Unlike the traditional cycling-clutch design, a variable displacement compressor spins whenever the vehicle’s engine is running. Diagnosing A/C performance complaints in a variable displacement system is similar to the diagnostic process for a traditional compressor. Only after ruling out non-compressor problems can you begin testing the variable displacement compressor itself. Does the swash plate respond differently to different loads? If not, is it a problem with the compressor, sensor inputs, or with the controller?

A traditional compressor pumps the same volume of refrigerant with every stroke of its pistons. If the number of strokes per second is low due to the engine idling, or high due to fast engine rpm, the amount of refrigerant pumped may be too little or too much for the current heat load. With clutch-type compressors, the only way to maintain refrigerant flow within the desired range is to cycle the compressor on and off as needed.

A clutch cycling switch, controlled by sensors measuring A/C system low side pressure and evaporator temperature, turns the compressor on when cooling is needed, and off as soon as the desired temperature is reached.

Cycling the compressor off when the desired temperature is reached conserves fuel. However, turning it back on when needed puts a big load on small engines, and creates a noticeable engine “burp†even on larger engines while at idle or cruising at low speeds.

Changing displacement on the fly

Variable displacement compressors (VDCs) are the solution. Unless there is a serious mechanical problem, the compressor is always spinning, so there is no instant-on high-rpm clutch kick-in to sap engine power, or the potentially-damaging demand that the unit accelerate from zero to several thousand rpm instantly.

VDC designs avoid these drawbacks — most don’t even have a clutch.

Note: Some of the latest Mercedes-Benz models, such as the CLA and 204 with the Eco Start/Stop option, have VDCs with a clutch added, the intention being to eliminate all drag. It’s not likely that these will find their way into your shop for years, however, so we will concentrate on pre-clutch VDCs here.

A great deal of careful engineering goes into developing the sophisticated, comfortable A/C systems of Mercedes-Benz vehicles. The introduction of the VDC represented a big advance in smoothness and efficiency.

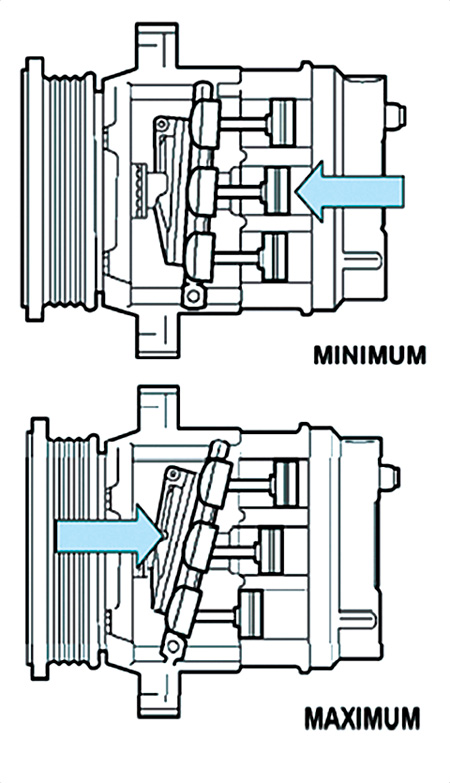

A variable angle swash plate allows the VDC to change refrigerant displacement on the fly. The swash plate sits at an angle around the compressor shaft. It functions much like the lobes on a camshaft. As the swash plate rotates, it pushes each piston up as the high end of the plate approaches the connecting rod, and allows high-side pressure to push them back down as the low end nears.A pulse width modulated (PWM) solenoid valve controls the angle of the swash plate. At the lowest inclination (almost perpendicular to the compressor shaft), swash plate rotation creates only a tiny piston stroke, moves very little refrigerant, and consumes almost no energy. At the maximum angle, the plate moves as much or more refrigerant than a traditional cycling clutch compressor.

Precision control

The control valve can vary the swash plate inclination to any degree between minimum and maximum. Through more precise metering of refrigerant than is possible with the on-off cycling of traditional compressors, Mercedes-Benz is squeezing every little bit of energy out of a gallon of fuel.

