear from bad camber and weak rebound from an old, bent strut. You can see the shadow of the cupped tread pattern.

There is a typically a dramatic and noticeable change in the ride and handling of vehicles that receive new Genuine Nissan struts. Customers will feel like their cars just came off the showroom floor again! Nothing from the aftermarket can restore that same feeling, despite all the marketing. By the same token, save yourself the hassle and installation headaches by using the correct parts to save time and provide reassurance that the job has been done properly.

0 Comments