Last time, we looked at the parts that provide the pinch, but the components that spin off all that thermal energy are more interesting from a scientific, technological standpoint.

Several of the major aftermarket manufacturers offer “big-brake” kits. When it comes right down to it, what you’re getting is an integrally-engineered heat-management system. Note the unusual slotting pattern on this integral rotor (courtesy Hawk).

Maybe you remember the old Firestone Tire advertising slogan, “Where the rubber meets the road.” While it doesn’t have quite the ring to it, saying that brake discs are “where kinetic energy is converted into heat” is somewhat similar — it’s the crux of the matter. Transforming the inertia present in a couple of tons of hurtling metal into huge numbers of Btus safely, smoothly, quietly, and repeatedly, then dissipating them into the atmosphere has required a great deal of engineering and materials development.

Numero uno

It seems logical to begin this story with the First Law of Thermodynamics, also known as the Law of Conservation of Energy, which states that energy cannot be created nor destroyed; it can only be converted from one form to another. Did you ever give any thought to where the potential chemical energy stored in all that gasoline you just burned to get up to speed goes? Well, first it’s changed into the heat energy that expands the charge and pushes the pistons down, which action rotates the crankshaft transforming it into mechanical energy (a certain percentage at least — the rest finds its way into the atmosphere by means of the exhaust and cooling systems). This performs the useful work of propelling your vehicle.

Gotta stop? Leaving the hydraulics out of it, the friction between the linings and the rotors converts most of the inertia of a hurtling mass of metal into, once again, thermal energy (deceleration is aided to some extent by air resistance and tire deformation), and that just disappears into the atmosphere and thus wasted (that’s what makes the regenerative-braking feature of hybrids and electrics attractive). The amount of heat discs have to throw off can be terrific — the temperature numbers we’ve been quoted for Formula 1 racing, for instance, are so high we have trouble believing them. Think maybe 1,000 deg. F. (540 deg. C). We’ve seen various equations that you can use to calculate how hot your brakes will get, which all require that you plug in weight, speed, time, swept area, rotor mass, etc. Sounds like too many variables to us, sort of like the computer models for climate change. Look them up if you want to practice your math, but the results won’t be as practical in choosing parts as the recommendations of reputable manufacturers.

The temperatures we’ve been told Formula 1 brakes reach are so astronomical we can’t believe them. So, we’re not quoting any numbers until we get sufficient verification.

What we hope you’ll gather from that little bit of physics is that, as a spokesman for a prominent high-performance brake maker tells HRP, “The total brake system is all about managing heat.” So, everything has to be appropriate to the specific application — calipers, fluid, friction material, and, our subject here, rotors.

Fade to . . . Yikes!

To put upgrades over stock systems into perspective, premium discs won’t really have much effect on stopping distance in one or two instances of hard deceleration. Their superior characteristics where heat dissipation is concerned, however, will go a long way to insure that you never have to experience that scary phenomenon known as fade following multiple panic stops, prolonged downhill braking, or road-racing conditions. You can expect other minor improvements, too, subtleties we’ll get to later.

We don’t care if you’re a Tour de France bicyclist, your legs aren’t strong enough to stop a car after fade sets in. We’ve felt it happening on race tracks and mountain driving, and we can say it gets your attention to a shocking degree.

Several factors are involved here. The resins that hold the friction material together can begin to vaporize at high temperatures (“out-gassing”), which results in a gaseous layer that separates the linings from the rotor — it’s similar to hydroplaning on your tires in wet weather. Modern friction recipes, however, aren’t nearly as prone to this as those from the past.

Bubbles

So, why do we still get fade during heavy braking with today’s excellent lining formulations? Again, it’s all about managing heat. If the Btus in the disc exceed what it can spin out and “pump” into the air stream, they have to go somewhere. Unfortunately, the main path for the excess is through the pads and into the caliper, although a small amount may travel into the wheel bearings and thence the spindle. Even the most high-tech brake fluid still has a boiling point. When that’s reached, bubbles start to form. As you should know, fluids are incompressible for all intents and purposes, so a solid liquid column can transmit force almost perfectly. Bubbles are a different story. They can easily be squeezed down into a smaller volume. So, stepping on the brake pedal when this unfortunate situation obtains compresses the bubbles instead of pushing the pads against the rotor.

Water is another matter. When the discs go over 212 deg. F. (100 deg. C), which doesn’t take much sporty driving, steam can form in the friction interface and cause a similar situation to the “hydroplaning” already mentioned. True, any disc brake is a whole lot better at scraping of H2O than drums were, but there are design features in many high-performance rotors that give it a better escape path.

If fade is our main enemy (there are others, but none so dangerous), what can be done to insure against it? The first step typically mentioned is to upgrade to bigger discs — size is one of the most crucial factors in heat absorption capacity and dissipation efficiency. The bigger diameter also increases the brake’s mechanical advantage as the pads are farther away from the axis of rotation.

