Volvo adopted the use of an electronic parking brake system on the 2007 S80 V8 and subsequently on the V70, XC70, and S80 T6 models. All Volvos 2015 and newer in the North American market are equipped with electronic parking brakes.

Volvo is, of course, not the only auto maker using these parking brake systems; a lot of other manufacturers have this option installed in their higher-end models as well.

A lot of technicians wonder, why the change from the old reliable parking brake systems that used a lever, cables and shoes?

Is it safer? In some cases, yes.

Is it a cheaper system? No.

Is it more reliable in some cases? Yes.

But the most likely answer is the same reason for a lot of the electronic CAN networked systems that have replaced older technology.

It’s all about weight savings, which affects efficiency, and the big one—emissions.

You may get some customers coming into your shop with complaints about the electronic parking brake system not working right. When you check it, there will be no stored codes and the system will work flawlessly for you.

So customer education will be a big part of your job in the future.

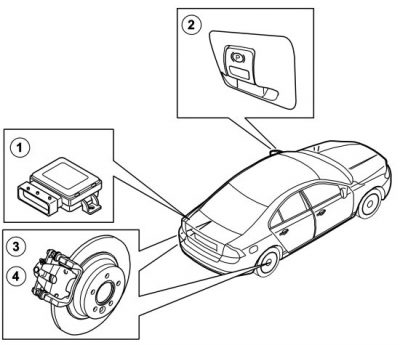

The Volvo EPB system uses a networked control module that is mounted near the Rear Electronic Module (REM) in the back of the car.

The system can be activated by the driver with a switch or, in some cases, the parking brake can be activated automatically by the control unit when the car is turned off and parked.

In most of the later models that are equipped with the electronic parking brake system, the parking brake can be set up to use the “hill holder” function that will apply the parking brakes temporarily when the car is stopped on a hill. This prevents the car from rolling backwards, and the parking brake will automatically disengage when the driver takes their foot off the brake and steps on the accelerator pedal.

How it works: Activating/deactivating the parking brake in stationary vehicles

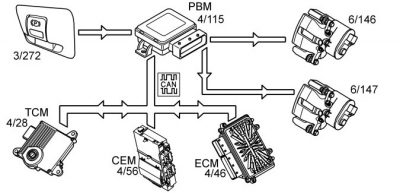

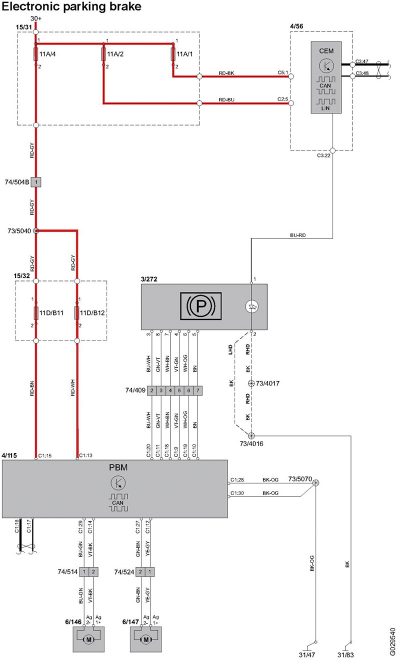

Vehicles are defined as stationary up to a speed of about 2 miles per hour. It is always possible to manually activate the parking brake. When the driver presses the parking brake switch (3/272), an analog signal is transmitted to the PBM (4/115), which activates the electric motor in the brake caliper (6/146-147). This, in turn, presses on the brake pads to deactivate (release) the parking brake. The parking brake module requires information about the following:

- Signal from the parking brake switch

- Start switch (start button) must have been activated or the engine must be running. Information about this is retrieved from the Central Electronic Module (CEM) (4/56) via the CAN network.

- Signal from the clutch pedal sensor or, alternatively, the brake pedal sensor.

The ECM (4/46) supplies information about the clutch pedal position. The ECM supplies information about the position of the brake pedal (applies to vehicles with manual transmission).

- Signal from the brake pedal sensor. The BCM (4/16) supplies information about the position of the brake pedal (applies to vehicles with automatic transmission).

