Whenever people see a carburetor-equipped supercharged engine in a hot vehicle, they can’t help noticing how impressive it looks, and they wonder how much power it produces. But they also see an engine they think is almost impossible to tune, is not very reliable, and will overheat at the drop of a hat. It doesn’t have to be that way.

This ‘56 Ford 292 Y-Block has a Paxton supercharger. That combo in a ‘57 held the NHRA L-Stock record for decades.

A supercharged engine doesn’t have to be a temperamental powerhouse as long as the engine is built, and tuned, to work with the supercharger. A properly-built supercharged engine will withstand the extra load on bearings and other parts caused by all the power the engine yields, and will have a compression ratio designed to work with the boost pressure and the octane of the gasoline it will be burning. Careful attention to choices and upgrades in several areas can tame the beast almost to respectability. These include:

- Cooling system

- Ignition system and timing

- Carburetor or carburetors

- Fuel supply

- Air/fuel mixture

Cooling and ignition systems

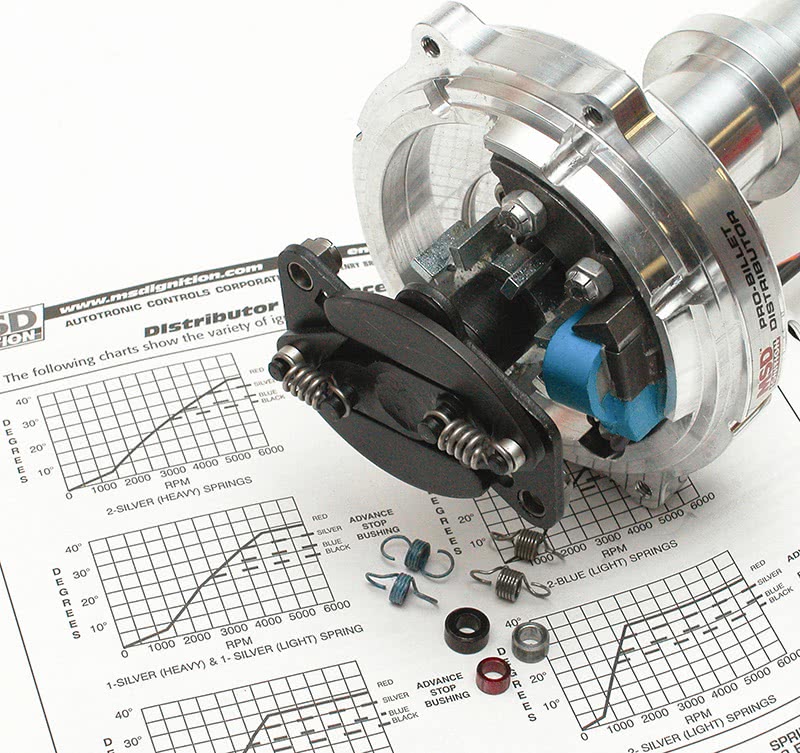

The cooling system, for instance, will need to be upgraded to carry enough heat away from an engine that’s producing a lot more power — and generating a lot more heat — than a non-supercharged engine. This may involve a more capable water pump, or even a larger radiator. The ignition system — spark advance curve and spark output — must be tuned for the unique demands of a supercharged engine. The system needs a lot more power output to fire the spark plug with, say, six psi of boost than is needed on a non-supercharged engine with a typical 9:1 compression ratio. Of course, as the boost pressure increases, the need for greater ignition spark output also increases.

This higher output will require upgraded spark plug wires, and the rest of the system must be up to the job of delivering all that extra energy to the spark plugs. Consult the supplier of the ignition system you are using to determine the recommended spark plug gap, and any other changes needed, for a supercharged engine. You probably will want to do some experimenting on your own to find the spark plug gap that works best for the needs of your particular engine.

A standard points-type ignition system with sufficient output to fire spark plugs with a gap of 0.035 in. in a non-supercharged engine may need the spark plug gap to be as small as 0.018 in. when used with on a supercharged engine with six psi of boost. The ideal ignition curve for a supercharged engine advances the spark quicker, yet provides less total spark advance, than for an engine without a supercharger. This quicker advance helps give the engine better throttle response until the supercharger boost pressure kicks in, but because the supercharger increases the pressure in the cylinders the engine will need less total spark advance to avoid detonation problems.

A good starting point for a supercharged 350 small-block Chevrolet with an 8:1 compression ratio and six psi of boost is an initial setting of 18 degrees BTDC and a total of 30 degrees of advance achieved at 3,000 rpm. This ignition timing curve is just a beginning, and must be tailored to your engine package for best performance.