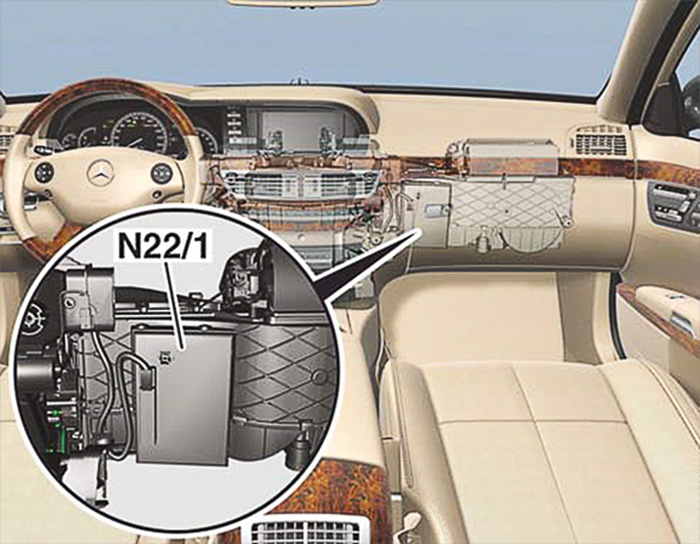

The PWM signal is generated by a SignalActivation Module (SAM). The SAM receives its marching orders from the Automatic Air Conditioning (AAC) control unit (Model 164 does not use the SAM; control is handled directly by the AAC). The ACC is the clearing-house of climate-related passenger comfort functions, including interior temperature selection, compressor solenoid valve control, and other a/c component actuation.

The AAC collects driver and passenger inputs through the unit’s dash controls. It combines them with inputs from the SAM and various sensors, including ambient, interior, evaporator, and coolant temperatures, plus sensors for refrigerant pressure, solar heat gain, and vehicle speed.

VDC diagnosis the easy way

You don’t need to analyze these variables because Mercedes-Benz engineers have programmed it all into the system. Computer algorithms interpret the inputs and make adjustments to the evaporator pressure target in real time.

So, all you need to know to determine whether a variable displacement compressor is the cause of a cooling performance complaint is, one, find out whether or not the compressor is capable of spinning; two, if it is receiving commands from the controller; and, three, if it is responding to the controller by adjusting the angle of the swash plate.

Push the right buttons

The swash plate in a variable displacement compressor is “hinged†so it can tilt at different angles. The higher tilt creates greater piston movement and higher pumping volume, or displacement, of refrigerant. When the swash plate angle is almost perpendicular to the compressor shaft, it generates almost no refrigerant displacement and consumes negligible energy.

Does the driver know how to operate the dash controls? The air conditioning only cools when the “A/C†button is lit or the “A/C Off†button is off. Sometimes it’s that simple.

To the driver’s credit, sometimes the system logic may take control away. For example, when sunlight hits the vehicle at an angle, sun sensors in the affected zone may cause extreme differences in outlet air temperatures and blower outputs from side to side, regardless of prior dash temperature settings.

Basics First

Before you begin testing the compressor, you must check basic mechanical functions:

- Make sure the A/C fuse is okay and that the blower motor is working (not seized or jammed).

- Check for proper A/C blend door operation. Switch the A/C temperature quickly from cold to hot and divert it to various passenger compartment outlets. Check to see if temperature changes and sufficient air comes out of each of the dash and other outlets as commanded.

- Is the condenser fan working? If the condenser is unable to dissipate enough heat from the refrigerant, it puts an excessive load on the compressor.

- Are there restrictions anywhere in the system? A plugged expansion valve, obstructed tubing, or possibly the presence of an A/C sealant additive will reduce refrigerant flow and increase the risk of the compressor seizing due to overheating.

Because it is always spinning whenever the engine is running, a variable displacement compressor needs to be constantly bathed in lubricant. The low lubricant quantity in today’s smaller systems puts a VDC at risk if even only a little lubricant is trapped in a restricted A/C component or hose.

Does the compressor spin?

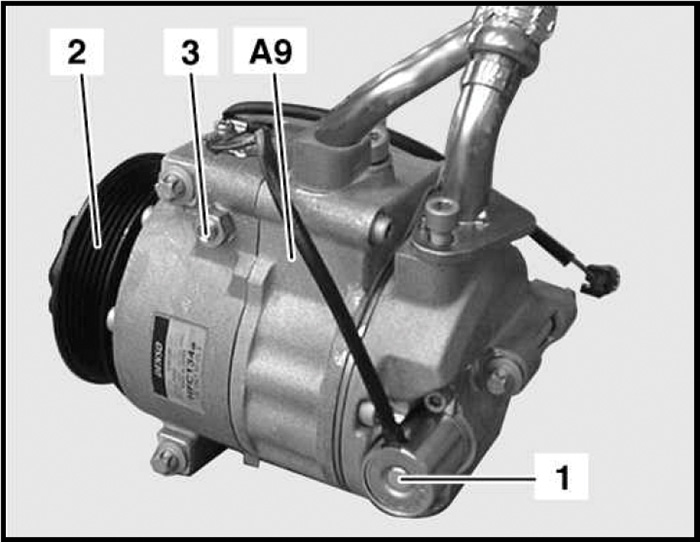

The control valve, labeled “1,†is what actually varies the angle of the swash plate according to the signal from the SAM (Signal Acquisition Module).