The PBM retrieves information from the above control modules by reading messages on the CAN network. If all conditions are met, the PBM activates the electric motor in the brake caliper and releases the brake pads.

Automatic deactivation of the parking brakes

This means that the parking brake is automatically released when the driver drives off. A condition for this is that the parking brake was activated when the car was stationary. The following information about the vehicle is required for the PBM (4/115) to release the parking brake at the right moment:

- Current gear (only automatic transmission), from TCM (4/28) via the CAN network.

- The engine torque, from the ECM (4/46) via the CAN.

- The vehicle angle, from the vehicle angle sensor in the PBM.

- The clutch pedal position (only manual transmission), from the ECM and CEM (4/56) via the CAN network.

- The gas pedal position from the ECM via the CAN.

The PBM uses the information above to calculate when the engine torque is sufficient for the vehicle to be stationary when the parking brake is released.

Activating/Deactivating the parking brake when moving

It is possible to activate the parking brake while moving, that is to say at speeds exceeding about

two miles per hour. But this is an emergency function which must only be used when the normal brakes are not functioning.

The condition is when the parking brake switch (3/272) is activated for the duration.

The ABS function is used to prevent overloading the parking brake and to quickly reduce the speed.

In order for activation of the parking brake while moving to be possible, the function of automatic deactivation when stationary must have been used.

When activating the parking brake when moving, the PBM (4/115) will transmit a request to the BCM (4/16) via the CAN network to brake the vehicle using the ABS function. When the speed is less than about two miles per hour, the PBM will take over the braking by activating the electric motor in the brake calipers (6/146-147).

Rolling brake test

The PBM has a function for a rolling brake test. The rolling brake test is used to check the function of the electrically operated parking brake, such as during the annual vehicle inspection.

The following conditions must be fulfilled for three seconds before the test and remain during the test for PBM to allow a rolling brake test:

- Speed front wheel: 0 miles per hour.

- Speed rear wheel: a little over 1 mile per hour to about 8 miles per hour.

- Ignition on/engine running.

- No trouble codes related to parking brake switch, electric motor in brake calipers, or speed signal from the BCM.

Remarks

If conditions for the rolling brake test are not met when the parking brake switch is activated, then the PBM will perform normal application of the parking brake.

There are two different ways to activate a rolling brake test:

- Activate (hold in) parking brake switch. When parking brake switch is activated, then the PBM will activate the electric motor in the brake calipers (6/146-147). This presses on the brake pads until minimum required brake force is reached. Then the brake force increases automatically every third second until the system’s maximum limit is reached. Increase of the brake force occurs in steps for a total of approximately ten seconds.

- Activate (press in) parking brake switch repeatedly. Activate (press in) parking brake switch once. When the parking brake switch is activated, the PBM will activate the electric motor in the brake calipers (6/146-147), which presses on the brake pads until minimum required brake force is reached. With repeated activation of the parking brake switch, the brake force increases in steps until the system’s maximum limit is reached.

Most technicians will only deal with these systems when they have to retract the calipers to replace the rear brake pads and/or rotors because the majority of these electronic parking brake systems are very reliable.

But as these cars get older and the miles get higher, these cars can begin to exhibit problems with these systems.

A lot of problems most shops see in the Volvo EPB systems will manifest in the calipers not being able to retract or the actuator motors sticking; in some rare cases, an EPB module can go bad.

Volvo has issued multiple Technical Journals that are related to possible problems with EPB systems.

So, as always, it’s a great idea to check for these when you are working a Volvo that has an issue in

the EPB system.

Here is one that has to do with an issue that may be caused after you use VIDA to download a software package to the EPB module.

This will need to be done when you replace the EPB control module.

The switch can fail but, if this happens, in most cases, a bad switch will leave the calipers in the disengaged position.

When the EPB switch fails, it may generate fault codes in the EPB control module and the CEM. A failed EPB switch will usually display a fault warning in the LCD screen on the DIM or instrument cluster.

Service: Check the parking brake

Check to see if it is possible to release the parking brake with the parking brake switch or by using the fault tracing function.

