Mercedes-Benz Safety Systems Help Avoid Accidents and Significantly Change Bumper Repair

Mercedes-Benz safety technology features state-of-the-art sensors that constantly monitor the position of the vehicle relative to other vehicles and obstacles. Software analyzes sensor data and, if necessary, sends commands to various safety systems to alert the driver to a potential problem. If the driver does not respond quickly, the system can pre-pressurize the brake master cylinder, reduce speed, or stop the vehicle, apply the brakes in a manner that prevents an unsafe lane change, or backing into an already-occupied space, and adjust seat belts, seat position, head rests, and other supplemental restraint components in preparation for a possible collision. All of this is made possible by short- and long-range radar and other sensor technologies. The safety sensors are embedded in or attached to the bumper and front grille, which makes bumper repair after a collision very different from the procedures of only a decade ago.

There are six Parktronic sensors in the front bumper of this 2010 GL 450. The small round sensor heads blend beautifully into the bumper, and enable several different safety functions, including adaptive cruise control, lane departure warning, and other collision avoidance systems.

Mercedes-Benz safety technology features state-of-the-art sensors that constantly monitor the position of the vehicle relative to other vehicles and obstacles. Software analyzes sensor data and, if necessary, sends commands to various safety systems to alert the driver to a potential problem. If the driver does not respond quickly, the system can pre-pressurize the brake master cylinder, reduce speed, or stop the vehicle, apply the brakes in a manner that prevents an unsafe lane change, or backing into an already-occupied space, and adjust seat belts, seat position, head rests, and other supplemental restraint components in preparation for a possible collision. All of this is made possible by short- and long-range radar and other sensor technologies. The safety sensors are embedded in or attached to the bumper and front grille, which makes bumper repair after a collision very different from the procedures of only a decade ago.

Automotive safety strategies have historically been passive in nature. Seatbelts, airbags, bumpers, and other devices sought simply to reduce the impact of a collision on the vehicle and its passengers. Over the past 15 years or so, however, new safety technologies have been developed that emphasize accident avoidance, and in more active ways than could be imagined only a few decades ago. Much of this new safety technology features high-tech sensors that see through the Mercedes-Benz front and rear bumpers, so bumper repair is no longer a simple straighten, patch, and re-paint job.

For example, ordinary cruise control keeps driving speed at a pre-set pace, but Adaptive Cruise Control helps maintain the desired distance between the vehicle and the one immediately ahead. This function is enabled by the Mercedes-Benz Distronic Plus system.

There are four Parktronic sensors in the rear bumper of this 2010 GL 450. Parktronic sensors in the rear help with lane departure warning and Parking Assist functions. There are similar sensors in the front bumper on many Mercedes-Benz models.

Distronic Plus features a combination of short-range radar sensors behind the bumper cover and a long-range sensor in the front grille. These sensors together measure the distance between vehicles, and allow the electronic logic to determine whether or not that gap is decreasing. The software assesses how quickly the gap is decreasing and determines how much braking power is needed to restore the gap to the preferred length. The system then progressively applies the brakes to slow the vehicle and restore the gap to the desired distance.

A vehicle traveling at 50 kmh (31 mph) covers 20 m (65 ft.) in two seconds. Adaptive Cruise Control alerts the driver to a dangerous situation via flashing lights in the dash or Head-Up Display, but does not wait for him or her to take action. Mercedes-Benz Distronic Plus radar technology is never vulnerable to the things that sometimes distract humans from the road ahead, and it responds faster and with more precise application of braking force than any driver could, no matter how skilled.

Mercedes-Benz Pre-Safe Brake is another example of active safety strategy. Pre-Safe Brake sensors scan the road ahead for potential problems. If they detect a vehicle ahead slowing, stopped, or crossing its path, or “see†pedestrians or other obstacle, the system alerts the driver.