Spark retard can help

The MSD Boost Timing Master system allows you to retard the timing one to three degrees per pound of boost pressure.

A spark retard system designed for a supercharged engine, such as MSD’s Boost Timing Master, can be used to retard the timing as the boost pressure increases. This type of system allows for a more aggressive advance curve so the engine will have good initial throttle response before the supercharger boost comes in, but will retard the spark as the boost pressure increases to avoid detonation [see Greg McConiga’s article on the dangers of detonation in the April issue of HOT ROD Professional]. This system can allow setting the total ignition timing at 36 degrees, with the system retarding the spark one to three degrees per pound of boost. Total spark timing can be retarded by as much as 20 degrees at one degree for each pound of boost pressure. Note: A supercharged engine should generally not rely on vacuum advance — the extra spark advance it typically supplies can lead to engine damage.

The correct carburetor(s)

If you expect your supercharged engine to perform as it should, the distributor advance curve will have to be tuned for the unique needs of “artificial respiration.”

Selecting the correct carburetor(s) is one of the most important choices you can make in setting up a supercharged engine because all that extra horsepower means a lot more air. If the correct air/fuel mixture isn’t available for all operating conditions, engine damage may result.

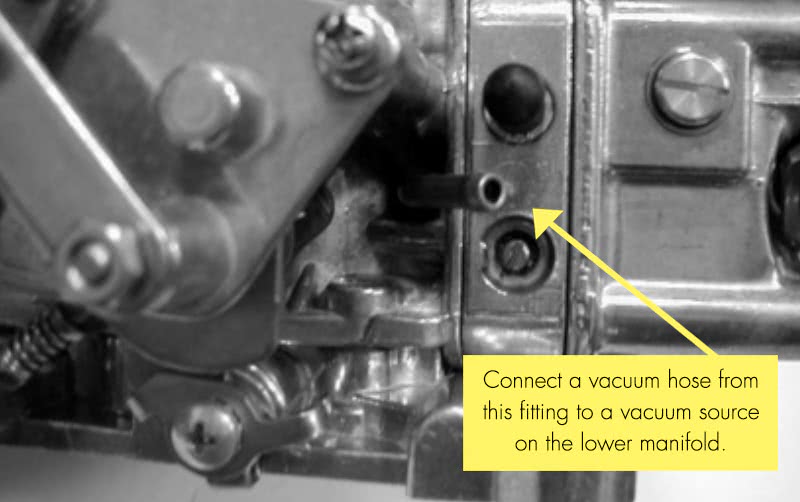

The most notable difference in a carburetor designed to be used with a supercharger is that the power valve includes a vacuum tube connection that mates with the boost pressure/vacuum signal in the intake manifold below the supercharger. This makes the power valve “boost referenced†— the it will supply the richer air/fuel mixture the engine needs when the supercharger’s boost pressure is creating more horsepower.

A standard performance carburetor’s power valve reads the vacuum at the base plate of the carburetor. If this type of carburetor is used on a supercharged engine, it will be reacting to the vacuum created by the supercharger instead of the vacuum or pressure that the supercharger is blowing into the engine. So, a power valve that is not boost-referenced will “see†a vacuum signal from the supercharger that is, in many cases, 10 in. Hg of vacuum higher than the actual engine vacuum. This will cause the power valve to stay closed because it is not reading the correct vacuum signal.

When the power valve does not open at the correct load conditions, the air/fuel mixture will be too lean, this can lead to internal engine damage.

If you must use a carburetor that does not have a boost-referenced power system, select a power valve or power piston spring that causes this carb circuit to open when the vacuum signal drops below 10 to 14 in. Hg. A properly-tuned supercharged engine with a boost-referenced power valve will work best, in most cases, with a power valve that opens at 4.5 in. Hg.

Selecting the correct air flow or cfm rating of the carburetor(s) is also very important if you expect the supercharged engine to supply maximum power and driveability. The first step in selecting the right carburetor(s) is to know how the vehicle will be driven most of the time. If the vehicle will be driven 90% of the time at part throttle, select a smaller carburetor(s) in the 500-650 cfm range. But if the engine will be operated at wide-open throttle 90% of the time, consider a larger cfm carburetor(s), knowing that low engine speed driveability may suffer.

The small amount of extra horsepower you will gain at higher rpm ranges by selecting a larger carburetor(s) may not be not be worth the driveability you will lose at part throttle!