Especially if you’ve been running aggressive linings and your rotors are pretty much shot anyway, this makes a cost-effective modification. Many “big brake” kits are available for accomplishing this. Just make sure you choose one from a company that does serious testing and has a good reputation.

Holes and slots

You can upgrade to cross-drilled or slotted discs, or a combination of the two as shown here (courtesy Stop Tech).

The installation of cross-drilled discs another possibility, although that’s what’s commonly included in the kits just mentioned. In the days of out-gassing friction formulas, the precisely-formed holes allowed the vapors to escape into the moving air that’s being thrown out around the circumference. Today, that action simply aids ventilation, thus cooling.

An additional thing the drillings accomplish is constant refreshment of the pads’ friction surfaces. They keep them nice and clean and deglazed for better feel and perhaps even shorter stopping. You might assume that this accelerates lining wear, but by all accounts it doesn’t.

The drawback to holey rotors is that cracks tend to develop around the drillings in extreme use. We’ve heard people say that they’d never use them because they fear complete breakage and loss of stopping ability. We did some research into this, and found that this just about never happens with brand-name discs.

The new Corvette ZO6 with the ZO7 option package stops via Brembo brakes that feature floating two-piece rotors made of carbon composite material (CCM) (courtesy Brembo).

Then there are slotted discs, which look pretty cool. They help somewhat with shedding heat, but their main purpose is the refreshment of the lining surfaces, especially when very aggressive racing pads are used. Depending on the way the slots are made, they can accelerate lining wear, perhaps to unacceptable levels for a street vehicle. A benefit that those of us who actually work on cars will appreciate is that they act as visual wear indicators.

Centrifugal air pumps

Perhaps you’re old enough to remember that some marginally-successful cars, such as the Chevette, used non-ventilated, solid rotors. Certainly, that is the cheap route, but it gives up at least half of the heat-radiating potential of the vented type. Not only do the latter have all that additional surface area inside, but they are designed as centrifugal pumps, picking up air near the hub and throwing it out of the vents.

Quality brake makers expend a lot of effort on the internal design to maximize this function — we’ve seen several photos of discs sliced lengthwise to reveal the configuration of the vents. They may be plain, straight radial channels, or have curved vanes that enhance the pumping action, although this makes it necessary to designate right- and left-side part numbers. Brembo, for one, has patented a “pillar vane” design that moves air almost as well, yet can be used on either side.

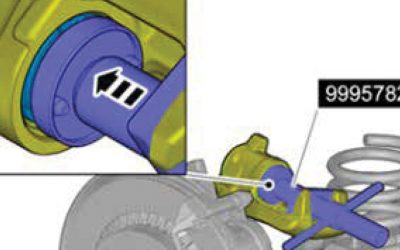

Another step up is the floating disc, in which the iron wear surface is joined to an billet-aluminum hub hat. Only available for certain high-performance models, these offer a big advantage in unsprung weight, and they can help mitigate the runout that results in DTV (Disc Thickness Variation, the real cause of pedal pulsation) — the mounting system is engineered to permit a greater degree of both radial and axial float. The look great, too.

Mercedes-Benz, which has always prided itself on its “Bremsen” (brakes auf Deutsch), tries to head off the need for upgrades by offering high-performance discs in the first place. Check out the weight difference between the McClaren fiber-reinforced ceramic and the AMG cross-drilled iron integral rotor (courtesy Mercedes-Benz).

The End of the Iron Age?

Beyond that, we get into the actual material the disc is made out of. Most are high-carbon cast iron, with perhaps molybdenum or other metals added to help handle heat and cut warpage. Some manufacturers subject the castings to special processes. Centric, for example, chills them to -300 deg. F. (-185 deg. C), then allows them to slowly return to room temperature. This deep cryogenic treatment is supposed to permanently and dramatically affect the metallurgical structure, which inhibits internal oxidation and increases thermal fatigue resistance. The company claims that this can result in up to three times the longevity of ordinary rotors.

Believe it or not, carbon ceramic, or fiber-reinforced ceramic, discs were first used by racing teams back in the late 1970s. They’ve been available in the aftermarket for years, but have only recently found their way into production cars. Advantages? How about saving 28 lbs. (12.7kG) on a Z28 Camaro? Or, consider that the very large composite discs on a Mercedes-Benz McClaren weigh only 14 lbs. (6.4kG) each, whereas the iron units on the company’s SL55 AMG are a comparatively-ponderous 34 lbs. (15.6kG). If you understand why reducing unsprung weight is a good thing for handling (less mass to change direction during jounce and rebound, hence faster movement and more consistent contact between the tire tread and the road), you’ll see why this is a big deal. That these high-tech discs are also much better at handling heat and much more resistant to warpage are important additional benefits.

by Bob Freudenberger

0 Comments