Pre-Safe Brake simultaneously initiates up to 40% of the available braking power. When the driver brakes, the appropriate amount of braking pressure is instantly applied, all the way up to 100% if the driver so chooses. And should the driver fail to respond, the system will apply full braking on its own, to help avoid or reduce the intensity of a collision. Independent studies show that this pre-charging of the brakes shaves enough off of the driver’s reaction time to effectively increase the occupant survival rate in an accident by 10 to 15%.

This ability to take control of vehicle braking is only part of the Mercedes-Benz active safety strategy. Pre-Safe also adjusts vehicle restraint systems within milliseconds, to prepare for a potential accident. It tightens the front seat belts, adjusts the front head restraints and passenger seat, and, if the vehicle is equipped with the Mercedes-Benz Memory System, can even close the windows and sunroof.

Collision avoidance sensors sit behind plastic grille covers in each side of the front bumper of this 2014 ML 350.

High-Tech Bumper Care

Suppose a customer comes in with the complaint that after a minor front collision, the Adaptive Cruise Control no longer works. You’ll need to add to your traditional collision-repair knowledge in order to help this motorist.

Mounted in the front bumper cover on vehicles equipped with the Parktronic system are six ultrasonic sensors. They cannot be repaired. If one has been impacted in a collision, it must be replaced. Even if only a few scratches penetrate the paint and dig into the sensor surface, complete replacement of the sensor is required.

If the repair involved replacement of the Distronic (DTR) control unit, the sensors that monitor rotational speed, yaw rate, and lateral acceleration, or of the steering column tube module, the DTR control unit must be initialized and recalibrated.

Another possible cause of problems with the short-range radar sensors is the sealing ring where the sensor seats into the bumper. The sensors and connectors are designed to be waterproof, and to resist a high degree of vibration and shock. If the sealing ring is damaged, it may allow vibration or moisture to overwhelm the sensor. A damaged sealing ring should be replaced.

Painting Bumpers

When it detects an obstacle (like the two-by-four stud we placed in front of this vehicle), the Parktronic system begins flashing red lights in two places on the dashboard.

Have you had a customer bring in a vehicle with the complaint that after another shop repaired a bumper, the backup assist, lane departure warning, or other collision avoidance system no longer works? It could be the paint job.

When painting the bumpers, it is important to ensure that the paint coat on the short-range radar sensors is of only minimal thickness. Too thick a coat can lead to malfunctions because the sensors see it as an obstacle in the vehicle’s path, rather than as merely excessive paint thickness. The system will respond by either keeping the warning lights or beepers constantly on, or shutting down completely after a certain amount of time to prevent full-time application of the brakes and activation of key elements of the supplemental restraint system.

The maximum paint thickness allowed at the sensors is the primer and two coats of paint (color and clear). Primer, color, and clear together count as one refinish, but the painter MUST be mindful of keeping each coat as minimal as possible.

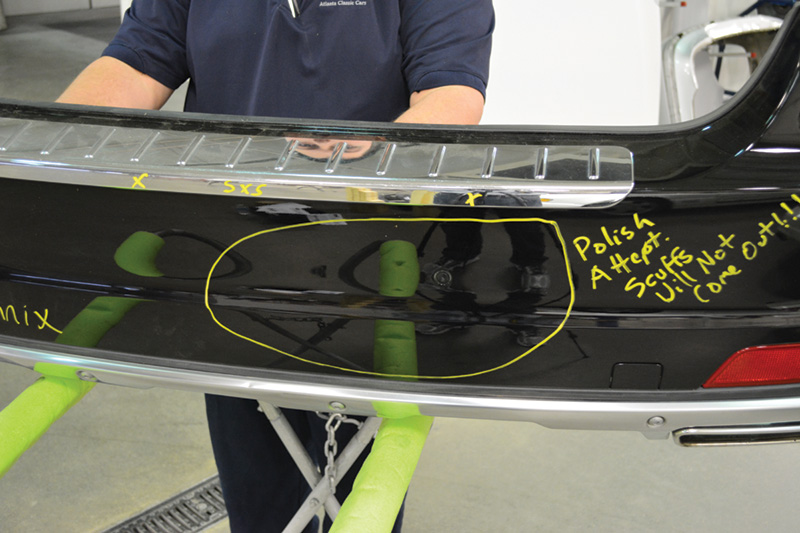

The scuffing over the Parktronic sensor in the rear bumper of this 2010 GL 450 is enough to require sensor replacement.

