Mercedes-Benz has always been an innovator in the automotive industry, and its powertrain technology shows this clearly. But besides the great leaps in engines that have produced the wonderful performance and efficiency of today, has anybody ever given any thought to how those engines are mounted in the chassis? Yes, indeed, and to a larger extent than you probably suspect.

It seems to be in the genes of Mercedes-Benz engineers to continuously look for any possible way to improve the company’s vehicles. Every aspect of those vehicles is thoroughly evaluated and an incredible amount of thought goes into every component, both existing and yet to come. Even something as simple as a door handle is studied and improvements are made. Most people don’t give much thought to door handles, but Mercedes-Benz has engineered a stronger one so that in the event of an accident you can get a good grip and open the door even if it has been damaged. This may seem like a small improvement, but we’re sure first responders appreciate this simple feature. This is how Mercedes-Benz approaches everything that its vehicles are composed of. Over the years, all kinds of dramatic technological advancements have been introduced into the automotive industry, and Mercedes-Benz has typically been a leader in this.

In recent decades, the world of personal transportation has gone through such rapid evolution that perhaps “revolution†is a more accurate word. As high technology has taken over, service technicians have seen more clearly than ever before the need to keep pace with it. Modern electronics started with fuel injection, ignition, and feedback engine management systems to control emissions and increase fuel economy. The electronics revolution continued with anti-lock brake systems (ABS), then traction control and the Electronic Stability Program (ESP). Mercedes-Benz was one of the first manufacturers that, in conjunction with Robert Bosch A.G., developed CAN (Controller Area Networks). This led the way for individual computerized systems to become integrated and work with each other to form systems like ESP. All this computerization, of course, adds a certain level of complexity to our jobs when something goes wrong. It’s our responsibility as technicians to learn continuously so we can provide competent diagnosis and service to our customers. There are some components, however, that you probably never would associate with electronic controls — motor mounts, for example.

Proactive

Engine Mount Design.

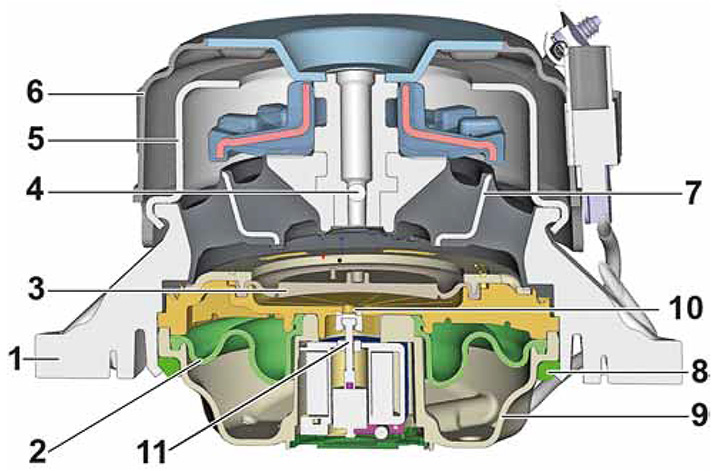

1. Flange

2. Seal bellows

3. Diaphragm

4. Check ball

5. Buffer stop

6. Protective cap

7. Hub

8. Retaining ring

9. Cover

10. Bore

11. Solenoid

There is a debate in this country over whether the automotive industry has suffered more from government bureaucracy forcing unnecessary change, or from the market forcing more socially-responsible developments. Regardless, Mercedes-Benz has responded admirably to these challenges. One of its major initiatives has been the development of diesel engines that give luxury vehicles levels of fuel efficiency previously achieved only by sub-compacts, along with astonishing performance and low emissions. Those attributes still wouldn’t sway the American consumer, however, if NVH (Noise, Vibration, Harshness) hadn’t been reduced almost to the levels of a gasoline burners. One of the factors in the success of that effort was the invention of an entirely new type of motor mount.Â