A smaller carburetor can still generate good power

This picture shows the vacuum hose that connects to a port on the manifold below the supercharger that goes to the tube behind the choke on this Holley carburetor’s boost-referenced power valve.

A supercharger can do a very good job of making a lot of horsepower even when the carburetor is on the small side. The Carter-designed AFB and AVS carburetors sold by Edelbrock, and the non-boost-referenced Holley-style carburetors can work well on a low-boost-pressure/mild blown engine. But when a carburetor does not have a boost-referenced power system, extreme care must be taken to avoid overly lean fuel mixtures, especially in off-idle and part-throttle driving conditions. The idle and off-idle systems on 500, 600 and 650-cfm Edelbrock carburetors can be modified to avoid an off-idle lean condition, so they can work well on a low-boost single or dual carburetor set-up. We tend to avoid the 750 and 800 cfm AFBs on street-driven blown engines, due to a lean part-throttle situation inherent in these carbs.

The fuel supply system must be capable of maintaining proper fuel pressure at all driving conditions. If the pressure drops, the air/fuel mixture will go too lean for the engine’s needs. If this happens while the engine is under boost, the result can be damage to pistons and rings. The fuel pump, fuel line size, and fuel tank vent system must work together to supply the carburetor(s) with enough fuel to support all the power the supercharged engine is capable of making.

Tuning the air/fuel mixture on a supercharged engine

Barry Grant Road Demon Jr. blower carbs use a connection on the base plate below the fuel bowls to supply the power valves with the correct vacuum signal for the needs of a supercharged engine.

Modern technology has supplied the tools that make it possible, at an affordable cost, to properly tune the air/fuel mixture of a supercharged engine. One of the best methods for determining what the air/fuel mixture (jetting) is — on any engine — is the use of a portable five-gas infrared exhaust gas analyzer. This measures the critical gases in the exhaust, then supplies readings that can show combustion efficiency, misfire, air/fuel ratio, and excessive combustion chamber heat (detonation).

The CO reading from an exhaust gas analyzer is a very accurate indicator of the air/fuel mixture that the engine is getting. The HC reading indicates the amount of unburned fuel in the exhaust — too much is an indicator of an engine misfire. The CO2 content in the exhaust is the product of complete combustion, so the best air/fuel mixture and the ideal ignition spark timing will create the highest CO2 reading. NOx content in the exhaust is created by excessive combustion chamber heat, and this gas can be seen as a precursor to detonation, and used as a warning. The O2 or oxygen reading can indicate a lean air/fuel mixture, an exhaust leak, that the engine has a “hot†cam — or it could be the result of the supercharger “blow-through†effect.

Note: If O2 content readings in the exhaust are above two to three percent, the dilution of the exhaust gases being measured can cause the accuracy of all of the gas readings — or wide-band oxygen sensor-based digital air/fuel ratio meter readings — to be suspect.

The air/fuel mixture can also be checked using a wide-band oxygen sensor-based digital air/fuel ratio meter. This method reads the oxygen/unburned combustibles content in the engine exhaust, then supplies an air/fuel mixture reading. The readings are normally very accurate, but this type of meter is subject to false readings created by the supercharger blow-through effect, exhaust leaks, engine misfire, or the valve overlap of a high-performance camshaft at low engine rpm and low-load conditions.

False lean readings

Any extra oxygen seen by the wide-band oxygen sensor as it looks at the exhaust will cause the meter to display a “false lean†reading. A digital air/fuel ratio meter is a very good, highly-portable, and low-cost method of determining what the air/fuel mixture is while the car is driven on the road at any condition from a light-load-cruise to a high-power, wide-open-throttle run down the race track.

A good power mixture for most low-boost engines is indicated by a CO reading of 6.6% — 12:1 air/fuel ratio — while a higher-boost supercharged engine might need a CO reading of 8.0% — 11.5 to 1 air/fuel ratio — or richer. This richer mixture can help control detonation created by the high boost pressure, but if it is too rich the engine will lose power. As mentioned earlier, a good starting place for power valve opening on a boost-referenced power system is 4.5 in. of vacuum — this allows the carburetor to supply the richer power mixture needed by the engine when the driver opens the throttle.