We should mention that pre-painted sensors are available for certain popular colors.

Plastic: Repair or Replace?

Damage to bumper covers and protective bumper strips in the form of cracks, holes, and scuff marks deeper than one millimeter can be fixed using the Teroson plastics repair kit (see the approved materials list at in the paint technology guidelines section).

The Teroson kit includes a cleaner that removes dirt, grease, and other contaminants, a primer that prepares the surface for filler, a two-part adhesive filler, and a glass fiber mesh. The filler hardens in 15 minutes under an infrared lamp. The fiber mesh reinforces the adhesive to help resist repair failure due to expansion and contraction of the plastic over time.

Mercedes-Benz short-range ultrasonic Parktronic sensors insert directly into the back of the plastic bumper, and include a seal that helps them resist road-induced vibration and shock.

With six sensors in the front and four in the rear bumper, it is easy for filler that is feathered out from the damaged spot to overlap one or more sensors. The addition of primer, basecoat, and clearcoat can then quickly build up to levels in excess of paint thickness maximums, rendering the affected sensors inoperable. If the damaged area is close enough so that the filler would overlap the sensor, replace rather than repair the bumper.

Bumper Basics

A Mercedes-Benz bumper consists of three or four basic components: a decorative plastic bumper cover, a foam impact absorber bar, a steel or aluminum reinforcement bar, and, depending on the vehicle model, outer protective strips.

The foam impact absorber bar is located between the decorative cover and the metal reinforcement. Its purpose is to compress and absorb some of the damage in a low-impact collision. Be careful when handling the foam inserts, as they snap easily.

The metal reinforcement bar attaches to the front crossmember and is designed to absorb some of the energy of a low-impact collision. In a two or three mile per hour “parking lot†incident, the damage to the vehicle may be limited to the bumper cover, impact absorber, and reinforcement bar.

An aluminum reinforcement bar is built onto the crossmember of the front module. A foam impact absorber sits between the decorative bumper cover and the reinforcement bar.

The Mercedes-Benz reinforcement bar is a single-use component, and cannot be repaired. If it has been damaged, it must be replaced.

Some models feature outer protective strips. Although primarily decorative, they are sacrificial plastic pieces. They are inexpensive and snap on using clips, so they are easily replaceable in the event of minor impact or scratch damage.

Bolt-on Modules

Front and rear modules absorb and deflect some of the impact energy of a collision away from valuable mechanical components. The modules bolt on to the upper and lower longitudinal members (frame rails). The bolt-on design helps reduce repair time and cost versus a welded full frame.

Additional Connectors in Mercedes-Benz front bumpers

- Washer Fluid Reservoir – On vehicles with a Headlamp Washer System, you must detach the electrical and fluid hose connections from the windshield washer fluid level indicator switch and pump, and remove the Washer Fluid Reservoir in order to access and replace the front bumper.

- The Outside Temperature Sensor – clips to the front bumper, and must be disconnected in order to remove the bumper.

The few, the proud, the knowledgeable

The Mercedes-Benz front module bolts onto the upper and lower frame rails. In a low impact (up to eight mph) accident, the front module may absorb all of the collision energy as it crumples, leaving the frame rails undamaged. In that scenario, repair involves simply bolting on a new front module.

These new safety features are based on cutting-edge sensor technology and are now being seen for the first time by many collision repair technicians. Dig into your Mercedes-Benz training information and learn how the systems work. You’ll find that knowing where a sensor is located, how it must be positioned to “see†so it can accurately estimate the vehicle’s position relative to nearby objects, and how your repair prep and painting procedures must adjust to avoid interference with sensor operation will make you an in-demand expert in your market.

0 Comments