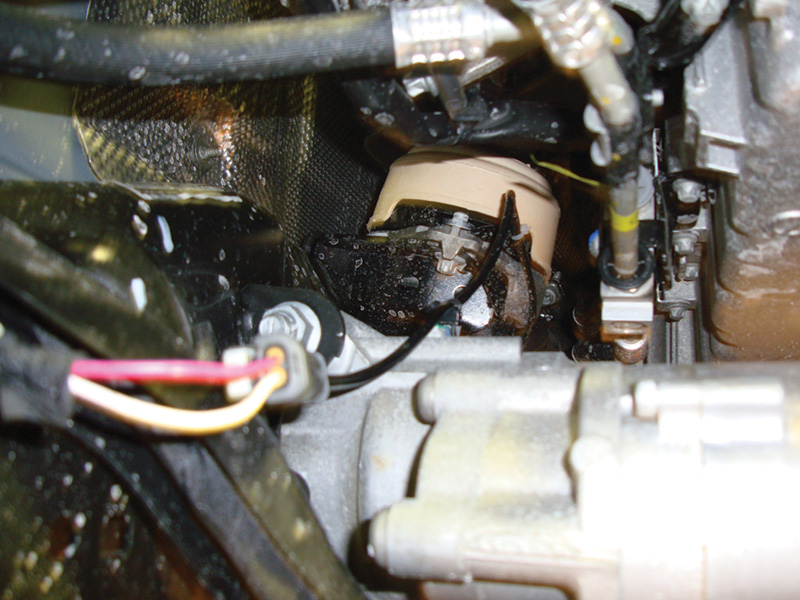

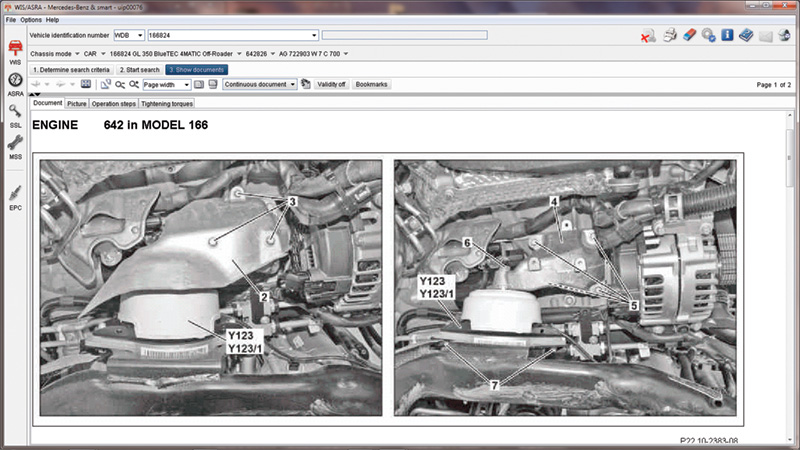

The two-wire harness is a surefire give-away that this is a computer-controlled mount. It is powered up by fuse F58. If you unplug the fuse and plug it back in with the key on, you should hear the mounts click.

Through most of automotive history, motor mounts have been mundane. In early cars, they were simply brackets, bolts, and nuts that held the engine rigidly to the chassis. Of course, that meant that all the vibrations, jerks, and shocks that originated with internal combustion were transferred directly to the unfortunate driver and passengers. It wasn’t long before mitigating that motoring unpleasantness became a priority. The first, and longest-running, attempt at accomplishing this reduction in vibration was the adoption of mounts that incorporated rubber isolators to absorb part of the unwanted harshness any reciprocating assembly transmits. Starting in the early 1930s, this idea was reasonably successful, if not ideal.

Much more could be done to isolate the delicate occupants of a vehicle from internal combustion’s basic brutality. So, Mercedes-Benz engineers developed motor mounts that did just that.

Most of the company’s vehicles currently on the road have hydraulic engine mounts that go beyond the simple idea of using rubber’s compressibility to reduce roughness — oil is the medium used to dampen the vibration a running engine generates. Somewhat similar to the principle of a suspension shock absorber, the oil is forced through an orifice between two chambers at the top and bottom of the mount as they are compressed and expanded by engine shake. When these fail, it’s from a loss of fluid, and typically causes a more sudden and pronounced clunking than you’d get from a gradually-dissolving rubber mount. Diagnosis is mostly a matter of observation. Is the bottom chamber flat? Is there oil present?