Boost-referenced carburetors avoid lean air/fuel mixture

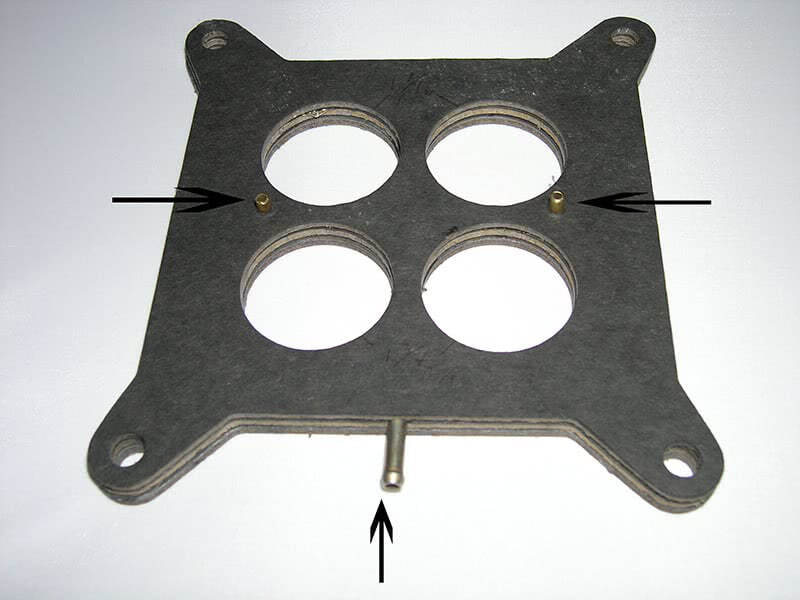

The vacuum tube on this prototype spacer would be used to supply the power system of a Carter-designed AFB or AVS carburetor with a boost-referenced vacuum signal.

A typical big-block Chevrolet engine with a 6-71 supercharger in a street rod accelerating down the road may have a vacuum reading of 12 in. Hg of vacuum above the supercharger — at the carburetor. But a vacuum reading below the supercharger where the boost-referenced power valve gets its reading — in the intake manifold — may be two to three in. Hg of vacuum. This would mean a boost-referenced power valve would be supplying the correct power mixture, but a non-boost-referenced power valve would supply a much leaner mixture, which could lead to detonation and/or engine overheating.

The target cruise mixture normally used on a mild-cam engine with low boost pressure would be 1.0% to 2.0% CO — 14.1-13.8:1 air/fuel ratio — but on a hot-cam, high-boost engine the target mixture we use is 3.0% CO, representing a 13.4:1 air/fuel ratio.

Power, performance, and appearance — some people prefer the old-school look of this ’32 Ford, but if you prefer new-school you could always supercharge your late-model Corvette.

Fuel pressure is a concern with blow-through

This flathead Ford has Ardun heads and a supercharger that breathes through two Stromberg 97 carburetors.

The first concern for an engine using a blow-through supercharger — where the carburetor is under boost — is fuel pressure. A special regulator that is boost-referenced, along with a high pressure/high volume fuel pump, is mandatory. The regulator senses the amount of boost and keeps the fuel pressure at a set point above the boost pressure. The setting that we see most often is 5.5 to 6.5 psi over the boost pressure. For example, with six psi of boost, the fuel pressure would need to be set at 11.5 to 12.5 psi. The two methods of pressurizing or blowing through the carburetor are:

- the carburetor is in a pressurized box

- a “hat†is used on top of the carburetor in place of the air cleaner.

If a hat is used, the throttle shafts will need to have seals installed to keep the fuel from blowing out through the clearance between the shaft and its bore. Every carburetor we are aware of was designed to work with the air flow coming in evenly from all directions as it travels through the air cleaner. But when the air is blown through with a supercharger, it may not supply all of the emulsion bleeds in the carburetor with the same air pressure or flow patterns.

Yes, you can have it all: power, performance, and that supercharged look. All it takes is the time to pick the correct parts and properly tune it for the special needs of a supercharged engine.

A marine-type flame arrester inside the air box or hat can help diffuse the air charge as it blows into the carburetor and its air bleeds — if some method of diffusing the air-charge is not used, the air flow blowing from just one side of the carburetor across the air bleeds may cause air/fuel mixture curve problems, possibly leading to engine damage from an overly lean or rich mixture in one or more cylinders.

So that’s the story — you can drive an awesome, supercharged machine that scorches tires at the touch of the throttle, but that is relatively well behaved when you want it to be. Match the supercharged engine with the correct carburetor(s) properly tuned and well-supplied with fuel, and an ignition system with the right parts and spark curve, and you have built a supercharged driving experience that is both enjoyable and trouble-free.

Â

0 Comments