Is the parking brake released?

- Yes – Troubleshooting complete

- No – Release the parking brake with the special tool

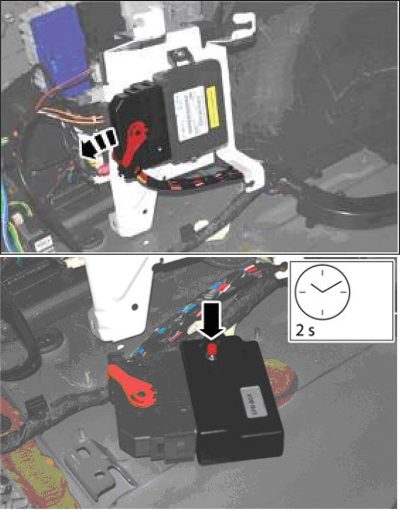

Release the parking brake with the special tool

| NOTE |

| Some variation may occur in the images; however, the essential information in the illustrations is always correct. |

Remedy in the following order:

- Ignition off.

- Expose Parking Brake Module (PBM).

- Unplug the connector for the Park Brake Module (PBM).

- Connect the special tool to Parking Brake Module (Use Volvo special tool marked EPB-BOX part number 9513014).

- Hold the button on the special tool pressed in for two seconds.

- Disconnect the special tool from the connector.

| NOTE |

| Do not plug in the connector for the Park Brake Module (PBM). |

EPB Diagnostics

| U = | DC voltage in volts (V) |

| Ubat = | Battery voltage (V) |

| Ulow = | Voltage approximately 0V |

| PWM = | Pulse width modulated signal in % |

| UAC = | AC voltage in volts (V) |

| f = | Frequency in Hertz (Hz) |

| t = | Time in seconds |

| % duty = | Duty cycle (pulse ratio in percent (%) |

Checking the supply voltage/ground terminal voltage feed parking brake module

The PBM is supplied with voltage via two voltage inputs on the control module.

- Power input 1 terminal #C1:13 (#13) is supplied with +30 via a fuse in the rear relay/fuse box (RJB) from the battery. The input also supplies voltage to the right brake caliper. In the case of an open circuit, the right brake caliper will not be activated.

- Power input 2 terminal #C1:15 (#15) is supplied with +30 via a fuse in the rear relay/fuse box (RJB) from the battery. The input also supplies voltage to the left brake caliper.

In case of open circuit, the left brake caliper will not be activated.

Checking the power supply

Check the voltage feed cable from the battery to the PBM #C1:13 (#13) and #C1:15 (#15) for open circuit, loose connection, or contact resistance and oxidation. Check the fuse. The voltage must be approximately battery voltage.

Ground connection for the Parking Brake Module (PBM)

The PBM has two ground inputs. Both ground inputs from the control module are connected via two separate ground leads to the same ground connection in the body. See the relevant wiring diagram for further information about the ground terminal.

- Ground input 1, #C1:28 (#28) is power ground and is connected to the ground connection in the body.

- Ground input 2, #C1:30 (#30) is power ground and is connected to the ground connection in the body.

Checking the ground terminal

Check the ground cables between the PBM #C1:28 (#28), #C1:30 (#30) and ground connection for open circuit, loose connection, contact resistance and oxidation. At ignition on, the voltage drop between the PBM ground connection and chassis connection may not be greater than 0.5 volts. Remedy as necessary.

Brake pad replacement

Replacing the rear brake pads on a Volvo that is equipped with electronic parking brakes is not that different from any car that has caliper pistons that have to be screwed in with a tool to open them.

The difference is that you will have to use a scan tool with bi-directional control, like Volvo’s VIDA.

You can also use Volvo’s EBD BOX (part number 9513014) to retract the caliper motors.

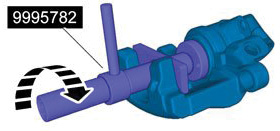

Once the calipers are in service position, you can use Volvo special tool 9995782 or the equivalent to push back the caliper pistons and replace the pads as usual.

0 Comments