Speaking of the working fluid, whenever you’re trying to track down an oil leak, say from a cam or timing chain cover, don’t overlook the possibility that the real culprit is a ruptured motor mount. We should also mention that some aftermarket parts suppliers substitute ordinary rubber mounts for the hydraulic type, which is another reason you should stick with Genuine Mercedes-Benz parts.

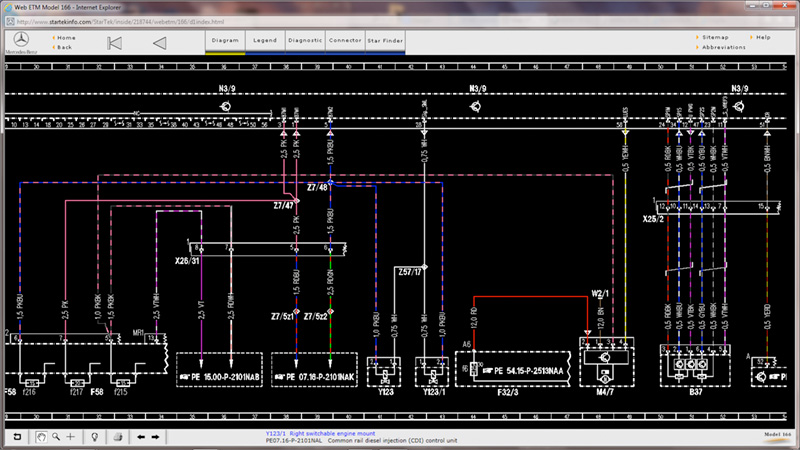

With a paid subscription to www.startekinfo.com you can access wiring diagrams. Here, you can see that components Y123 and Y123/1 are the switchable engine mounts. They’re wired together so both mounts get grounded at the same time by the ME.

Computer control?