With a variable displacement unit, there is no on-off cycling click sound, because if everything is working properly, the compressor is always spinning. Instead of ear-checking the compressor, you’ll have to check pressures. Refer to the Mercedes-Benz specifications in the Workshop Information System (WIS) to see what the pressures should be at current ambient temperatures.

Note: You can always refer to WIS for a more structured diagnosis approach. Â

Just has been the case for decades, if you have a full refrigerant charge when you first attach gauges without the engine or A/C system running, the psi reading will likely be close to the ambient temperature in Fahrenheit. When in doubt, start with a recover/recharge to make sure that the system contains the correct amount of refrigerant.

Turn the A/C on and look at your gauges. If you have any pressure differential at all, the compressor is spinning. If you see no or extremely low pressure, loosen and re-torque the compressor bolts, following the torque sequence in the Mercedes-Benz specifications. If the compressor bolts were torqued in an incorrect sequence during a previous field installation, it can cause binding in the internal mechanism. The compressor could hang up intermittently or be unable to adjust its swash plate.

Can we talk?

Another thing to check is whether or not a signal is reaching the compressor control valve from the SAM. Refer to your Mercedes-Benz documentation for how to find out if you have a connector problem between the computer and the control valve. Some control valves rely on grounding through the compressor. The presence of corrosion may insulate this ground causing control problems. Sometimes just loosening and retightening mounting bolts and the ground lug will resolve this.

Does the Swash Plate adjust?

The driver’s-side SAM generates a pulse width modulated (PWM) signal to tell the compressor control valve what refrigerant displacement level is needed for conditions.

Set the blower to low and rev the engine to high rpm. Note the system pressure. Then change to high blower and regular rpm. You have thus changed the load on the compressor, and you should see substantial changes in pressures. These changes confirm that the swash plate is moving, and the variable displacement function is operating.

If the swash plate isn’t adjusting, you have a problem with either the control valve or the internals of the compressor.

Who’s in control?

If the compressor is spinning, and the swash plate is adjusting displacement so you see different pressures at different load levels, but the system is still not cooling properly, check the control valve. Cross reference the pressure results you’ve seen with Mercedes-Benz performance specs at various loads.

If the control valve is not operable, replace the compressor. Currently, the control valve itself is not a serviceable item.

Shear madness

The ACC (NC22/1) combines input from the dash controls with feedback from a variety of onboard sensors, and applies algorithms to make A/C function decisions that help Mercedes-Benz vehicles maintain their fuel-sipping attributes.

When a VDC compressor seizes up, a shear pin on the pulley breaks off, allowing it to free spin, no longer locked to the compressor shaft. So, the seized compressor won’t destroy the accessory belt, and the shear pin breaking off will prevent shutting the engine down and creating a “walk-home†situation for the vehicle owner.

If pin has sheared, you must replace the compressor — but only after determining what caused it to seize up. Finding the root cause is important for preventing a a quick and unfortunate compressor job comeback.

Compressor seizing is generally due to a lack of lubrication, which commonly means a lack of refrigerant charge. Look for a leak other than at the compressor, or an obstruction somewhere in the system preventing the free flow of lubricant.

Variable displacement hides the charge level

In an undercharged VDC, the control valve reduces displacement, keeping refrigerant on the low side longer to help maintain the pressure at the desired level. In an overcharged system, the control valve will decrease displacement to try to bring the pressure within specifications.

There are, of course, more diagnostic checks you can perform on temperature and other sensor inputs. The checks we’ve discussed will let you know if the variable displacement compressor is operating properly.

Even though a variable displacement compressor is different from a traditional unit, air conditioning complaint diagnosis follows a similar path. If there is a problem and you believe it is in the compressor, replace it. If you think it is the control valve, that is an integral part of the compressor, so, again, replace the compressor. Â

0 Comments