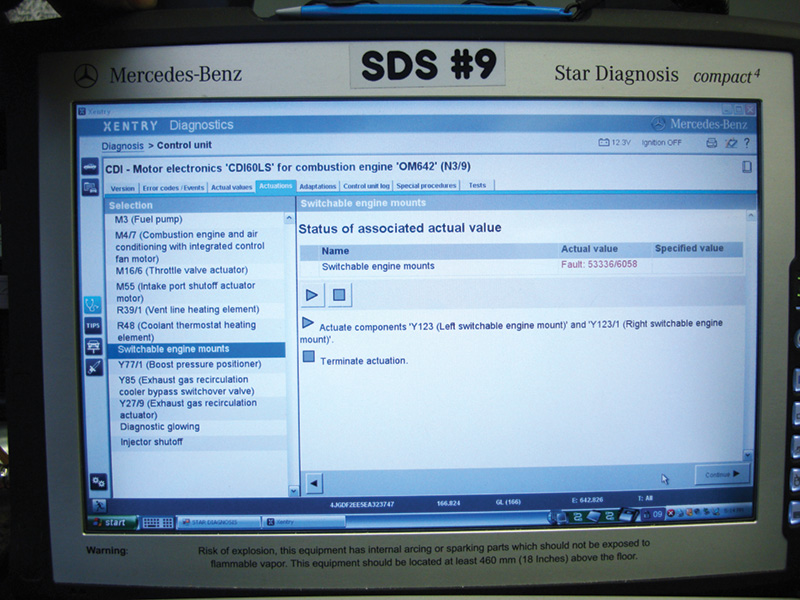

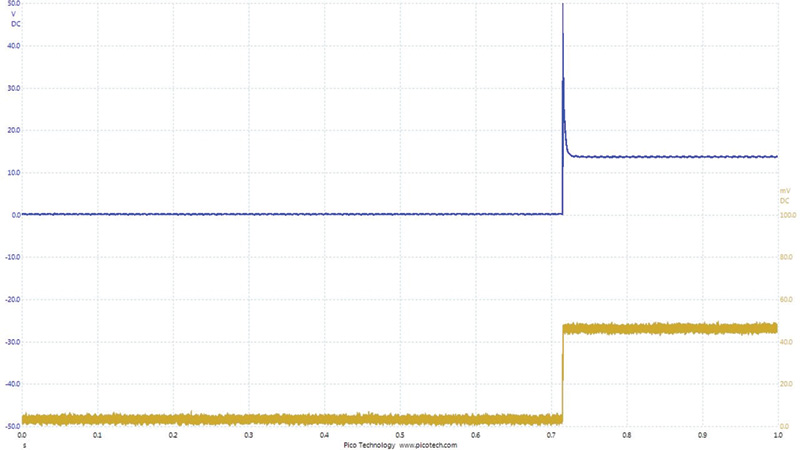

If you have made the investment in Xentry, you have the ability to bi-directionally control outputs. One of these is the switchable engine mounts.

While hydraulic motor mounts work quite well, they’re still passive. They have no ability to adapt to the differing conditions encountered as engine modes change. Since transforming the public perception of the characteristics of diesel-powered cars is turning out to be a lengthy process, Mercedes-Benz has been doing everything possible to reach that goal. Not only with sophisticated common-rail injection with multiple events and ingenious after-treatment of the exhaust, but also by giving an unsung and overlooked part a fresh look: the lowly motor mount. In order to endow its diesels with a smoothness that rivals that of a gasoline engine, Mercedes-Benz has developed computer-controlled mounts.

These new “electric†or “switchable†engine mounts were introduced in 2011 on the Mercedes-Benz M-Class with the 642 diesel (166 Chassis). Instead of hydraulic oil, they use air contained in three bellows. An internal electrical solenoid valve either connects the air chambers together, offering a large volume of air for the compression and expansion that absorbs vibrations, or closes off the chambers from one another for a firmer mounting (the default position is the “hard†setting with the chambers isolated).

These modern motor mounts are still serviced in the same way as a conventional unit with the minor exception that there is an electrical connector to unplug. With your paid subscription to www.startekinfo.com, you can access WIS and get a step-by-step procedure for diagnosing and replacing the new mounts.

Two wires run from the harness to the solenoid, one 12V, and the other ground, which is controlled by the ME (Motor Electronics). Even with sophisticated common-rail injection, diesels can be rough during cranking and starting, and tend to shudder when shut down. So, the ME is programmed to activate the solenoid during these modes, making a relatively-large volume of air available to absorb any harshness. This is called the “soft†setting. The solenoid is either energized or off, there’s no in-between.

Xentry and DMM

Although you may not be seeing these mounts for years, you should still know how to diagnose them. If you’ve invested in Xentry software, you can activate the solenoid at will and monitor both the amp draw and the computer’s ability to control the ground side of the circuit. You can also use your DMM (Digital Multi-Meter) to check the resistance of the solenoid and look for an open winding. You should read about 27 ohms with a good solenoid.

Here we are looking at the activation of the switchable engine mounts with the Xentry software. Notice how the ME simply grounds the solenoids in the upper trace. The lower trace shows the amperage draw of a single engine mount.

The power feed is fuse F58. This fuse also supplies the diesel fuel injection system solenoids, the pressure regulating valve, and the quantity control valve. So, a short circuit or any other failure that causes the fuse to blow will cause a no-start condition, and the mounts will default to “hard,†which won’t be noticed with the engine stopped. These mounts may be incorporated into other models in the future, so be sure to check the wiring diagrams for the car at hand by visiting StarTekInfo.com.

Removal and replacement is basically the same as with any other engine mount. There are two fasteners that hold it to the engine sub-frame, and a single fastener to the engine mounting bracket. The only additional step is unplugging the electrical connector.

As we said earlier, with modern technology being applied to more and more aspects of automobiles, it is your responsibility as an ISP (Independent Service Provider) to keep pace with these changes and continue your education. This allows you to keep giving your customers what they expect from you. It’s also in your own best financial interests.

0 Comments